SENSTAR UltraWave BR100 User manual

Product

Guide

UltraWave BR100™

Microwave Detection Sensor

E5DA0102-001, Rev A

July 23, 2020

BR100 Product Guide

Senstar Corporation

Website: www.senstar.com

Email address: info@senstar.com

E5DA0102-001, Rev A

July 23, 2020

Senstar and the Senstar logo are registered trademarks, and BR100 and Silver Network are trademarks of Senstar Corporation. Product names

and Company names included in this document are used only for identification purposes and are the property of, and may be trademarks of,

their respective owners. Copyright © 2019, Senstar Corporation. All rights reserved.

The information provided in this guide has been prepared by Senstar Corporation to the best of its ability. Senstar Corporation is not

responsible for any damage or accidents that may occur due to errors or omissions in this guide. Senstar Corporation isnot liable for any

damages, or incidental consequences, arising from the use of, or the inability to use, the software and equipment described in this guide.

Senstar Corporation is not responsible for any damage or accidents that may occur due to information about items of equipment or components

manufactured by other companies. Features and specifications are subject to change without notice. Any changes or modifications to the

software or equipment that are not expressly approved by Senstar Corporation void the manufacturer’s warranty, and could void the user’s

authority to operate the equipment.

The figures included in this document are for illustration purposesonly, and may differ from the actual equipment.

Senstar Corporation’s Quality Management System is ISO 9001:2015 registered.

Compliance:

Canada: Industry Canada IdentificationNumber: transmitter 1454B-BR100

Europe:

This device complies with ETSI standard EN 300 440 for European operation The

use of shielded cablesis required for compliance.

Service statement - We ensure that our products are correctly applied to achieve the maximum benefits for the end-user. We work

hand-in-hand with our customers and remain accessible through all stages of a project - from concept to deployment to long-term

support. We provide design assistance, site surveys, installation support, comprehensive documentation, training, post-installation

annual calibration and maintenance visits, electronics and software extended warranty, rapid factory repair service and on-call/

emergency service. Contact Senstar Corporation to inquire about how a package can be customized for your unique applications.

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the following two conditions: (1) This device

may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired

operation.Any Changes or modifications notexpressly approced by the party responsible for compliance could void the user's authority to

operate the equipment.

Ce dispositif est conforme aux normes CNR d’Industrie Canada applicables aux appareils radio exempts de licence. Son fonctionnement est

sujet aux deux conditions suivantes : 1) le dispositif ne doit pas produire de brouillage préjudiciable; et 2) il doit accepter tout brouillage reçu, y

compris un brouillage susceptible de provoquer un fonctionnement indésirable.

Tout changement ou modification non expressément approuvé par la partie responsable de la conformité peut annuler le droit de l'utilisateur à

utiliser l'équipement.

USA: FCC Identification Number: I5T-BR100

FCC Certification - This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may

not cause harmful interference, and (2) this device must accept any interference received, including interference thatmay cause undesired

operation.

Any Changes or modifications notexpressly approced by the party responsible for compliance could void the user's authority to operate the

equipment.

This equipment has been testedand found to comply with the limits for a Class B digital device, pursuant to Part 15 ofthe FCC Rules. These

limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

-Consult the dealer or an experienced radio/TV technician for help.

This equipment complies with ISEDC radiation exposure limits set forth for an uncontrolled environment. This transmitter must not be co-located

or operating in conjunction with any other antenna or transmitter.This equipment should be installed and operated with minimum distance 20cm

between the radiator &you body.

Cet équipement est conforme aux limites d'exposition aux rayonnements ISEDC définies pour un environnement non contr?lé. Cet émetteur ne

doit pas être colocalisé ou fonctionner en conjonction avec une autre antenne ou un autre émetteur.Cet équipement doit être installé et exploité

à une distance minimale de 20cm entre le radiateur et le corps.

