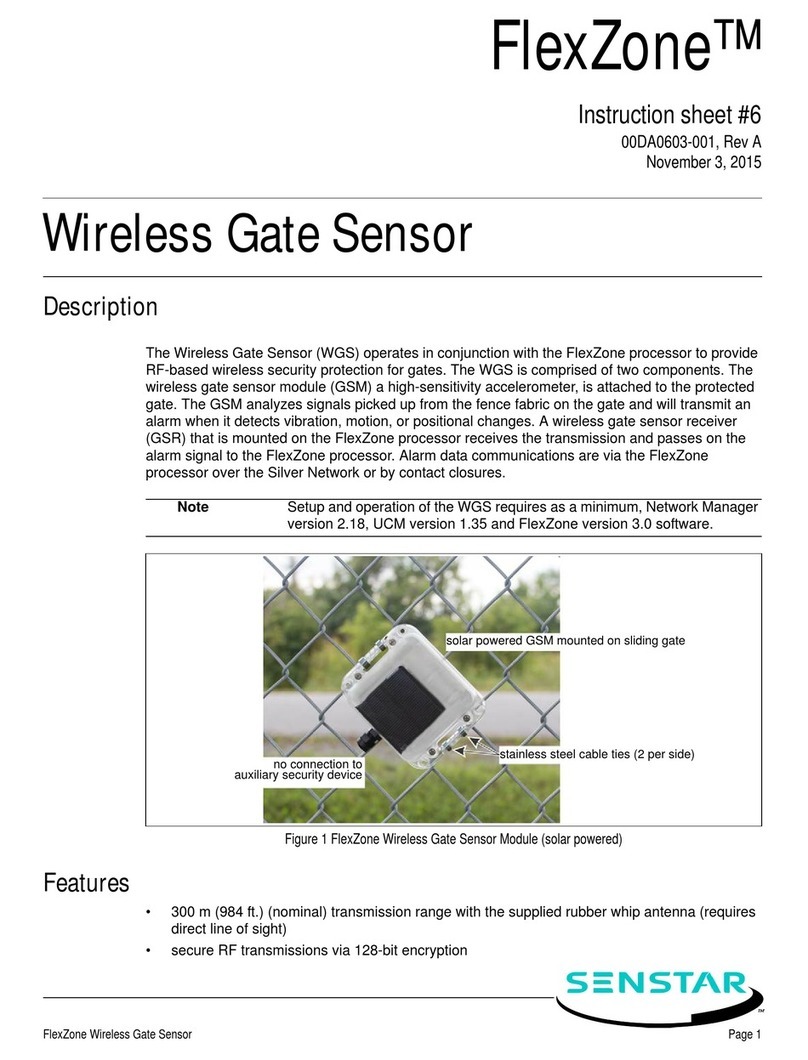

SENSTAR FiberPatrol FP400 User manual

Product

Guide

FiberPatrol®

Fiber Optic Fence Protection Sensor

F4DA0102-001, Rev B

January 13, 2020

FP400 Sensor

Page 2 FP400 Product Guide

F4DA0102-001, Rev B

January 13, 2020

website: www.senstar.com

email: info@senstar.com

FiberPatrol, Senstar and the Senstar logo are registered trademarks, and Silver Network is a trademark of Senstar Corporation.

Product names and Company names included in this document are used only for identification purposes and are the property

of, and may be trademarks of, their respective owners. Copyright © 2019, Senstar Corporation, all rights reserved.

The information provided in this guide has been prepared by Senstar Corporation to the best of its ability. Senstar Corporation is

not responsible for any damage or accidents that may occur due to errors or omissions in this guide. Senstar Corporation is not

liable for any damages, or incidental consequences, arising from the use of, or the inability to use, the software and equipment

described in this guide. Senstar Corporation is not responsible for any damage or accidents that may occur due to information

about items of equipment or components manufactured by other companies. Features and specifications are subject to change

without notice. Any changes or modifications to the software or equipment that are not expressly approved by Senstar

Corporation void the manufacturer’s warranty, and could void the user’s authority to operate the equipment.

The figures included in this document are for illustration purposes only, and may differ from the actual equipment.

Approvals:

Canada: This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations.

