Sensit P400 User manual

INSTRUCTION MANUAL

Read and understand instructions before use.

Ex d ia IIC T4, Gb, IP65

-20° C to 50° C

DEMKO 12 ATEX 1102012

0891

II 2 G

SENSIT®GOLD instruments are Approved

UL913,

For Class 1, Division 1, Groups A, B, C and D

Hazardous locations when used with approved

alkaline batteries or rechargeable battery pack.

IP65

Temp code: T4, -20° C to 50° C

7WA6

SENSIT® P400 GAS MONITOR

For use with combustible gases and optionally available oxygen and toxic gases.

Intrinsically safe for use in:

Manufactured by:

SENSIT Technologies

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

Warning!

To reduce the risk of explosion do not mix old batteries with used batteries, or

mix batteries from different manufacturers.

Warning:

To prevent ignition of ammable or combustible atmospheres, disconnect

power before servicing.

Warning:

Substitution of components may impair intrinsic safety.

Warning:

Not for use in atmosphere of oxygen greater than 21%

Warning:

To prevent the risk of ignition of ammable atmospheres, batteries must only

be changed in an area known to be non-hazardous.

Warning:

To maintain intrinsic safety, service must be performed by factory authorized

technicians with approved replacement parts only.

CAUTION:

Lithium backup cell may explode if mistreated. Do not recharge, disassemble

or dispose of in re.

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

SENSIT® P400 Instruction Manual

TABLE OF CONTENTS

General Description .................................. 4

Parts and Accesories ................................. 5

Physical Specicaitons ............................... 6

Safety Precautions..................................... 6

Operational Specicaitons ......................... 7

Sensor Specications & Alarms...............9-10

Function Indicators .................................. 11

Battery Installation...............................12-13

Operation and Use .............................14-22

Bump Test - Calibration ............................ 23

P400 Motorized Pump............................. 27

User Menu .........................................28-30

Warranty ................................... Back Cover

3

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

4

General Description

The Sensit P400 is a state of the art personal gas monitor used to alert users of

potentially hazardous gases in the work area. This monitor may have 1-5 sensors

installed including combustible gas (LEL only), oxygen and/or 2 additional toxics

such as CO, SO2, HCN and H2S. A combination CO/H2S sensor is available

as a single sensor location.

Alarms are in 3 forms. Audible alarms are 98db; visual via 6 super-bright

LEDS and enhanced display readings; vibration from the vibrating motor. Unique

alarms for Low level (preset), time weighted average (TWA) based on 8 hour

average exposure maximums, short term exposure limit (STEL) based on 15 minute

average exposure maximums, high levels for immediate health threats, total or

accumulated exposure over time, and “high-high” for potential immediate danger.

Operator safety is uniquely and efciently increased with the use

of the Immediate Detection System (IDS). The IDS provides the

operator a tick style indication that gas conditions are changing,

before the alarm level. If so equipped, this feature can be enabled

through the supervisor menu.

The housing is made of a eld proven brand of polycarbonate (LEXAN) with a

permanently adhered rubber-like protective outer covering. This is resilient to

environmental factors and most impacts.

The buttons located on the side of the housing provide simple and intuitive user

operation.

The user menu has several user functions plus a supervisor set-up selection.

This allows a supervisor to make adjustments to those operational features eld

personnel should not be adjusting. This is password protected.

A graphic display provides all readings and information. On screen prompts

and information make use very simple.

A single green LED at the top indicates the instrument is functioning properly,

bump test and calibration have been performed as required.

Calibration is accomplished either manually using the menu function or using a

SCal 400 automatic docking station. The manual calibration process is extremely

simple. Once the menu item is selected attach the gas and wait for the process

to be completed.

Data logging is automatic if enabled. The internal memory provides approximately

75 hours of capacity. Uploading is accomplished using the Link-400 Station with

SmartLink Sofware.