BR100 Product Guide Page 3

Table of contents

1 System planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5

Site design - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Zone conditions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Zone height - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6

Mounting angle - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Microwave offsets - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Power requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Power over Ethernet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Alarm data communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Local control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Remote control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Relay contact ratings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Silver Network specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Cable ports - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Mounting posts/surfaces - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Surface-mount applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

BR100 alarm reporting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Fast Alarm Response - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Automatic gain control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

2 Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -13

Mounting the BR100 units - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Mounting angle - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

Post-mounting procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Initial post-mount alignment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Surface mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Surface mounting procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Initial surface-mount alignment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Transmitter/receiver wiring connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

T4 - power input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

T4, T5 - input/outputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

Relay contact ratings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Cable ports - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Making the I/O wiring connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Enclosure tamper switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Power supply connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Local power supply - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Power over Ethernet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Silver Network alarm data communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Page 4 BR100 Product Guide

Silver Network connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Stacking BR100 units - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -21

3 Setup and calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -23

Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -23

Transmitter setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -24

Setting the transmitter unit’s Frequency Pair - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

Setting the address - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

Receiver setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -26

Network configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -27

Specify the Auxiliary I/O control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -27

Auxiliary device/self-test input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -27

Input configuration procedure (Local control mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Input configuration procedure (Remote control mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Output relays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -28

Output relay setup (Local control mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Output relay setup (Remote control mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Receiver calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -30

Optimizing the alignment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -30

System verification tests - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

4 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -35

BR100 unit maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -35

BR100 site maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -35

BR100 testing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -36

Beam-break alarm test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Remote self-test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Correcting nuisance alarm problems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -36

Verifying the BR100 alignment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -37

Updating the firmware - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -38

a Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -39

b Parts list - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -41

BR100 Product Guide Page 5

1 System planning

The BR100 Microwave Detection Sensor is designed for outdoor perimeter intrusion detection.

BR100 consists of a microwave transmitter unit and receiver unit, which detect motion in a defined

area (see Figure 1). The transmitter emits microwave energy, which the receiver constantly

monitors. Any motion in the detection zone causes a variation in the received signal. The signal

variations are processed by the receiver, which declares a sensor alarm when the received signal

meets the criteria for a valid target.

Site design

To achieve the narrowest detection zone with the highest probability of detection (Pd) the BR100

requires a straight, flat, detection zone free of obstacles and depressions. The zone must be

completely free of standing and running water. The minimum distance between the beam

centerline and any object (fences, buildings, vehicles, trees, bushes, shrubs, etc.) is outlined in

Table 1. These numbers are typical conditions and can vary depending on site conditions including

zone length, unit mounting height, ground cover, type of obstacle and its mobility, etc. The

following separation distances are the minimum requirements. Increase the separation distance

between the beam centerline and any objects whenever possible.

Figure 1 BR100 microwave detection zone

transmitter/receiver separation minimum clearance

(centerline to object) midpoint zone width

10 m (33 ft.) 0.2 m (0.66 ft.) 0.4 m (1.3 ft.)

25 m (82 ft.) 0.5 m (1.6 ft.) 1.0 m (3.3 ft.)

50 m (164 ft.) 1.0 m (3.3 ft.) 2.0 m (6.6 ft.)

75 m (246 ft.) 1.5 m (5 ft.) 3 m (10 ft.)

100 m (328 ft.) 2.0 m (6.6 ft.) 4.0 m (13.2 ft.)

Table 1 Unit separation/minimum clearance

partial coverage

mounting height

full coverage

detection zone partial coverage

beam centerline

offset area offset area

Site design

Page 6 BR100 Product Guide

Zone conditions

The detection sensitivity of each zone depends on several factors:

• the required level of security

• an acceptable nuisance alarm rate (NAR)

• microwave unit alignment

• the ground conditions

• physical constraints (terrain, trees, fences, buildings, etc.)

• available space for the detection zone

For the highest level of detection sensitivity and the narrowest beam-width, the terrain must be

level to grade ± 7.5 cm (3 in.) and the surface must be free of vegetation and either paved, or

covered with a 10 cm (4 in.) layer of crushed stone (2 cm {0.75 in.} max.). (At ranges up to 100 m

the BR100 shall detect a 35 kg (77 lb) human walking, running, hands and knees crawling, prone

crawling, rolling, or jumping.)

For mid-level detection sensitivity the terrain must be level to grade ± 15 cm (6 in.) and the surface

must be paved, or covered with crushed stone, or hard packed dirt or clay, or closely mowed

grass. (At ranges up to 100 m the BR100 will detect a 35 kg (77 lb) human walking, running, hands

and knees crawling or jumping.)

For low level detection sensitivity (beam break alarm) the terrain must be level to grade ± 23 cm

(9 in.) and the surface must be paved, or covered with crushed stone, or hard packed dirt or clay,

or closely mowed grass. (At ranges up to 100 m the BR100 will detect a 35 kg (77 lb) human

walking, running or jumping.)

Zone height

The height of the microwave field at midspan is approximately equal to the minimum required

clearance between the beam centerline and an object (see Table 1) plus the unit mounting height.