Industry Canada ICES-003, issue 4 requirements for Class A devices.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

USA: This device complies with part 15, subpart B of the FCC Rules. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) this device must accept any interference received, including any

interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation.This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

- Reorient or relocate the receiving antenna.

- Increase the separation distance between the equipment and the receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Europe: This device conforms to the protection requirement of council directives 89/336/EEC on the approximation of the laws

of member states relating to Electromagnetic compatibility, amended by directive 93/68/EEC.

EN50130-4:2011+A1:2014, EN61000-6-3:2007/A1:2011, RoHS3, REACH

Service statement - We ensure that our products are correctly applied to achieve the maximum benefits for the end-user. We

work hand-in-hand with our customers and remain accessible through all stages of a project - from concept to deployment to

long-term support. We provide design assistance, site surveys, installation support, comprehensive documentation, training,

post-installation annual calibration and maintenance visits, electronics and software extended warranty, rapid factory repair

service and on-call/emergency service. Inquire about the Senstar Care Program and how Senstar Care can be tailored to fit

your unique security requirements,

FP400 Product Guide Page 3

Table of contents

1 System description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

System details - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

FP400 components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

FP400 Processor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Relay outputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9

Auxiliary inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -9

LED indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Network communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Zone kit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Start Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

End Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Weatherproof splice enclosure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Sensor cable/non-detecting lead-in cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Cable ties - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

2 Site planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -15

FP400 configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Linear zone configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Closed loop configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

FP400 fiber drop points - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Lightning protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Site survey - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 19

Fence condition - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Supported fence types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

Site analysis checklist - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

3 Installing the FP400 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -21

FP400 installation overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

Laser light safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

Optical fiber safety - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Fiber optic cable handling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Sensor cable performance specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Additional cable requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Cable loss limits (maximum attenuation) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Cable handling recommendations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 23

Installation recommendations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 23

Page 4 FP400 Product Guide

Sensor fiber length matching - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -23

Fence height considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -23

Double pass coverage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -24

Climb-over deterrent hardware - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -25

Barbed wire - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

Gates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -26

Gate bypasses - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

Protecting swinging gates with sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 27

Determining cable length requirements for gates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Using the cable management kit at the hinged side of protected gates - - - - - - - - - - - - - - - 28

Selecting conduit for below ground bypasses - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -29

Solid wall conduit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Split wall conduit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Sensitivity loops for tension posts and corner posts - - - - - - - - - - - - - - - - - - - - - - - - - -30

Service loops - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Deploying the sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

Sensor cable splices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

Illustrated installation requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

Sensor cable and below ground bypasses - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Installing the sensor cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -36

Attaching sensor cable to the fence - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -37

Attaching the sensor cable at protected gates - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

Installing the FP400 processor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -39

Mounting options: - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -39

Rack-mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

DIN Rail mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

Surface mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 41

Free-standing or fence post mounting the enclosure - - - - - - - - - - - - - - - - - - - - - - - - - - - - 42

Processor connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -43

Sensor cable connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Wiring connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Power connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Ground connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Relay outputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 44

Relay contact ratings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 44

Auxiliary inputs/Self-test inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45

Silver Network alarm data communication - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -45

Silver Network specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

Silver Network data path connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 47

FP400 fusion splices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -49

Preparing the start and end modules for splicing - - - - - - - - - - - - - - - - - - - - - - - - - - - -50

Start module splices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

End module splices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

Fusion splicing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -51

Recommended tools - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 51

Cut cable applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 51

Expressed cable applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 51

Protecting splices inside STP enclosures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -53

FP400 Product Guide Page 5

4 Calibration & setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -57

FP400 alarm detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 57

Intruder detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Cut intrusion detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Climb intrusion detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

Detection parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 59

FP400 initial calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 60

Intrusion simulations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 60

Cut simulation (tap test) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 60

Climb simulation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 60

Testing the fence condition - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

The Universal Configuration Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

Connecting the UCM via USB - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 62

Sensor calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 63

Adjusting the RX Cable (Gain) settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 63

Setting the detection parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 63

Setting the cut detection parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 64

Setting the climb detection parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 64

Setting the cable supervision parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

Setting the Supervision Duration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

Setting the Supervision Threshold - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

Mitigating weather related nuisance alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 65

Processor setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 66

Specify the Auxiliary I/O control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 66

