SENSTAR FlexPS User manual

Product

Guide

FlexPS®

Fence-mounted Perimeter Intrusion Detection Sensor

G5DA0102-001 Rev G

July 8, 2015

Page 2 FlexPS Product Guide

Senstar Corporation

Website: www.senstar.com

Email address: info@senstar.com

G5DA0102-001 Rev G

July 8, 2015

FlexPS, Senstar and the Senstar logo are registered trademarks, and Armour-FLEX, Silver Network, and Crossfire are

trademarks of Senstar Corporation. Product names and Company names included in this document are used only for

identification purposes and are the property of, and may be trademarks of, their respective owners. Copyright © 2015, 2011,

Senstar Corporation, all rights reserved. Printed in Canada.

The information provided in this guide has been prepared by Senstar Corporation to the best of its ability. Senstar Corporation is

not responsible for any damage or accidents that may occur due to errors or omissions in this guide. Senstar Corporation is not

liable for any damages, or incidental consequences, arising from the use of, or the inability to use, the software and equipment

described in this guide. Senstar Corporation is not responsible for any damage or accidents that may occur due to information

about items of equipment or components manufactured by other companies. Features and specifications are subject to change

without notice.

The figures included in this document are for illustration purposes only, and may differ from the actual equipment.

Approvals

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any interference received, including interference that may cause

undesired operation.

Any changes or modifications to the software or equipment that are not expressly approved by Senstar Corporation void the

manufacturer’s warranty, and could void the user’s authority to operate the equipment.

Europe:

This device conforms to EN 61000-6-4: 2001 relating to Electromagnetic compatibility for emission standards for industrial

environments.

This device conforms to EN 50130-4: 1995 + amendments A1: 1998 & A2: 2003 relating to Electromagnetic compatibility for

immunity requirements for components of fire, intruder, and social alarm systems.

The use of shielded cables is required for compliance.

Senstar Corporation’s Quality Management System is ISO 9001:2008 registered.

Service statement - We ensure that our products are correctly applied to achieve the maximum benefits for the end-user. We

work hand-in-hand with our customers and remain accessible through all stages of a project - from concept to deployment to

long-term support. We provide design assistance, site surveys, installation support, comprehensive documentation, training,

post-installation annual calibration and maintenance visits, electronics and software extended warranty, rapid factory repair

service and on-call/emergency service. Contact Senstar Corporation to inquire about how a package can be customized for

your unique applications.

FlexPS Product Guide Page 3

Table of Contents

1 System planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Installation overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Security factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8

Fence structures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8

Standard fence types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Chain-link fence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Weld-mesh fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Palisade fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Climb-over deterrent hardware - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Razor ribbon - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Gates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Other structures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Environment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Site Survey - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Perimeter layout guidelines - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Sensor cable selection rules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Cable layout guidelines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Cable length calculator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Fence height recommendations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Fence corners and heavier gauge posts - - - - - - - - - - - - - - - - - - - - - - - - - 16

Service loops - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Drip loops - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Non-sensitive lead-in cable (MEX sensor cable) - - - - - - - - - - - - - - - - - - - 17

Non-sensitive lead-in cable (Mark 2 sensor cable) - - - - - - - - - - - - - - - - - - 17

Gate bypass - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Gate bypass modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Armour-FLEX - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Processor location guidelines - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

AC/DC Power source and wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Power over Ethernet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Grounding considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

Alarm monitoring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

Auxiliary inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

NM Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

Audio listen-in - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

Cable connectors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Equipment requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Page 4 FlexPSProductGuide

2 Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -23

Installing the sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -23

Cable handling rules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -23

Mark 2 cable conditioning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -24

Cable conditioning procedure (part 1 - loosening the center conductor) - - 24

Cable conditioning procedure (part 2 - cable flossing) - - - - - - - - - - - - - - - 25

Installing cable on chain-link fences - - - - - - - - - - - - - - - - - - - - - - - - -26

Bend radius - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

At fence posts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

At corners or heavier gauge posts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Service loops - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Sensor cable overlaps - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Installing cable on chain-link - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Drip loops - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Installing terminators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -31

Installing terminators on MEX cable - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Installing terminators on Mark 2 cable - - - - - - - - - - - - - - - - - - - - - - - - - - 32

Splicing cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -34

Splicing MEX sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 34

Splicing Mark 2 sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

Installing cable on gates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -36

Gate bypass cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Bypass cable installation instructions - - - - - - - - - - - - - - - - - - - - - - - - - - 37

Installing sensor cable on swinging gates - - - - - - - - - - - - - - - - - - - - - - - 37

Sliding gates with cable protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

Installation at a sliding gate on the outside of the perimeter - - - - - - - - - - - 39

Gate disconnect assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -39

Installation instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Installing Armour-FLEX sensor cable - - - - - - - - - - - - - - - - - - - - - - - -40

Mark 2 Armour-FLEX cable conditioning procedure - - - - - - - - - - - - - - - - 41

Cable conditioning procedure (part 1 - loosening the center conductor) - - 41

Cable conditioning procedure (part 2 - cable flossing) - - - - - - - - - - - - - - - 43

Installation instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 44

Installing cable on barbed wire - - - - - - - - - - - - - - - - - - - - - - - - - - - - -47

On razor ribbon - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

Installing cable on weld-mesh fence - - - - - - - - - - - - - - - - - - - - - - - - -47

Installing cable on palisade fence - - - - - - - - - - - - - - - - - - - - - - - - - - -48

Installing the FlexPS processor - - - - - - - - - - - - - - - - - - - - - - - - - -49

Free-standing or fence post mounting the enclosure - - - - - - - - - - - - - - - - 50

Surface mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 53

Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -53

Sensor cable/lead-in cable connections - - - - - - - - - - - - - - - - - - - - - -54

Jumper settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -55

Relay outputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -56

Relay contact ratings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 56

Auxiliary inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -56

Flex audio - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -57

Input/output wiring connections - - - - - - - - - - - - - - - - - - - - - - - - - - - -58

Silver Network wiring connections - - - - - - - - - - - - - - - - - - - - - - - - - -60

Silver Network specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 60

Silver Network data path connections - - - - - - - - - - - - - - - - - - - - - - - -62

Power connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -65

Local power supply - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

Power over Ethernet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

Battery power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

FlexPS Product Guide Page 5

3 Calibration & setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - -67

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 67

Calibration terminology - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 68