There are two recommended mounting heights for the BR100: 55 cm (22 in.) and 95 cm (37 in.).

(e.g., for a microwave pair with a unit separation of 50 m and a mounting height of 55 cm the zone

height is approximately 1 m + 0.55 m = 1.55 m or 5.1 ft.). For applications that require additional

zone height it is possible to stack two, or three BR100 units on one mounting post. Table 2

provides approximate zone height comparisons between single stack and double stack

configurations. Figure 2 illustrates a double stacked BR100 configuration.

Note Certain obstacles with large cross sections such as loose fences

and large sheets of metal (e.g., a tractor trailer) require additional

clearance. For this kind of obstacle, double the recommended

separation distance.

Tx/Rx separation configuration approximate zone height

50 m (164 ft.) single stack 1.55 m (5.1 ft.)

double stack 1.95 m (6.4 ft.)

100 m (328 ft.) single stack 2.55 m (8.4 ft.)

double stack 2.95 m (9.7 ft.)

Table 2 Extended zone height examples

Site design

BR100 Product Guide Page 7

Mounting angle

For microwave pairs with a unit separation of 50 m or less, the microwave units are mounted with

a 5º pitch (toward the ground). This provides the optimum signal strength, when combining the

direct signal and the reflected signal at the receiver unit (see Figure 6).

Microwave offsets

The areas immediately above and below the transmitter and receiver antennas are not exposed to

the microwave energy. The microwave offset area describes the distance from the unit’s mounting

position to the point where the beam reaches the ground. For a mounting height of 55 cm, the

coverage is effectively right up to the mounting post. For a 95 cm mounting height there is an

approximate offset area of 1.35 m (4.4 ft.). Only partial coverage is provided in the offset area. Full

coverage begins where the offset area ends (see Figure 3). The offset distances in the example

drawings are based on a mounting height of 95 cm (37 in.). As the mounting height increases, the

offset increases. Different types of offsets are shown in Figure 4.

Figure 2 Stacking BR100 units

Figure 3 Offset area

receiver units transmitter units

maximum zone height

mounting

heights

135 cm

55 cm

partial coverage

partial coverage

beam centerline

full

coverage

detection

zone

offset area

1.35 m 4.4 ft.

95 cm

(37 in.)

Site design

Page 8 BR100 Product Guide

Power requirements

The BR100 sensor (transmitter and receiver) consumes 2 W (nominal). Both the transmitter and

receiver can operate on a wide range of input voltages (12 to 48 VDC). The required gauge of the

power cable depends on the power supply capacity, the number of BR100 units being powered

and the lengths of the power cable runs. In locations where AC power may not be stable or

reliable, an uninterruptable power supply (UPS) is recommended for primary power.

Power over Ethernet

Both the transmitter and receiver units can receive power over Ethernet (PoE). Silver Network

based BR100 pairs have the option of using Ethernet communications. To use this powering

option requires a PoE class 3 switch that is located within 100 m (328 ft.) of the transmitter/

receiver, and minimum Category 5 shielded network cable.

Figure 4 Offset arrangement examples

CAUTION Senstar strongly recommends the use of external lightning protection

devices for all outdoor cable runs (i.e., power, I/O, Ethernet, RS-422).

Note Senstar recommends using a fully managed PoE switch to supply

power to the BR100 transmitter/receiver.

detection zone

protected area

beam

centerline

corner offset

95 cm (37 in.) mounting height

basket weave layout

for odd shaped perimeters

1 m (3.3 ft.)

2.7 m (8.9 ft.)

parallel offset

95 cm (37 in.) mounting height

T

R

T

R

R

R

R

R

RR

T

T

T

T

T

T

T

T

T

T

T

T

R

R

R

T

1.35 m

(4.4 ft.)

1.35 m

(4.4 ft.)

Site design

BR100 Product Guide Page 9

Alarm data communications

BR100 alarm data communications can be provided in two ways, via relays in Local control mode

and over the Silver Network in Remote control mode. Each BR100 unit (transmitter and receiver)

has two user-configurable relay outputs and one input. The relay contacts are held in the closed

position during normal operation and open to signal an event, or if power is lost.

Local control mode

In Local control mode, the receiver’s two outputs can be configured to signal Microwave Alarm,

Input Power Fail, Enclosure Tamper, Hardware Faults and Fail Safe (system fail). A momentary

switch input to the unit’s Aux input is used to activate an electronic self-test of the transmitter/

receiver unit. Figure 5 shows the selectable input/output (I/O) parameters for Local control mode.

