SENSTAR OmniTrax User manual

Product

Guide

Ranging Buried Cable Intrusion Detection Sensor

A4DA0102-001, Rev J

December 3, 2019

OmniTrax®

Page 2 OmniTrax Product Guide

Senstar Corporation

Website: www.senstar.com

Email address: info@senstar.com

A4DA0102-001, Rev J

December 13, 2019

OmniTrax, XField, FlexZone, µltraWave, FlexPS, Sennet, Perimitrax, Senstar and the Senstar logo are registered trademarks,

and Silver Network, StarNeT 1000 and Sentrax are trademarks of Senstar Corporation. Other Product names and Company

names included in this document are used only for identification purposes and are the property of, and may be trademarks of,

their respective owners. Copyright © 2017, 2007, Senstar Corporation. All rights reserved. Printed in Canada.

The information provided in this guide has been prepared by Senstar Corporation to the best of its ability. Senstar Corporation is

not responsible for any damage or accidents that may occur due to errors or omissions in this guide. Senstar Corporation is not

liable for any damages, or incidental consequences, arising from the use of, or the inability to use, the software and equipment

described in this guide. Senstar Corporation is not responsible for any damage or accidents that may occur due to information

about items of equipment or components manufactured by other companies. Features and specifications are subject to change

without notice.

Equipment certifications and approvals:

Canada:

Industry Canada has authorized this equipment for operation in Canada as a license exempt device under the following

conditions:

The OmniTrax system requires professional installation, which must ensure that the General Field Strength Limits listed in

Tables 2 and 3 of RSS-210 are not exceeded.

This device may not cause radio interference, and this device must accept any interference received.

USA:

FCC identifier: I5T-A4EM0101

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment.

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any interference received, including interference that may cause

undesired operation.

Any changes or modifications to the software or equipment that are not expressly approved by Senstar Corporation void the

manufacturer’s warranty, and could void the user’s authority to operate the equipment.

The OmniTrax system requires professional installation.

Europe:

This device conforms to EN 61000-6-4: 2001 relating to Electromagnetic compatibility for emission standards for industrial

environments.

This device conforms to EN 50130-4: 1995 + amendments A1: 1998 & A2: 2003 relating to Electromagnetic compatibility for

immunity requirements for components of fire, intruder, and social alarm systems.

The use of shielded cables is required for compliance.

Senstar Corporation’s Quality Management System is ISO 9001:2008 registered.

Senstar Corporation’s intellectual property is protected by the following patents:

Canada - 2204485

USA - 7576648

Europe - U.K. 2318689

Patents issued and pending in other Countries.

OmniTrax Product Guide Page 3

OmniTrax terminology

•cable set - Two sensor cables (TX and RX) connected to one side of a processor. For SC1

sensor cable, the cable set is encased in a single outer jacket.

•cable pair - Two sensor cable sets connected through decouplers (TXA to TXB and RXA to

RXB). A cable pair can be comprised of either the two sides of a single processor, or the A-

side of one processor and the B-side of another processor.

•lead-in cable - Each sensor cable is comprised of a specified length of detecting sensor

cable, plus an extra 4 m of detecting cable in which the detection field builds to full strength,

plus 20 m of integral lead-in cable. The lead-in cable is fully shielded and does not allow the

detection signal to “leak” out of the cable and form the detection field. The lead-in cable is

connected to the processor and runs to the detection start point, without forming a detection

field. The junction between the lead-in cable and the detecting cable is marked with red bands.

•meter - The meter is the basic unit of measure for OmniTrax cable. On a 400 m cable set, the

processor analyzes 424 m of cable, which includes the lead-in cable. The meter is used to

define cable segments and alarm zones. The sensitivity profile records the cable sensitivity for

each meter of detecting sensor cable.

•range bin - Range bin is a term common to radar technology, and is used for precise target

location. With OmniTrax, there are up to 40 range bins per sensor cable (including lead-in).

The processor analyzes the received signals from the sensor cables and locates targets to

within one meter by processing the range bin response for signal strength and timing.

•cable segment - A cable segment is made up of a contiguous group of meters, and is used for

display and control purposes. Cable segments are software-defined during setup. The cable

segment is the finest granularity unit that is defined by the end-user. Each cable set can be

divided into up to 50 cable segments. Cable segments are used to create alarm zones, and

therefore, must begin and end where alarm zone boundaries are required. A cable segment

can be a part of one zone, and a cable segment can have one relay associated with it (up to

10 relays are available for reporting sensor alarms when using the optional relay output card).

In addition to the cable margin (alarm threshold) that is set for the full length of detecting cable,

a second cable margin can be set for each cable segment. Cable segments can also be

defined as inactive, whereby detecting cable will not report valid targets (by assigning a cable

segment to zone 0).

•alarm zone - An alarm zone is made up of one or more cable segments, and is used for the

control and annunciation of sensor alarms (access/secure, graphic map display with precise

target location). There can be up to 50 alarm zones per Silver Network based processor (over

two cable sets). Alarm zones are defined in software to match the site-specific zone layout

details (e.g., CCTV, fence sections, gates, buildings, etc.). Any grouping of segments can be

assigned to an alarm zone. The cable segments do not have to be contiguous, and can come

from both cable sets on one processor (not two processors). There can be a zone within

another zone, and a zone can bridge inactive cable segments. Zone 0 does not report targets,

and is used to identify lead-in cable, cable bypasses, and to set detecting cable to inactive.

Zone 0 does not count in the 50 zone total.

•location accuracy - OmniTrax location accuracy for a single valid target is to within one

meter. However, phase ambiguities can result in a location deviation of up to 4 m for a valid

target.

