SENSTAR FiberPatrol FP1100X Series Technical manual

Site Planning

Guide

FiberPatrol®

Ranging Fiber Optic Fence Protection Sensor

FPDA0102-401, Rev F

January 8, 2019

& Installation

FP1100X/FP1400 series

Page 2 FiberPatrol Site Planning & Installation Guide

FiberPatrol

FPDA0102-401, Rev F

January 8, 2019

Website: www.senstar.com

FiberPatrol, Senstar and the Senstar logo are registered trademarks, and Silver Network is a trademark of Senstar Corporation.

Product names and Company names included in this document are used only for identification purposes and are the property

of, and may be trademarks of, their respective owners. Copyright © 2016, Senstar Corporation, all rights reserved. Printed in

Canada.

The information provided in this guide has been prepared by Senstar Corporation to the best of its ability. Senstar Corporation is

not responsible for any damage or accidents that may occur due to errors or omissions in this guide. Senstar Corporation is not

liable for any damages, or incidental consequences, arising from the use of, or the inability to use, the software and equipment

described in this guide. Senstar Corporation is not responsible for any damage or accidents that may occur due to information

about items of equipment or components manufactured by other companies. Features and specifications are subject to change

without notice.

The figures included in this document are for illustration purposes only, and may differ from the actual equipment.

Compliance

The use of shielded cables is required for compliance.

Canada: This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

USA: This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device

may not cause harmful interference, and (2) this device must accept any interference received, including any interference that

may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

Any changes or modifications to the software or equipment that are not expressly approved by Senstar Corporation void the

manufacturer’s warranty, and could void the user’s authority to operate the equipment.

Europe: This device conforms to EC low voltage directive 2006/95/EC.

Senstar Corporation’s Quality Management System is ISO 9001:2015 registered.

Service statement - We ensure that our products are correctly applied to achieve the maximum benefits for the end-user. We

work hand-in-hand with our customers and remain accessible through all stages of a project - from concept to deployment to

long-term support. We provide design assistance, site surveys, installation support, comprehensive documentation, training,

post-installation annual calibration and maintenance visits, electronics and software extended warranty, rapid factory repair

service and on-call/emergency service.

FiberPatrol Site Planning & Installation Guide Page 3

Table of contents

1 System description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5

Principles of operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

FiberPatrol sensor system details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

FP1100X configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Alarm reporting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

FP1100X Series Cable length requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

FP1400 sensors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

FiberPatrol components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Processor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Controller - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Start module/fiber patch panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Outdoor splice enclosure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

End module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Sensor cable/non-detecting lead cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Cable ties - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Isolation loops - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Buried vault - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

2 Site planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

FiberPatrol configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Loop configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Open-ended loop configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Split configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Line configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Extended lead configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Site survey - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Chain-link fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Weld-mesh fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Fence height considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Climb-over deterrent hardware - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Barbed wire - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Razor ribbon/concertina - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

Gates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Gate bypasses - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Page 4 FiberPatrol Site Planning & Installation Guide

Protecting swinging gates with FiberPatrol - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Gate protection for periodically bypassed gates (independent zones) - - - - - - - - - - - - - - - - 23

Determining cable length requirements for gates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 24

Using the cable management kit at the hinged side of protected swinging gates - - - - - - - - 24

Protecting masonry walls and buildings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -25

Selecting conduit for below ground bypasses - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -26

Solid wall conduit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

Split wall conduit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

Sensitivity loops for heavy gauge posts and corner posts - - - - - - - - - - - - - - - - - - - - - -27

Service loops - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Isolation loops - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Cable bypasses for buildings and structures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Deploying the sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -31

Sensor cable splices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -31

Site analysis checklist - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

Cable requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -33

Equipment requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -33

3 Installing FiberPatrol - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

FiberPatrol installation overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -35

Laser light safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -35

Optical fiber safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -36

Fiber optic cable handling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -36

FiberPatrol sensor cable performance specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Additional cable requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Cable loss limits (maximum attenuation) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

Cable handling recommendations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

Illustrated installation requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

FiberPatrol sensor cable and below ground bypasses - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

FiberPatrol installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -42

Attaching the sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -43

Attaching the sensor cable at protected swinging gates - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Masonry walls and buildings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -44

Control equipment installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -46

FiberPatrol splices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -48

4 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 51

Recommended maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -51

a System component list - - - - - - - - - - - - - - - - - - - - - - - - -53

b Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -55

c Location/calibration table - - - - - - - - - - - - - - - - - - - - - - - -59

FiberPatrol Site Planning & Installation Guide Page 5

1 System description

Principles of operation

The FiberPatrol fence-mounted perimeter intrusion detection sensor system, detects and locates

intruders using fiber optic technology. FiberPatrol senses and locates minute vibrations in the

fence fabric caused by climbing, cutting, lifting, or otherwise disturbing the fence fabric. A fiber

optic sensor cable is attached to a perimeter fence. The controller unit transmits a laser light into

two single-mode fibers in the sensor cable. The controller picks up the back-scatter reflections

caused by fence motion or vibrations in the fence fabric and sends the data to the processor unit.

The processor determines the magnitude and location of the disturbance, and triggers an alarm

when the disturbance meets the criteria for a valid intrusion.

The sensor cable is a communication-grade single-mode fiber optic cable intended for outdoor

installation. The cable includes two dedicated sensing fibers. Depending on the particular fiber

optic cable used, at least 10 dark fibers are available for other perimeter applications (e.g., CCTV,

data communication, etc.). The sensor cable is generally available in lengths up to 12 km (7.5 mi.)

and requires professional installation using telecom industry standard practices. All fiber splices

require fusion splicing, and the sensor unit fiber optic connections use FC/APC type connectors.

FiberPatrol can operate as a standalone sensor, which communicates alarm conditions via

optional relay output modules. A PC-based security management system, such as the Alarm

Integration Module, or StarNeT, can serve as the primary operator interface for a FiberPatrol

system. FiberPatrol can also report alarms to 3rd party security management systems (SMS) via

the Network Manager Service. The security management system monitors the FiberPatrol sensor,

and can report alarms to an operator on a graphical site-map.

The FiberPatrol system includes Windows-based configuration software, which is used to setup

and calibrate the system. The configuration software enables sensor calibration, detection

parameter adjustments and system configuration settings.

FiberPatrol sensor system details

• passive, fiber optic, fence mounted outdoor perimeter intrusion detection system

• uses standard outdoor rated telecommunication grade single-mode fiber optic cables

• additional dark fibers available for auxiliary perimeter device communications

• models available for single pass coverage for fences up to 3 m (10 ft.) high

• no power required for outdoor components

• outdoor components unaffected by lightning, EMI, or electrical transients

Page 6 FiberPatrol Site Planning & Installation Guide

• outdoor rated splice enclosures for fiber termination and access to fibers

• indoor components are rack-mountable in a standard EIA 19 in. equipment rack:

• processor - locates disturbance, triggers alarms, monitors system status, includes

FiberPatrol system software, configuration software and Network Manager software

• controller - transmits laser light into two dedicated fibers and receives and isolates back-

scatter signals, analyzes received signal, passes information to processor for analysis

• start module - 1RU splice tray for connecting non-detecting lead cable to patch cables in

the equipment room, separates the backscatter reflections from the transmitted laser light,

and passes the backscatter to the controller unit

• LCD keyboard/monitor/mouse combo - 1 RU user interface provides control,

maintenance, calibration and configuration access to the FiberPatrol processor

FP1100X configurations

There are three distinct configurations for the FP1100X series sensor:

• Loop configurations in which the two sensors run in opposite directions in the fiber optic cable.

• Split configurations in which the two sensors run in opposite directions, in two fiber optic

cables.

• Line configurations in which both sensors run in the same direction in the fiber optic cable.

