SENSTAR IntelliFIBER User manual

IntelliFIBER™

Perimeter Protection Fiber Optic Disturbance Sensor

Product

Guide

C6DA1102-001, Rev F

First edition

August 26, 2009

Senstar Corporation

119 John Cavanaugh Drive

Carp, Ontario

Canada K0A 1L0

Tel: +1 (613)-839-5572

Fax: +1 (613)-839-5830

Website: www.senstar.com

Email address: info@senstar.com

C6DA1102-001, Rev F First edition

August 26, 2009

Sennet and Senstar are registered trademarks, and IntelliFIBER, StarNeT 1000, Intelli-FLEX and the Senstar logo are trademarks

of Senstar Corporation. Product names and Company names used in this guide are included for identification purposes only, and

are the property of, and may be trademarks of, their respective owners.

Copyright © 2009, 2008, 2006, 2004, 2003, 2002 Senstar Corporation. All rights reserved. Printed in Canada.

The information provided in this guide has been prepared by Senstar Corporation to the best of its ability. Senstar Corporation is

not responsible for any damage or accidents that may occur due to errors or omissions in this guide. Senstar Corporation is not

liable for any damages, or incidental consequences, arising from the use of, or the inability to use, the software and equipment

described in this guide. Senstar Corporation is not responsible for any damage or accidents that may occur due to information

about items of equipment or components manufactured by other companies. Features and specifications are subject to change

without notice. Any changes or modifications to the software or equipment that are not expressly approved by Senstar

Corporation void the manufacturer’s warranty, and could void the user’s authority to operate the equipment.

Senstar’s Quality Management System is IS0 9001:2000 registered.

Approvals

Canada: This Class B digital apparatus meets all requirements of the Canadian Interference -Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement sur le matériel brouilleur du Canada.

USA: This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may

not cause harmful interference, and (2) this device must accept any interference received, including any interference that may

cause undesired operation.

The use of shielded cables is required for compliance.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation.This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which

can be determined by turning off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

- Reorient or relocate the receiving antenna.

- Increase the separation distance between the equipment and the receiver.

- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Europe: This device conforms to the protection requirement of council directives 89/336/EEC on the approximation of the laws of

member states relating to Electromagnetic compatibility, amended by directive 93/68/EEC.

The use of shielded cables is required for compliance. The use of a CE marked audio system is recommended.

Senstar’s intellectual property is protected by the following patents:

USA: 6,934,426.

UK: GB2396694

Patents pending in other countries.

About this guide

This is the overall product guide for the IntelliFIBER fiber optic disturbance

sensor using either the relay or multiplex version processor.

This guide includes information to assist you in selecting, installing, calibrating

and maintaining the components for your IntelliFIBER system.

Chapter 1 covers laser class type and precautions when using fiber; Chapter 2

describes the principles of operation. Chapter 3 provides a visual breakdown of

the components. Chapter 4 deals with site planning guidelines, fence applications

and layout guidelines. Chapter 5 provides information for equipment setup and

the installation instructions for different fence types. Chapter 6 describes the

Configuration Module and how it functions with IntelliFIBER system. Chapter 7

covers system calibration and zone profile evaluation. Appendix A covers

troubleshooting and maintenance. Appendix B is a spare parts list. Appendix C is

a component specification list. Appendix D covers multiplex processor

components. Appendix E defines the optical power budget and loss limits. The

Glossary covers IntelliFIBER terms. The Index provides a quick reference to find

specific information quickly in the Guide.

Figures

The figures contained in this document are for illustration purposes only, they

may differ from the actual equipment.

Abbreviations

The following abbreviations are used throughout this guide:

• AC - alternating current

• DC - direct current

• I/O - input/output

• LCD - liquid crystal display

• LED - light emitting diode

• NC - normally closed

• NO - normally open

• UPS - uninterruptible power supply

Related reference documents

Here is a list of the documents that you can refer to for more information:

Document Number Document Name

C6DA0302-001 Intelli-FLEX DC/DC Relay Version

product guide

C6DA0402-001 Intelli-FLEX Multiplex Version product

guide

M0DA0302-001 Sennet Product Guide

C6DA0118-001 Intelli-FLEX & IntelliFIBER Site

Survey (Commercial Version)