•target resolution - OmniTrax target resolution is in reference to two valid targets

simultaneously crossing the cables. In this case, two targets that are crossing within 24 m of

each other inside a period of three seconds or less, can merge and be reported as one target.

The single reported target can be located anywhere within the 24 m span of cable.

Page 4 OmniTrax Product Guide

Using this guide

This guide provides the information necessary to design, install, setup and calibrate an OmniTrax

system. Chapter 1 is an introduction to OmniTrax perimeter security; chapter 2 provides site

planning information; chapter 3 covers enclosure installation details; chapter 4 describes sensor

cable installation, cable fittings, cable splices, cable repair, and cable tests; chapter 5 details

system powering and data communications, and the processor wiring connections; chapter 6

describes system setup and calibration; and chapter 7 covers the Silver Network. The appendices

provide system component ordering information, recommended installation materials, component

specifications, and details about using the UltraLink I/O system in Network Manager mode for

reporting OmniTrax alarm conditions.

Figures

The figures included in this document are for illustration purposes only, and may differ from the

actual equipment.

Abbreviations

The following abbreviations are used throughout this guide:

• I/O - input/output

• I/P - input

• NAR - nuisance alarm rate

• NC - normally closed

• NIC - Network Interface Card

• NIU - Network Interface Unit

• NM - Network Manager

• NO - normally open

• OC2 - OmniTrax®dual sensor cables (300 m / 400 m lengths)

• O/P - output

• Pd - probability of detection

• RF - radio-frequency

• ROC - Relay Output Card

•RX-receive

• SC1 - single cable OmniTrax cable set (max. 200 m length cable sets)

• SC2 - dual cable OmniTrax cable set (max. 200 m length cable sets)

•TX-transmit

• UCM - Universal Configuration Module

• UIC - Universal Input Card

Service statement - We ensure that our products are correctly applied to achieve the maximum benefits for the end-user. We

work hand-in-hand with our customers and remain accessible through all stages of a project - from concept to deployment to

long-term support. We provide design assistance, site surveys, installation support, comprehensive documentation, training,

post-installation annual calibration and maintenance visits, electronics and software extended warranty, rapid factory repair

service and on-call/emergency service. Contact Senstar Corporation to inquire about how a package can be customized for

your unique applications.

OmniTrax Product Guide Page 5

Table of contents

Equipment certifications and approvals: - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2

1 System description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -13

OmniTrax sensor system details - - - - - - - - - - - - - - - - - - - - - - - - - -13

Sensor cable layout details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

System calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

OmniTrax calibration parameters: - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Universal Configuration Module (UCM) features - - - - - - - - - - - - - - - - - - - - - - - - 15

Security management systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Benefit summary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

OmniTrax components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -16

Processor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Enclosure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

The telecom enclosure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Customer supplied enclosure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Sensor cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

OC2 sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

SC2 sensor cable sets - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

SC1 sensor cable sets - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Using mixed cable types on a perimeter - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

OmniTrax components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Silver Network components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 24

Installation overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -26

2 Site planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -29

Site survey - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -29

Site photographs/video - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Measurements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Weather conditions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Snow coverage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Lightning protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Water table - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Completing the site survey - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Site analysis checklist - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Planning the cable path - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -31

Installation mediums - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -31

Page 6 OmniTrax Product Guide

Soil types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

Light soil extreme - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

Heavy soil extreme - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

Man-made mediums (concrete, asphalt, crushed stone) - - - - - - - - - - - - - - - -33

New concrete - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -33

Concrete > 13 cm (5 in.) thick (no metal reinforcement) - - - - - - - - - - - - - - - - - - - -33

Concrete < 13 cm thick (no metal reinforcement) - - - - - - - - - - - - - - - - - - - - - - - -33

Concrete (with metal reinforcement) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -34

Asphalt - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -34

Crushed stone - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -34

Using geotextile fabric in sensor cable installations - - - - - - - - - - - - - - - - - - - -35

Above ground berm installation using geotextile fabric - - - - - - - - - - - - - - - - - -35

Landfill - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -35

Grade changes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -35

Sensor cable burial depths - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Sensor cable spacing (OC2, SC2) - - - - - - - - - - - - - - - - - - - - - - - - - 36

Protection of buried cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 37

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -37

Road and sidewalk crossings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -38

Turning corners - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

Making gradual turns in soft mediums - - - - - - - - - - - - - - - - - - - - - - - - - - - - -38

Making gradual turns in concrete - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -39

OmniTrax cable set separation - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

Single/dual cable set separation, one processor - - - - - - - - - - - - - - - - - - - - - -41

Obstacles - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

Separation distances from obstacles - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -42

Separation distances from pipes, conduits and cables - - - - - - - - - - - - - - - - - - - - -42

Separation distances from existing buried leaky sensor cable systems - - - - - - - - -43

Installation near drainage culverts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -43

End of cable set obstacles - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -45

Mid-cable obstacles (cable bypasses) - - - - - - - - - - - - - - - - - - - - - - - - - - - - -46

Beginning of zone obstacles - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -47

Fences - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -47

Buildings, gateways and other structures - - - - - - - - - - - - - - - - - - - - - - - - - - -47

Road crossings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -48

Decouplers and obstacles - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -48

Moving objects - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -48

Metal objects or obstructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -49

Pipes, conduits, and electrical cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -49

Drainage culverts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -49

Water - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -49

Sensor cable bypasses- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

Sensor cable bypasses (software bypass) - - - - - - - - - - - - - - - - - - - - - - - - - -50

Sensor cable bypasses (hardware bypass) - - - - - - - - - - - - - - - - - - - - - - - - - -51

Lead-in cable splices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -51

Adding lead-in cable (OC2) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -51