Auxiliary (Aux) inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 66

Local control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 66

Remote control mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 66

Input configuration procedure (Remote control mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - 67

Output relays - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 68

Output relay setup (Local control mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 68

Output relay setup (Remote control mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 68

Setting the processor network address - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 68

Network configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 69

System test procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 70

5 Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -71

Recommended maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 71

Updating the firmware - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 72

a System component list - - - - - - - - - - - - - - - - - - - - - - - - - 73

b Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 75

Page 6 FP400 Product Guide

FP400 Product Guide Page 7

1 System description

The FiberPatrol FP400 is a fence-mounted perimeter intrusion detection system that detects

intruders using a fiber optic sensor cable that is attached to the fence. The FP400 processor uses

interferometry technology to measure the strain in the sensor cable caused by climbing, cutting,

lifting, or otherwise disturbing the fence fabric. The processor monitors four independent sensor

zones, each with up to 300 m (984 ft.) of sensor cable.

The sensor cable is communication-grade single-mode fiber optic cable intended for outdoor

installation. The cable includes 12 fibers and each detection zone requires 2 dedicated fibers. The

number of unused (dark) fibers available for other perimeter applications depends on the

configuration of the zones. The sensor cable is easily attached to the fence with UV resistant cable

ties. All fiber splices require fusion splicing and the fiber optic connections to the processor use

SC/APC type connectors.

For each sensor zone, the processor transmits laser light through an optical output channel (TX)

into a fiber in the lead-in cable. Up to 20 km (12.4 mi) of non-detecting lead-in cable carries the

light to the start module where it is sent down the two sensing fibers. At the end of the zone, the

end module reflects the light back to the start module, which in turn sends it to the processor

through an optical input channel (RX). The processor analyzes the detection signals from each

zone and triggers an alarm when a fence disturbance meets the user-defined criteria for a valid

intrusion.

Figure 1 Senstar block diagram - single zone closed perimeter example

start module

maximum single zone cable length = 300 m (984 ft.)

non-detecting lead-in cable

equipment room

perimeter

processor security management

max. length 20 km (12.4 mi.)

system or other alarm

annunciator

splice enclosure

end module

splice enclosure

Page 8 FP400 Product Guide

There are two methods of controlling the processors inputs and outputs (I/O) Local control mode

and Remote control mode. In Local control mode, the FP400 operates as a standalone sensor

which communicates alarm and supervision conditions via 6 onboard relays. Alternatively, in

Remote control mode, the FP400 communicates with a security management system (SMS) via

the Silver Network Manager. The SMS uses the outputs as control points, and the inputs to report

the status of auxiliary security equipment.

Silver Network based processors can use Ethernet, EIA-422 copper wire, multi-mode or single-

mode fiber optic cable for alarm data communications. A PC-based SMS, such as Senstar’s Alarm

Integration Module, StarNet 2, or Symphony, can serve as the primary operator interface for an

FP400 system. The FP400 can also communicate with a third party SMS via the Network Manager

Interface. The security management system monitors the sensor, and can report alarms to an

operator on a graphic site-map. The FP400 sensor’s user interface is the Windows-based

Universal Configuration Module (UCM) software, which is used to setup and calibrate the system.

The UCM enables sensor calibration, detection parameter adjustments, system configuration

settings, and real time signal monitoring and recording.

System details

• fiber optic, fence-mounted outdoor perimeter intrusion detection system

• uses standard outdoor rated telecommunication grade single-mode fiber optic cable

• 4 independent sensor alarm zones, each with up to 300 m (984 ft.) of sensor cable

• up to 20 km (12.4 miles) of non-detecting lead-in cable to each sensor zone

• processor supervision of lead-in cable and detecting cable

• 2 dedicated sensor fibers required for each detection zone

• additional dark fibers available for other perimeter applications

• single pass coverage for chain-link and welded mesh fences up to 3 m (10 ft.) high

• dual pass coverage for higher fences

• no power required for outdoor sensing components (excluding processor)

• sensor cable unaffected by lightning, EMI, or electrical transients

• compact, outdoor rated splice enclosures for start modules, end modules and fiber drop points

• panel-mount processor (outdoor mounting requires a customer supplied weatherproof field

distribution box)

• can be mounted on any stable flat surface (vertical or horizontal)

• rack-mounted on a custom EIA-19 in. equipment rack shelf (p/n F4KT0500)

• DIN rail mounted (requires DIN rail mounting kit p/n F4KT0600)

• post-mounted outdoors on, or separate from, the protected fence

Note The length of each FP400 sensor zone is based on the length of the

detecting sensor cable, not the physical length of the fence.