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

5

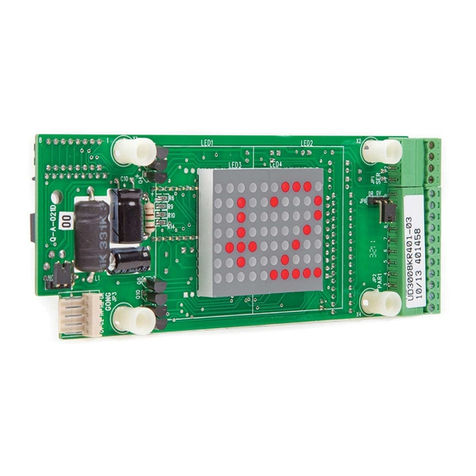

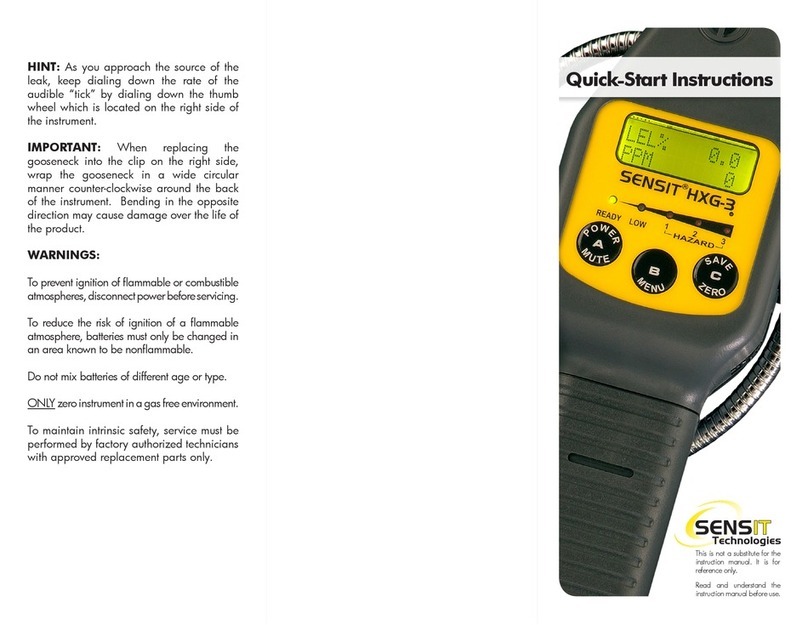

BELT CLIP (ON BACK)

COMPLIANCE/STATUS INDICATOR

ALARM LEDs

SENSOR AREA

SENSOR FILTER

FUNCTION BUTTONS

SOUNDER

GRAPHIC DISPLAY w/BACK LIGHT

SENSIT® P400 GAS MONITOR

Standard Accessories

(Included with Instrument)

• Four alkaline batteries

• Battery door removal tool (#0 Phillips)

• Filter removal tool (3/32 Allen Wrench)

• Calibration cup

• Instruction manual

Replacement Parts

• Sensor Filter

• Belt clip

• Battery pack – alkaline

• Battery pack – rechargeable

PARTS AND ACCESSORIES

Optional Accessories

• Conned space entry probe

w/hand aspirator

• Motorized pump

• Conned space entry probe

• Conned space entry probe

lters – coalescing

• Bump test adapter

• Calibration kits

• SCal 400 Station

o Network connections

and software separate

• Data logging Report Software - SmartLink

• Rechargeable Battery Pack

• Battery Charger Station

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

6

Safety Precautions

3 After any exposure to high concentrations (beyond LEL) of combustible gases

the instrument should be tested for proper operation (see bump test). High

concentrations of such gases may damage the sensor.

3LEL sensor poisoning may occur after exposure to gases that contain silicone,

lead, halogens and sulfur. If exposure has occurred or may be suspected the

instrument should be tested for proper operation (see bump test).

3For Canada, prior to each days use a bump test is required.

3 Read and understand instructions prior to use.

3Always start the instrument in a gas free environment.

3Do not use in environments exceeding 21% oxygen content.

3Do not mix batteries of different type or age.

3Service can only be performed by factory authorized personnel.

3Tampering with this product may void warranty.

3Only use Sensit Technologies approved parts and accessories.

3Do not change batteries or service in a combustible atmosphere.

3Never use an instrument known to be damaged or out of calibration.