Adding lead-in cable (SC1/SC2 sensor cable) - - - - - - - - - - - - - - - - - - - - - - - - - - -52

Splice kits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -52

Perimeter layout - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

OmniTrax Product Guide Page 7

Starting the perimeter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 52

Minimum sensor cable lengths - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 53

Cable selection guidelines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 53

Sensor cable burial depth - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 54

Sensor cable spacing (OC2, SC2) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 54

Cable layout at processors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 54

Placement of decouplers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

Decoupler options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 56

Perimeter termination - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 56

Connected blocks of processors - - - - - - - - - - - - - - - - - - - - - - - - - -57

Sensor cable supervision - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 57

Alarm zone selection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Alarm zone boundaries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Corners - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Equipment location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -59

Processor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 59

Protective posts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 59

System power and data communication - - - - - - - - - - - - - - - - - - - - -60

System power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -60

Powering options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

Power and data via the sensor cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

Local power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

Network power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 62

Power supply options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 62

Battery power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 62

Alarm data communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -63

Alarm communication options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 63

Local control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 64

Fail-safe relay operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 64

Local control mode functions (self-test inputs) - - - - - - - - - - - - - - - - - - - - - - - - - - 64

Remote control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

Remote control mode functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

Processor address - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

Using a maintenance network for standalone processors - - - - - - - - - - - - - - - 66

NM Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 66

System power and data configurations - - - - - - - - - - - - - - - - - - - - - - - - -66

Standalone power/contact closure alarm - - - - - - - - - - - - - - - - - - - - - - - - - - - 66

Network power - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 67

Additional lightning protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 69

System design - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -70

System drawings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -71

Sample site drawings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 71

Residential & commercial applications - - - - - - - - - - - - - - - - - - - - - -80

Single vs. dual trench selection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 80

Sensor cable burial depth - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 80

Sensor cable path selection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 80

Buried water pipe and electrical cable avoidance - - - - - - - - - - - - - - - - - - - - - 81

Protection against gardening and landscaping damage - - - - - - - - - - - - - - - - - 81

Protection for roadway and sidewalk crossings - - - - - - - - - - - - - - - - - - - - - - - 82

Installation tips - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -82

Page 8 OmniTrax Product Guide

3 Installing enclosures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 83

The OmniTrax enclosure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 83

System grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -85

Points to remember - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -85

Installing a telecom style enclosure - - - - - - - - - - - - - - - - - - - - - - - - 86

Required tools and equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -86

Installation procedure for telecom enclosures - - - - - - - - - - - - - - - - - - - - - - - -87

Preparation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -87

Building the foundation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -88

Installing the telecom enclosure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -88

Installing the OmniTrax enclosure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -89

Indoor wall-mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -91

Wall-mount procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -91

Using a customer-supplied enclosure - - - - - - - - - - - - - - - - - - - - - - 92

Replacing the processor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 94

Removing the processor and backplate - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -94

Replacing the processor and backplate - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -94

4 Installing the sensor cables - - - - - - - - - - - - - - - - - - - - - - - - 97

Cable installation overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 97

Installation guidelines - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 97

Preparation of trenches - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 98

Required equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -98

Trench dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -99

Digging the trenches - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -99

Narrow cable spacing (single trench) - - - - - - - - - - - - - - - - - - - - - - - - - - - - -100

Standard cable spacing (dual trench) - - - - - - - - - - - - - - - - - - - - - - - - - - - - -101

Burial with a crushed stone topping - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -102

Burial in crushed stone - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -103

Burial under asphalt - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -103

Burial under a narrow strip of asphalt - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -103

Micro-trenching or boring under a narrow paved strip - - - - - - - - - - - - - - - - - - - -105

Burial under a large asphalt paved surface - - - - - - - - - - - - - - - - - - - - - - - - - - - -105

Burial in clay - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -107

Burial in moderate clay soil (OC2/SC2 cables only) - - - - - - - - - - - - - - - - - - - - - -107

Burial in heavy clay soil - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -107

Preparation of slots in concrete - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 109

Crossing surface cracks and expansion joints - - - - - - - - - - - - - - - - - - - - - - - - - -109

Transition from a slot to a trench - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -110

Required equipment and materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -110

Slot dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -111

Cutting the basic slot - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -111

Completing the slot installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -112

Above ground berm installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 113

Sensor cable start points - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 115

Detecting cable crossover - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -115

Aligning the lead-in cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -115

Start point configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -117

Digging the lead-in cable trench - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -119

OmniTrax Product Guide Page 9

Laying the sensor cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 120

Required equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 120

Dispensing sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 120

Installing cable fittings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -121

Installing ferrite beads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 121

Points to remember - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -121

Installing connectors on OC2 sensor cable - - - - - - - - - - - - - - - - - - - - - - - - 121

OC2 connector installation procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -122

Part 1: Preparing OC2 sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -122

Part 2: Installing the connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -124

Installing connectors on SC1 and SC2 sensor cable - - - - - - - - - - - - - - - - - - 126

Required tools - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -126

SC1 and SC2 cable strip dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -127

Installing decouplers and terminators - - - - - - - - - - - - - - - - - - - - - - - - - 132

Terminating an unused cable side - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 132

Unused cable side termination procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - -132

Sealing the heatshrink over decouplers/splices - - - - - - - - - - - - - - - - - - - - - 133

OC2/SC2 decoupler installation procedure - - - - - - - - - - - - - - - - - - - - - - - - 133

OC2/SC2 decoupler installation (method 1 - active loops) - - - - - - - - - - - - - - 134

OC2/SC2 decoupler installation (method 2 - adjoining trenches) - - - - - - - - - 135