The loop configuration provides single cable cut immunity whereby detection will continue over the

full length of the perimeter in the event of a single cut in the sensor cable. In the split configuration,

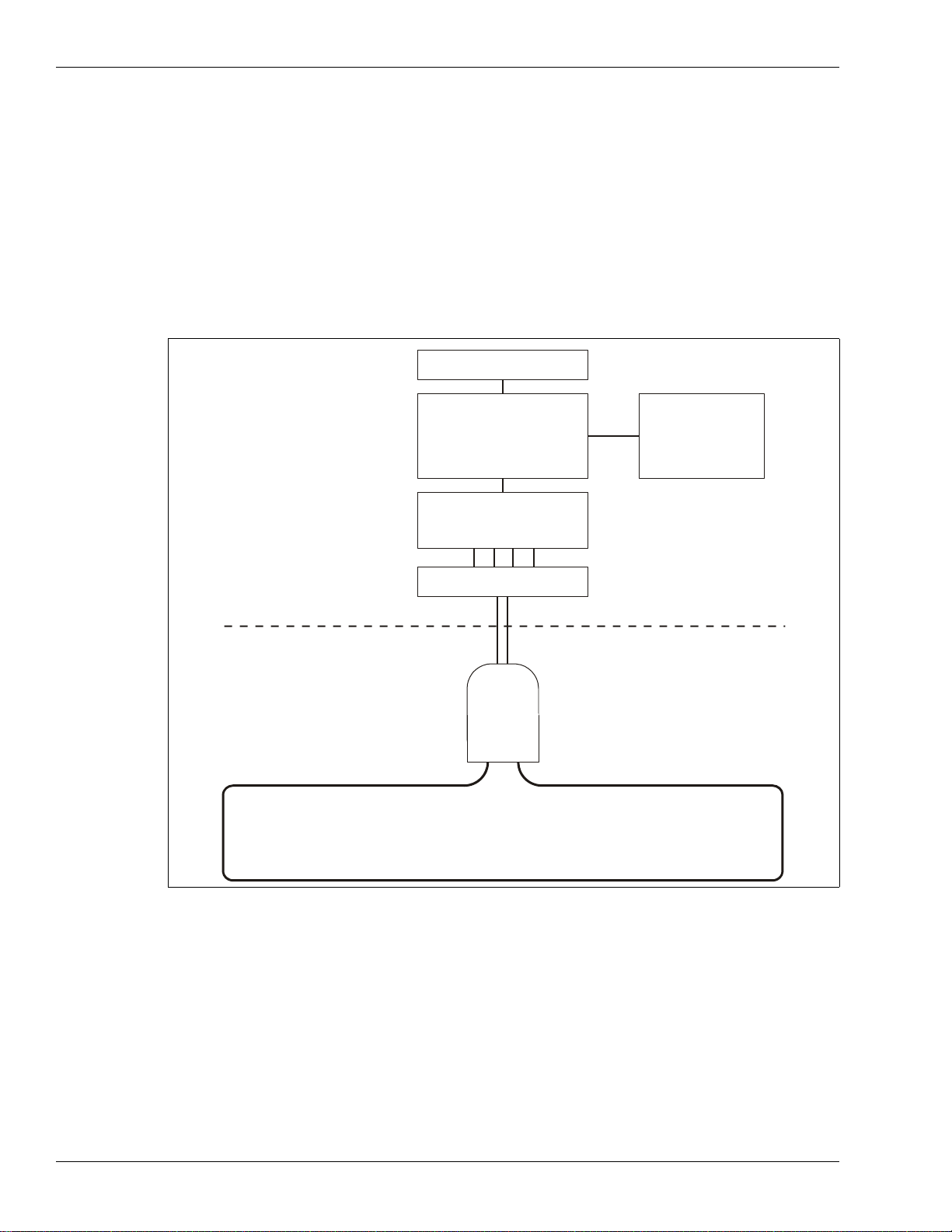

Figure 1: FiberPatrol block diagram - fully closed loop redundant configuration

splice

enclosure

with end

modules

fiber optic sensor cable

non-detecting lead cable

fiber optic

control room

perimeter

controller

start module

fiber optic patch panel

processor

keyboard/monitor/mouse

security

system

management

FiberPatrol Site Planning & Installation Guide Page 7

the two sensors work independently to provide twice the linear length of protection as compared to

the loop configuration. However, a cut cable ends detection beyond the point of the cut. In the line

configuration, the two sensors run in the same direction in the sensor cable and work in tandem for

alarm detection. With the line configuration, a cut cable ends detection beyond the point of the cut.

Alarm reporting

The FiberPatrol sensor can be incorporated into any system, which accepts contact closure alarm

data. However, contact closure alarm notification does not provide precise target location. A

contact closure based FP1100X Series system can be configured to report up to 262 distinct alarm

zones, plus system supervision and fail alarms through the UltraLink I/O system. A contact closure

based FP1400-08 system can be configured to report up to eight distinct alarm zones (up to 28

alarm zones via the optional add-on modules) plus system supervision and fail alarms through the

UltraLink I/O system. The FP1400-12 system can be configured to report up to twelve distinct

alarm zones (up to 44 alarm zones via the optional add-on modules) plus system supervision and

fail alarms.

The FiberPatrol sensor can communicate with third party security management systems through

the Network Manager Interface. In this case, the FiberPatrol security perimeter can be displayed

on a graphic site map as a series of alarm zones (e.g., when a sensor alarm occurs, the zone

flashes to identify the alarm’s location). Key features of a FiberPatrol system include:

• user-configurable alarm zone display

• fast response time (1 second or less)

• digital recording of alarm history

• FP1100X Series - up to 1440 software defined alarm zones (software defined alarm zones

enable the redistribution of alarm zones and zone lengths to accommodate changes in

security equipment and requirements)

• alarm location accuracy typically within 4 m (13 ft.) increases the overall efficiency of the

entire security system

• FP1400-08 - up to 8 software defined alarm zones (software defined alarm zones enable the

redistribution of alarm zones and zone lengths to accommodate changes in security

equipment and requirements)

• up to 28 software defined alarm zones via optional add-on modules

• FP1400-12 - up to 12 software defined alarm zones (software defined alarm zones enable the

redistribution of alarm zones and zone lengths to accommodate changes in security

equipment and requirements)

• up to 44 software defined alarm zones via optional add-on modules

FP1100X Series Cable length requirements

Note The distance reported by the FiberPatrol sensor unit is the optical

distance of the sensor fiber within the cable. This length is similar to a

measurement made by OTDR equipment. The optical distance can be

up to 3% greater than the cable length due to the Helix factor of the

fiber optic cable.

Note To ensure that there is enough sensor cable to cover the fence and

any installation variations, Senstar recommends ordering a 15%

overage (e.g., to protect 1 km of fence, order 1.15 km of sensor cable).

Page 8 FiberPatrol Site Planning & Installation Guide

The FiberPatrol FP1100X Series fence protection system is available in eight models, which are

based on the required length of fiber optic cable. Careful site planning is essential to ensure the

components that are ordered, are the correct components for the application. The following table

includes the FP1100X Series models that are available for fence-mounted applications:

FP1400 sensors

The FiberPatrol FP1400 Series fence protection system is available in two models:

The FiberPatrol FP1400-08 system provides up to 2.5 km (1.55 mi.) of combined fiber optic sensor

cable and non-detecting lead cable and reports alarm conditions in 8 independent alarm zones

(expandable to 28 alarm zones via the optional add-on modules).

The FiberPatrol FP1400-12 system provides up to 5 km (3.1 mi.) of combined fiber optic sensor

cable and non-detecting lead cable and reports alarm conditions in 12 independent alarm zones

(expandable to 44 alarm zones via the optional add-on modules).

Model number Description

FP1100X-01 • up to 1.5 km (0.93 mi.) of detection processing for cut-immune

configurations

• up to 3 km (1.86 mi.) of detection processing for non cut-immune

configurations

FP1100X-03 • up to 3 km (1.86 mi.) of detection processing for cut-immune

configurations

• up to 6 km (3.73 mi.) of detection processing for non cut-immune

configurations

FP1100X-06 • up to 6 km (3.73 mi.) of detection processing for cut-immune

configurations

• up to 12 km (7.46 mi.) of detection processing for non cut-immune

configurations

FP1100X-09 • up to 9 km (5.59 mi.) of detection processing for cut-immune

configurations

• up to 18 km (11.18 mi.) of detection processing for non cut-immune

configurations

FP1100X-12 • up to 12 km (7.46 mi.) of detection processing for cut-immune

configurations

• up to 24 km (14.91 mi.) of detection processing for non cut-immune

configurations

FP1100X-16 • up to 16 km (9.94 mi.) of detection processing for cut-immune

configurations

• up to 32 km (19.9 mi.) of detection processing for non cut-immune

configurations

FP1100X-20 • up to 20 km (12.43 mi.) of detection processing for cut-immune

configurations

• up to 40 km (24.85 mi.) of detection processing for non cut-immune

configurations

FP1100X-25 • up to 25 km (15.53 mi.) of detection processing for cut-immune

configurations

• up to 50 km (31.07 mi.) of detection processing for non cut-immune

configurations

FiberPatrol components

FiberPatrol Site Planning & Installation Guide Page 9

FiberPatrol components

Processor

The FiberPatrol processor supports two independent fiber optic sensors (S1, S2) and can monitor

up to 1440 distinct alarm zones. The alarm zones are defined in software, and do not depend on

cable length. The processor operates on 100 to 240 VAC, 50/60 Hz power and can annunicate

alarm conditions with contact closure outputs or via the Network Manager software. The processor

has dual redundant power supplies, which include an audible alert output that is activated in the

event that one of the power supplies fails. There is a pushbutton switch located between the two

power supplies that will silence the alert tone. Figure 2: illustrates front and rear views of a

FiberPatrol processor and controller.