Remote control mode

In Remote control mode, alarm and supervision data is carried over the network cables and each

unit’s two relays are available as output control points for the security management system (SMS).

The supervised input on each unit can be used to report the status of an auxiliary security device

to the SMS. In Remote control mode, a self-test is initiated by a command from the SMS. To

communicate on the Silver Network requires either RS-422 or Ethernet (PoE) cable.

CAUTION Input Power Fail, and Fail Safe conditions indicate that the BR100

sensor is not operational.

Figure 5 Local control mode I/O configuration parameters

Note You can setup a Silver Network to enable calibration, maintenance

and diagnostic access to your BR100 units from a central control

facility, and select Local control mode to use the receiver’s two

relay outputs to signal alarm and supervision conditions.

Aux Control selection (Local or Remote)

Input configuration parameters

Output configuration parameters

Site design

Page 10 BR100 Product Guide

Relay contact ratings

The solid state relays are Form A (N.O.) rated for 60 V @ 100 mA maximum, non-inductive load.

In Remote control mode, you can configure the relays as steady ON, flash mode (ON-OFF-ON-

OFF, etc.), or pulse mode (ON for a period, then OFF). For flash and pulse modes, the relay

Active/Inactive times are selectable. In Local control mode the relays remain active for the event’s

duration or for the selectable Hold Time, whichever is longer. The relay contacts are held in the

closed position during normal operation and open to signal an event, or if power is lost.

Silver Network specifications

• Data rate - fixed 57.6 k bps

• Maximum 60 devices spread over up to 4 independent network loops

• Two communication Channels (Side A, Side B)

• Response time - 1 second, or less from alarm source to Network Manager (per loop)

• Network termination - not required

• Transmission media/maximum separation distances between sensors:

• RS-422 copper wire - 1.2 km (0.75 mi.) - 2 pairs per Channel

• Ethernet - Category 5 shielded cable, 100 m between PoE switch and microwave unit

Cable ports

Each BR100 unit includes a single 22 mm (0.875 in.) cable port fitted with a compression gland,

and two provisional rear entry cable ports (requires removal of circuit card and drilling the plastic

enclosure at the locations identified with alignment marks). The compression gland is for cable

sizes 4.3 mm to 11.4 mm (0.17 in. to 0.45 in.). If required, the enclosure can be fitted with 13 mm

(1/2 in.) conduit (not included) in place of the compression gland.

Mounting posts/surfaces

The BR100 units mount easily on posts with an outside diameter ranging between 4.8 cm and

11.4 cm (1.875 in. and 4.5 in.). The posts must be plumb, firmly set in the ground, and unable to

rotate or move. For areas where the ground freezes, the posts must be protected against potential

frost heaving. A 2.5 m (8 ft.) post is generally used with 1 m (3.3 ft.) of the post buried in a concrete

footing. Figure 6 is an illustration of a post-mounted BR100 unit.

Note Senstar recommends hiring a local fencing contractor to install the

BR100 mounting posts.

Consult the local building code for information on installing mounting

posts.

Site design

BR100 Product Guide Page 11

Surface-mount applications

The post-mount bracket can also be used to mount a BR100 unit on a fixed stable surface. If you

are considering a surface mount application, the transmitter receiver alignment must be carefully

planned, as the mounting bracket cannot be easily adjusted in the horizontal plane for surface

mount applications. The hardware required for fastening the bracket to the surface is not included.

Figure 7 illustrates a surface mounted BR100 unit.

Figure 6 Post installation and unit mounting

Figure 7 Surface mounting example

4.8 to 11.4 cm post

power and alarm

wiring in conduit

BR100 unit

mounting height from

top of mounting bracket

ground level

buried conduit

to alarm panel

& power supply

rebar

through post

concrete footing

Consult the local construction codes for information about using

concrete footings in ares where ground freezing occurs.

*

to ground

power and alarm

wiring in conduit

BR100 unit

mounting height from top of

mounting bracket to ground

ground level

mounting

bracket

via provisional

(drilled) cable port

Site design

Page 12 BR100 Product Guide

BR100 alarm reporting

The BR100 system reports a sensor alarm when a target disturbs the microwave field. If a large

target (e.g., a vehicle) enters the microwave field and blocks the beam, the BR100 sensor goes

into alarm and continues the alarm until the object leaves the field. If the calibration parameters

are outside the valid range at startup, or during operation, the BR100 system goes into constant

alarm until the calibration problem is corrected. The receiver unit also signals an alarm if it does

not see the transmitter on startup.