Installing decouplers in hard surface slots - - - - - - - - - - - - - - - - - - - - - - - - - 136

Installing decouplers on SC1 sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - 137

SC1 decoupler installation procedure (method 1 - active cable loop) - - - - - - - - - -137

SC1 decoupler installation procedure (method 2 - terminators) - - - - - - - - - - - - - -138

Installing terminators - OC2/SC2 sensor cable - - - - - - - - - - - - - - - - - - - - - - 139

Terminators in slots - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 141

Cable splices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -141

Required equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -141

Points to remember - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -141

Cable splice procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -142

Lead-in cable splices (OC2 sensor cable) - - - - - - - - - - - - - - - - - - - - - - - - - - - - -143

Splicing in additional OC2 lead-in cable (10 m or less) - - - - - - - - - - - - - - - - - - - -143

Splicing in additional OC2 lead-in cable (greater than 10 m) - - - - - - - - - - - - - - - -143

Lead-in cable splices (SC1/SC2 sensor cable) - - - - - - - - - - - - - - - - - - - - - - - - -143

Splicing in additional SC1/SC2 lead-in cable (15 m or less) - - - - - - - - - - - - - - - -143

Splicing in additional SC1/SC2 lead-in cable (greater than 15 m) - - - - - - - - - - - -144

Sensor cable bypasses - hardware bypass - - - - - - - - - - - - - - - - - - - - - - - - - - - -144

Software bypass - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -145

Cable tests - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -146

Equipment required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -146

Cable pair - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -146

Cable set - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -147

Sensor cable tests - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 148

Single cable continuity test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -148

Insulation resistance test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -149

Leakage resistance test (all cable pairs) - - - - - - - - - - - - - - - - - - - - - - - - - - - - -150

Cable-pair continuity test (network decouplers) - - - - - - - - - - - - - - - - - - - - - - - - -151

Cable-set continuity test (open ended perimeter) - - - - - - - - - - - - - - - - - - - - - - - -152

The surface test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 152

Repairing sensor cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -154

Ground faults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -155

Decoupler faults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -155

Testing for faults (Required equipment) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -155

Page 10 OmniTrax Product Guide

Test sequence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -155

Additional tests - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -155

Decouplers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -155

Cable damage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -155

Replacing decouplers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -156

Assessing cable damage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -156

Required equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -156

OmniTrax OC2 components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -157

OmniTrax SC1/SC2 components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -157

Repairing detecting sensor cable damage - - - - - - - - - - - - - - - - - - - - - - - - -157

Superficial damage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -157

Minor damage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -157

OC2 (< 1 cm) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -157

SC1 (< 1 cm) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -158

SC2 (< 1 cm) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -158

Moderate damage (1 to 45 cm) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -158

Severe damage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -159

Severe damage (< 3m) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -159

Severe damage (> 3m) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -160

Repairing non-detecting sensor cable damage - - - - - - - - - - - - - - - - - - - - - -162

Repositioning non-detecting cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -162

Replacing non-detecting cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -162

5 Power and data connections - - - - - - - - - - - - - - - - - - - - - - 163

48 VDC network power supply - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -163

Sensor cable power fuse installation rules - - - - - - - - - - - - - - - - - - - - - - - - -164

Auxiliary power supply module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -165

Installing the backup battery kit - - - - - - - - - - - - - - - - - - - - - - - - - - 167

Battery installation procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -167

Telecom enclosure wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 168

Connecting the telecom enclosure tamper switch - - - - - - - - - - - - - - - - - - - - - - -170

Processor features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 171

Relay output alarm communication - - - - - - - - - - - - - - - - - - - - - - - 173

Relay ratings and settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -174

AUX I/P (self-test) connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -174

Local control mode wiring connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -174

Connection procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -175

Network communication - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 176

Relay ratings/settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -177

AUX I/P specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -177

Sensor cable lightning protection - - - - - - - - - - - - - - - - - - - - - - - - 179

Installation procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -179

Replacing the gas capsule - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -181

Installing auxiliary cards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 182

Auxiliary card installation procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -183

Network Interface card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -183

Relay output card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -185

Relay ratings/settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -185

Universal Input card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -186

OmniTrax Product Guide Page 11

6 Calibration & setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -187

Calibration overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -187

The Universal Configuration Module - - - - - - - - - - - - - - - - - - - - - - -190

Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -192

Assigning the processor address (Silver Network processors) - - - - - - - - - - - 192

Specifying the processor synchronization - - - - - - - - - - - - - - - - - - - - - - - - - 193

Synchronization setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -193

Mutual interference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -194

Transmitter Duty Cycle: - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -194

Transmitter Coding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -194

Setting the initial configuration parameters - - - - - - - - - - - - - - - - - - - - - - - - 195

Using the optional local backup battery - - - - - - - - - - - - - - - - - - - - - - - - - - - 196

Setting the input/output control mode and adding an option card - - - - - - - - - 196

OmniTrax calibration - Sensitivity Profile and Transmitter Power - - - - - - - - 197

Recording the Sensitivity Profile - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -198

Editing the Sensitivity Profile - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -199

Setting the Transmitter Power level - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -203

Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -204

Setting the full-length cable margin - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 204

Cable margin procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -205

Defining the cable segments and alarm zones - - - - - - - - - - - - - - - - - - - - - - 205

Defining the lead-in cable segment as non-detecting - - - - - - - - - - - - - - - - - - - - -206

Defining the detecting cable segments - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -206

Setting the cable segment margins - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 207

Cable segment margin procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -207

Target speed settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 208

STC filter settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 209

Auxiliary I/O configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 209

Auxiliary (AUX) inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 211

Local control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -212

Remote control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -212

Input wiring configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 212

Input configuration procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -213