Figure 2: FiberPatrol processor

Front view

Rear view

power supply

processor

controller

processor

controller

alert tone

reset switch

FiberPatrol components

Page 10 FiberPatrol Site Planning & Installation Guide

Controller

The FiberPatrol controller (see Figure 2:) generates the laser light signal that is transmitted into the

fiber sensors. The controller collects the backscatter reflections created by vibrations in the

protected fence, analyzes the signal, and passes the data to the processor.

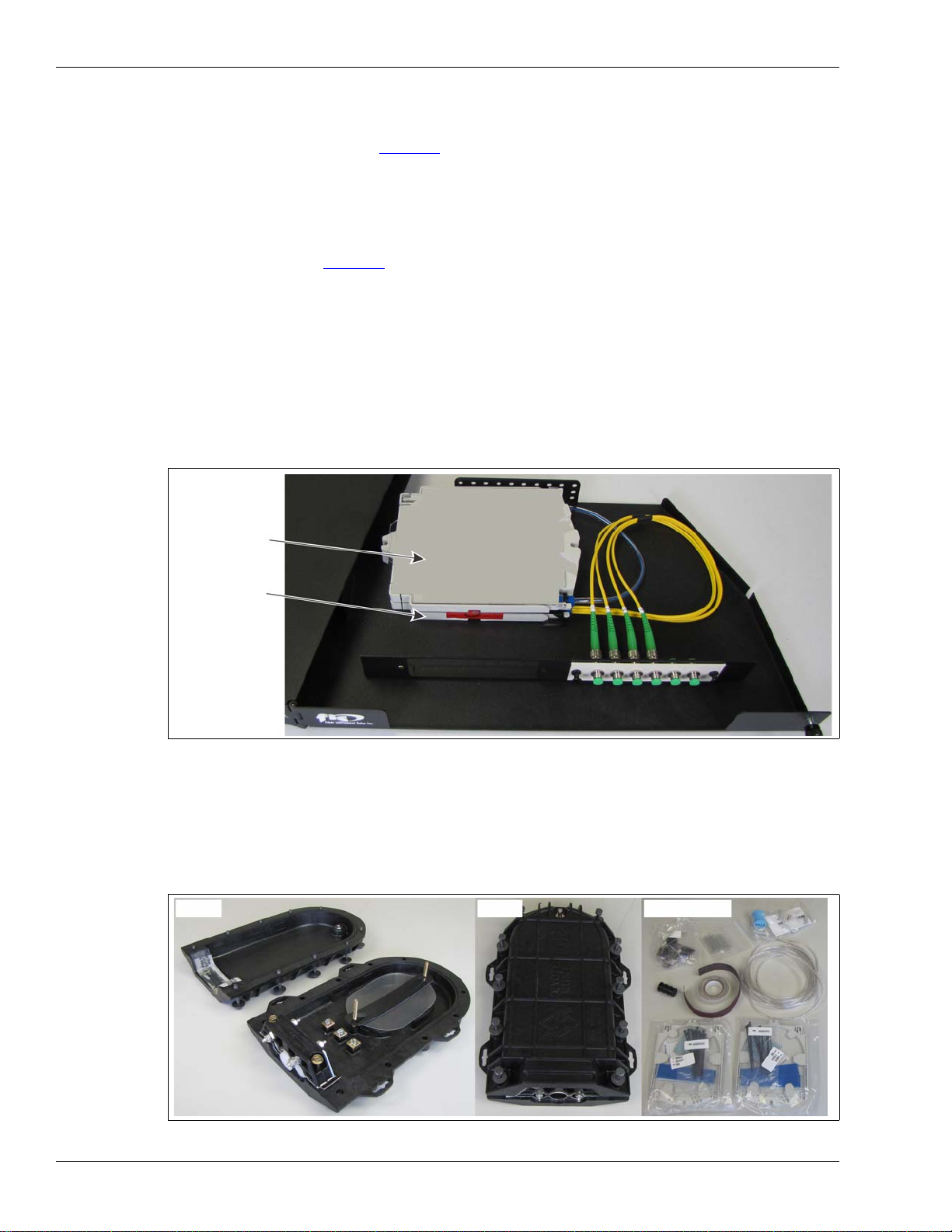

Start module/fiber patch panel

The start module (see Figure 3:) connects the non-detecting lead cable to the sensor unit in the

equipment room. The start module is housed in a 1 RU fiber patch panel along with a splice tray.

The two sensor fibers from the lead cable must be spliced to two fibers from the start module. Four

additional fibers from the start module are factory spliced to four fiber pigtails, which are attached

to FC/APC connectors on the outside of the of the enclosure. Fiber patch cables then connect the

four fibers to the FiberPatrol controller. The splice tray includes six unused protective sleeves,

which are available to provide access to the dark fibers in the lead/sensor cable. Optionally, a

second splice tray can be added to the enclosure, to make connections to any additional fibers

that are being used. In some configurations, an end module is incorporated into the start module

enclosure inside the rack mounted fiber patch panel. Refer to Chapter 2, Site planning for

additional details.

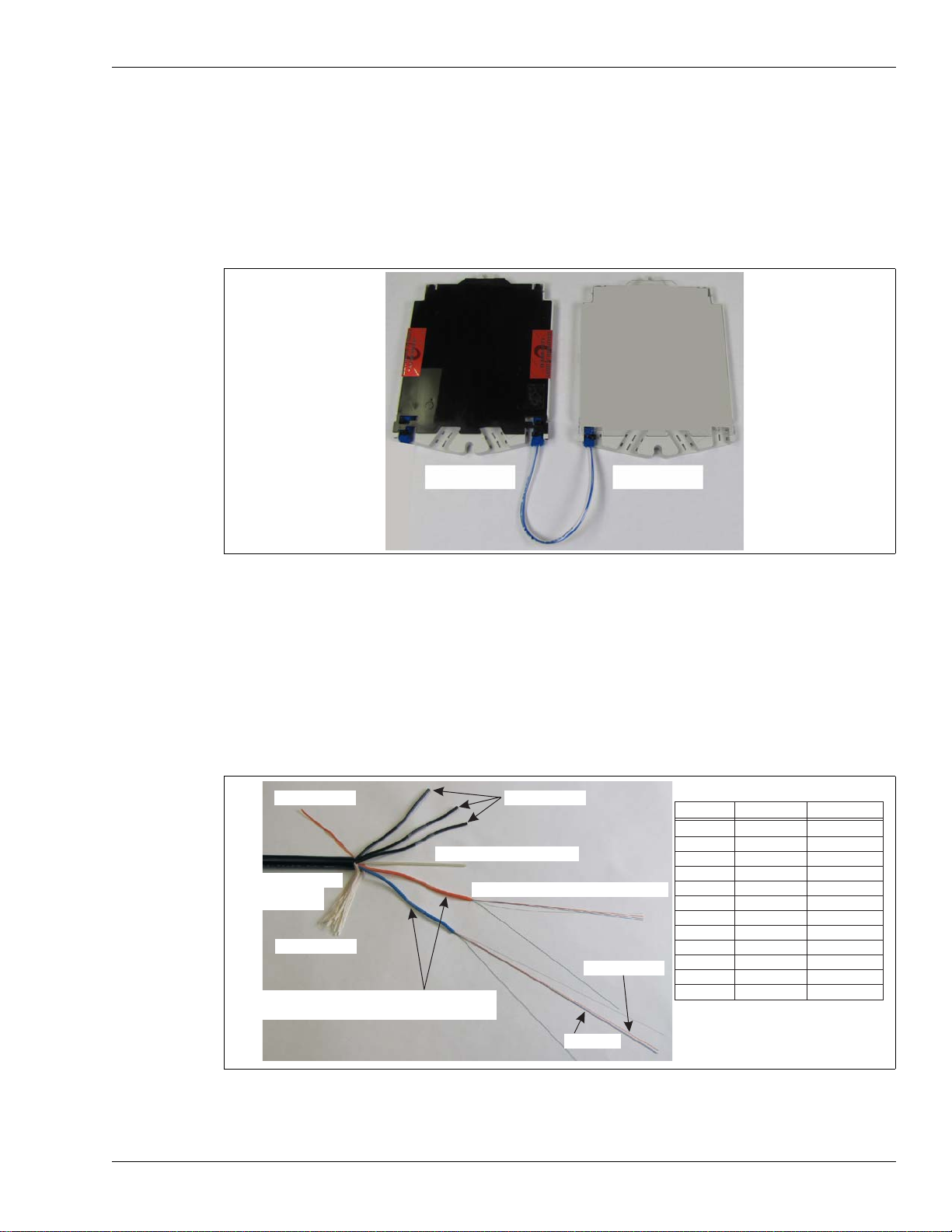

Outdoor splice enclosure

The outdoor splice enclosure houses all field splices for the FiberPatrol system. The splice

enclosure is also used to protect the FiberPatrol end module when it is installed outdoors. The

splice enclosure is generally mounted on the protected fence.