Physical Specications

Size: 5.2” x 3.2” x 1.7” (13.2x8.1x4.0 cm)

Weight: 12oz oz. (340g)

Construction: Certied to IP65

Intrinsic Safety: Certied to:

UL913 Class 1 Div 1 Group ABCD T4

ATEX II 2 G Ex ia d IIC T4

Designed to meet (pending approval)

IECEX Ex ia d IIC T4

CSA 22.2 No’s 157 & 152

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

7

Operational Specications

Temperature: -4° to 122° F (-20 to 50C)

Humidity: 10 - 90% RH (Non Condensing)

Duty Cycle: 8 hours (Default)

Response time: T90 ≤ 20 Seconds

Alarms

Sound: 98db @ 15” (30cm)

Sight: Display Alerts

6 - 270° viewable red LED’s (all sides)

Touch: Vibration

Settings: All Alarms are set at OSHA values.

Three levels of alarm depending on concentration or time

weighted average (TWA) and short term exposure level (STEL)

requirements.

Low, TWA, STEL, High and High-High alarms are differentiated

by alarm sound and displayed message.

Immediate Detection System: Optional

Tick increases at 50, 60, 70, 80, 90% of alarm values for

toxic sensors. LEL Sensor tick increases are at 10 – 90% of

alarm value in 10% increments.

Power Source: 4 “AA” type alkaline batteries

Use only PROCELL PC1500

NiMH rechargeable battery pack

SENSIT PART NO 871-00021

Pump ow: ≥0.35 lpm (optional external pump)

Battery life: ≥ 24 hours continuous operation (alkaline)

≥ 15 hours cont. operation (rechargeable)

Response Time: Initial response <3 seconds

T90 LEL CO H2S O2 <20seconds

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

8

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

9

LEL (catalytic)

0 – 100% LEL with over range protection.

Calibration gas selections include methane, propane and pentane.

0.1-2.0 (adjustable) % LEL resolution; ±10% of read accuracy;

Low Alarm = 10%; High Alarm = 20%; HHigh Alarm = 50%;

Calibration gas is 50%LEL of CH4, Propane or Pentane.

Oxygen (galvanic fuel cell)

0 – 25% 0.1% resolution; ±0.2% of scale accuracy;

High Alarm = ≤19.5% and ≥23.5%;

Low and HH Alarms not activated;

Bump gas is 18.5% oxygen

Carbon Monoxide (electrochemical)

0 –999ppm (extended range available 0-1999ppm);

1ppm resolution; ±5ppm or10% of read accuracy;

Low Alarm = 50ppm; High Alarm = 200ppm; HH not activated;

Calibration gas is 100ppm CO

Hydrogen Sulde (electrochemical)

0 – 100ppm; 1ppm (0.1 option) resolution; ±2ppm or 10% of read accuracy;

Low Alarm = 10ppm; High Alarm = 25ppm; HH not activated;

Calibration gas is 25ppm H2S.

Hydrogen Cyanide (electrochemical)

0 – 30ppm; 0.1ppm resolution; ±1ppm or 10% of read accuracy;

Low Alarm = 4.7ppm; High Alarm= 10ppm; HH not activated;

Calibration gas is 10ppm HCN.

Sensor Specications & Alarms

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

Chlorine (electrochemical)

0 – 30ppm; 0.1ppm resolution; ±1ppm or 10% of read accuracy;

Low Alarm = 5ppm; High Alarm = 10ppm; HH not activated;

Calibration gas is 5ppm Cl2.

Sulfur Dioxide (electrochemical)

0 – 20ppm; 0.1ppm resolution; ±1ppm or 10% of read accuracy;

Low Alarm = 10ppm; High Alarm = 25ppm; HH not activated;

Calibration gas is 10ppm SO2

Nitrogen dioxide (electrochemical)

0 – 250ppm; 1ppm resolution; ±2ppm or10% of read accuracy;

Low Alarm = 10ppm; High Alarm = 25ppm; HH not activated;

Calibration gas is 10ppm NO2

Ethylene oxide (electrochemical)

0 – 10ppm; 0.1ppm resolution; ±1ppm or 10% of read accuracy;

Low Alarm = 1ppm; High Alarm = 5ppm; HH not activated;

Calibration gas is 5ppm ETO.

Phosphine (electrochemical)

0 – 10ppm; 0.1ppm resolution; ±1ppm or 10% of read accuracy;

Low Alarm = 1ppm; High Alarm = 5ppm; HH not activated;

Calibration gas is 5ppm PH3.