Understanding FlexPS alarm detection - - - - - - - - - - - - - - - - - - - - - - 69

Intruder detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 69

Cut detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 69

Climb/crawl-under detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 70

FlexPS initial calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 70

Intrusion simulations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 70

Testing the fence condition - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 71

Connecting the UCM via USB - - - - - - - - - - - - - - - - - - - - - - - - - - - - 71

Sensor calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 71

The Calibrate tool - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 71

Adjusting the Cable setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 71

Setting up the Cut Alarm parameters - - - - - - - - - - - - - - - - - - - - - - - 72

Setting up the Climb Alarm parameters - - - - - - - - - - - - - - - - - - - - - - 72

Preventing weather related nuisance alarms - - - - - - - - - - - - - - - - - - 73

Adjusting the Audio Gain - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 73

Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 74

Specify the Auxiliary I/O control mode - - - - - - - - - - - - - - - - - - - - - - 74

Auxiliary (Aux) inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 74

Local control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 74

Remote control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 74

Input configuration procedure (Remote control mode) - - - - - - - - - - - - - - - 75

Output relays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 76

Output relay setup (Local control mode) - - - - - - - - - - - - - - - - - - - - - - - - - 76

Output relay setup (Remote control mode) - - - - - - - - - - - - - - - - - - - - - - - 76

Setting the processor address - - - - - - - - - - - - - - - - - - - - - - - - - - - - 76

Network configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 76

System test procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 77

The Zone profile - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 78

4 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -79

Adjusting the Filter Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 80

Using the Power Grid filters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 81

Replacing the processor/battery - - - - - - - - - - - - - - - - - - - - - - - - - 81

Removing the processor assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - 81

Replacing the battery - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 81

Replacing the processor assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 82

Updating the firmware - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 83

Adjusting low sensitivity cable - - - - - - - - - - - - - - - - - - - - - - - - - - - 83

Low spot near the end of the cable - - - - - - - - - - - - - - - - - - - - - - - - - 84

Low spot near the middle of a sensor cable - - - - - - - - - - - - - - - - - - - 84

a Parts list - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -85

b Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -89

c NM Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -91

UCM configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 92

Page 6 FlexPSProductGuide

FlexPS Product Guide Page 7

1 System planning

Introduction

The FlexPS fence protection system uses microphonic sensor cable mounted on a fence, to detect

vibrations caused by climbing, cutting, lifting, or otherwise disturbing the fence fabric. Each FlexPS

processor can monitor the activity from one or two sensor zones up to 300 m (984 ft.) long, and will

report the alarm and supervision status of each zone. A single pass of sensor cable will protect

fences up to 2.5 m (8 ft.) high. Additional passes of sensor cable are recommended for fences that

are higher than 2.5 m.

FlexPS can also be used on many other types of building material (e.g., brick, stone, concrete,

cinder-block, stucco, wood, drywall, ceramic). However, due to the different vibration transmission

characteristics of each type of fence or building material, one zone of a processor should be used

on only one type of surface. Contact Senstar Customer service for additional details on non-

standard FlexPS applications.

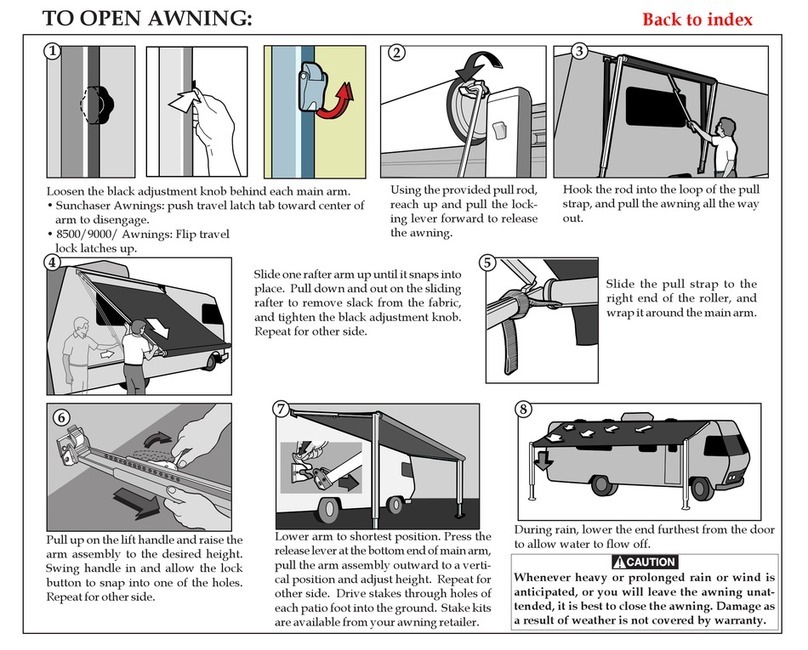

Installation overview

Installing a FlexPS system is a four step process:

1. Plan and design the system.

2. Prepare the mounting surface, and install the sensor cable and terminator.

3. Install the processor and enclosure.

• ground rod

• power supply

• alarm communication wiring

• lead-in cable if the processor will be located away from the protected surface

4. Setup and calibrate the system.

Note When using FlexPS to protect a surface other than chain-link or

weld-mesh fencing, Senstar strongly recommends installing and

testing a single short-length sensor zone before installing a

complete system.

Security factors

Page 8 FlexPS Product Guide

Security factors

There are many important factors to consider when planning a fence-mounted perimeter security

system:

• Fence height - The fence must be high enough to present an effective barrier to climb-over

intrusions. It should also include climb-over deterrent hardware such as barbed wire or razor

ribbon. Senstar recommends that the minimum fence height for a FlexPS installation be 2.5 m

(8 ft.). A lower fence can be quickly and easily breached with a climbing aid such as a ladder.

• Fence condition - FlexPS detects intrusions by picking up the minute vibrations or fence noise

caused by an intrusion attempt. Therefore, the fence must be in good condition to prevent any

metal on metal contact or vibrations caused by environmental effects. It may be necessary to

upgrade the perimeter fences to ensure they present sufficient barriers against climb over and

crawl under intrusions. If you are not sure of the suitability of your fence for a FlexPS sensor,

Senstar recommends hiring a local fencing contractor to inspect, and if required, repair the

fence.

• Alarm assessment/response - What happens when the system triggers an alarm? Can the

alarm be assessed visually? Does the site include CCTV coverage to verify the event? Does

an operator monitor the system? Does the system contact a remote monitoring service? How

long does it take the alarm response to arrive at the zone? Does the system activate sirens

and lights to deter an intruder?