Figure 3: FiberPatrol start module/splice tray

Figure 4: FiberPatrol outdoor splice components

Rear view

splice tray

start module

open closed consumables

FiberPatrol components

FiberPatrol Site Planning & Installation Guide Page 11

End module

The end module terminates the laser light at the end of each detecting fiber, without causing

undesirable reflections. There are 3 types of end modules available, a single end module

(FPMA0212) a double end module (FPMA0222) and a combined double start/end module

(FPMA0223).The end module can be located outdoors in a splice enclosure or indoors with the

start module, in the fiber patch panel. The location of the end module depends on the sensor cable

configuration.

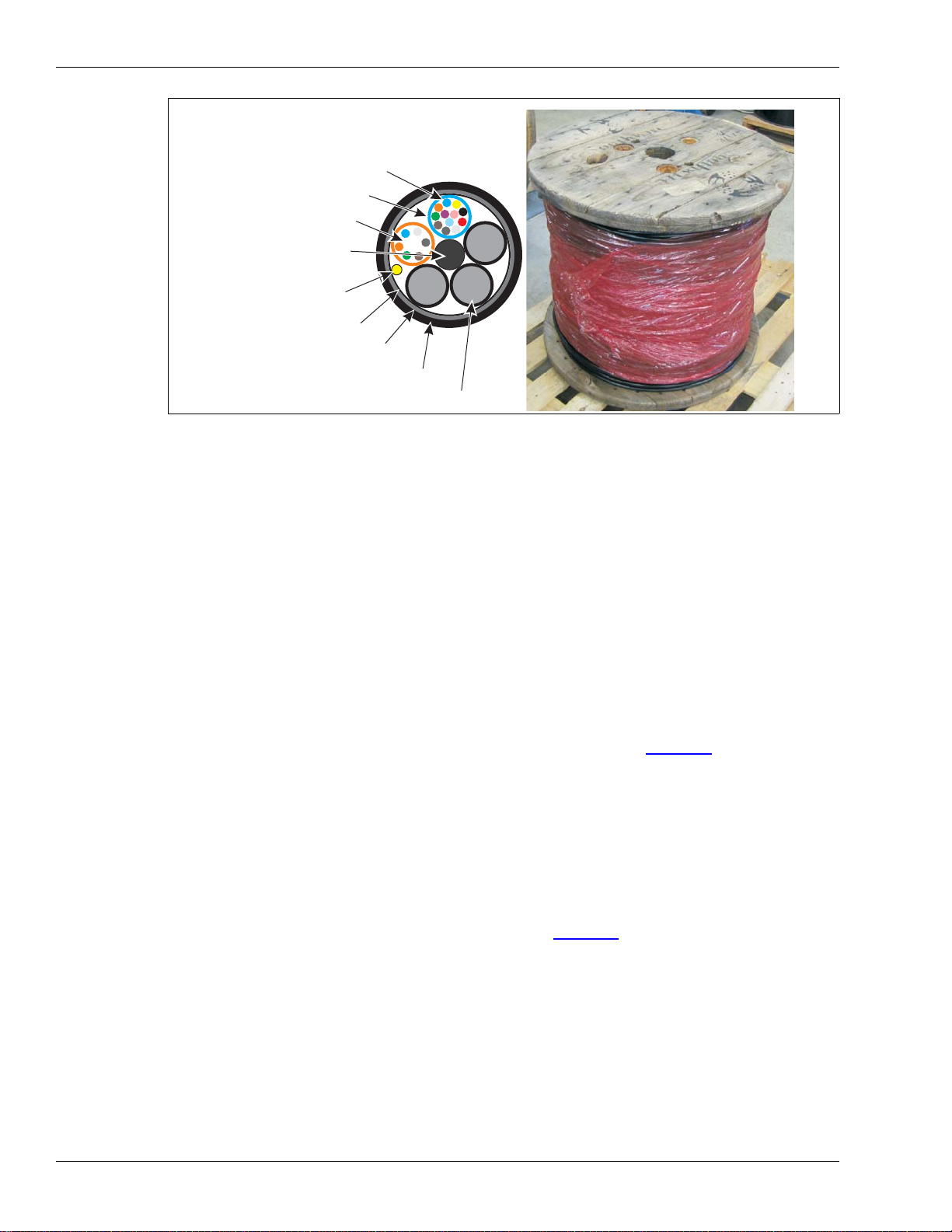

Sensor cable/non-detecting lead cable

FiberPatrol sensor cable is telecommunication grade single-mode fiber optic cable with a medium

density polyethylene outer jacket and a waterblock system. The non-armored loose tube cable is

comprised of a 5 unit fiber optic core (PE filler units and 12-fiber/6-fiber buffer tubes) a central

strength member and a rip cord. Sensor cable can be ordered in lengths to match application

requirements. The non-detecting lead cable is identical to the sensor cable, with detection

sensitivity being controlled via software.

Figure 5: FiberPatrol outdoor splice components

Figure 6: FiberPatrol sensor cable description

end module splice tray

fiber # color

1

2

3

4

5

6

7

8

9

10

11

12

blue

orange

green

brown

gray

white

red

black

yellow

purple

rose

aqua

designation

S1

S2

dark

dark

dark

dark

dark

dark

dark

dark

dark

dark

blue tube fiber designations

3 mm color-coded 12-fiber buffer tubes

filler tubes

E-glass strength rod

ripcord

MDPE outer jacket

S2 (orange)

S1 (blue)

kevlar filler

11.4 mm OD

with water blocking gel

9/125 µm with 250 µm coating

FiberPatrol components

Page 12 FiberPatrol Site Planning & Installation Guide

Cable ties

FiberPatrol sensor cable is attached to the fence with stainless steel cable ties. The stainless steel

cable ties provide long life and a high level of security. A cable tie tool is required to attach the

stainless steel ties to the fence. The stainless steel cable ties are available with bare metal or vinyl

coated in lengths of 8, 14, and 20 inches. For situations in which the FiberPatrol cable will be

installed on a temporary fence and will be redeployed later, UV resistant polyethylene cable ties

are recommended.

Sensitivity loops

Corner posts, terminal posts and heavy gauge tension posts generally have a dampening effect on

nearby fence vibrations. To compensate for this, use sensitivity loops at all corner posts, terminal

posts and heavy gauge tension posts on the fence. The sensitivity loops provide additional sensor

cable for areas that typically produce lower levels of fence noise (see Figure 32).

Service loops

Service loops provide extra sensor cable for making future repairs, and for making fusion splices.

A 10 m (33 ft.) service loop is recommended for every 300 m (984 ft.) of installed sensor cable. A

10 m service loop is also recommended on the hinged side of each gate that is protected by

sensor cable. In addition, a 10 m (33 ft.) splice point service loop is required for each section of

sensor cable at all splice enclosure locations. A 10 m service loop is typically comprised of 5

circular loops of cable with a 60 cm (2 ft.) diameter (see Figure 34).

Isolation loops

Isolation loops are optional, but are recommended for situations where a zone needs to be

isolated from adjacent zones (e.g., gate isolation). Isolation loops are also recommended as a

buffer between detecting sensor cable and software defined non-detecting cable. Fence-mounted

isolation loops use 14 in. steel cable ties to secure 7 loops of sensor cable to the fence. The 7

loops have a 60 cm (2 ft.) diameter, which requires approximately 13 m of sensor cable.