Sensor Specications & Alarms (Continued)

10

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

CO = Carbon Monoxide

O2 = Oxygen

H2S = Hydrogen Sulde

Cl2 = Chlorine

SO2 = Sulfur Dioxide

NO2 = Nitrogen Dioxide

HCN = Hydrogen Cyanide

ETO = Ethylene Oxide

PH3 = Phosphine

Function Indicators

Display will indicate sensor type installed.

11

Consult Sensit Technologies for additional sensor availability.

Combustible gas sensing displays the calibration gas type used.

Ch4=methane; PRO=propane; PEN=Pentane;

The letter “P” indicates the pump is operating

A SD card symbol indicates datalogging is activated “ “

A letter “T” indicates the IDS is activated for the particular gas

Inadequate battery power is indicated by a beep and the display reading BAT LOW.

The battery voltage is constantly displayed. BAT LOW is displayed at 4.2v. BAT FAIL

at 4.0v.

Sensor failures are indicated by displaying FAIL in place of the sensor readings.

Air Flow block or inadequate pump output is indicated by the display reading FLOW

BLOCKED and audible/visual alarms.

Properly attached pump is momentarily indicated by displaying “PUMP STARTING”

followed by a 4 second countdown. When the pump is detached the display will

show “PUMP DISABLED” and alarms will activate. Press the upper right button to

acknowledge or properly reattach the pump.