The transmitter and receiver units are housed in weatherproof enclosures. Each enclosure

contains electronic circuitry and an antenna. Both units include tamper switches and can be

configured to report enclosure tamper alarms.

Fast Alarm Response

The BR100 receiver includes a Fast Response channel that bypasses the sensor’s advanced

signal processing algorithms when enabled. This causes the BR100 receiver to function like a

classic analog microwave sensor. With Fast Response enabled, BR100 will trigger an alarm as

soon as the microwave signal exceeds the Threshold setting. The Fast Response channel

provides early alarm notification, but can also cause an increase in the nuisance alarm rate (NAR).

Fast Response is intended for use in high-security applications that include a sterile zone.

However, Fast Response should NOT be used in Sally Port areas.

Automatic gain control

The BR100 microwave sensor employs automatic gain control (AGC) to ensure the received

signal remains at an optimal level. If the receiver detects an increase, or attenuation of the

transmitted signal the AGC gradually adjusts the signal gain to maintain proper detection.

Note If the BR100 signal is blocked continuously for a period that

exceeds 30 seconds, the system may be prone to nuisance alarms

or have a reduced probability of detection for 30 seconds after the

blocking object leaves the microwave field.

BR100 Product Guide Page 13

2 Installation

The cover on each BR100 unit enclosure is secured with two captive screws that are factory

installed to a finger-tight torque specification. There are no user-serviceable components inside

the compartment. The cover should only be removed:

• to access the circuit card assembly for setup and calibration purposes (via a UCM connection)

• to make the wiring connections

• if the unit will be fitted with conduit

• if the provisional rear entry ports are required

To access the circuit card assembly, remove the two screws on the enclosure cover. When

replacing the cover, tighten the screws until finger-tight. Do not over-tighten the screws.

The BR100 transmitter and receiver units are almost identical, with no visual difference in circuitry.

Each unit is identified by labels on the enclosure and the PCB. Figure 8 shows a BR100 receiver

and illustrates the unit’s features. The receiver’s diagnostic activity LEDs are listed in Table 3.

Figure 8 BR100 receiver unit

USB port

power

S1 tamper

switch

connection

diagnostic connect UCM

LEDs

relays 1 & 2

self-test or

AUX input

antenna array

Ethernet (PoE)

comm LEDs

RS-422 Side A

RS-422 Side B

Page 14 BR100 Product Guide

Mounting the BR100 units

Mount the transmitter and receiver units on their respective posts using the hardware provided.

The mounting height of the transmitter and receiver units is measured from the top of the mounting

bracket to the ground’s surface. The initial recommended mounting height is either 55 cm (22 in.)

or 95 cm (37 in.). The BR100 units can also be mounted on a wall or other flat stable surface. Both

the transmitter and receiver units must be mounted at the same height above ground. During

mounting, the two units must be aligned to point directly at each other.

Mounting angle

For microwave pairs that are separated by 50 m (164 ft.) or less, adjust each BR100 unit to have a

5º pitch (toward the ground). The 5º pitch combines the reflected signal and the direct signal to

create the strongest received signal possible for short range applications. The calibration testing

will determine if the mounting angle is correct for your installation.

LED # Description LED # Description

D3 door open: enclosure door open D10 fault: comm fault on B-side

D4 USB active: active UCM connection D14 speed: communication speed

D5 TXA: transmitting data on A-side D15 duplex: 2-way communications

D6 RXA: receiving data on A-side D16 alarm: microwave sensor alarm active

D7 fault A: comm fault on A-side D17 fail: major malfunction no detection

D8 TXB: transmitting data on B-side D18 heartbeat: indicates health of system

D9 RXB: receiving data on B-side

Table 3 BR100 diagnostic LEDs

Figure 9 Mounting bracket

mounting post collar

bracket

BR100 unit

BR100 Product Guide Page 15

Post-mounting procedure

1. Pass the gear clamp through the slots in the mounting bracket.

2. Tighten the mounting bracket assembly on the BR100 unit.

3. On the mounting post, measure the mounting height of the BR100 unit and mark the post at

that point.

4. Wrap the gear clamp around the post and tighten until snug against the post so that the BR100

unit is at the correct height (top of mounting bracket is at the measured mark).

5. Aim the BR100 unit at the second mounting post, and using an 8 mm (5/16 in.) nut driver or

socket, finish tightening the gear clamp with the BR100 unit at the specified height.