Figure 7: FiberPatrol sensor cable/non-detecting lead cable

cross section

color coded individual fiber

color coded 12 fiber buffer tube

PE filler unit (X 3)

central strength member

binder tape

ripcord

MDPE outer jacket

waterblock system

color coded 6 fiber buffer tube

FiberPatrol components

FiberPatrol Site Planning & Installation Guide Page 13

Buried vault

Another method for zone to zone isolation is to move the sensor cable off the fence through

conduit and then form a 13 m (43 ft.) isolation loop inside a buried vault. The cable is then run

through another section of conduit and back onto the fence where it continues as another zone.

Figure 8: provides the dimensions for the FiberPatrol buried vault.

Figure 8: Buried vault dimensions

46 cm

69 cm

(27 in.)

(18 in.)

49.5 cm

(19.5 in.)

82 cm

(32.25 in.)

103 cm

(40.5 in.)

top view

end view side view

NOTE: dig hole 51 cm (20 in.) D X 76 cm (30 in.) W X 107 cm (42 in.) L

FiberPatrol Site Planning & Installation Guide Page 13

2 Site planning

FiberPatrol configurations

The recommended method for installing FiberPatrol sensor cable is to use the minimum number of

splices possible; i.e., run a single length of cable from the equipment room to the fence, and

continue for as far as site conditions will allow you to go. Use splices for the start module, the end

module, and at any site features where a continuous run of cable is impractical or impossible.

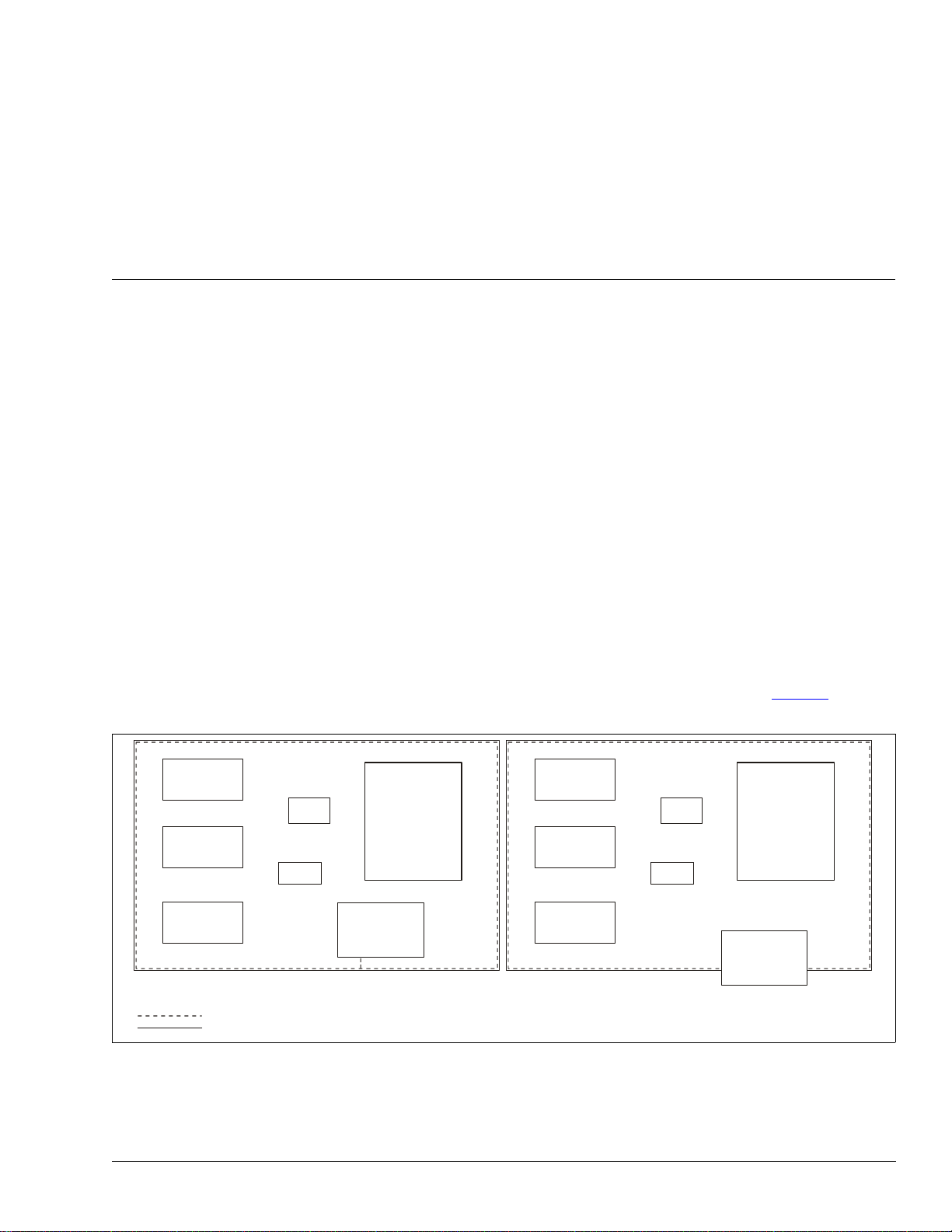

Loop configurations

The loop configuration provides single cable cut redundancy for a closed perimeter. The sensor

unit is located anywhere along the perimeter length with the start and end points of the detecting

sensor cables co-located in a splice enclosure. Non-detecting lead cable carries the signal from

the sensor unit to the start point of the detecting cable. The two sensing fibers S1 and S2 run in

different directions around the perimeter. In the event of a cut or severely damaged sensor cable,

detection will continue around the perimeter in both directions to the location of the damage. There

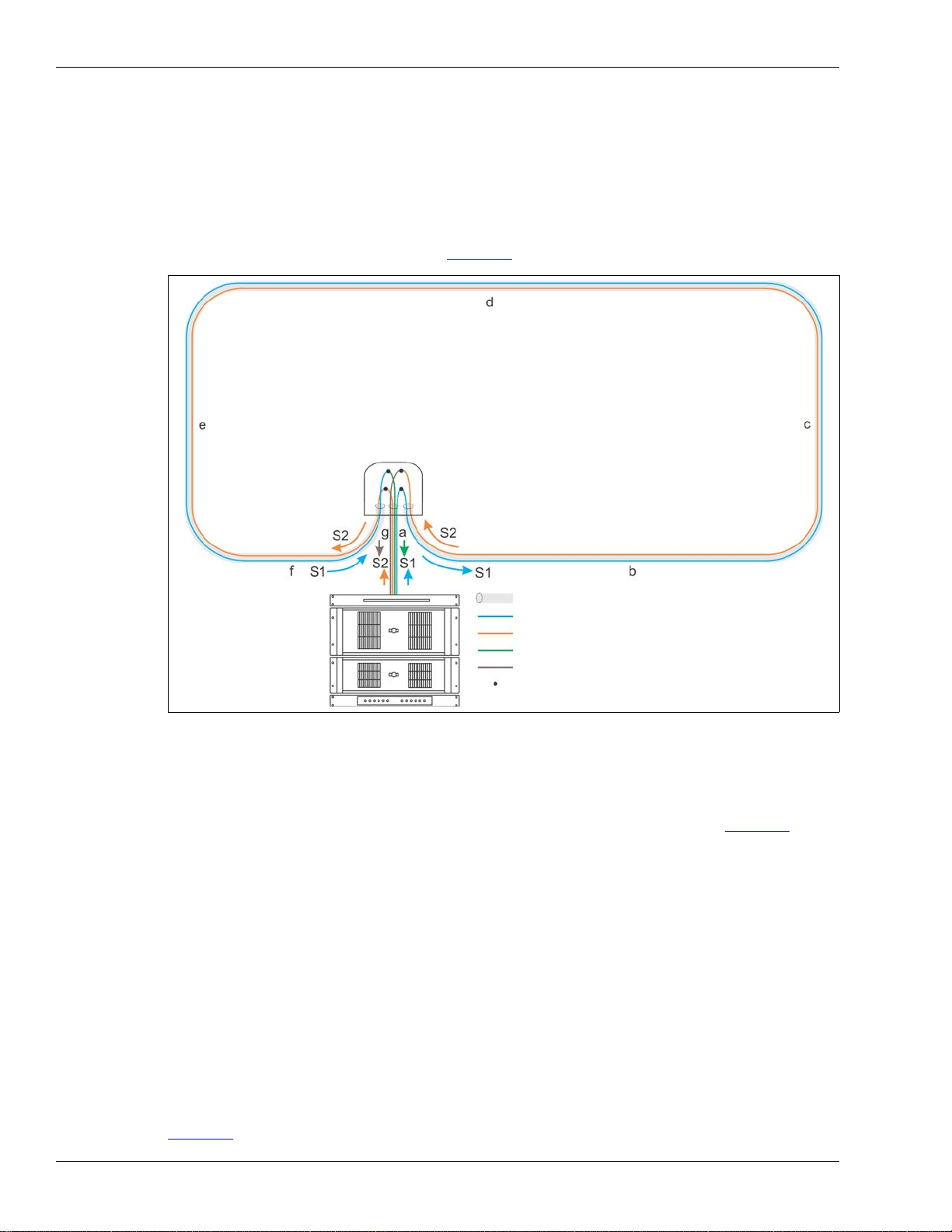

are two types of redundant loop configurations, fully closed and partially closed. Figure 9 provides

a comparison of the two.