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

12

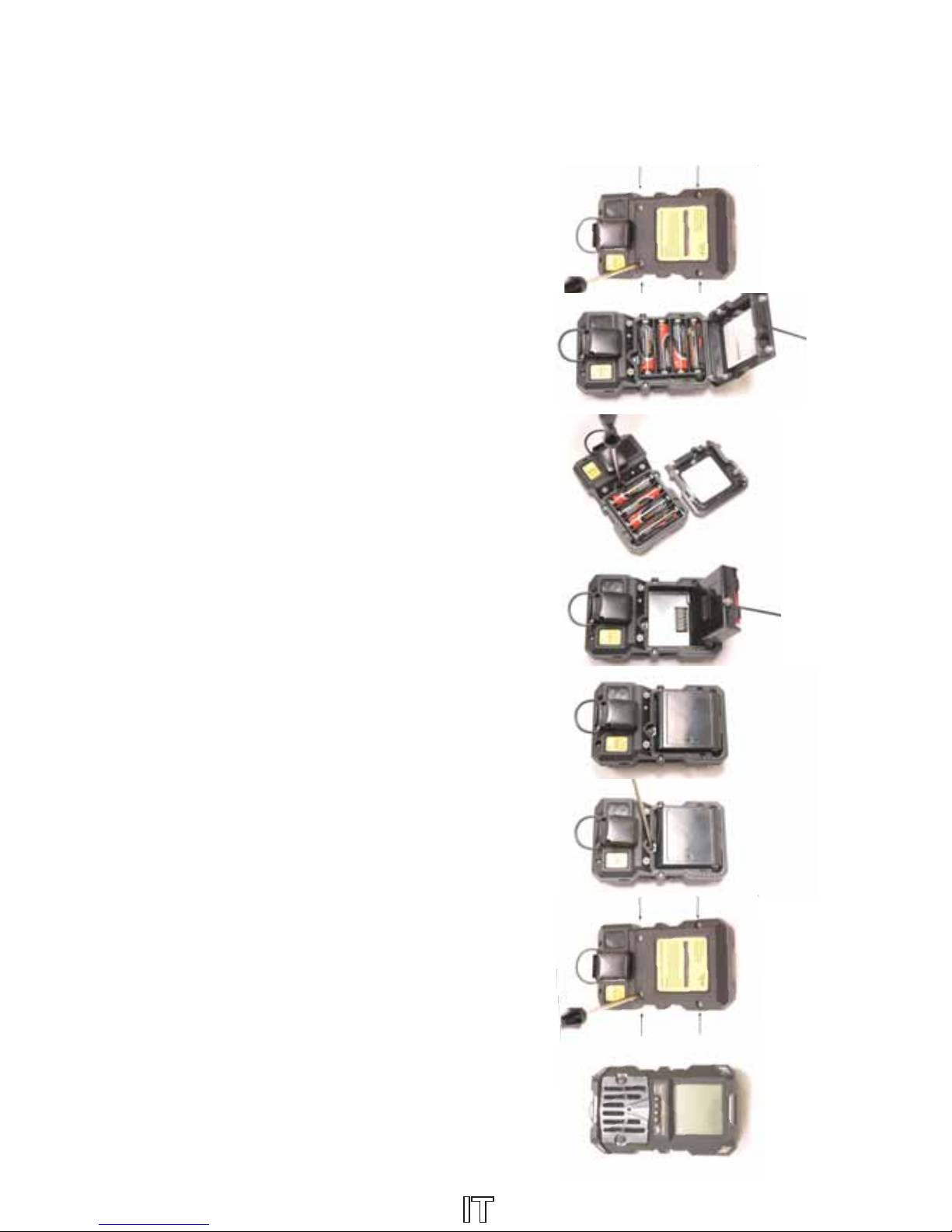

Operation - Battery Installation - Alkaline Batteries

Caution: Always change batteries in an environment free of combustible gas.

Follow your local regulations for proper disposal of alkaline batteries.

1. The battery compartment is located

on the bottom of the back side of the

housing. Loosen the four #0 Phillips type

screws recessed at the top outer edges

of the battery compartment cover.

2. Remove the battery compartment cover

by pulling it away from the main body

of the instrument at the top of the

battery housing. This will release the

bottom hinge locks for cover removal.

3. Remove and install four new approved

alkaline “AA” type batteries. Note the

polarity. If the batteries are installed

incorrectly no damage to the instrument

will occur though it will not operate.

4. Insert the bottom of the battery

compartment cover into the housing and

rotate the cover into position.

5. Tighten the four retaining screws.

Do not over tighten.

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

13

Operation - Battery Installation - Rechargeable Pack

Caution: Always change batteries in an environment free of combustible gas.

Use only Sensit Technologies approved battery pack. Follow your local regulations

for proper disposal of the rechargeable battery pack.

1. The battery compartment is located on the

bottom of the back side of the housing Loosen

the four #0 Phillips type screws recessed at the

top outer edges of the battery compartment

cover.

2. Remove the battery compartment cover by

pulling it away from the main body of the

instrument at the top of the battery housing. This

will release the bottom hinge locks for cover

removal.

3. Loosen the #0 Phillips screw retaining at the

base of the alkaline or rechargeable pack.

4. Gently remove the pack by pulling upward and

allowing the battery pack retaining tabs to slide

out of the holder.

5. Insert the retaining tabs of the battery pack into

position and push gently into position.

6. Replace and secure the retaining screw. Do

not over tighten.

7. Insert the bottom of the battery compartment

cover into the housing and rotate the cover

into position.

8. Tighten the four retaining screws. Do not over

tighten.

9. Recharging is accomplished through the use

of approved battery charger. Charging pins

are located on the front housing of the P400.

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

14

Operation – Instrument Charging

Caution: Do not attempt to recharge alkaline batteries.

Use only Sensit Technologies battery pack and charger.

1. Connect battery charger to proper electrical source

(100vac – 240vac) using supplied wall adapter.

Do Not Substitute

a. The green LED will illuminate

2. Lay the P400 face down into the charger cradle.

a. Green LED on and ashing Red LED

indicate charging in progress

b. Green and Red LED constantly on

indicate full charge

c. Green and Red LED ashing indicate a

charging error. Disconnect and retry.

Operation – Button use from working display

1. Power ON

Press upper right button (O) until the display

illuminates to power on.

2. Power OFF

Press and hold upper right (O) + upper left

(r) buttons for 6 seconds at the same time to

power off.

3. Access User Menu

Press and hold lower right (X) + lower left (s)

buttons for 3 seconds to access the user menu

4. Save Current Data (Snapshot)

Press and hold any button for 2 seconds to

save current data (snapshot)

5. Activate Backlight

Press and release any button to activate the

backlight for the preset time (30 seconds

default).

6. Reset IDS

Press and release any button to reset IDS

indicator (if activated).

O

X

r

s

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

15

Operation – Button Use From Menu

1. Press and hold lower right (X) + lower left (s) buttons for 3 seconds to access the

user menu.

