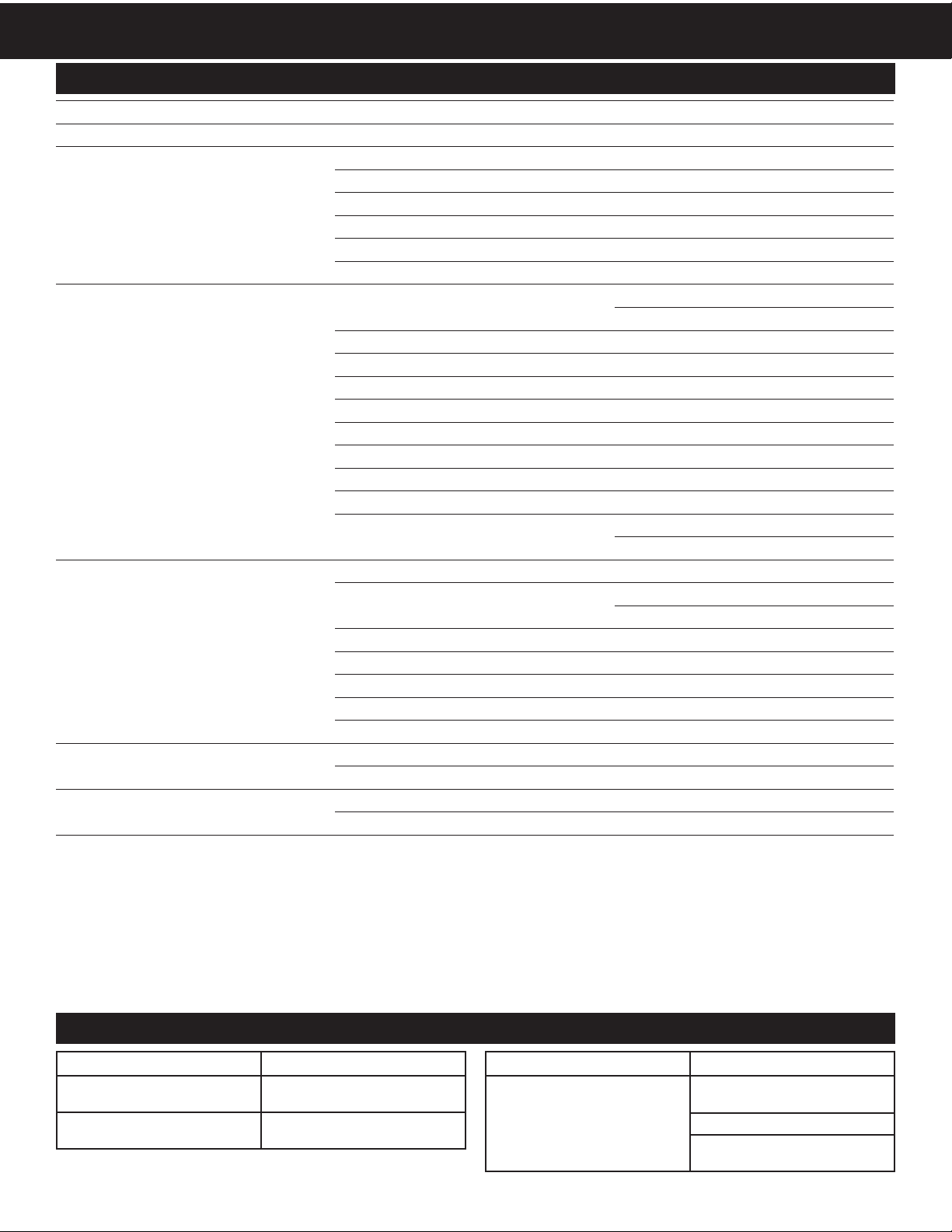

SPECIFICATIONS

TROUBLESHOOTING

Symptom Solution

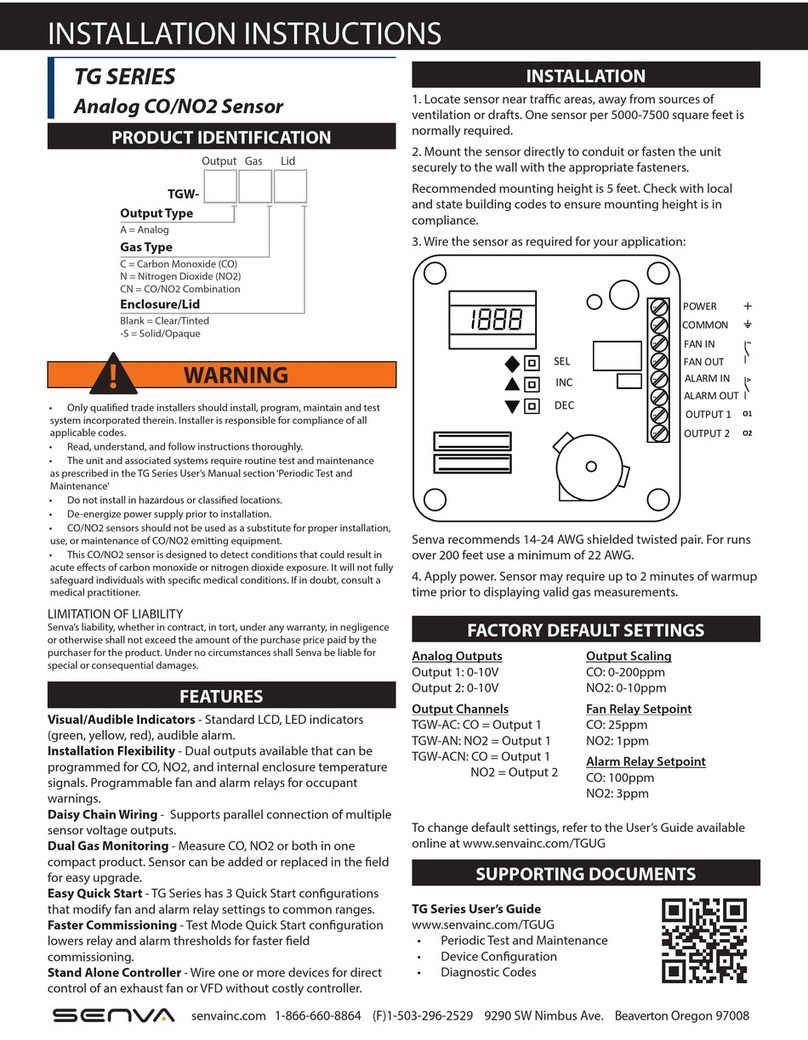

No output Check wiring. Ensure power supply

meets requirements.

Reading error Verify unit is located away from

hot/cold sources.

Power supply 12-30vdc/24vac (1), 100mA max.

Outputs Voltage Only 3-wire 0-5v/0-10v (2) (jumper)

CO2

Type Non-dispersive Infrared (NDIR)

Accuracy +/-40ppm, +/-3% of reading

Response time 60 seconds to 90% reading

Update rate 3 seconds

Output scaling 0-2000ppm (default), 0-5000ppm (option)

Programmable set-point output Solid-state, 1A@30VAC/DC, N.O.

Relative Humidity

Accuracy 2% models, +/-2% over 10 to 90% range

3% models, +/-3% over 20 to 80% range

Resolution 0.05%RH

Hysteresis +/-1%RH

Non-linearity Factory linearized <1%RH

Temperature coecient Fully compensated by on-board sensor

Response time (3) 30s

Output update rate 2s

Operating range 0 to 100%RH (non-condensing)

Long term drift <0.5%RH per year

Operating conditions (4) -20 to 60oC @ RH >90%

-20 to 80oC @ RH = 50%

Temperature (Transmitter)

Scaling 50 to 95oF (10-35oC)

Accuracy, (-20 to 70oC range) 2% models, <+/-1oC; 0.5oC typ@25oC

3% models, <+/-2oC; 0.5oC typ@25oC

Resolution 0.01oC

Repeatability +/-0.1oC

Response time (2) 30s

Output update rate 2s