Figure 9 FiberPatrol example fully closed & partially closed configuration comparison

FiberPatrol sensor cable

perimeter fence

administration

administration

fully closed perimeter partially closed perimeter

FiberPatrol configurations

Page 14 FiberPatrol Site Planning & Installation Guide

In some instances it is desirable to have a single length of cable running between the equipment

room and the start of the perimeter. This is most common in installations where the sensor unit

equipment is located at a distance from the perimeter. In this case, a dual start/dual end module is

located in the equipment room, and a single lead cable runs to the perimeter fence. Fusion splices

are used to join S1 (blue) in the lead cable to S1 (blue) in the detecting cable. S1 blue runs around

the perimeter and is spliced to S1 (green) in the lead cable going back to the end module in the

equipment room. S2 (orange) in the lead cable is spliced to S2 (orange) in the detecting cable. S2

orange runs around the perimeter and is spliced to S2 (brown) in the lead cable going back to the

end module in the equipment room (see Figure 10).

A fully closed perimeter can also be obtained by using a dual start module in the equipment room

and a dual end module located inside a splice enclosure at the start of the perimeter. A single lead

cable runs from the equipment room to the perimeter and S1 and S2 run in opposite directions

around the perimeter with both terminated in the start point splice enclosure (see Figure 11).

The partially closed loop configuration uses a dual start/end module in the equipment room and

has two lead cables. This configuration also provides single cut redundancy for a partially closed

perimeter. The two sensing fibers S1 and S2 run in different directions around the perimeter. In the

event of a cut or severely damaged sensor cable, detection will continue around the perimeter in

both directions to the point of the damage.

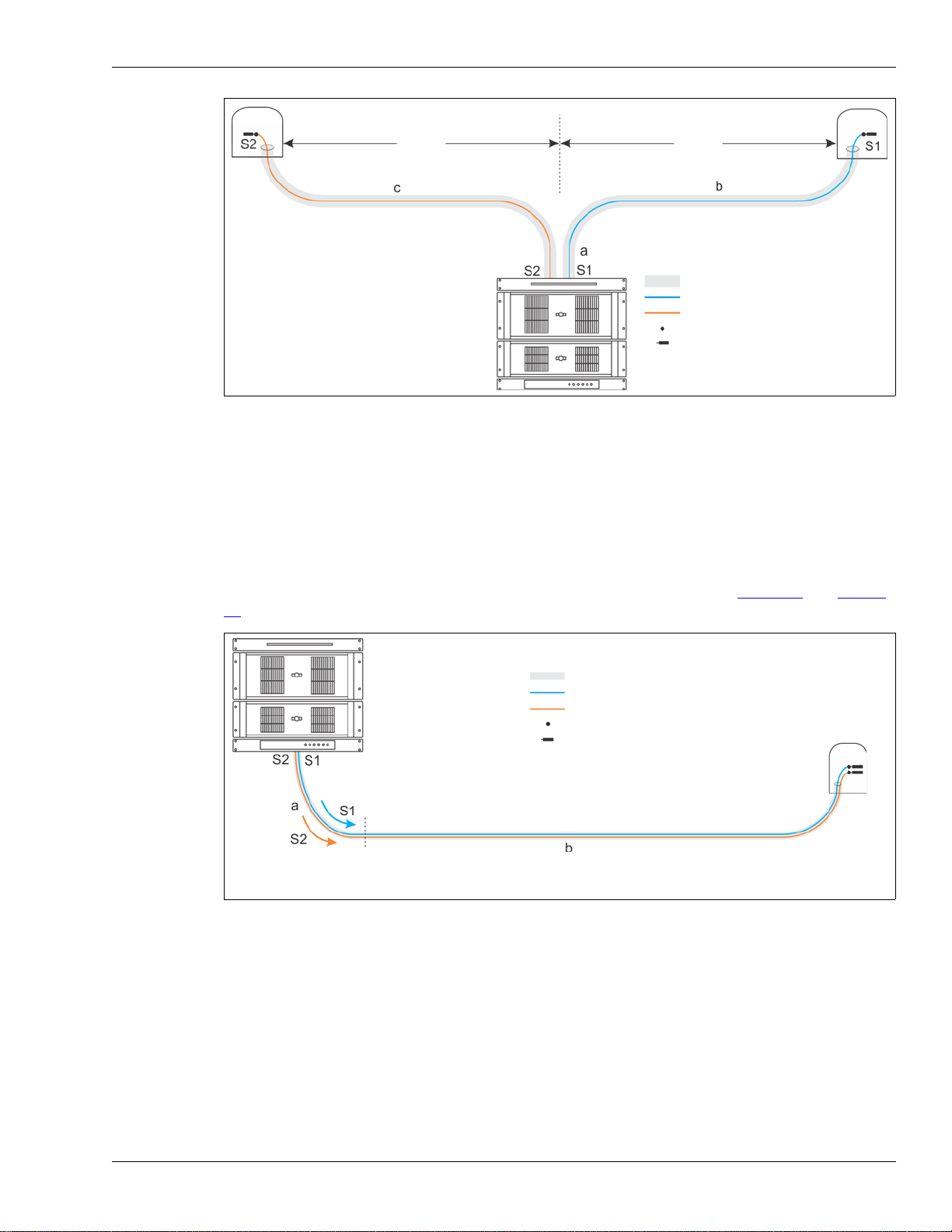

Open-ended loop configuration

The open-ended loop configuration provides single fiber break redundancy for an open-ended

perimeter. The sensor unit can be located anywhere along the perimeter length with the start and

end points of the detecting sensor cables located at opposite ends. The two sensing fibers S1 and

S2 run in different directions for the length of the cable. Two additional fibers are used to bring the

lead fibers to the opposite ends of the perimeter, where they are spliced to the detecting fibers.

The two detecting fibers run from one end of the perimeter to the other in opposite directions (see

Figure 13).

Figure 10 FiberPatrol fully closed redundant loop configuration

FiberPatrol sensor cable

fiber optic cable (sensor cable/lead cable)

S1 (sensor fiber 1 - internal to fiber optic cable)

S2 (sensor fiber 2 - internal to fiber optic cable)

fusion splice

splice enclosure

sensor unit

equipment

Note: Cable length = a + b + c + d + e + f + g

dual start/end module

S1 (sensor fiber 1 - spliced return to sensor unit)

S2 (sensor fiber 2 - spliced return to sensor unit)

FiberPatrol configurations

FiberPatrol Site Planning & Installation Guide Page 15

Figure 11 FiberPatrol fully closed redundant loop configuration

Figure 12 FiberPatrol partially closed redundant loop configuration

FiberPatrol sensor cable

fiber optic cable (sensor cable/lead cable)

S1 (sensor fiber 1 - internal to fiber optic cable)

S2 (sensor fiber 2 - internal to fiber optic cable)

fusion splice

fiber optic termination

splice enclosure

sensor unit

equipment

Note: Cable length = a + b + c + d + e + f

dual end module

FiberPatrol sensor cable

fiber optic cable (sensor cable/lead cable)

Note:

S1 (sensor fiber 1 - internal to fiber optic cable)