Output relay setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 214

Local control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -214

Remote control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -214

Relay configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -214

Linking relays to cable segments (local control mode) - - - - - - - - - - - - - - - - - 214

Specify the network connection and synchronization scheme - - - - - - - - - - - 215

Clutter display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 216

Historic clutter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -217

Locating the detection field centerline - - - - - - - - - - - - - - - - - - - - - - - - - - - - 218

7 The Silver Network - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -219

Silver Network overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 219

Network components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -220

Silver Network Manager - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 220

Network Interface Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 220

Network Interface Card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 221

OmniTrax sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 222

XField sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 222

Page 12 OmniTrax Product Guide

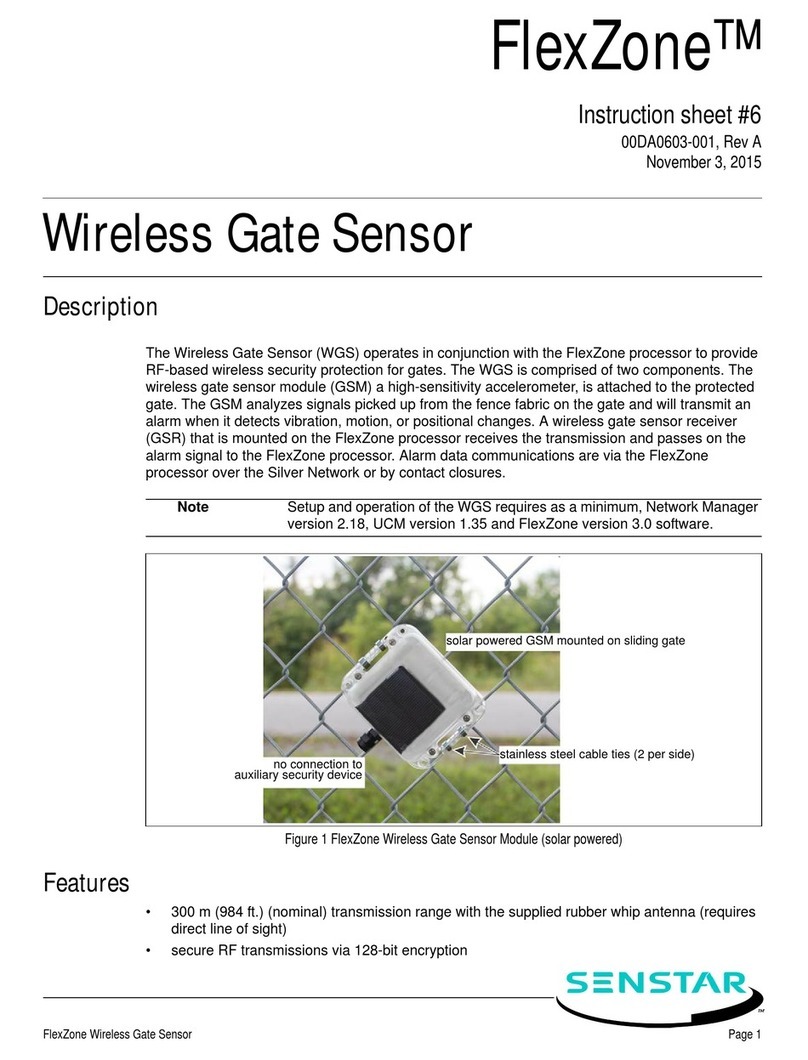

FlexZone sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -222

FlexPS sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -222

Senstar LM100 sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -222

FiberPatrol FP400 sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -223

16 I/16 O processor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -223

UltraWave microwave sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -223

UltraLink scalable I/O system - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -223

Universal Configuration Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -224

Silver Network repeater - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -224

Network configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 225

Silver Network specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -225

OmniTrax network communication and synchronization options - - - - - - - - - - - - -225

Connection diagrams - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -228

Redundant configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -232

Silver Network point assignments - - - - - - - - - - - - - - - - - - - - - - - 233

StarNeT 1000 point assignments - - - - - - - - - - - - - - - - - - - - - - - 234

a System component list - - - - - - - - - - - - - - - - - - - - - 235

Supplier’s information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 240

Sealant materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -240

Other sealant suppliers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -241

Application equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -241

Backer rod - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -242

Concrete sealers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -242

Metal foil - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -243

Geotextile fabric - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -243

b Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - 245

c NM Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 249

UCM configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -250

OmniTrax Product Guide Page 13

1 System description

OmniTrax sensor system details

OmniTrax is a covert perimeter intrusion detection sensor system, that locates intruders with

pinpoint accuracy using ported coaxial cable technology. A set of sensor cables are buried around

the perimeter of a site. The transmit (TX) cable distributes radio-frequency (RF) signals along the

cable path and the Receive (RX) cable picks up the signals and carries them back to the

processor. An electromagnetic detection field forms around the cables, and the processor triggers

an alarm when an intruder disturbs the field.

The OmniTrax sensor can operate as a standalone sensor, which receives 12 VDC local power

and communicates alarm conditions via relay outputs. Optionally, OmniTrax processors can be

part of a Silver Network in which 48 VDC power and alarm data are carried from processor to

processor over the sensor cables. The alarm data can also be carried over EIA-422 copper wire,

or fiber optic cable. The alarm data is sent to a Network Interface Unit, which translates the data

and passes it to a Windows-based Network Manager. The Network Manager interprets the data

and passes it to a security management system (SMS) for presentation to an operator. Silver

Network based OmniTrax processors can collect and report alarm data from other security

devices, such as microwave sensors or fence detection systems via two Aux (auxiliary) inputs.