• Probability of detection (Pd) vs. nuisance alarm rate (NAR) - With a fence-mounted intrusion

detection system there is always a trade-off between the probability of detection and the

nuisance alarm rate. A properly calibrated system will provide a high Pd by matching the

sensor’s sensitivity (cable gain) to the fence and cable type.

Fence structures

All fence panels in a sensor zone should be similar in type, size and condition. Ensure that there

are no loose panels, fittings or metal parts that can move and cause nuisance alarms. A shake test

in which you grip the fence fabric in the middle of a panel and gently shake it back and forth with

an increasing motion will help identify any loose pieces. Listen for metal-on-metal contact and

correct any problems found. Verify that there are no washouts or depressions under the fence that

could allow an intruder access. Ensure that there is no vegetation or other objects that can make

contact with the fence in windy conditions.

Fence structures

FlexPS Product Guide Page 9

Standard fence types

Chain-link fence

Chain-link fence is comprised of steel wires that are bent lengthwise into zig-zag patterns. The zig-

zag wires are vertically woven to form the characteristic diamond pattern. The fence fabric is

attached to fence posts approximately 3 m (10 ft.) apart. Tension wires are often used to stiffen the

fence fabric at the top, bottom and middle of the fence. Chain-link fences are available in different

heights and are sometimes vinyl coated.

Weld-mesh fences

A typical weld-mesh fence section consists of steel wire welded into a grid, with horizontal spacing

differing from vertical spacing. These fence sections are secured to fence posts and to top and

bottom rails.

Palisade fences

Palisade fences usually consist of vertical metal stakes that are attached to horizontal support

members, which are supported by metal posts. The effectiveness of FlexPS on a palisade fence

depends on the characteristics and construction of the particular fence. Palisade fences conduct

vibrations well and any attempt to cut into the fence will be detected. However, because the fence

is rigid, climb-over intrusion attempts are more difficult to detect on a palisade fence than on than

chain-link or weld-mesh fences. A trial on a section of the palisade fence is recommended before

an entire system is installed to determine if the climb-over detection meets the site requirements.

Climb-over deterrent hardware

Barbed wire outriggers must be secure to prevent movement due to environmental conditions.

Install bracing wires between the outrigger supports to prevent the barbed wires from spreading

apart. Each barbed wire strand should be taut and tightly secured at each support. Any extension

arms or outriggers attached to post tops should have a tight press-fit or be spot-welded. Remove

or fasten any loose or rattling equipment.

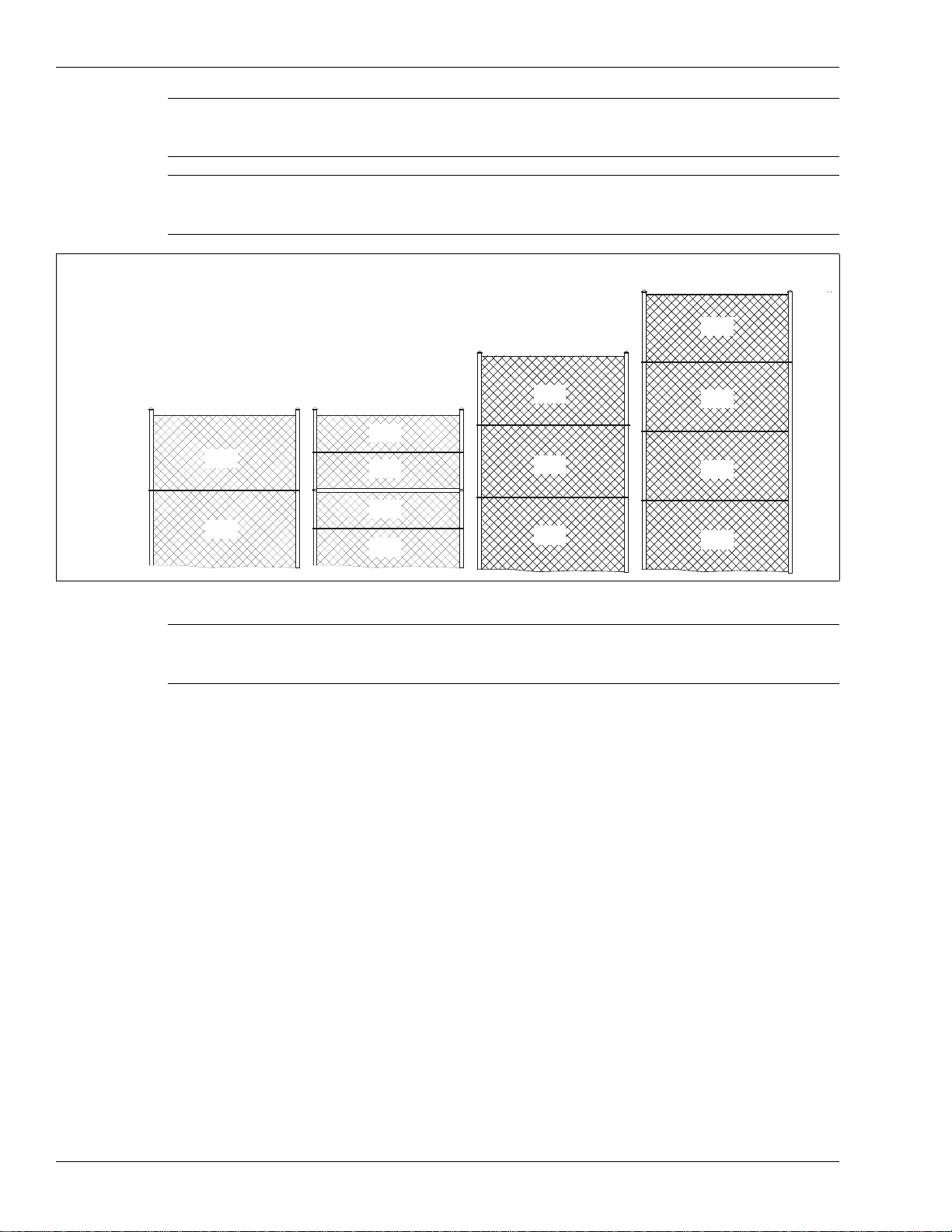

Figure 1: Fence types

Note Ornamental palisade fences, which use non-metallic support pillars

(e.g., concrete or brick)may not be suitable for use with the FlexPS

system. The non-metallic pillars can make the fence vulnerable to

climb-over intrusions.

chain-link weldmesh palisade

Fence structures

Page 10 FlexPS Product Guide

Senstar recommends using Armour-FLEX cable when protecting barbed wire. To protect both the

fence and the barbed wire, use one zone of Armour-FLEX cable installed in a saw tooth pattern on

the barbed wire, and use sensor cable on the fence fabric for the second zone (see Figure 2: ).