FP400 components

FP400 Product Guide Page 9

FP400 components

FP400 Processor

The FP400 processor operates on 12 to 48 VDC input power, or can be powered by PoE, and

consumes 2 W (nominal).

Relay outputs

The FP400 processor has 6 user-configurable Form C relay outputs rated for 30 V @ 1 A max.

When the processor is set to Local control mode, the relays are used to signal alarm and

supervision conditions. For network based processors (set to Remote control mode) alarm data is

carried over the network cables and the six relays are available as output control points from the

security management system.

Auxiliary inputs

The processor includes 2 voltage sensing self-test/auxiliary device inputs. In Local control mode

the inputs are used to activate electronic self-tests. In Remote control mode the inputs are used to

report the status of 1 or 2 auxiliary security devices to the host SMS.

Figure 2 FP400 processor connections

USB port for UCM

2 voltage sensing auxiliary device/self-test inputs 6 Form C relay outputs

DC input

front

rear

or PoE

option card mounting

Zone 1

receive Zone 4

receive

Zone 2

receive Zone 3

receive Zone 1 Zone 4Zone 2 Zone 3

transmit transmit transmit transmit

setup and configuration system activity LEDs

panel

panel

FP400 components

Page 10 FP400 Product Guide

LED indicators

The processor includes 10 LED indicators to visually display its current status. Figure 3 shows the

front and rear panel LEDs and Table 1 provides the display state details.

Network communications

The FP400 processor includes an Ethernet port for network communications and power (PoE).

Alternatively, a network interface card (NIC) can be plugged into the processor to enable Silver

Network communications via EIA-422 copper wire, or fiber optic cable. Network communications

are managed by the Silver Network Manager (NM) and communication to a third-party SMS can

be made via the Network Manager Interface.

Zone kit

The zone kit (p/n F4KT0200) includes a start module, an end module, 10 splice sleeves, and

labels for the SC/APC connections to the processor. For each sensor zone, 2 SC/APC connectors

with 1 m (3.3 ft.) fiber leads are harvested from the start module. The 2 connectors are spliced to 2

fibers in the lead-in cable for the connection between the processor and the lead-in cable. The

SC/APC connectors are labeled to ensure they are connected to the appropriate TX and RX ports

on the processor. The non-detecting lead-in cable runs between the processor and the start

module located at the beginning of the sensor zone. At the start point of the zone, the two fibers in

the lead-in cable are spliced to one side of the start module. The two fibers on the other side of the

start module are spliced to two fibers in the detecting section of sensor cable. The detection zone

Figure 3 FP400 LED indicators

LED Name LED OFF LED Green LED Red LED Amber

PWR (2) power OFF power ON power fault N/A

LASER Laser OFF Laser ON Laser fault N/A

SD no SD card card in (steady) / writing (blinks) SD card fault N/A

COM A no activity side A A side receive (blinks) A side fault N/A

COM B no activity side B B side receive (blinks) B side fault N/A

ZONE 1 disabled enabled and secure zone alarm supervision

ZONE 2 disabled enabled and secure zone alarm supervision

ZONE 3 disabled enabled and secure zone alarm supervision

ZONE 4 disabled enabled and secure zone alarm supervision

Table 1 LED indications

Note Network communications can use either the onboard Ethernet, or an

optional NIC, not both.

Note Each sensor zone requires one, or two, splice enclosures. Splice

enclosures are ordered separately.

front panel LEDs rear panel LEDs

FP400 components

FP400 Product Guide Page 11

begins at this point, and runs for up to 300 m (984 ft.) of sensor cable. At the end of the detection

zone the two sensor fibers are spliced to the end module which terminates the zone. The start

module and end module are protected inside weatherproof splice enclosures. Depending on the

sensor zone configuration, a start module or a second end module can be co-located in the end

module’s splice enclosure. Figure 4 shows the zone connection kit contents.