2. Press either the upper or lower left button to scroll through the selections.

3. Press the upper right button to select a menu item.

4. Press the lower right button to return to the working display.

Menu items include:

a. Set Time – change clock time (24hr basis)

b. Set Date – change date. ddMONyyyy format

c. Auto Zero – perform a re-zero of all sensors.

d. Auto Cal – Calibrate all sensors

e. Peak Hold – Show Peak readings on display (102 Maximum Entries)

f. Bump Test – Perform sensor/alarm function test

g. Bump Log – displays last 93 bump tests for each sensor

including date/time (93 Maximum Entries)

h. Cal Log – displays last 10 gas calibrations for each

sensor including date/time. (10 Maximum Entries)

i. Data Log – View contents of automatic data log. (10752 Maximum Entries)

j. Snapshots – View instant saves (100) which includes all readings

and date/time (102 Maximum Entries)

k. Event Log – displays all alarm events including date/time (120 Maximum Entries)

l. Settings – Display operational info such as alarm settings

m. Supervisor – Supervisor adjustable features (password protected)

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

16

Operation - Start Up

Caution: Always start instruments in an area known to be of normal oxygen

content and to be free of combustible gases and contaminants.

1. Push and hold the upper right button (O) until the instrument activates.

2. The instrument will perform a set of self tests. During this time the display will

show:

a. System Check

i. Name of company/user (optional)

ii. Serial number

iii. Battery check

iv. Calibration gas type

v. Software version number

vi. Time

vii. Date

b. UI Check – User Interface check (alarm activations)

i. Top Red LED

ii. Bottom Red LED

iii. Top Green LED

iv. Sounder

v. Vibration

1. Each alarm activation test is indicated

by reverse display highlight and remains

on for 3 seconds

c. Warm Up

i. Display “Please wait” for a minimum of 10 seconds.

ii. If a power supply failure occurs, the instrument will display

“SERVICE REQD” followed by a listing of the type of failure.

VIB VOLT: FAIL indicating a voltage failure to the vibratory motor

BIAS VOLT: FAIL indicating a voltage failure to the electrochemical sensors

EX VOLT: FAIL indicating a failure to the combustible gas sensor

A countdown timer will show the amount of time

remaining before the instrument turns off.

Pressing the two top buttons will also power the

instrument off immediately.

Consult Sensit Technologies for further assistance.

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

17

Operation - Start up (Continued)

d. Auto Zero – indicating automatic zeroing process (clean air only)

i. Displays sensor type and PASS or FAIL

ii. If a sensor indicates FAIL the information

will be in reverse contrast.

1. Press any button to acknowledge

and continue warm up

e. Calibration due dates (when scheduled calibration is due next)

i. Displays sensor type and number of days remaining

ii. If a sensor is past due the displayed information will be in reverse

contrast

iii. Press any button to acknowledge calibration past due (if activated).

1. Use left side buttons to highlight SKIP or CALIBRATE

a. SKIP allows operation. Info will be recorded

b. CALIBRATE allows for immediate manual or automated

calibration.

f. Optional Bump Test

i. Display will prompt user to perform bump test if activated as part

of the supervisor set up.

ii. Onscreen selection allows SKIP or BUMP.

iii. Bump test is updated automatically for next required test upon

successful completion.

g. Sensit Logo will be displayed

h. Working display

3. All readings show horizontally “gas type” “concentration”

“unit of measure” and IDS status (if enabled).

4. The instrument is now reading gases as ltered through the ambient dust lter on

the front of the instrument.

a. To check lter remove two 3/32 Allen screws from the front of the

instrument. Check and/or clean lter prior to each days use with

warm water only. For Filter Replacement, see page 22.

5. A green ickering LED indicates the instrument has been bump tested and

calibrated per company regulations and is operating normally.

Caution:

Always check the lter membrane for damage

or excessive dirt or dust which will prevent gas

samples from being sensed.

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

18

Operation - Field Use

1. After successful start up, test the work area based on State, Federal,

Municipal or Company work procedures.

2. To test conned spaces

a. The entire instrument can be lowered with a tether by attaching to

the ring on the suspender clip on the back of the instrument. When

tethering, it is best to operate the instrument using the “Peak Hold”

function. Use Menu Function to enable.

b. Use a probe with the aspirator assembly. See page 27 for details.

c. Use the Motorized sample system. See page 27 for details.

