SENSIRION SEN5 Series User manual

www.sensirion.com Version 1.0 –June 2021 1/5

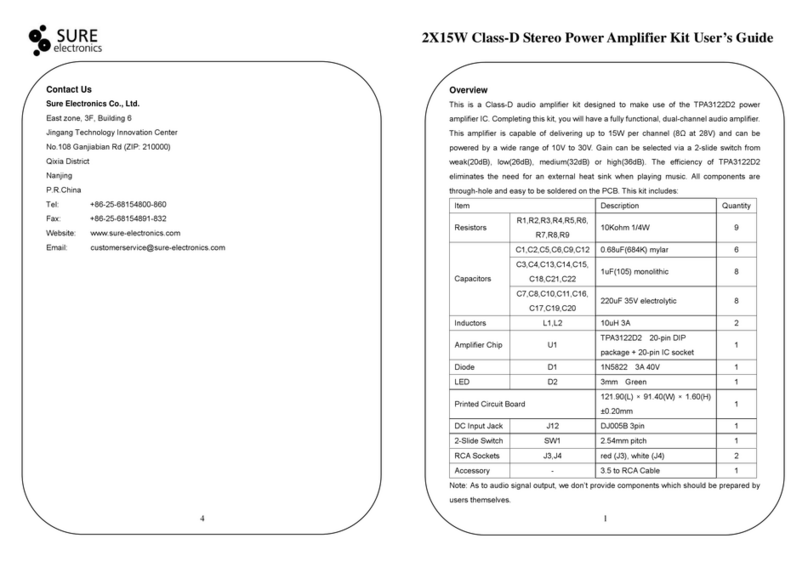

Handling Instructions

For SEN5x Environmental Sensor Node

Introduction

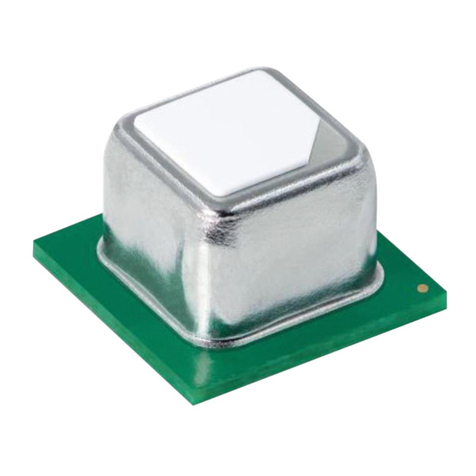

The Sensirion SEN5x environmental node is a combo sensor that is based on a PM2.5 sensor, containing one

or a combination of Sensirion SHTxx humidity and temperature sensor and a Sensirion SGPxx VOC sensor.

For taking advantage of the outstanding performance of the SEN5x, some precautions must be taken during

storage, assembly, and packaging. Therefore, please read the following instructions carefully - preferably

during design-in phase and before production release of the respective device. Special attention is required

regarding the exposure to volatile organic compounds, i.e. high concentration and long exposure time to

respective gases shall be avoided. Such conditions are known to occur in manufacturing environment and/or

during storage. Therefore, proper handling and choice of materials are crucial.

1Handling

SEN5x sensors shall be handled with care. If the product is dropped on a hard surface from a height >1m the part must

be discarded and replaced by a new one.

The inherent design of this component causes it to be sensitive to electrostatic discharge (ESD). To prevent ESD-induced

damage and/or degradation, take customary and statutory ESD precautions when handling this product.

2Exposure to Chemicals

SHTxx Humidity and temperature sensors, as well as SGPxx VOC sensors are highly accurate environmental sensors

and as such they are not ordinary electronic components. The openings in the SEN5x housing exposes these

environmental sensors to the environment and make them susceptible to pollutants. While applying sensors in the field

in ambient environment is not critical, pollutants are known to occur in manufacturing environments and during storage.

Please carefully follow the guidelines in this application note to ensure that you can benefit of the outstanding

performance of the SEN5x.

The SEN5x shall not get in close contact with volatile chemicals such as solvents or other organic compounds.

Especially high concentration and long exposure must be avoided. Ketenes, Acetone, Ethanol, Isopropyl Alcohol,

Toluene, etc. are known to cause drift of the humidity and VOC reading –irreversibly in most of the cases. Please note

that such chemicals are integral part of epoxies, glues, adhesives, etc. and outgas during baking and curing. These

chemicals are also added as plasticisers into plastics, used for packaging materials, and do out-gas for some period.