IntelliFIBERproduct guide • • • toc-1

Table of contents

1Beforeyoustart

Precautions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Laser Safety Classes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Laser light DANGER - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1

Before you install and use the IntelliFIBER system - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Fiber optic cable handling - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Fiber optic cable installation safety rules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Care of fiber optic connectors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Cleaning connectors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-2

Connector cover- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-3

2 Principles of operation

How IntelliFIBER works - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

System technology- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1

IntelliFIBER detector daughter card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-2

Adaptive signal processing- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

Intrusion alarms- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

Cut detection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-3

Climb detection- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-4

Nuisance/False Alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

False alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

Nuisance alarms - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

System supervision - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-5

Power fail - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

Low DC voltage shutdown- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

Tamper state - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-6

3 System components

Components Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-1

Standard components - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3-2

Table of contents

Other SENSTAR Accessories manuals

SENSTAR

SENSTAR FPS 2-2 User manual

SENSTAR

SENSTAR UltraWave BR100 User manual

SENSTAR

SENSTAR FiberPatrol FP400 User manual

SENSTAR

SENSTAR FiberPatrol FP1100X Series Technical manual

SENSTAR

SENSTAR FlexZone User manual

SENSTAR

SENSTAR FlexPS User manual

SENSTAR

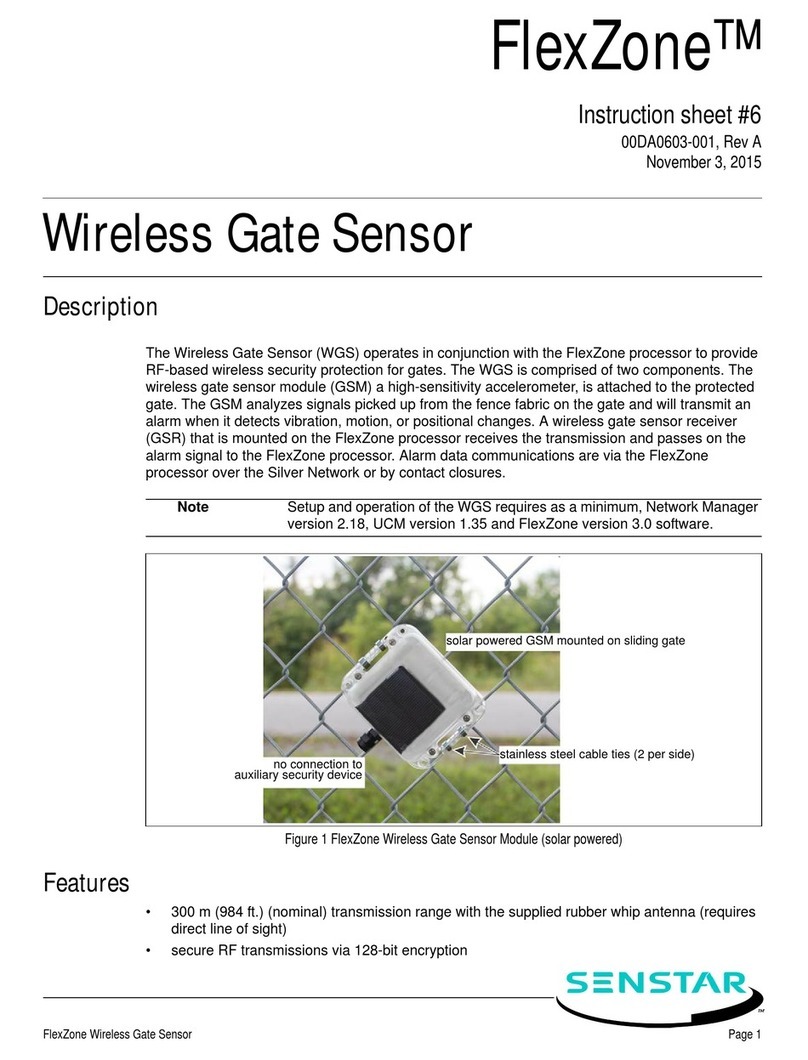

SENSTAR FlexZone WGS User manual

SENSTAR

SENSTAR OmniTrax User manual

SENSTAR

SENSTAR FiberPatrol FP1150 Series User manual