This configuration allows both zones to be properly calibrated for the specific mounting surface.

Razor ribbon

FlexPS sensor cable can be installed on razor ribbon. However, due to the likelihood of the sensor

cable being damaged, Armour-FLEX cable is recommended. The razor ribbon must be secured so

that it does not move in the wind. Use tensioning wires to secure the coil and to prevent the razor

ribbon from separating if it is cut.

Figure 2: Recommended cable installation on barbed wire fence

Figure 3: Razor ribbon

Armour-FLEX on barbed wire array

sensor cable on fence fabric

both channels of one processor used:

CH A with Armour-FLEX on barbed wire

CH B with sensor cable on fence fabric

bracing wire

barbed wire array

outrigger

fence fabric

razor ribbon

Armour-FLEX sensor cable

tensioning wires (2)

Fence structures

FlexPS Product Guide Page 11

Gates

Gates should consist of fence fabric on a rigid frame that includes horizontal and vertical bracing.

• Firmly attach all gate hardware accessories (minimum free-play).

• Make sure that double gates have travel stops (rigid anchors).

• Prevent locking hardware from moving in the wind.

• Prevent sliding gate track hardware, supports, guides, etc., from rattling in the wind.

There are generally two types of gates used with fences, swinging gates and sliding gates. The

type of gate protection required is determined by:

• the type of gate

• the frequency of gate use

• when the sensor is active

• the type of ground beneath the gate

• the overall protection plan (the number of zones and their location relative to the gate in

question)

Gates in a FlexPS zone that are not protected by the sensor are bypassed using non-sensitive

lead-in cable (see Figure 36: ). The lead-in cable is installed inside conduit, underground, from one

side of the gate to the other. The sensor zone continues beyond the gate, and another technology

is used to provide protection in the area of the gate (e.g., a microwave sensor).

Occasionally, it is not possible to dig underground to continue the active zone coverage on the

other side of a gate. There are three standard solutions for this situation:

• Install the cable on the ground surface, under a secured, protective cable mat.

• End the zone at the gate.

• Connect the cable across the gate using quick-disconnect connectors.

Other structures

The FlexPS sensor can be used on other types of fences and structures. It can be deployed on

wooden fences, walls, along the top of concrete or brick walls to detect climb-overs, inside

conduits to protect sensitive data cables, on pipes to prevent sabotage, etc. For installation

information on walls, buildings, wrought iron, or other fence types contact Senstar Customer

Service.

Environment

Ensure that the ambient temperature, as measured inside the enclosure, is within the range of -40

to +70º C (-40 to +158º F). For installations in environments which include hot sunny periods,

install a sun shield to protect the enclosure from direct sunlight, or install the enclosure in a shady

area. Extra care must be taken at sites that experience strong winds on a regular basis. The fence

must be maintained in excellent condition to prevent any metal to metal contact caused by the

wind. All vegetation (weeds, brush, trees, etc.) must be cleared from around the fence area.

Vegetation must not touch or hang over the fence fabric. Any objects that may contact the fence

must also be removed from the perimeter.

Note Always install and test a short FlexPS zone (< 100 m) before

installing a full system on a non-standard mounting surface.