3. For instruments with the optional auxiliary

pump attached, connect the probe assembly.

Test each level you wish to check for 90

seconds to make sure the work area is safe.

4. During use in the work area, the suspender

clip will secure the instrument to a belt or

clothing. A “D” ring is part of the clip if you

wish to hang the instrument near the area

where personnel are performing work.

5. To view the display in a darkened

environment, push and release any button.

The backlight will remain on for 30 seconds.

6. The Immediate Detection System (IDS)

will begin to tick when the preset value is

exceeded. The tick will incrementally increase with each increased change

in concentration. Push any button to reset.

7. During alarms conditions the backlight will illuminate, the LED’s will ash,

the vibrator will activate and the alarm sound will be heard. Only during

LOW alarms when TWA alarms are activated can the sound be muted and

the vibrator deactivated by pressing any button (Using snooze feature in

supervisor menu-default is off so no mute is possible). The LED’s will continue

to ash during the mute phase.

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

Operation - Field Use (Continued)

8. During STEL alarms no muting or deactivating is

possible.

9. During HIGH or HIGH HIGH alarms no muting

or deactivating is possible.

10. Any gas that is in the alarm mode, the alarm

type will be displayed in reverse dark contrast.

If the IDS feature is activated, it will be reversed

in gray contrast.

11. The LEL sensor has a maximum reading of

110%. This reading will latch if the oxygen

level also drops below 15% while in this over-

range reading.

12. Latching alarms, if the feature is activated,

require the push of a button to disable any alarm only if the gas concentration

has reduced at a non-alarm level.

13. When the shift time feature is enabled and the end of shift alarm activates

press the button corresponding to Yes or No for continuing shift. Each

acknowledgement adds one additional hour.

14. Snapshot is performed by pressing any button for 2-3 seconds. This will store all

onscreen readings for upload or review. The screen will ash momentarily.

15. Battery low indication will activate when the battery voltage reaches 4.1v. At

4.0v the instrument will turn off.

16. If the automatic power off alert activates press any button to add one additional

hour of runtime.

19

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

20

Alarms

Caution: During any alarm follow company procedures!

The Sensit P400 has a wide range of alarm types that can be activated through

the User Set Up menu. The alarm types range from those with a simple set point

to those using TWA and STEL measurements required by those customers with

more sophisticated users or operational standards as implemented by an industrial

hygienist.

Each alarm will cause a unique display message and alarm cycle to be heard based

on the level or severity of the gas mixture present. During any alarm the working

display will highlight the particular gas, the concentration and the backlight will be

turned on. Other alarm indications will include:

• Low Alarm/TWA alarm = Display in reverse contrast; Display alarm type

“Low” or “TWA”; Top and bottom LED’s will ash and vibrating motor will

operate for 1 second intervals; alarm sound will be heard; all alarms will

repeat every 2 seconds; muting will cause the contrast to become grey in color.

• High alarm = Display in reverse contrast; Display alarm type “Hi”; Top and

bottom LED’s will ash 1/2 of a second intervals; alarm sound will be heard

every 1/2 of a second interval; the vibrating motor will operate every 1/2 of a

second intervals; for all alarms will repeat every 2 seconds; no muting is possible.

• HiHi/STEL alarm = Display in reverse contrast; Display alarm type “HiHi” or

“STEL”; Top and bottom LED’s will ash 2/10ths of a second intervals; alarm

sound will be heard every 1/10th of a second interval; the vibrating motor will

operate every 1/2 of a second intervals; for all alarms will repeat every 2

seconds; no muting is possible.

1.888.475.5235

info@Sensit-Direct.com

SENSIT-Direct.com

Table of contents

Other Sensit Measuring Instrument manuals

Sensit

Sensit GOLD 100 User manual

Sensit

Sensit HCN User manual

Sensit

Sensit CO User manual

Sensit

Sensit ULTRA-TRAC APL Programming manual

Sensit

Sensit CO User manual

Sensit

Sensit HCN User manual

Sensit

Sensit GOLD G2 User manual

Sensit

Sensit HXG-3 Programming manual

Sensit

Sensit P100 User manual

Sensit

Sensit PTS350A User manual