Operating range -40 to 120oC (sensor only)

Operating Environment Temperature 32 to 122oF (0-50oC)

Humidity 0-95%RH, non-condensing

Enclosure Material ABS Plastic

Dimensions 4.85”h x 3.25”w x 1.19”d

Automatic CO2 Calibration feature:

When CAL mode is set to ON, the sensor will automatically track low ambient CO2 levels and gradually make adjustments to

compensate for sensor drift due to long-term aging of the IR light source. In applications where CO2 levels are continuously

elevated, or spaces are occupied day and night, it is recommended to leave the automatic calibration OFF. If the sensor module is

replaced in the eld, the automatic adjustments can be reset by selecting the RST (reset) option in the CAL menu.

(1) One side of transformer secondary is connected to signal common. Dedicated transformer is recommended.

(2) 15-30vdc/24vac power supply voltage required for 10 volt output.

(3) Time for reaching 63% of reading at 25oC and 1 m/s airow.

(4) Long term exposures to conditions outside normal range or high humidity may temprarily oset the RH reading (+3%RH after 60 hours.)

Symptom Solution

Reading error

Verify control panel software is

congured for correctly.

Verify accuracy of test instrument.

Install insulation behind sensor to

prevent air ow from inside wall.

Revised 7/3/2014 Document #152-0110-0A