Site Survey

Page 12 FlexPS Product Guide

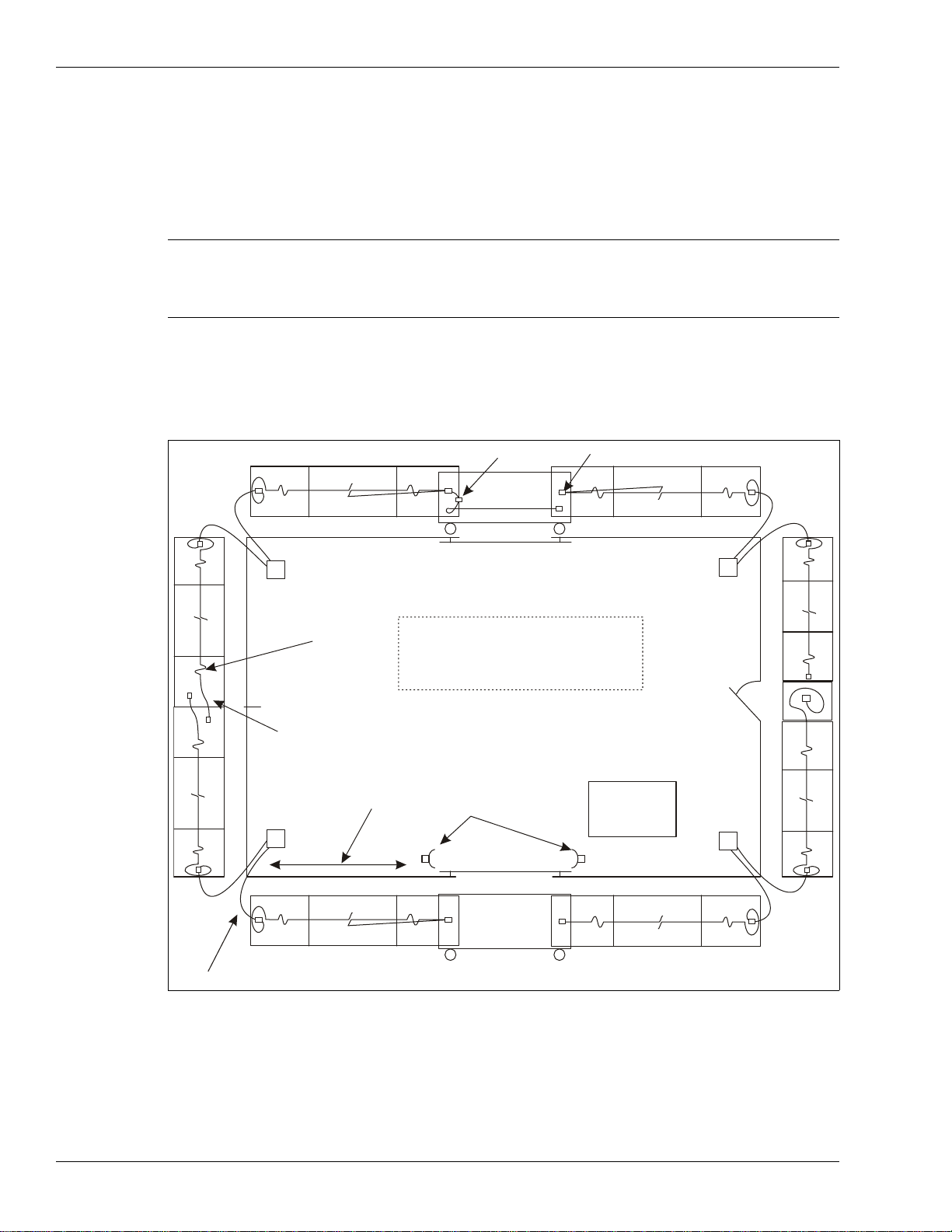

Site Survey

Conduct a site survey to ensure that site conditions are suitable for a FlexPS sensor system. The

primary concern is the condition of the fences and gates.

Indicate the following on the site plan:

• The locations of existing structures (include fences, gates, buildings, roads, etc.). Verify that

mounting surfaces comply with established standards for installation and stability.

• The locations of obstacles such as vegetation and trees.

Note Sites that include a fence line that abuts the primary perimeter

fence can be vulnerable to climb over intrusions where the two

fences meet. To increase security in this situation, extend the

FlexPS zone for at least 2 m onto the abutting fence.

Figure 4: Sample site plan

gate disconnect terminator (typical)

sally port gate

(included in Z6) proc #2

swinging gate

(included in Z3)

NOTE:

proc #1

proc #4

proc #3

service

loops

end of zone overlap

(approx. 1.5 m, 5 ft.)

also required at start points

app. max. 270 m (886 ft.) microwave sensor main

building

gate disconnect

not required

- drip loops at each splice/termination

- service loops

- sensitivity loops at corner posts

sally port

gate

Z1 Z2

Z3

Z4

Z5

Z6

Z7

Z8

Z9

lead-in cable (typical)

Perimeter layout guidelines

FlexPS Product Guide Page 13

Perimeter layout guidelines

Use a site plan to mark the locations for the FlexPS components:

• Sensor cable - indicate the cable layout for each zone.

• Lead-in cable - Indicate the layout if lead-in cable is being used (at the processor, for a

bypass).

• Cable connectors - indicate the type of connection (splice, terminator).

• FlexPS processors (note the addresses for network based processors).

• Power supply - indicate the type of power supply and the power distribution plan.

• Alarm communication wiring (relay output or network alarm communications).

Sensor cable selection rules

There are two types of sensor cable available for use with the FlexPS system, MEX cable and

Mark 2 cable. MEX cable uses a fixed center conductor and contains a permanent electrical

charge. Mark 2 cable uses a loose center conductor inside a clear tube and generates an electrical

signal through the triboelectric effect.

Figure 5: Mark 2 and MEX sensor cable reels

150 m (492 ft.) reel

Mark 2 sensor cable

300 m (984 ft.) reel

MEX sensor cable

Perimeter layout guidelines

Page 14 FlexPS Product Guide

Use MEX sensor cable on standard chain-link, weldmesh and expanded metal fences. MEX

cable is thinner and lighter than Mark 2 sensor cable and does not require conditioning. MEX

sensor cable comes in 100 m (328 ft.) 200 m (656 ft.) and 300 m (984 ft.) lengths.

Use Mark 2 sensor cable on vinyl coated chain-link fences, on palisade fences, and on fences

that are used around sites with a high level of EMI such as electrical and solar power generating

stations. Mark 2 sensor cable has a higher sensitivity than MEX sensor cable, and requires cable

conditioning before it can be installed. Mark 2 sensor cable comes in 150 m (492 ft.) lengths. Two

lengths of Mark 2 can be spliced together to provide a 300 m (984 ft.) sensor cable.

Cable layout guidelines

• The sensor cable must be mounted on the same or similar type of surface for each zone.

• The maximum length of sensor cable is 300 meters (984 ft.) per zone.

• The smallest allowable bend radius for MEX sensor cable is 4 cm (1.6 in.).

• The smallest allowable bend radius for Mark 2 sensor cable is 7.5 cm (3 in.).

• The smallest allowable bend radius for Armour-FLEX sensor cable is 15 cm (6 in.).

• The sensor cable should follow the ground contour to maintain a constant height above the

ground.

Figure 6: MEX and Mark 2 cable comparison

Note Contact Senstar Customer Service for applications advice when

ordering FlexPS sensor cable.