S2 (sensor fiber 2 - internal to fiber optic cable)

sensor unit equipment

Cable length = a + b + c + d + e + f + g

includes

dual start/

dual end modules

FiberPatrol configurations

Page 16 FiberPatrol Site Planning & Installation Guide

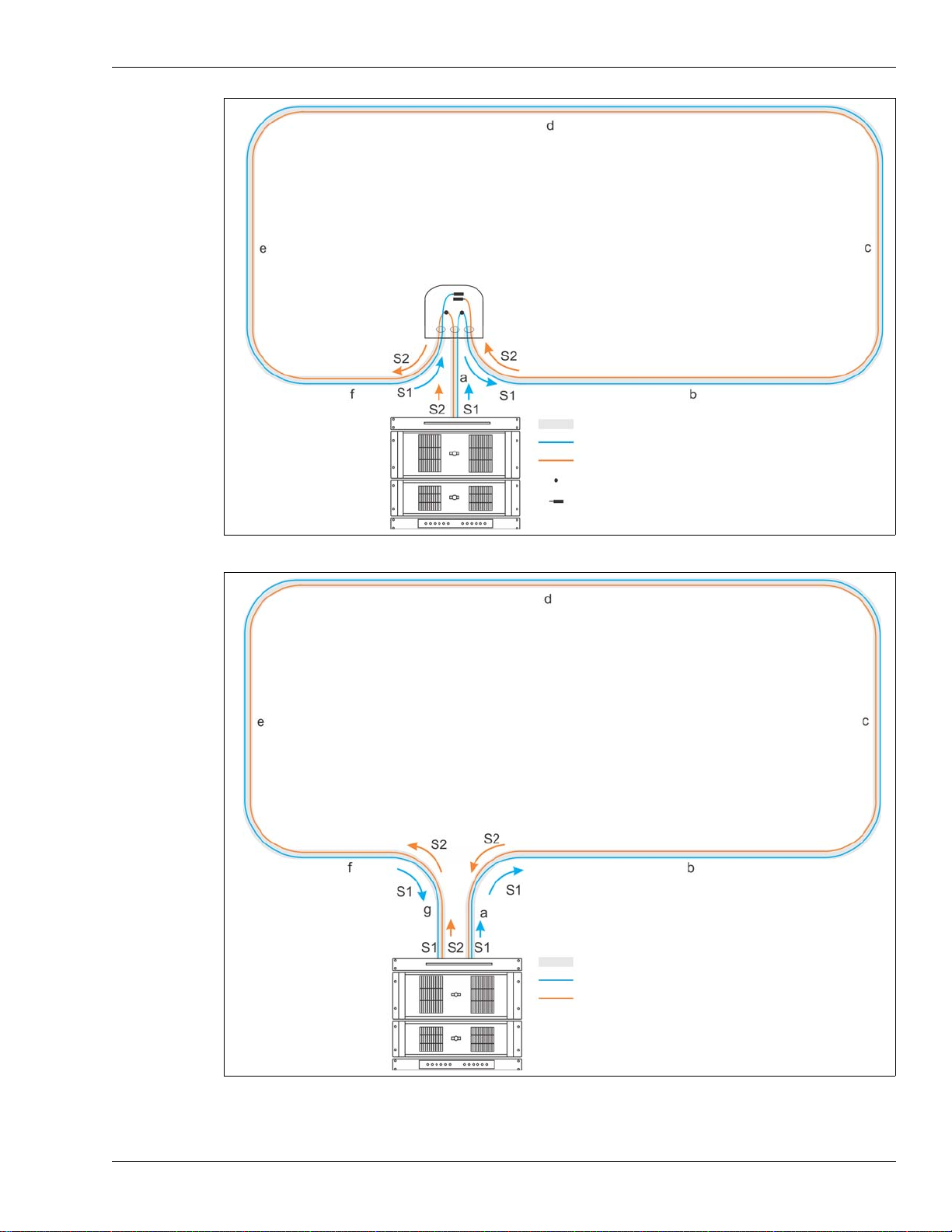

Split configuration

The split configuration provides extended length coverage for an open-ended perimeter. To get the

maximum length coverage the sensor unit is located near the mid-point of the protected section of

fence. The sensor cable runs in opposite directions along the fence with each end module located

up to 25 km away from the sensor unit. One sensor fiber provides detection in each direction with

S1 running in one direction and S2 running the opposite way. A splice enclosure is required at the

start point on the fence to use one lead cable from the sensor unit to the perimeter (see Figure 14).

Using two lead cables eliminates the need to have the start point splice (see Figure 15).

Figure 13 FiberPatrol open-ended loop configuration

Figure 14 FiberPatrol split configuration (1 lead cable)

fiber optic cable (sensor cable/lead cable)

Note:

S1 (sensor fiber 1 lead)

S2 (sensor fiber 2 lead)

fusion splice

fiber optic termination

splice enclosure splice enclosure

sensor unit equipment

Cable length = a + 2b + 2c

S1 (sensor fiber 1 detecting)

S2 (sensor fiber 2 detecting)

single end module

splice enclosure

single end module

includes dual start module

fiber optic cable

Note:

S1

S2

fusion splice

fiber optic termination

splice enclosure splice enclosure

sensor unit equipment

Cable length = 2a + b + c

single end module

splice enclosure

single end module

includes dual start module

25 km

(max.)

25 km

(max.)

FiberPatrol configurations

FiberPatrol Site Planning & Installation Guide Page 17

Line configurations

The line configuration is typically used when the sensor unit equipment is located at one end of the

protected perimeter, and the perimeter extends away from the equipment room in one direction.

The line configuration does not provide single cut redundancy for the full length of the sensor

cable. In the event of a cut or severely damaged sensor cable, detection will continue between the

start of the detecting sensor cable and the cut/damaged point in the cable. Figure 16 and Figure

17 illustrate the line configuration.

If necessary, the non-detecting lead cable can be spliced to the detecting cable at the start point of

the sensor cable. Splices may also be required for other site specific features.

Figure 15 FiberPatrol split configuration (2 lead cables)

Figure 16 Recommended line configuration

fiber optic cable

Note:

S1

S2

fusion splice

fiber optic termination

splice enclosure

sensor unit equipment

Cable length = 2a + b + c

single end module

splice enclosure

single end module

includes dual start module

25 km

(max.)

25 km

(max.)

fiber optic cable (sensor cable/lead cable)

S1 (sensor fiber 1 - internal to fiber optic cable)

S2 (sensor fiber 2 - internal to fiber optic cable)

fusion splice

fiber optic termination

splice enclosure

sensor unit

equipment

beginning of detecting cable

non-detecting lead cable

NOTES: Splices may be required at the beginning of the detecting cable and at other site specific features,

due to installation constraints and conditions.

Cable length = a + b

FiberPatrol configurations

Page 18 FiberPatrol Site Planning & Installation Guide

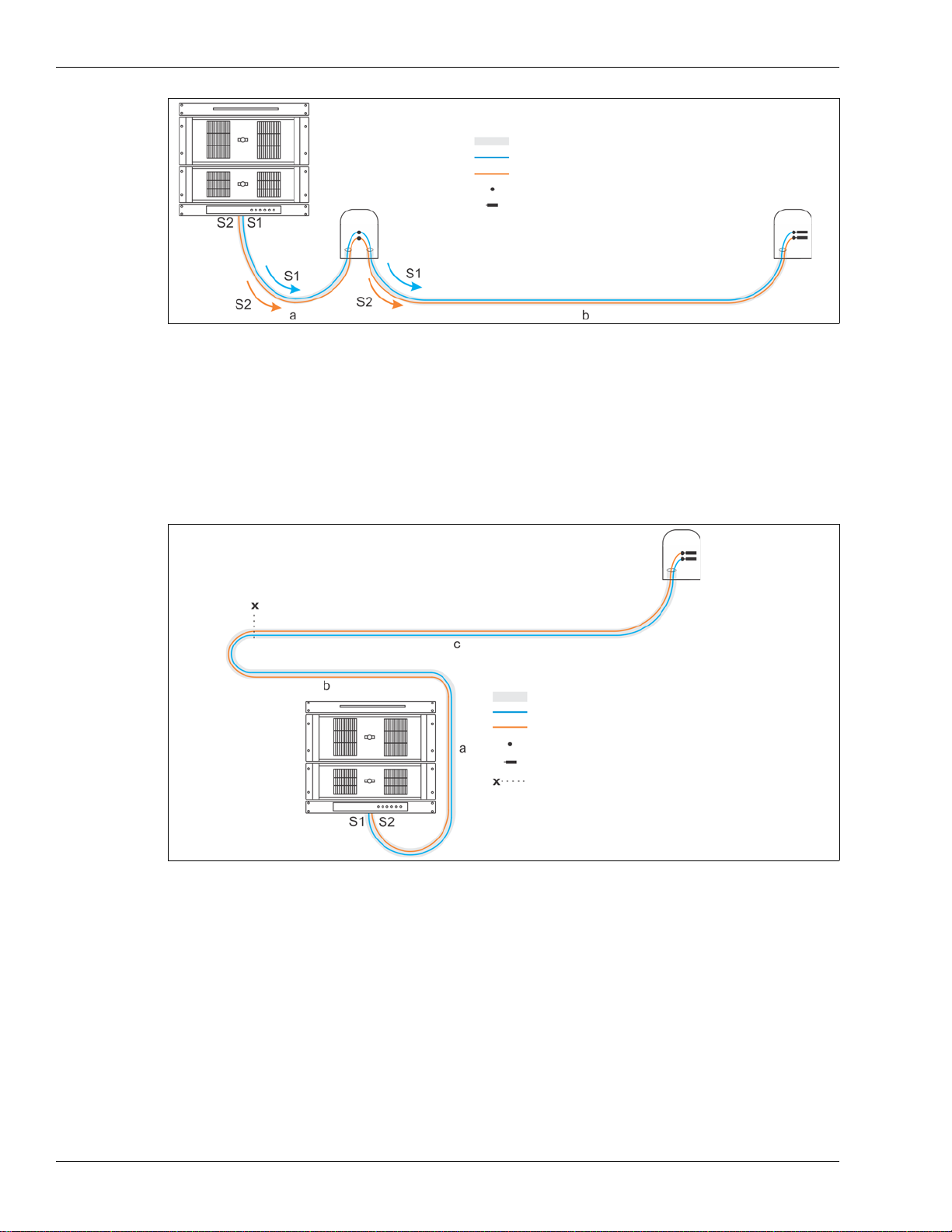

Extended lead configuration

The extended lead configuration is a variation of the line configuration in which lead cable runs