Acids and bases may affect the sensor irreversibly and shall be avoided: HCl, H2SO4, HNO3, NH3etc. Also Ozone in

high concentration or H2O2have the same effect and therefore shall be avoided. Please note, that above examples

represent no complete list of harmful substances.

The sensor shall not get in contact with cleaning agents. Applying cleaning agents to the sensor may lead to drift of the

humidity and VOC reading.

Ensure good ventilation (fresh air supply) to avoid high concentrations of volatile chemicals (solvents, e.g. ethanol,

isopropanol, methanol, acetone, cleaning solutions, detergents…).

www.sensirion.com Version 1.0 –June 2021 2/5

3Packing and Storage

Prior to assembly or use of the sensors it is strongly recommended to store the sensors in the original packaging.

During storage, SEN5x sensors shall be oriented such that the air inlet and outlet are not facing up.

Sensors shall always be stored in a well-ventilated environment, with temperature and relative humidity within the limits

specified in the respective datasheet.

SEN5x Sensors as well as products containing SEN5x sensors shall not be packaged in outgassing plastic materials

which could cause sensor pollution. Besides metal-in antistatic shielded ESD bags, paper or cardboards based

packaging, deep drawn plastic trays (PE, PET, PP) may be considered. Do not use antistatic polyethylene bags (light

blue, pink or rose color); be very careful with bubble foils and foams.

Be careful about stickers present inside the packing (e.g. on the housing of the device). Sticker size should be kept to

a minimum, and the sticky side shall fully adhere onto a surface.

Please note that many packaging materials may be provided with additives (plasticizers) which may have a polluting

effect on the sensor. Generally speaking, if a material emits a strong odor you should not use it. Additives may also be

added to materials which are listed for recommended use. For high safety, device housing and shipment packaging

must be qualified. Such a qualification test may contain exposure of the final device with sensor in its shipment

packaging to temperature ≥55°C for at least 168 hours. (If shipping or storage conditions are expected to be harsh, the

qualification test conditions for the packing material have to be customized.) The sensor reading then shall show no

changed deviation against a reference compared to same measurements before the exposure.

4Assembly

Regarding adhesives and encapsulants the material in the following tables may be used –according to respective

datasheets, applied and fully cured in well ventilated environment (fresh air supply). Materials and brands not listed in

the following tables may be harmful and shall be tested carefully before applying.

Epoxy Adhesives

Manufacturer

Product

EPO-TEK

H70E/S

Other Recommended Materials

Manufacturer

Product

Teflon

PEEK

Polycarbonate (PC)

ABS

FR4 PCB

Viton seals (after thermal outgassing)

Hot melts may absorb water and thus may have an impact on the humidity response time of the sensor in the device.

Therefore, hot melt shall be applied sparingly.

The sensor shall be mounted into the device, if possible, after all materials that are used in the assembly process have

completely cured or dried out. Otherwise ensure good ventilation (fresh air supply) in curing ovens and assembly lines.

Ensure recommendations in this application note are equally considered during repair and rework of assemblies

containing sensors.

Be particularly careful when using strong cleaning agents (e.g. detergents, alcohols, brominated or fluorinated solvents).

Cleaning any part of a product might lead to high concentration of cleaning agents on the sensor. Please remove any

www.sensirion.com Version 1.0 –June 2021 3/5

sensors or devices containing sensors before cleaning the production area and tools. Ensure good ventilation (fresh air

supply) and that any solvents have evaporated before resuming production.

5Disclaimer

The above given restrictions, recommendations, materials, etc. do not cover all possible cases and items.

The material recommendations are given regarding pollution of SHT and SGP sensors which are part of SEN5x and

assume optimal processing for avoiding VOC in process –the materials were not tested regarding other properties like

reliability, performance, usability or mechanical properties. The material recommendations have been compiled with our

best knowledge at the time of writing. Manufacturers may change the compounds without notice, which can lead to

reduced Sensor performance due to outgassing.