Start Module

The detection for each sensor zone begins at the start module. One side of the start module is

connected to the TX and RX ports of the processor through the lead-in cable. The other side is

connected to the two sensing fibers in the detecting cable. The start module includes 4 SC/APC

connectors, which are cut off with 1 m fiber leads. Two of the connectors are labeled and used for

the connection between the lead-in cable and the processor. The start module is fence-mounted

inside a weatherproof enclosure at the beginning of the detection zone.

Note The 2 leads on each side of the start module are interchangeable.

Connect the 2 leads on one side of the start module to the lead-in

cable and connect the 2 leads on the other side of the start module to

the detecting cable.

Figure 4 FP400 zone kit

1.5 m (5 ft.) SC/APC leads

start module

end module

labels for SC/APC connectors

10 splice sleeves

FP400 components

Page 12 FP400 Product Guide

End Module

The detection for each sensor zone is terminated by the end module. The two sensor fibers in the

detecting cable are spliced to two end module fibers. The end module includes 2 SC/APC

connectors, which are cut off with 1 m fiber leads. The end module is fence-mounted inside a

weatherproof enclosure at the end of the detection zone.

Weatherproof splice enclosure

The outdoor-rated weatherproof splice enclosure (p/n F4KT0100) protects the optical components

and field splices for the FP400 sensor system. The enclosure includes two cable ports and sealing

grommets sized for the sensor cable. The splice enclosure can contain up to 12 splices including a

start module, an end module, a start module and end module, or two end modules. It can also be

used to protect the lead-in cable splices at the processor location.

Sensor cable/non-detecting lead-in cable

The sensor cable is telecommunication grade outdoor-rated central loose tube single-mode fiber

optic cable with a polyethylene outer jacket and a waterblock system. The non-armored loose tube

cable is comprised of a central 12-fiber buffer tube and 2 fiberglass reinforced plastic (FRP)

strength members. The sensor cable is also used as the non-detecting lead-in cable for the

connection between the processor and the start module. Sensor detection begins at the start

module of each zone. Figure 6 illustrates the sensor cable with a fiber designation table indicating

the recommended use of the individual fibers. Sensor cable can be ordered in lengths of 250 m

(820 ft. p/n F4SP0100) and 1000 m (3,280 ft. p/n F4SP0101).

Figure 5 FP400 outdoor splice components

Note Contact Senstar Customer Service if the installation requires additional

dark fibers. Higher capacity sensor cable is available from the factory.

However, the higher capacity cable requires larger splice enclosures to

accommodate the larger cable.

splice enclosure

with start module closed splice

enclosure

start module

end module

FP400 components

FP400 Product Guide Page 13

Cable ties

FiberPatrol sensor cable is attached to the fence with durable plastic UV-resistant cable ties

(p/n GH1210-1000). The cable ties come in bags of 1000 pieces and one bag can attach

approximately 300 m of sensor cable to a fence. The recommended spacing is 30 cm (1 ft.) and

the cable ties are hand tightened to hold the sensor cable snuggly against the fence. Mechanical

tightening devices cannot be used as over-tightening the cable ties will have an adverse effect on

the sensor’s detection.

Figure 6 Sensor cable details

Figure 7 Sensor cable cross section

12-fiber buffer tube with water blocking gel

dual FRP strength members

polyethylene

TX 1 RX 1

TX 2

RX 2

TX 3

RX 3

TX 4

RX 4

4 dark fibers

fiber usage recommendations

TX1

RX 1

TX 2

RX 2

TX 3

RX 3

TX 4

RX 4

dark

dark

dark

dark

1

2

3

4

5

6

7

8

9

10

11

12

blue

orange

green

brown

gray

white

red

black

yellow

purple

rose

aqua

fiber # color designation

outer jacket

cross section

color coded individual fiber

gel-filled 12 fiber

dual FRP

polyethylene outer jacket

(blue = TX1)

strength members

buffer tube

250 m reel

1,000 m reel

FP400 components

Page 14 FP400 Product Guide

FP400 Product Guide Page 15

2 Site planning

FP400 configurations

The recommended method for installing the sensor cable is to use the minimum number of splices

possible for each sensor zone. This includes 2 splices for the lead-in cable connections to the

processor, 4 splices for the start module, and 2 splices for the end module. Midspan access

techniques are recommended for non-spliced (expressed) fibers passing through an enclosure.