Network based processors can also use the output relays to activate and control auxiliary security

equipment in response to commands from the host SMS.

A PC-based security management system, such as Senstar’s Alarm Integration Module, StarNeT

1000, or StarNet 2 can serve as the primary operator interface for an OmniTrax system. The

security management system monitors the OmniTrax sensor, and can report alarms to an operator

on a graphical site-map.

Senstar’s Windows-based Universal Configuration Module (UCM) is the calibration and diagnostic

support tool for OmniTrax. The UCM connects directly to the processor via USB or remotely

through the Silver Network Manager. The UCM enables sensor calibration, detection parameter

adjustments and system configuration settings. The UCM also provides real time diagnostics and

sensor plot modes.

• volumetric, terrain following, covert, outdoor perimeter intrusion detection system

• lockable NEMA 4 rated aluminum enclosure with integral tamper switch

• telecom style pedestal enclosure with integral tamper switch

• typical above ground detection field - 1 m high X 3 m wide (3.3 ft. X 10 ft.)

detection field also extends below ground

OmniTrax sensor system details

Page 14 OmniTrax Product Guide

• a processor monitors one, or two, cable sets each up to 400 m (1312 ft.) long (max. 800 m)

• OC2 sensor cable includes 300 m (984 ft.) or 400 m of detecting cable, plus 20 m (65 ft.)

of lead-in (non-detecting) cable

• processor supports SC2 sensor cables for installations where shorter lengths of cable

(max. 200 m, 656 ft.) are required

• OmniTrax supports retrofit applications for Perimitrax installations, however, a preliminary

site visit is strongly recommended due to the age of the sensor cables

• lightning protection on sensor cables and all I/O, additional lightning protection available and

recommended for sensor cables and copper data lines

• alarm communication options

• relay output (standalone/Silver Network)

• via the sensor cables (Silver Network)

• EIA-422 (Silver Network)

• fiber optic - single mode and multi-mode (Silver Network)

• combinations of the different alarm communication options can be used

Sensor cable layout details

• minimum 16 m (52 ft.) sensor cable length for standalone processors (including 6 m, 20 ft. of

lead-in cable)

• minimum 75 m (246 ft.) sensor cable length, per processor, for cables that are connected

through decouplers (including 6 m, 20 ft. of lead-in cable per processor) 150 m (492 ft.) sensor

cable separation between connected processors

• up to 50 unique software defined segments per cable set, 100 per processor, segments are

used for display and control purposes

• up to 50 distinct software defined alarm zones per processor, each zone includes one or more

cable segments

• a zone can include multiple segments; zones can go around corners; skip over inactive

segments; include zones within zones; include segments from both the A-side and B-side

cable sets

• segments of detecting cable can be defined as inactive in software (will not report alarms)

• splice kits available for cable repair and bypasses

• standard burial depth in soil - 23 cm (9 in.)

• cable spacing ranges from 10 cm to 2.0 m (4 in. to 6.5 ft.)

• power and data communications carried over sensor cables (Silver Network)

System calibration

• UCM software simplifies calibration, and provides powerful maintenance and diagnostic tools

• UCM computer can connect directly to processor through the USB port, or remotely through

the Silver Network Manager

• a calibration walk down the centerline of the cable set creates a sensitivity profile for the entire

sensor cable (the sensitivity profile is stored in the processor)

the sensitivity profile tracks and records any variations in detection sensitivity resulting from

cable burial depth, cable spacing and soil conductivity

• the calibration walk determines the recommended transmitter power level for the selected

cable side

• the sensitivity profile enables a uniform cable margin (alarm threshold) for each meter of cable

OmniTrax sensor system details

OmniTrax Product Guide Page 15

• an additional cable margin can be defined for each cable segment to increase or decrease the

detection sensitivity within the segment

• processor synchronization is used to prevent mutual interference between nearby processors

OmniTrax calibration parameters:

• sensitivity profile - the recorded signal response magnitude for each meter of cable based on

the calibration walk

• cable margin - the nominal number of dB that the alarm threshold is below the recorded

sensitivity profile for a sensor cable

• segment margin - an additional cable margin can be set for each defined cable segment

• detection threshold - the cable sensitivity profile minus the cable margin and segment margin

• target speed settings (low speed) - the time constant associated with low speed targets is set

on a per cable basis

• target speed settings (high speed) - the time constant associated with high speed targets is set

on a per cable basis

Universal Configuration Module (UCM) features

The UCM is a Windows based software application, which serves as the configuration,

maintenance and support tool for the OmniTrax processor. The UCM connects directly to the

processor via USB cable, or remotely through the Silver Network Manager. When connected, the

UCM recognizes the OmniTrax processor and displays OmniTrax specific configuration screens.

System integrators use the UCM to calibrate and setup the OmniTrax system. The UCM defines

cable segments, alarm zones, cable margins, input/output configuration and control parameters.

Security management systems

Standalone OmniTrax sensors can be incorporated into any system, which accepts contact

closure alarm data. However, contact closure alarm notification does not provide precise target

location. Silver Network based OmniTrax systems are compatible with Senstar’s Security

Management Systems including StarNeT 1000, StarNet 2 and the Alarm Integration Module.

Network based processors can communicate with third party security management systems

through the Network Manager Interface (NMI). The OmniTrax security perimeter can be displayed

on a graphic site map as a series of alarm zones (e.g., when a sensor alarm occurs, the zone line

flashes, an alarm star flashes to identify the alarm’s exact location, and an audible alarm sounds).

An operator acknowledges the alarm, assesses the cause of the alarm, then either alerts security

and resets the alarm (intruder), or accesses the zone (authorized personnel).