Mark 2 cable

polyethylene

jacket

braided

shield loose solid

center conductor

clear tube

foil

clear tube

center conductor

aluminum foil

braided shield

outer black jacket

center conductor

braided shield

outer black jacket

MEX cable

polyethylene

jacket braided

shield fixed stranded

center conductor

dielectric core

MEX cable

Mark 2 cable

fixed center

conductor

loose center

conductor

dielectric core

Perimeter layout guidelines

FlexPS Product Guide Page 15

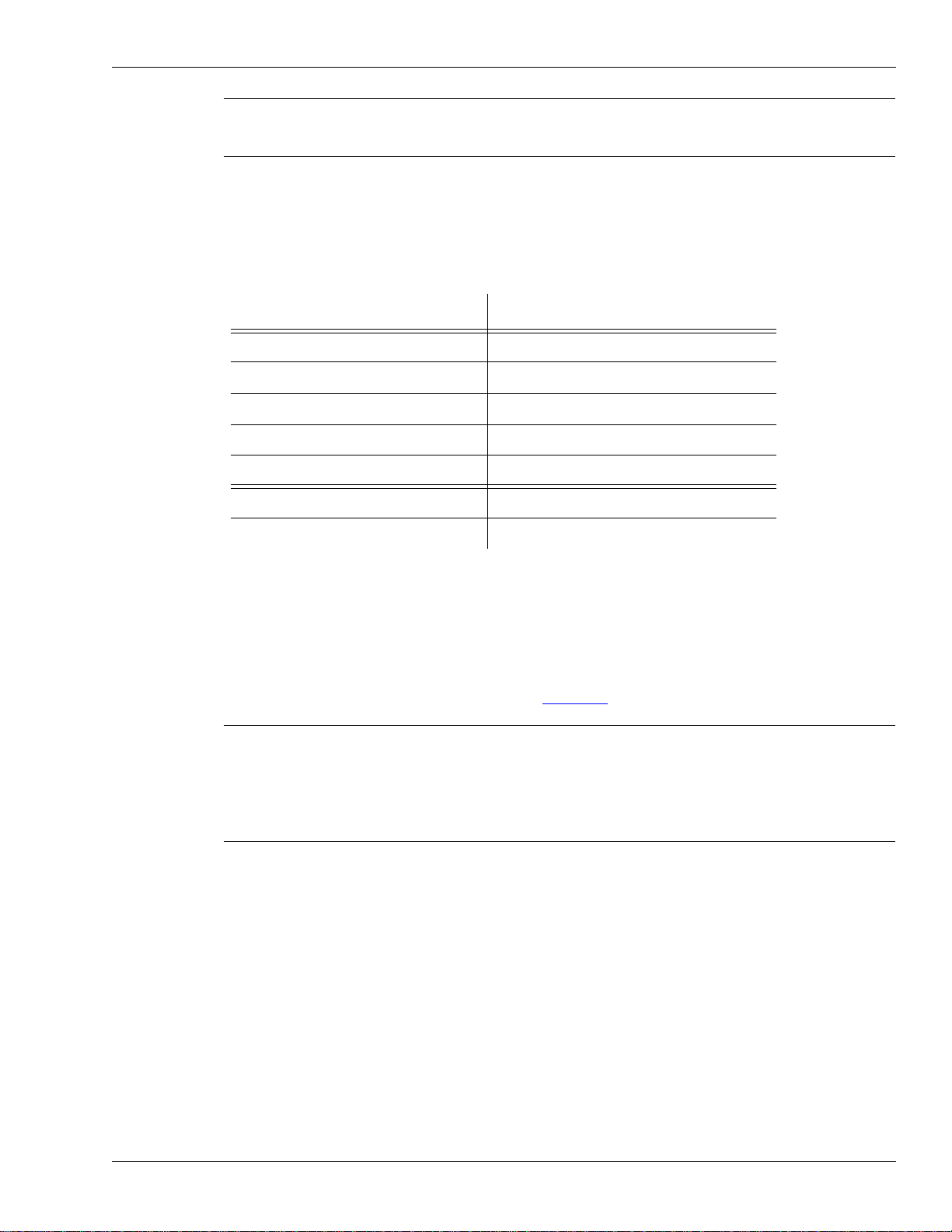

Cable length calculator

Typically, a zone requires approximately 10% more cable than the linear zone length. The

following table provides a guideline for calculating the amount of sensor cable required for a zone

(in meters):

Fence height recommendations

The following cable spacing recommendations provide good security on well maintained fences.

However, depending on the security requirements and the fence condition, it is possible to use

alternate cable spacing. For example, on a high quality fence, in excellent condition, you could use

a single pass of cable to cover a 3 m (10 ft.) fence. However, to ensure the highest Pd, Senstar

recommends the following cable spacing (see Figure 7: ):

• For standard fences up to 2.5 meters (8 ft.) tall - a single pass of MEX sensor cable at 1/2 the

fence height.

• For standard fences greater than 2.5 m and less than 4.5 m (15 ft.) tall - a double pass of MEX

sensor cable at 1/3 and 2/3 the fence height.

• For standard fences exceeding 4.5 m - three or more equally spaced passes of MEX sensor

cable. This depends on the fence fabric and structure, and on the site’s security requirements.

• For vinyl coated fences up to 2.5 meters (8 ft.) tall - a double pass of Mark 2 sensor cable at

1/3 and 2/3 the fence height.

For higher vinyl coated fences, use double the recommended cable passes of Mark 2 cable for

standard chain-link of similar height.

• For palisade fences that are less than 1.8 m (6 ft.) high, a single pass of Mark 2 cable along

the top rail.

• For palisade fences that are greater than 1.8 m (6 ft.) high, use a dual pass of Mark 2 cable

along the top and middle rails.

Note Senstar strongly recommends installing the sensor cables on the

secure side of the perimeter (the side of the fence opposite the

threat).

zone element required cable length

start point + 1 m

service loops + 0.75 m X (linear zone length / 15)

corner and heavy gauge posts + 3.5 m X number of posts

cable terminations and splices + 0.5 m each

linear zone length + _ _ _ _ _ (zone length in meters)

required length of cable per pass = _ _ _ _ _ (total length in meters)

total length X number of passes = _ _ _ _ _ cable length (max. 300 m)

Note The term standard refers to uncoated chain link, weld mesh, and

expanded metal fences. Painted fences are included in the standard

fence type, but the fence must be painted before the sensor cable is

attached. If a fence will be painted after the sensor cable is installed, the

cable must be removed while the fence is being painted, and then

reinstalled after the paint has completely dried.

Perimeter layout guidelines

Page 16 FlexPS Product Guide

Fence corners and heavier gauge posts

Corner posts and heavier gauge support posts tend to dampen the fence’s vibration transmission

characteristics. Therefore, use cable loops at corner posts and heavy gauge support posts, to

increase the sensitivity. Each sensitivity loop requires approximately 3.5 m (11.5 ft.) of sensor

cable.

Service loops

Service loops provide extra sensor cable along the fence to make cable repairs. Allot 75 cm

(30 in.) of cable each 15 m (50 ft.) for a service loop. Locate the U-shaped service loops at fence

posts.

Drip loops

Drip loops raise the connector above the sensor cable to prevent water from running along the

cable and accumulating in the enclosure. Drip loops also relieve strain resulting from temperature

changes that cause the cable to expand and contract. Form the drip loop by raising the connector

15 cm (6 in.) above the level of the cable run. Allot 50 cm (20 in.) of cable for each splice or

termination.

Note If the lower edge of the fence fabric is embedded in a concrete

footing, or below ground, use an additional cable pass on the lower

section of fence to increase the sensitivity.

Note If the fence framework includes an intermediate (middle) rail, then

there must be at least one cable pass above the rail and one cable

pass below the rail.

Figure 7: Cable pass recommendations

Note Fences that use vinyl privacy slats may not be suitable for use with

a FlexPS sensor system, as the privacy slats have a tendency to

dampen vibrations.

h > 4.5 m (> 15 ft.)

h = 2.5 to 4.5 m (8 to 15 ft.)

h = 2.5 m (8 ft.)