Figure 8 illustrates an FP400 sensor zone with the minimum 8 fusion splices.

The FP400 detection zone runs between the start module and end module, and can include up to

300 m of sensor cable. For planning purposes approximately 15% extra cable should be budgeted

for splice point service loops and installation variations. The 15% overage allows one sensor zone

to protect approximately 255 m (840 ft.) of perimeter fence. For longer perimeters, the 4 zones can

be installed back to back thereby extending coverage to a maximum length of 1.2 km (0.75 mi.) of

sensor cable. Four contiguous zones of sensor cable can cover approximately 1 km (0.62 mi.) of

fence. The coverage length can be extended indefinitely by networking multiple FP400 sensors

back to back.

Some FP400 zone configurations require only 2 dedicated fibers. For those configurations there is

no need to express the 10 unused fibers through the enclosure. In this situation, it is acceptable to

cut the sensor cable and splice only the required fibers. In the example drawings in Figure 9, a and

b require expressed fibers but c does not. In the example drawings in Figure 11, a requires

expressed fibers but b and c do not.

Figure 8 Single zone linear configuration (minimum splices)

Note Expressing fibers through splice enclosures reduces the number of

fusion splices required in the field, and helps to keep the signal loss to a

minimum.

FP400 processor

up to 20 km (12.4 mi.) of lead-in cable max. detecting cable = 300 m (984 ft.)

fusion splice

start module

end module

splice enclosure

detection

start point detection

end point

non-detecting Zone 1

FP400 configurations

Page 16 FP400 Product Guide

Linear zone configuration

The linear zone configuration is used when the start point and end point of the detection zone are

separated by some distance. In this case, the processor module is connected to the start module

by lead-in cable at the beginning of the sensor zone. The sensor zone runs for up to 300 m to an

end module. Figure 9 illustrates three block diagrams of FP400 linear configurations, and Figure

10 shows a back-to-back 8 zone configuration.

Closed loop configuration

The loop configuration provides a closed perimeter. The processor is located within 20 km of the

perimeter fence with two splice enclosures housing the start and end points of the detecting

sensor cable. Non-detecting lead-in cable carries the laser light signals between the processor

and the start module at the beginning of the detection zone. The sensor zone runs for up to 300 m

of detecting cable to the end module. Figure 11 illustrates three block diagrams of FP400 closed

loop configurations.

The closed loop configuration can be used as a single zone with up to 300 m of detecting cable

(see Figure 13). It can also be used with two, three, or four zones providing up to 1.2 km of

detecting sensor cable per processor. With careful planning, the start module and end module

splice enclosures can be located on either side of a gate, with the gate protected by another

sensor technology (e.g., a wireless gate sensor, or a microwave).

Figure 9 Single processor linear zone configurations

Figure 10 Two processor linear zone configuration (8 zones)

SSESE ESE

SESE ESE

S

ES

SE

SE

SE

E = end modules

S = start module

FP400

processor

FP400

processor

FP400

processor

a

b

c

SE SEESESESSE SESE

E = end modules

S = start module

FP400

processor FP400

processor

Z1 Z2 Z3 Z4 Z5 Z6 Z7 Z8

FP400 configurations

FP400 Product Guide Page 17

Figure 11 Closed loop configurations

S

E

S

S

E

EE

SE

SE

S

E

S

E

S

E

S

E

SE

SE

E = end module

S = start module

S

processor

processor

Z1

Z2Z3

Z4

Z1

Z2

Z3

Z4 Z2

Z3

Z4

Z1

FP400

FP400

processor

FP400

a

b

c

FP400 configurations

Page 18 FP400 Product Guide

FP400 fiber drop points

In the standard configurations, fiber drop points to access dark fibers for other perimeter

applications are possible at end module enclosures which include a single end module. The

enclosure’s second cable port can be used to connect an auxiliary device such as a CCTV

camera. The dark fibers that will be accessed should be expressed through the start module

enclosure. Figure 14 illustrates this concept. For sites which require additional dark fibers or

additional drop locations, Senstar can supply multi-tube fiber cable. To use these larger diameter

cables also requires the use of larger splice enclosures and some additional components. Contact

Senstar for information about using multi-tube fiber cable with the FP400 system.