6. Verify the mounting height.

7. For BR100 units that are separated by 50 m or less, adjust the pitch of each unit to a 5º angle

toward the ground.

8. Repeat for the second BR100 unit.

Initial post-mount alignment

For optimal performance, ensure that the BR100 transmitter and receiver are aimed directly at

each other, and that the mounting height is correct for both units.

1. Verify the mounting height of each unit (ground to top of mounting bracket).

2. If required, loosen the transmitter’s gear clamp slightly, and then carefully aim the transmitter

directly at the receiver.

3. Tighten the transmitter’s gear clamp.

4. If required, loosen the receiver’s gear clamp slightly, and then carefully aim the receiver

directly at the transmitter.

5. Tighten the receiver’s gear clamp.

6. If required, loosen the bolts that attach the mounting bracket and tilt the units (in the vertical

axis) toward each other. Re-tighten the bolts.

7. For BR100 units that are separated by 50 m or less, adjust the pitch of each unit to a 5º angle

toward the ground.

Surface mounting

The BR100 mounting bracket can be used to surface mount the transmitter and/or receiver. The

mounting bracket is removed from the unit and is attached to the surface. The microwave unit is

then reattached to the mounting bracket. Customer-supplied hardware (7 mm, 1/4 in.) is used to

attach the assembly to the mounting surface.

Note The UCM includes a received signal strength indicator (RSSI)

which serves as an aid during final alignment.

CAUTION For surface mount applications, the two mounting surfaces

must face toward each other. Surface mounted BR100 units

cannot be rotated in the horizontal axis. If required, use shims

to adjust the horizontal alignment of surface mounted units.

Page 16 BR100 Product Guide

Surface mounting procedure

1. Measure the mounting height of the unit from the ground and mark the surface at that point.

2. Using an 11 mm (7/16 in.) wrench, remove the hardware attaching the mounting bracket to the

unit.

3. Hold the mounting bracket against the mounting surface so the top of the bracket is level with

the mounting height mark and then mark the two holes on the mounting surface.

4. Drill two holes in the mounting surface.

5. Attach the mounting bracket to the surface using appropriate fasteners.

6. Measure and verify the mounting height.

7. Re-attach the BR100 unit to the mounting bracket.

8. Mount the second BR100 unit.

Initial surface-mount alignment

To ensure optimal performance, it is critical that the BR100 transmitter and receiver are aimed

directly toward each other, and that the mounting height is correct for both units.

1. Verify the mounting height of each unit.

2. If required, loosen the mounting hardware on the post collars, and use shims so that the

BR100 transmitter and receiver point directly at each other (horizontal adjustment).

3. Tighten the mounting hardware.

4. If required, loosen the bolts attaching the mounting bracket and aim the units toward each

other (in the vertical axis). Re-tighten the bolts.

Figure 10 Mounting setup

Note If the microwave pair is separated by 50 m or less, adjust the

pitch of both units to a 5º angle (toward the ground).

post mounting slots

mounting bracket

7 mm (0.25 in.) mounting holes

BR100 Product Guide Page 17

Transmitter/receiver wiring connections

The BR100 wiring connections are made on 45º spring terminal blocks. The spring terminals

accept wire sizes from 16 to 24 AWG with a 9 mm (0.35 in.) strip length. The DC power input is

made on T4 and the input/output (I/O) connections are made on T4 and T5. Each unit’s auxiliary

(AUX) input is available when using Remote control mode (network alarm data communications).

The self-test input is available in Local control mode (relay output alarm signaling).

T4 - power input

The BR100 units require 12 to 48 VDC to operate. Connect DC power to T4 pin 1 (-VDC) and

T4-2 (+VDC) or use PoE (T9).

T4, T5 - input/outputs

T5 connects to output 1 and output 2, and T4 connects to the auxiliary (AUX) or self-test input (see

Figure 12 for connection details).

In Local control mode, the two outputs can be configured via the UCM to report user-specified

alarm and supervision conditions (see Alarm data communications on page 9). A momentary

switch input to the self-test input activates an electronic test. Self-test activation requires a

normally open, unsupervised momentary switch input. The momentary switch input must be

closed for a minimum of the time specified in the Filter Window parameter (via the UCM). See

Table 4 for example input wiring diagrams and supervision resistor values.

In Remote control mode, the two outputs are used by the security management system (SMS) as

output control points. The AUX input is available to report the status of an auxiliary security device

to the SMS. The input’s status is determined via an internal reference voltage, and the

configuration of the contact closures and supervision resistors. Any change in the input’s status is

reported to the SMS.