Benefit summary

Advantages of the OmniTrax sensor system include:

• calibrated sensitivity profile, automated transmitter power level and individual cable margin for

each meter of sensor cable provide uniform detection sensitivity for the full cable length,

enhanced sensor performance with an increased Pd and decreased NAR/FAR

• software defined cable segments and alarm zones enable the redistribution of alarm zones,

zone lengths, and cable margin settings to accommodate changes in security equipment and

requirements

• precise display of an alarm’s location to within 1 m (3.3 ft.)

• 1.0 second or less alarm response time per network loop (from target crossing cables to

Network Manager receiving notification)

• user-configurable alarm zone display (typically, as colored lines on a scale site map; alarm

zones can also remain invisible until an alarm occurs)

OmniTrax components

Page 16 OmniTrax Product Guide

• alarm zone length is not dependent on cable length

• a maximum of 50 distinct alarm zones spread over up to 800 m of detecting cable per

processor dramatically reduces the overall sensor cost by eliminating the need for one

processor per two zones (1 processor = up to 50 zones over 800 m)

• the UCM facilitates locating nuisance alarm sources and cable faults

• digital recording of alarm history

• power and data can be passed over the sensor cables

• OC2 sensor cable can be installed by a cable plow

• backwards compatible with Perimitrax sensor cables for retrofit applications

OmniTrax components

Processor

The OmniTrax processor supports two separate sensor cable sets, and can monitor 50 distinct

alarm zones over up to 800 m of detecting cables. The alarm zones are defined in software, and

are not dependent on cable length, or cable side. The processor operates on 12 to 48 VDC power

and can annunicate alarm conditions with contact closure outputs or via the Silver Network.

The processor is mounted on an aluminum backplate and is shipped inside a lockable,

weatherproof enclosure. Non-detecting lead-in cables connect to the external bulkhead

connectors on the bottom of the OmniTrax enclosure. Mini-coax cables inside the enclosure

Note Senstar does not recommend using Sentrax sensor cables with

OmniTrax processors due to the age of the Sentrax cables.

Figure 1: OmniTrax processor

OmniTrax components

OmniTrax Product Guide Page 17

connect the bulkhead connectors to the processor circuit card. Four cable glands on the

enclosure’s bottom provide access for the power cable, ground wire, alarm communication wiring

and the self-test or auxiliary device wiring.

The OmniTrax processor includes four output relays and two self-test/auxiliary inputs. A relay

output card (ROC) is available to provide eight additional outputs. For Silver Network based

processors, a universal input card (UIC) is available to increase the processor’s input capacity by

eight. A processor can use either an ROC or a UIC, but not both.

Each network based processor requires a Network Interface Card (NIC) which serves as the

communications interface to the Silver Network. There are five variants of the NIC, with each being

specific to the network media. EIA-422 copper wire connections are made on removable terminal

blocks, and ST connectors are used for single-mode and multi-mode fiber optic cable.

There are two selectable control modes for the OmniTrax processor’s relay outputs and AUX

(auxiliary) inputs. The control mode is set in software via the UCM. The default setting is local

control mode, in which the OmniTrax processor controls the relays to signal alarm and supervision

conditions, and the AUX inputs are self-test inputs. Using the optional ROC, you can configure up

to ten distinct alarm zones per processor for relay output alarm communications. For Silver

Network based processors, remote control mode enables the host SMS to operate the processor’s

relays, as output control points, and the AUX inputs function as auxiliary device inputs.

Enclosure

The weatherproof OmniTrax enclosure (IP66/NEMA 4) is painted aluminum and includes two

latches on the top for locking the door (locks not included) and hinges on the bottom to allow the

door to hang freely for easy access. There are two sets of mounting studs on the enclosure door,

one for the optional 6 VDC local backup battery and the other for the optional 12 VDC auxiliary

device power supply. The enclosure includes a vent to prevent gas build-up from battery charging.

An enclosure tamper switch is included with a harness that connects directly to the processor. For

outdoor installation, the OmniTrax enclosure must be installed inside a second enclosure to

protect the lead-in cables and the sensor cable connections. The two options for the second

enclosure are a telecom style enclosure, which is available from Senstar, or a Customer supplied

enclosure. The processor can also be mounted indoors in a secure area on a stable fixed surface.

Figure 2: OmniTrax weatherproof and telecom style enclosures

OmniTrax components

Page 18 OmniTrax Product Guide

The telecom enclosure

The telecom style enclosure is used for outdoor installations, to provide additional security and

protection from the elements. The telecom enclosure is ground mounted in a concrete base. The

concrete base must be set above ground level in areas prone to ice and on high ground in areas

prone to flooding. Once the telecom enclosure is installed in the concrete base, a custom bracket

is installed inside, and an OmniTrax enclosure is mounted on the bracket. The telecom style

enclosure comes with a tamper switch that connects to the OmniTrax processor to indicate when

the telecom enclosure is opened.

Customer supplied enclosure

A Customer supplied enclosure must be large enough to accommodate the OmniTrax enclosure

with a service loop for the sensor cables, power cables and I/O wiring. If the OmniTrax processor

will use the local battery option, the enclosure must be properly ventilated. It is also possible to

mount a power supply beside the processor if the enclosure is large enough. The recommended

size for a Customer supplied enclosure without a power supply and using lightning arrestors is

69 cm W X 58 cm H X 20 cm D (27 in. W X 23 in. H X 8 in. D). For a Customer supplied enclosure

that includes space for a 48 VDC network power supply and lightning arrestors the recommended

dimensions are 69 cm W X 69 cm H X 20 cm D (27 in. W X 27 in. H X 8 in. D). If lightning arrestors

are not being used the height of the enclosure can be reduced by 10 cm (4 in.). A Customer

supplied enclosure should include an internal mounting plate for the OmniTrax enclosure.