1/2 h

1/2 h

1/3 h

1/3 h

1/3 h

1/4 h

1/4 h

1/4 h

1/4 h

sensor cable

and vinyl coated fences

single pass

double pass

triple pass

1/4 h

1/4 h

1/4 h

1/4 h

double pass (minimum)

fences with a middle rail

Perimeter layout guidelines

FlexPS Product Guide Page 17

Non-sensitive lead-in cable (MEX sensor cable)

Non-sensitive lead-in cable is almost identical to MEX sensor cable, but does not detect vibrations.

Lead-in cable is available in lengths of 30 m (98 ft.), 150 m (492 ft.) and 300 m (984 ft.). It allows

you to install the processor away from the start of the sensor zone, and is also used to bypass

gates, buildings, and other structures (see Figure 10: ). The recommended maximum length of

lead-in cable for a zone with 300 m of sensor cable is 150 m (492 ft.). This length can be extended

for zones that use shorter lengths of sensor cable (e.g., a zone with 200 m of sensor cable can use

up to 250 m of lead-in cable).

Non-sensitive lead-in cable (Mark 2 sensor cable)

For Mark 2 sensor cable, standard coaxial cable is used for lead-in cable and bypasses. The

length of non-detecting cable that can be used with Mark 2 is determined by the coaxial cable’s

capacitance. The following table includes the approved coaxial cable types that may be used as

lead-in cable with Mark 2 sensor cable, and the maximum lead-in lengths.

The maximum length of non-sensitive cable is based on a zone with 300 m of Mark 2 sensor

cable. The length of non-detecting cable may be extended, provided the length of the Mark 2

sensor cable is reduced accordingly.

Gate bypass

If there is a gate within a FlexPS sensor zone, you require a sufficient amount of lead-in cable to

bypass the gate, even if the gate is protected by sensor cable. Bury the bypass cable in PVC

conduit. See Figure 36: for an example of a bypassed gate, which uses a microwave system to

provide security across the gate.

Gate bypass modules

The gate bypass module is used to bypass a protected gate without triggering an intrusion alarm.

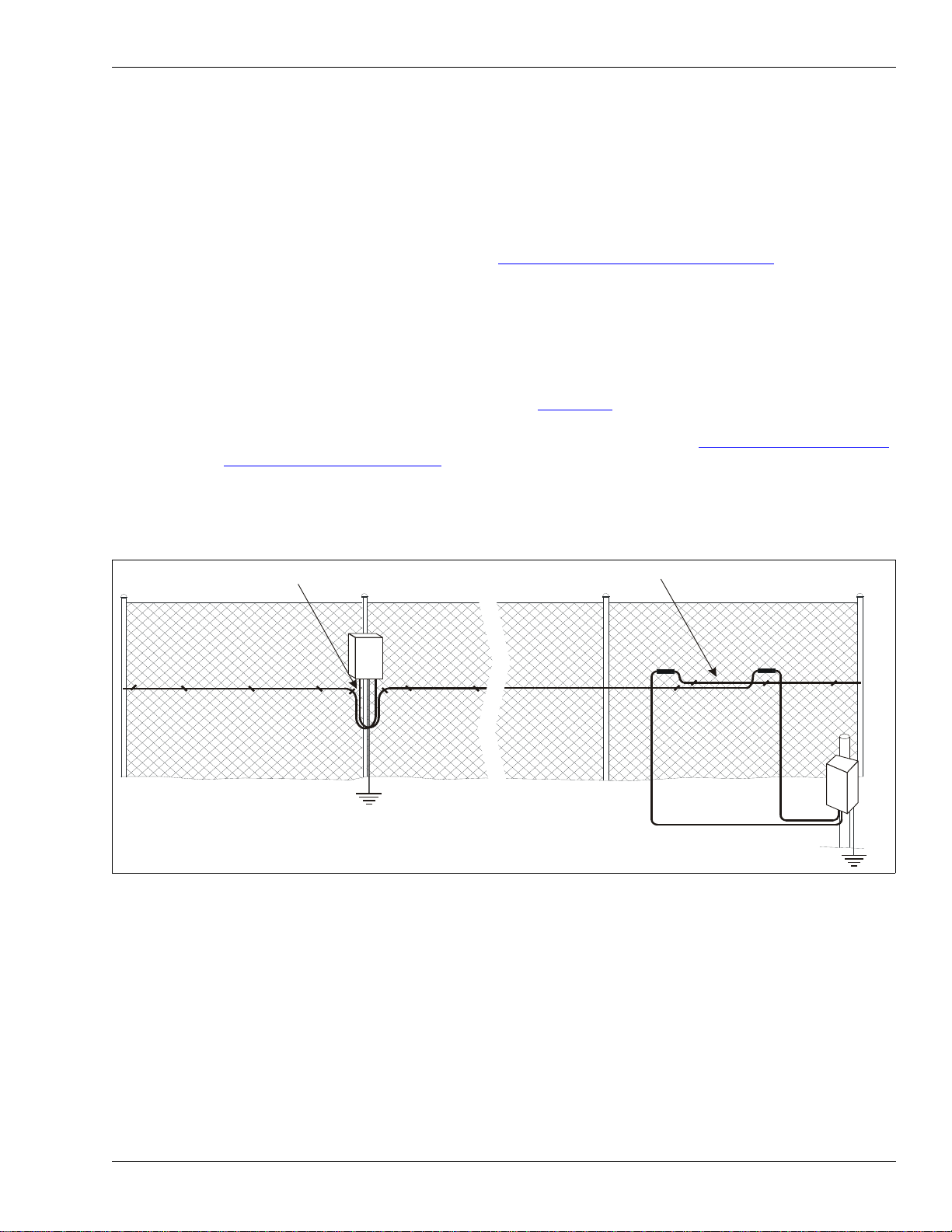

Refer to instruction sheet G5DA0103 for detailed installation instructions for the gate bypass

modules. See Figure 8: and Figure 9: for illustrations of gate bypass modules.

Non-sensitive cable type Maximum length

RG-59/U, 69 pf/m (21 pf/ft.) 116 m (380 ft.)

RG-62/U, 43 pf/m (13 pf/ft.) 186 m (610 ft.)

Perimeter layout guidelines

Page 18 FlexPS Product Guide

There are two types of gate bypass modules available:

• Local bypass module for manual activation (key switch)

When the key is in the access position:

The sensor cable is shunted around the gate or terminated at the gate, depending on the

configuration.

The status contacts close giving a signal to the annunciator device.

Removing the faceplate opens the tamper switch.