Figure 11 Wiring connections

Figure 12 Transmitter/receiver wiring connections

(12 to 48 VDC)

Ethernet (PoE)

self-test or

AUX input

relays 1 & 2

RS-422 A-side

RS-422 B-side

power input

(12 to 48 VDC)

AUX input

output 1

output 2

self-test input

In Local control mode the default setting for output 1 is ON = sensor alarm; output 2 is ON = supervision alarm.

In Local control mode you can use the UCM to specify the conditions that will activate output 1 and output 2.

A-Side RS-422 B-Side RS-422

Ethernet

PoE

Page 18 BR100 Product Guide

Relay contact ratings

The solid state relays are Form A (N.O.) rated for 60 V @ 100 mA maximum, non-inductive load.

The relay contacts are held in the closed position during normal operation and open to signal an

event, or if power is lost.

Cable ports

Each BR100 unit includes one 22 mm (0.875 in.) cable port fitted with a compression gland. Pull

the cables through the compression gland, into the enclosure and through the locking nut. Then

install the compression gland in the cable port. After making the wiring connections, tighten the

compression gland to provide weather protection and strain relief.

Alternatively, there are two provisional cable entry ports that are indicated on the back of the unit.

To use the provisional ports you must remove the unit’s circuit card assembly (CCA) and drill the

holes in the plastic enclosure. The cable glands or conduit fittings required for the rear ports are

customer supplied.

Making the I/O wiring connections

1. Pull the data cable into the enclosure.

2. Prepare the data cable leads - strip length = 9 mm (0.35 in.).

3. Make the wiring connections on the appropriate terminals (see Figure 12).

Enclosure tamper switch

Each BR100 unit includes a tamper switch to indicate if the enclosure cover is removed

(closed = secure, open = tamper).

Power supply connection

When a central low voltage power supply is being used for primary power, it should be powered

from an uninterruptible power source.

• To power the system from a central source, run the power distribution cable around the

perimeter and tap off to each BR100 unit.

• In a weatherproof junction box near each BR100 unit, splice the power cable to a lighter gauge

pigtail. Connect the negative lead to T4-1 (-) and connect the positive lead to T4-2 (+) (see

Figure 12).

Local power supply

To use a local DC power supply, the power supply must be outdoor rated and installed in its own

weatherproof enclosure. The local power supply can be mounted on the same post as the BR100

unit to keep the wire run to a minimum. Connect the negative lead to T4-1 (-) and connect the

positive lead to T4-2 (+) (see Figure 12).

Note The contact closure input to the AUX input must be voltage-free.

WARNING! DO NOT bring AC mains power into the BR100 enclosure. If a local

power supply is being used, it must be installed in its own

weatherproof enclosure. Consult the local electrical code for

information about the connection of AC mains to your power supply.

BR100 Product Guide Page 19

Power over Ethernet

For power over Ethernet, a fully managed class 3 PoE switch is recommended. In this

configuration, minimum Category 5 shielded Ethernet cable is also required and the maximum

distance between the BR100 transmitter/receiver and the PoE switch is 100 m (328 ft.). To use

PoE, connect the PoE switch to the Ethernet port on the CCA.

Silver Network alarm data communications

Silver Network connections

Figure 13 illustrates the data flow directions for an RS-422 based Silver Network. Figure 14 shows

an RS-422 based Silver Network using the loop configuration and Figure 15: illustrates an

Ethernet based Silver Network using the Star configuration.

Note The BR100 units can use either Ethernet or RS-422 for network

communications.

CAUTION Senstar strongly recommends the use of external lightning protection

devices for all outdoor cable runs (i.e., power, I/O, PoE, RS-422).

Figure 13 Silver Network RS-422 data flow

RS-422

* Use single point grounding, connect one end of the cable shield

to ground, trim back the other end and leave it disconnected.