Figure 12 Two processor closed loop configuration (8 zones)

Figure 13 Single zone closed loop configuration (minimum splices)

S

E

S

S

E

E

SE

SE

E = end modules

S = start module

S

processor

Z1

Z2Z7

Z4

Z8

Z6 Z3

Z5

FP400 processor

FP400

SE

E

SE

FP400 processor

max. lead-in cable = 20 km

max. detecting cable = 300 m

fusion splice

start module

end module

splice enclosure

fiber pig tails

Site survey

FP400 Product Guide Page 19

Lightning protection

Silver Network based FP400 sensors using IP-based communications sometimes include outdoor

runs of Ethernet cable. In some cases, it is desirable to add external surge protectors to the comm

link for lightning protection. The following surge protectors have been tested and approved for use

with Senstar IP-based sensors. Figure 51: illustrates the connection details.

• L-Com HGLN-CAT6-HP

• L-Com AL-CAT6HPJW (weather resistant)

• Laird ESP-100-POE

Site survey

The first step in installing a Senstar FP400 fence protection system is to conduct a detailed site

survey. The survey assesses the site conditions to determine the specific installation requirements

including the fence type, fence condition, fence length, zone layouts, sensor cable route, non-

detecting lead-in cable length, length of sensor cable required to cover the perimeter, and the

location for the processor.

Create a scale drawing of the site (e.g., CAD drawings), which indicates the locations of:

• head end equipment - FP400 processor, power supply and SMS

• fences (include type, length and condition)

• gates (include type and size)

• buildings and other structures

• roads, driveways, sidewalks, paths, parking areas

• trees, bushes, dense vegetation (near perimeter)

• non-detecting lead-in cable

• detecting sensor cable

• other existing or planned security equipment (e.g., CCTV cameras, security lighting, etc.)

Figure 14 Fiber drop point

PTZ camera

end module

start module

lead-in cable to processor

Site survey

Page 20 FP400 Product Guide

Fence condition

The fence must be properly installed, tensioned, and maintained to provide effective intrusion

detection with the FP400 sensor. The fence should be uniform in height and quality, and should be

high enough to present an effective barrier against climb-over intrusions. It is also recommended

that a climb-over barrier, such as barbed wire or concertina, be installed along the top of the fence.

The condition of the fence is critical to the efficient operation of the FP400. Breaks in the fence

structure, or slack portions of fence fabric, will inhibit the transmission of fence vibrations to the

sensor cable. Poor fence conditions can also cause metal on metal contact noise during inclement

weather that will result in nuisance alarms.

Supported fence types

• chain-link

• welded-mesh

• expanded metal

• palisade

It is possible to use the FP400 sensor to protect other fence types, as well as buildings and walls.

However, revised installation techniques are required.

Site analysis checklist

Note Fences used in conjunction with the FP400 sensor must meet industry

standards for security fences.

To prevent nuisance alarms, remove or secure any signs, loose fittings,

locks, gate hardware, nearby vegetation, and anything else that can

move and make contact with the fence.

Note Senstar recommends installing the sensor cable on a representative

section of the building or wall to test and verify that the detection

sensitivity meets the security requirements, before installing a complete

system.

Description

create a site plan

accurate CAD drawings with precise measurements

detailed description of fences (type, condition, height, fence rails, climb over

deterrent hardware, other cables, conduit, or signs attached to fence)

detailed description of gates (type, condition, location, size)

locate all obstacles on site survey

spur fences or fences abutting the perimeter fence

sidewalks, paths, roads, driveways

buildings, walls and other structures

utilities (sewers, pipes, conduits and electrical cables, etc.)

Table of contents

Other SENSTAR Accessories manuals

SENSTAR

SENSTAR FiberPatrol FP1100X Series Technical manual

SENSTAR

SENSTAR FlexZone User manual

SENSTAR

SENSTAR FPS 2-2 User manual

SENSTAR

SENSTAR FlexPS User manual

SENSTAR

SENSTAR IntelliFIBER User manual

SENSTAR

SENSTAR FiberPatrol FP1150 Series User manual

SENSTAR

SENSTAR FlexZone WGS User manual

SENSTAR

SENSTAR OmniTrax User manual

SENSTAR

SENSTAR UltraWave BR100 User manual