from the sensor unit to one end of the perimeter. The detecting fibers S1 and S2 run the full length

of the perimeter from one end to the other. The extended lead configuration does not provide

single cut redundancy for the full length of the sensor cable. In the event of a cut or severely

damaged sensor cable, detection will continue between the start of the sensor zone, and the cut/

damaged point in the cable.

Figure 17 line configuration with start point splice

Figure 18 FiberPatrol extended lead configuration

fiber optic cable (sensor cable/lead cable)

S1 (sensor fiber 1 - internal to fiber optic cable)

S2 (sensor fiber 2 - internal to fiber optic cable)

fusion splice

fiber optic termination

splice enclosure

splice enclosure

sensor unit

equipment

Note: Cable length = a + b

FiberPatrol sensor cable

fiber optic cable (sensor cable/lead cable)

Note:

S1 (sensor fiber 1 - internal to fiber optic cable)

S2 (sensor fiber 2 - internal to fiber optic cable)

fusion splice

fiber optic termination

splice enclosure

sensor unit

equipment

Cable length = a + b + c

dual end module

indicates software defined start of detection

Site survey

FiberPatrol Site Planning & Installation Guide Page 19

Site survey

The first step in installing a FiberPatrol fence protection system is to conduct a detailed site survey.

The survey assesses the site conditions to determine the specific installation requirements

including the fence type, fence condition, fence length, zone layouts, sensor cable route, non-

detecting lead cable length, length of sensor cable required to cover the perimeter, and the

location for the electronic components.

Create a scale drawing of the site (e.g., CAD drawings), which indicates the locations of:

• fences (include type and condition)

• gates (include type and size)

• buildings and other structures

• roads, driveways, sidewalks, paths, parking areas

• trees, bushes, dense vegetation (near perimeter)

• location of sensor cable

• other existing or planned security devices (e.g., CCTV cameras, security lighting, etc.)

Fences

The fence must be properly installed, maintained, and tensioned, to provide effective intrusion

detection with FiberPatrol. The fence should be uniform in height and quality, and should be high

enough to present an effective barrier against climb-over intrusions. It is also recommended that a

climb-over barrier, such as barbed wire or concertina, be installed along the top of the fence. The

condition of the fence is critical to the efficient operation of the FiberPatrol sensor system. Breaks

in the fence structure, or slack portions of the fence fabric, will inhibit the transmission of the fence

vibrations to the sensor cable. Poor fence conditions can also cause metal on metal contact noise

that will result in nuisance alarms.

Chain-link fences

The chain-link fence fabric should meet the following specifications:

• maximum range of deflection 10 cm (4 in.) when a 22.5 kg (50 lb) force is applied

perpendicular to the center of a panel (pushing and pulling) (based on 3 m, 10 ft. post spacing)

• minimum height of 2.4 m (8 ft.) with climb-over deterrent hardware securely mounted on top

Weld-mesh fences

A typical weld-mesh fence section consists of 3 mm (0.1 in.) diameter steel wire welded into a grid

configuration, with horizontal spacing differing from the vertical spacing. These fence sections are

secured to fence posts and to the adjacent fence panel sections. The sections of weld-mesh fence

are either welded together or connected using clips, bolts or rivets. The minimum recommended

Note Fences used in conjunction with the FiberPatrol sensor must meet

industry standards for security fences.

Note Any fence movement which can cause metal-to-metal contact is a

potential source of nuisance alarms.

This manual suits for next models

11

Table of contents

Other SENSTAR Accessories manuals

SENSTAR

SENSTAR FiberPatrol FP400 User manual

SENSTAR

SENSTAR UltraWave BR100 User manual

SENSTAR

SENSTAR FPS 2-2 User manual

SENSTAR

SENSTAR FlexZone User manual

SENSTAR

SENSTAR FiberPatrol FP1150 Series User manual

SENSTAR

SENSTAR FlexPS User manual

SENSTAR

SENSTAR OmniTrax User manual

SENSTAR

SENSTAR IntelliFIBER User manual

SENSTAR

SENSTAR FlexZone WGS User manual

Popular Accessories manuals by other brands

ekwb

ekwb EK-FC980 GTX Strix Backplate Installation and mounting manuals

Hytronik

Hytronik HC005S/I Installation and instruction manual

Philips

Philips SVC2522W Specification sheet

BEA

BEA WIZARD PLUS user guide

Pilz

Pilz PSEN i1 operating instructions

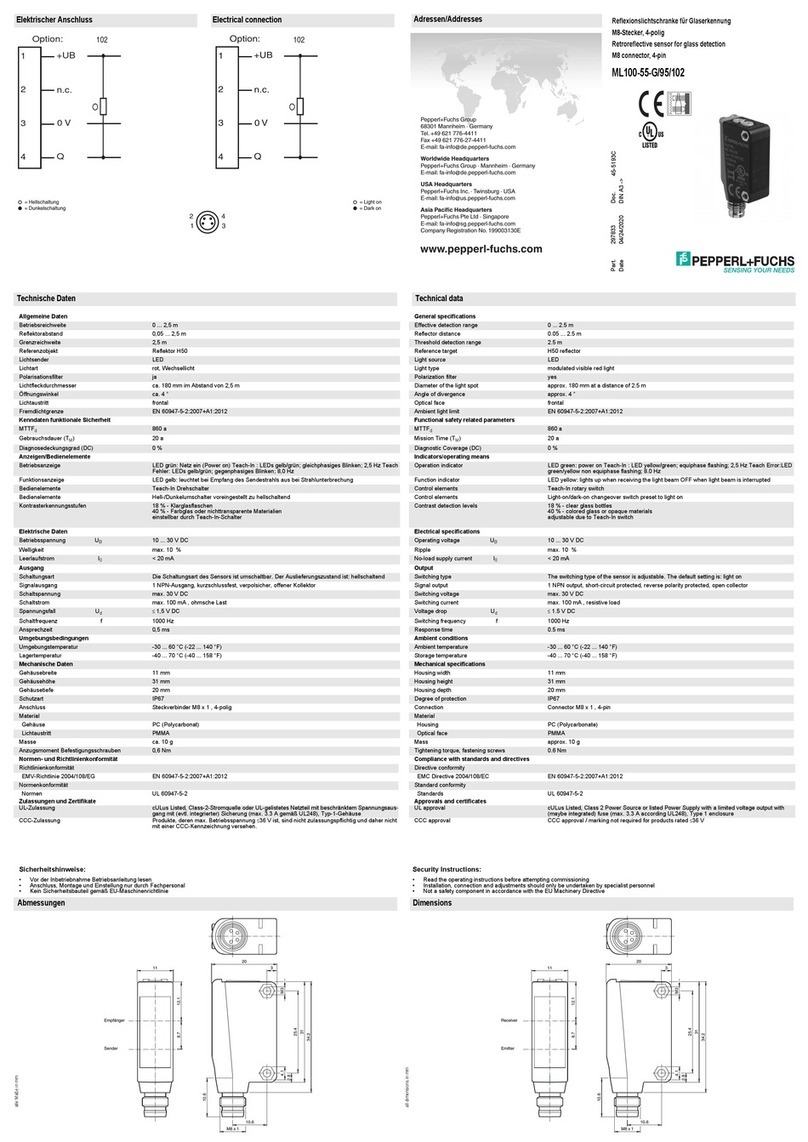

Pepperl+Fuchs

Pepperl+Fuchs ML100-55-G/95/102 quick start guide