This document is not to be considered complete and is subject to change without prior notice.

www.sensirion.com Version 1.0 –June 2021 4/5

6Revision History

Date

Revision

Changes

15. June 2021

1.0

Initial version

7Important Notices

7.1 Warning, Personal Injury

Do not use this product as safety or emergency stop devices or in any other application where failure of the product could result in

personal injury. Do not use this product for applications other than its intended and authorized use. Before installing, handling, using or

servicing this product, please consult the data sheet and application notes. Failure to comply with these instructions could result in

death or serious injury.

If the Buyer shall purchase or use SENSIRION products for any unintended or unauthorized application, Buyer shall defend, indemnify and hold

harmless SENSIRION and its officers, employees, subsidiaries, affiliates and distributors against all claims, costs, damages and expenses, and

reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized

use, even if SENSIRION shall be allegedly negligent with respect to the design or the manufacture of the product.

7.2 ESD Precautions

The inherent design of this component causes it to be sensitive to electrostatic discharge (ESD). To prevent ESD-induced damage and/or

degradation, take customary and statutory ESD precautions when handling this product.

See application note “ESD, Latchup and EMC” for more information.

7.3 Warranty

SENSIRION warrants solely to the original purchaser of this product for a period of 12 months (one year) from the date of delivery that this product

shall be of the quality, material and workmanship defined in SENSIRION’s published specifications of the product. Within such period, if proven to

be defective, SENSIRION shall repair and/or replace this product, in SENSIRION’s discretion, free of charge to the Buyer, provided that:

▪notice in writing describing the defects shall be given to SENSIRION within fourteen (14) days after their appearance;

▪such defects shall be found, to SENSIRION’s reasonable satisfaction, to have arisen from SENSIRION’s faulty design, material, or workmanship;

▪the defective product shall be returned to SENSIRION’s factory at the Buyer’s expense; and

▪the warranty period for any repaired or replaced product shall be limited to the unexpired portion of the original period.

This warranty does not apply to any equipment which has not been installed and used within the specifications recommended by SENSIRION for

the intended and proper use of the equipment. EXCEPT FOR THE WARRANTIES EXPRESSLY SET FORTH HEREIN, SENSIRION MAKES NO

WARRANTIES, EITHER EXPRESS OR IMPLIED, WITH RESPECT TO THE PRODUCT. ANY AND ALL WARRANTIES, INCLUDING WITHOUT

LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSLY EXCLUDED AND

DECLINED.

SENSIRION is only liable for defects of this product arising under the conditions of operation provided for in the data sheet and proper use of the

goods. SENSIRION explicitly disclaims all warranties, express or implied, for any period during which the goods are operated or stored not in

accordance with the technical specifications.

SENSIRION does not assume any liability arising out of any application or use of any product or circuit and specifically disclaims any and all liability,

including without limitation consequential or incidental damages. All operating parameters, including without limitation recommended parameters,

must be validated for each customer’s applications by customer’s technical experts. Recommended parameters can and do vary in different

applications.

SENSIRION reserves the right, without further notice, (i) to change the product specifications and/or the information in this document and (ii) to

improve reliability, functions and design of this product.

Copyright©2020, by SENSIRION.

CMOSens®is a trademark of Sensirion

All rights reserved

www.sensirion.com Version 1.0 –June 2021 5/5

8Headquarters and Subsidiaries

Sensirion AG

Laubisrütistr. 50

8712 Stäfa

Switzerland

phone: +41 44 306 40 00

fax: +41 44 306 40 30

www.sensirion.com

Sensirion Korea Co. Ltd.

phone: +82 31 337 7700~3

info-kr@sensirion.com

www.sensirion.com/kr

Sensirion China Co. Ltd.

phone: +86 755 8252 1501

info-cn@sensirion.com

www.sensirion.com/cn

To find your local representative, please visit www.sensirion.com/distributors

Table of contents

Other SENSIRION Accessories manuals

SENSIRION

SENSIRION SCD4 Series User manual

SENSIRION

SENSIRION EK-P3 User manual

SENSIRION

SENSIRION SCD42 User manual

SENSIRION

SENSIRION LD20 Series Installation guide

SENSIRION

SENSIRION SCD30 User manual

SENSIRION

SENSIRION SCD40-D-R2 User manual

SENSIRION

SENSIRION SHT4x User manual

SENSIRION

SENSIRION SCD30 User manual

SENSIRION

SENSIRION SCD4x User manual

SENSIRION

SENSIRION SCD4 Series User manual