Page 20 BR100 Product Guide

Figure 14 Silver Network RS-422 wiring diagram

Figure 15: Silver Network Ethernet wiring diagram

11

223344

55

RXB+

RXB-

GND

TXB+

TXB-

RXA+

RXA-

GND

TXA+

TXA-

11

223344

55

12345 12345

1

1

2

2

3

3

4

4

5

5

1

2

3

4

5

1

2

3

4

5

12345 12345

RXB+

RXB-

GND

TXB+

TXB-

RXA+

RXA-

GND

TXA+

TXA-

RXB+

RXB-

GND

TXB+

TXB-

RXA+

RXA-

GND

TXA+

TXA-

RXA+

RXA-

GND

TXA+

TXA-

12345

R

X

B

+

R

X

B

-

G

N

D

T

X

B

+

T

X

B

-

12345

maximum 60 devices

max. distance between devices = 1.2 km (3/4 mile)

first device second device last device

shield shield

shield shield

shield

shield

NOTE: Use single point grounding - connect one end of the cable shield, trim back the other end and leave it disconnected.

Network Interface Unit

lightning

arrestors lightning

arrestors

to Network Manager

maximum 60 devices

first transmitter

receiver or

Network

max. cable run

receiver or

receiver or receiver or

Manager

computer

security

management

system

computer

between device

and PoE switch

Category 5 shielded Ethernet cable

class 3

PoE

switch

processor

processor

processor processor

processor

100 m (328 ft.)

receiver or

second transmitter

receiver or

processor

third transmitter

fourth transmitter fifth transmitter

last transmitter

Table of contents

Other SENSTAR Accessories manuals

SENSTAR

SENSTAR FiberPatrol FP400 User manual

SENSTAR

SENSTAR FPS 2-2 User manual

SENSTAR

SENSTAR FlexZone User manual

SENSTAR

SENSTAR IntelliFIBER User manual

SENSTAR

SENSTAR FiberPatrol FP1100X Series Technical manual

SENSTAR

SENSTAR FiberPatrol FP1150 Series User manual

SENSTAR

SENSTAR FlexPS User manual

SENSTAR

SENSTAR OmniTrax User manual

SENSTAR

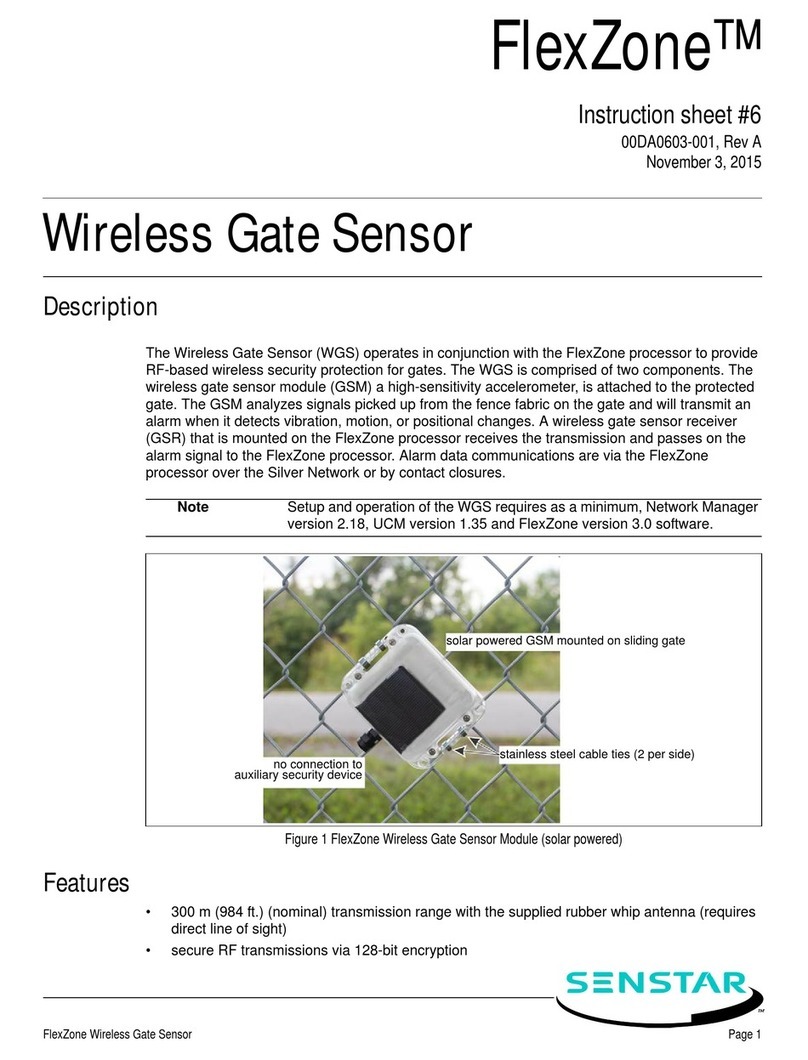

SENSTAR FlexZone WGS User manual