Sensor cables

There are three types of sensor cables available with the OmniTrax system. The type of cable you

choose depends on the length of your perimeter, the installation media, the installation space, the

type and number of obstacles, and the cable path. When designing your site, you should plan on

using approximately 5% more sensor cable than the total length of the perimeter.

• OC2 sensor cable - requires one or two trenches, or two slots, available in lengths of 300 and

400 m of detecting cable + 20 m lead-in

• SC2 sensor cable - requires one or two trenches, or two slots, available in lengths of 50, 100,

150 and 200 m of detecting cable + 20 m of lead-in

• SC1 sensor cable - requires one trench, available in lengths of 50, 100, 150 and 200 m of

detecting cable + 20 m of lead-in

Figure 3: Customer-supplied enclosure

OmniTrax components

OmniTrax Product Guide Page 19

OC2 sensor cable

OC2 cable is supplied on a 61 cm w X 41 cm (24 in. X 16 in.) center-diameter reel. The 300 m

cable reel weighs approximately 39.5 kg (87 lb), and the 400 m reel weighs approximately 51.5 kg

(113.5 lb). Each sensor cable includes an additional 4 m (13 ft.) of detecting cable, which allows

the detection field to build up to full strength at the start point, plus 20 m (66 ft.) of non-detecting

lead-in cable for the connection to the processor. The OC2 cables are shipped with TNC

connectors and ferrite beads. Each side of the processor requires two sensor cables (one TX

cable and one RX cable).

Note Contact Senstar Customer Service BEFORE using SC1 sensor

cable.

OC2 sensor cable (dual cable system):

• 300 m or 400 m lengths with 20 m of integral

lead-in cable

• ferrite beads and TNC connectors field-

installed

• graded foil opening for uniform detection

• requires one or two trenches, or two slots

• extremely durable

• power and data over sensor cables

• recommended for long perimeters

SC2 sensor cable (dual cable system):

• 50 m, 100 m, 150 m, 200 m lengths with

20 m of integral lead-in cable

• ferrite beads and TNC connectors field-

installed

• graded foil opening for uniform detection

• requires one or two trenches, or two slots

•durable

• power and data over sensor cables

• use for shorter perimeters

SC1 sensor cable (single cable system):

• 50 m, 100 m, 150 m, 200 m lengths with

20 m of integral lead-in cable

• ferrite beads and TNC connectors field-

installed

• graded foil opening for uniform detection

• requires one trench or slot

•durable

• power and data over sensor cables

• use in sites with hard surface slots or

numerous installation limitations

Figure 4: Available cable types

OC2 - two identical

individual cables (TX/RX) drain

braid dielectric

core

center

conductor

foil

outer

grey jacket

cable OD

12.07 mm ± 0.23

(0.475 ± 0.009)

semi-conductive

polyethylene jacket SC2 - two identical

individual cables high density

polyethylene

protective jacket

center

conductor

aluminum foil

(partial covering)

cable OD

8 mm ± 0.23

(0.315 ± 0.009)

foam core

SC1 - single siamese

cable encasing two

leaky coax cables

drain braid

foam core

center conductor

aluminum foil

(partial covering)

semi-conductive

polyethylene jacket

8.64 mm ± 0.33

(0.34 in. ± 0.013)

14.41 mm ± 0.33

(0.567 in. ± 0.013)

high density polyethylene

protective jacket

OmniTrax components

Page 20 OmniTrax Product Guide

SC2 sensor cable sets

In an SC2 sensor cable system two sensor cables are buried in parallel around the site. One cable

serves as the transmit cable and the other serves as the receive cable. Each sensor cable

includes an additional 4 m (13 ft.) of detecting cable, which allows the detection field to build up to

full strength at the start point, plus 20 m (66 ft.) of non-detecting lead-in cable for the connection to

the processor. The SC2 cables are shipped with TNC connectors and ferrite beads.

SC1 sensor cable sets

The SC1 sensor cable consists of two ported coaxial cables in a single outer jacket with one

transmit cable and one receive cable. SC1 sensor cable should be used at sites where installation

space is extremely limited, there are numerous obstacles, or where the cable path meanders.

Each sensor cable includes an additional 4 m (13 ft.) of detecting cable, which allows the detection

field to build up to full strength at the start point, plus 20 m (66 ft.) of non-detecting lead-in cable for

• 2 OmniTrax sensor cable

reels

(300 or 400 m cable sets)

• 20 m lead-in cable (marked

by red band)

• 6 TNC male connector kits

• 42 ferrite beads

• cable marking tape

• cable identification labels

• arbor hole in reel 4 cm

(1.5 in.)

Figure 5: OmniTrax OC2 sensor cable set

• 2 SC2 sensor cable reels

(50, 100, 150, 200 m cable sets)

• 20 m lead-in cable (marked by

red band)

• 4 TNC male connector kits

• 20 ferrite beads

• cable marking tape

• cable identification labels

Figure 6: OmniTrax SC2 sensor cable set

Table of contents

Other SENSTAR Accessories manuals

SENSTAR

SENSTAR FPS 2-2 User manual

SENSTAR

SENSTAR IntelliFIBER User manual

SENSTAR

SENSTAR FiberPatrol FP1150 Series User manual

SENSTAR

SENSTAR FlexZone WGS User manual

SENSTAR

SENSTAR FlexPS User manual

SENSTAR

SENSTAR FiberPatrol FP400 User manual

SENSTAR

SENSTAR FiberPatrol FP1100X Series Technical manual

SENSTAR

SENSTAR FlexZone User manual

SENSTAR

SENSTAR UltraWave BR100 User manual