• Remote bypass module for remote activation

Remote operation from the display and control system requires a voltage input to the gate

bypass module to energize the bypass relay.

When the relay is energized, the sensor cable is either shunted around the gate or terminated

at the gate, and the bypass module’s status contacts close to signal the annunciator.

If the cover is removed from the bypass housing, the tamper switch opens to signal the

annunciator.

Figure 8: Gate bypass module example

Figure 9: Gate bypass modules

gate bypass module

gate bypassed

splice kit

gate protected

bypass cable

MODEL 2490-2

SECURE ACCESS

MODEL 2490-1

local gate bypass module remote gate bypass module

Perimeter layout guidelines

FlexPS Product Guide Page 19

Armour-FLEX

Armour-FLEX is FlexPS sensor cable encased in a flexible metallic conduit. There are two types of

Armour-FLEX cable, MEX and Mark 2. Armour-FLEX protects the sensor cable from damage and

vandalism, as well as from the sun and weather. Steel cable ties or wire ties are the recommended

fasteners for Armour-FLEX, although UV resistant cable ties can also be used. Armour-FLEX is

available in lengths of 100 meters (328 ft.). Up to three lengths can be spliced together to create a

300 meter (984 ft.) cable. Armour-FLEX splices must be enclosed inside outdoor rated electrical

junction boxes (condulets). Refer to the Sensor cable selection rules on page 13 to select the

correct type of Armour-FLEX cable for your application.

Processor location guidelines

The FlexPS processor can be mounted outdoors on a post, either on, or separate from, the fence

on which the sensor cables are installed (see Figure 10: ). A rigid fixed post is recommended for

outdoor applications. The maximum distance away from the fence that the processor can be

installed is determined by the non-sensitive lead-in cable length (see Non-sensitive lead-in cable

(MEX sensor cable) on page 17). The FlexPS processor can also be installed indoors or outdoors

on a flat stable surface. A post-mount kit is available for post sizes from 4.5 cm to 12.7 cm (1.75 in.

to 5 in.). The hardware required for mounting the processor on a flat surface is customer-supplied.

For installations in which the enclosure must be locked, there is a lockable mounting kit available.

The lockable kit can be used to post-mount or surface mount the FlexPS enclosure.

AC/DC Power source and wiring

The FlexPS processor operates on a wide range of input voltages (12 to 48 VDC). The power

supply, the number of processors, and the lengths of the power cable runs will determine the

gauge of the power cable wiring. In locations where AC power may not be stable or reliable, an

uninterruptable power supply (UPS) should be used for primary power. The following tables

include power cable/load recommendations for 24 VDC and 48 VDC power supplies. The table

assumes a maximum power consumption of 2 W per processor (with NIC and backup battery).

Figure 10: Processor location/ start point overlaps

service loop overlap for fence-mounted processor

lead-in cable

earth ground

1.5 m overlap for post-mounted processor

(consult the local electrical code for grounding requirements) earth ground

Perimeter layout guidelines

Page 20 FlexPS Product Guide

Power over Ethernet

Silver Network based processors using Ethernet communications have the option of using Power

over Ethernet technology to power the FlexPS processor. To use this powering option requires a

PoE standard class 3 switch that is located a maximum of 100 m (328 ft.) from the processor, and

Category 5 network cable. Power over Ethernet is supplied to the processor’s Network Interface

card (NIC) and the power output on the NIC is connected to the power input on the processor.

zone length processor

separation wire gauge power supply

output voltage number of

processors power supply

connected to

processor #

300 m (984 ft.) 600 m (1968 ft.) 18 AWG

(1.02 - 1.27 mm) 24 VDC 5 3

48 VDC 9 5

250 m (820 ft.) 500 m (1640 ft.) 18 AWG

(1.02 - 1.27 mm) 24 VDC 5 3

48 VDC 11 6

200 m (656 ft.) 400 m (1312 ft.) 18 AWG

(1.02 - 1.27 mm) 24 VDC 5 3

48 VDC 11 6

150 m (492 ft.) 300 m (984 ft.) 18 AWG

(1.02 - 1.27 mm) 24 VDC 7 4

48 VDC 13 7

100 m (328 ft.) 200 m (656 ft.) 18 AWG

(1.02 - 1.27 mm) 24 VDC 7 4

48 VDC 17 9

50 m (164 ft.) 100 m (328 ft.) 18 AWG

(1.02 - 1.27 mm) 24 VDC 11 6

48 VDC 25 13

Table 1 Power supply/power cable loads (18 AWG power cable)

zone length processor

separation wire gauge power supply

output voltage number of

processors power supply

connected to

processor #

300 m (984 ft.) 600 m (1968 ft.) 16 AWG

(1.29 - 1.53 mm) 24 VDC 5 3

48 VDC 13 7

250 m (820 ft.) 500 m (1640 ft.) 16 AWG

(1.29 - 1.53 mm) 24 VDC 7 4

48 VDC 13 7

200 m (656 ft.) 400 m (1312 ft.) 16 AWG

(1.29 - 1.53 mm) 24 VDC 7 4

48 VDC 15 8

150 m (492 ft.) 300 m (984 ft.) 16 AWG

(1.29 - 1.53 mm) 24 VDC 9 5

48 VDC 15 8

100 m (328 ft.) 200 m (656 ft.) 16 AWG

(1.29 - 1.53 mm) 24 VDC 11 6

48 VDC 21 11

50 m (164 ft.) 100 m (328 ft.) 16 AWG

(1.29 - 1.53 mm) 24 VDC 15 8

48 VDC 31 16

Table 2 Power supply/power cable loads (16 AWG power cable)

CAUTION The PoE NIC is intended to supply power only to the processor on

which it is mounted. Do not attempt to power an auxiliary device with

the PoE NIC.

Note Senstar strongly recommends the use of a fully managed PoE switch to

connect and power IP based FlexPS processors.

Table of contents

Other SENSTAR Accessories manuals

SENSTAR

SENSTAR FPS 2-2 User manual

SENSTAR

SENSTAR FlexZone WGS User manual

SENSTAR

SENSTAR FiberPatrol FP1150 Series User manual

SENSTAR

SENSTAR UltraWave BR100 User manual

SENSTAR

SENSTAR OmniTrax User manual

SENSTAR

SENSTAR FlexZone User manual

SENSTAR

SENSTAR IntelliFIBER User manual

SENSTAR

SENSTAR FiberPatrol FP1100X Series Technical manual

SENSTAR

SENSTAR FiberPatrol FP400 User manual