senva TG Series User manual

INSTALLATION INSTRUCTIONS

senvainc.com 1-866-660-8864 (F)1-503-296-2529 9290 SW Nimbus Ave. Beaverton Oregon 97008

TG SERIES

Analog CO/NO2 Sensor

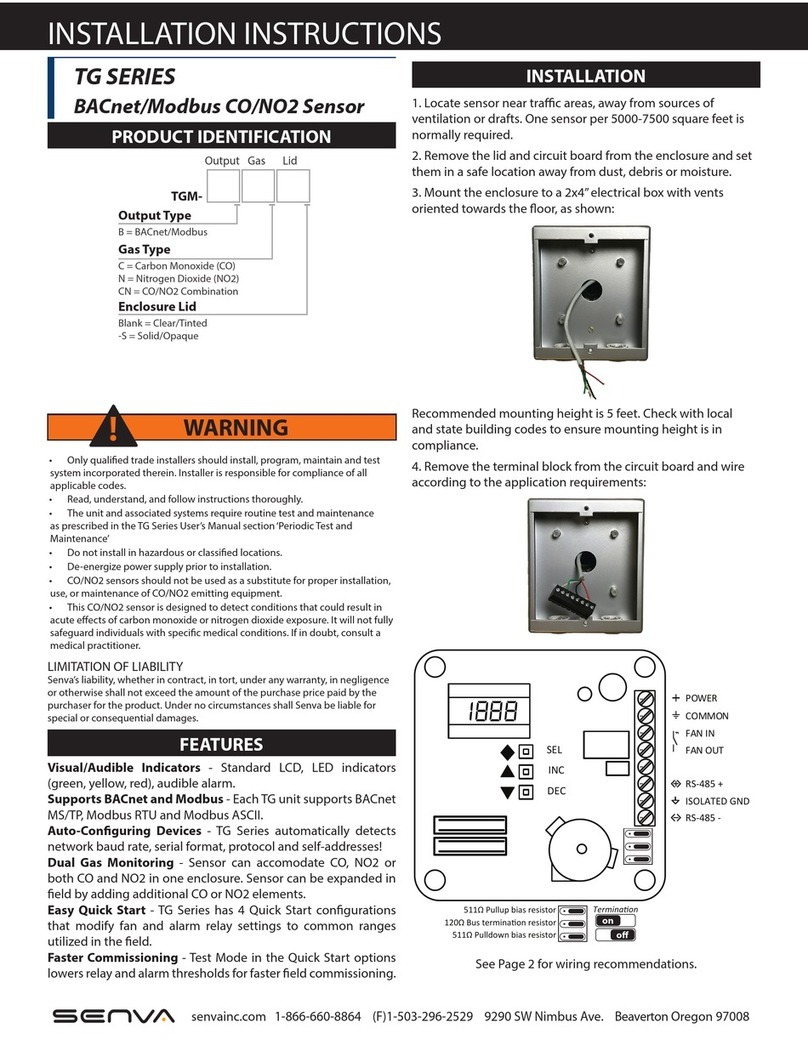

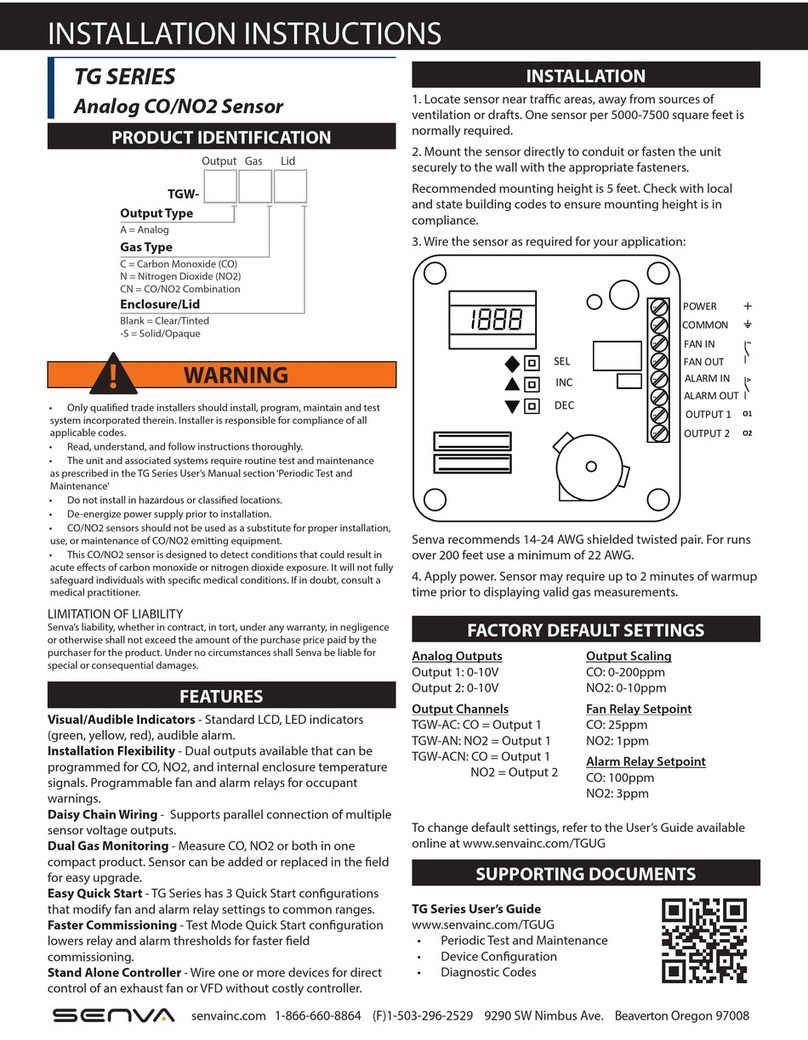

INSTALLATION

jMount sensor on or near duct and secure using holes on

enclosure.

kInstall and plumb pickup tubes as shown:

LO W HI GH

A I R FLO W

Connect tubes to

hose barb ttings

on sensor.

Recommended pickup tube length from duct to TG enclosure

for a 90% change in 15 minutes is as follows:

Given Tube Length Recommended Minimum Flow Velocity for

15 minute 90% change

inches m/s ft/min mph

6 1.3 261 3.0

12 1.4 270 3.1

18 1.4 279 3.2

24 1.6 317 3.6

30 1.7 335 3.8

36 1.7 340 3.9

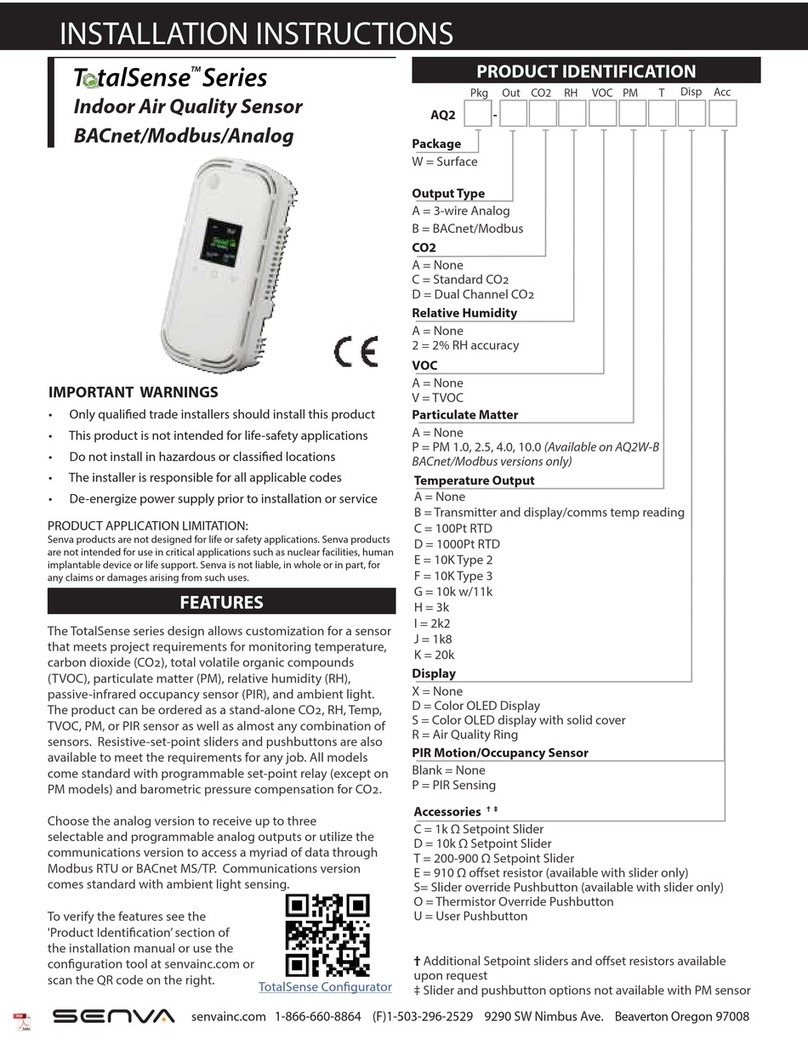

lWire the sensor as required for your application:

SEL

INC

DEC

POWER

COMMON

FAN IN

FAN OUT

ALARM IN

ALARM OUT

OUTPUT 1

OUTPUT 2

F A

O1

O2

Recommended cable type is 14-24 AWG shielded twisted pair.

For runs over 200 feet use a minimum of 22 AWG.

Analog Outputs

Output 1: 0-10V

Output 2: 0-10V

Output Channels

TGH-AC: CO = Output 1

TGH-AN: NO2 = Output 1

TGH-ACN: CO = Output 1

NO2 = Output 2

To change default settings, refer to the User’s Guide available

online at www.senvainc.com/TGUG

DEFAULT SETTINGS

FEATURES

Visual/Audible Indicators - Standard LCD, LED indicators

(green, yellow, red), audible alarm.

Installation Flexibility - Dual outputs available that can

be programmed for CO, NO2, and temperature signals.

Programmable fan and alarm relays for occupant warnings.

Daisy Chain Wiring - TG Series supports parallel connection of

multiple sensor voltage outputs.

Dual Gas Monitoring - Sensor can accomodate CO, NO2 or

both CO and NO2 in one enclosure. Sensor can be expanded in

eld by adding additional CO or NO2 elements.

Easy Quick Start - TG Series has 4 Quick Start congurations

that modify fan and alarm relay settings to common ranges

utilized in the eld.

Faster Commissioning - Test Mode in the Quick Start

options lowers relay and alarm thresholds for faster eld

commissioning.

Stand Alone Controller - Wire one or more devices for direct

control of an exhaust fan or VFD without costly controller.

PRODUCT IDENTIFICATION

TGH-

Output Type

A = Analog

Gas Type

C = Carbon Monoxide (CO)

N = Nitrogen Dioxide (NO2)

CN = CO/NO2 Combination

Enclosure Lid

Blank = Clear/Tinted

-S = Solid/Opaque

Output Gas Lid

Output Scaling

CO: 0-200ppm

NO2: 0-10ppm

Fan Relay Setpoint

CO: 25ppm

NO2: 1ppm

Alarm Relay Setpoint

CO: 100ppm

NO2: 3ppm

SUPPORTING DOCUMENTS

TG Series User’s Guide

www.senvainc.com/TGUG

• Periodic Test and Maintenance

• Device Conguration

• Diagnostic Codes

LIMITATION OF LIABILITY

Senva’s liability, whether in contract, in tort, under any warranty, in negligence

or otherwise shall not exceed the amount of the purchase price paid by the

purchaser for the product. Under no circumstances shall Senva be liable for

special or consequential damages.

• Only qualied trade installers should install, program, maintain and test

system incorporated therein. Installer is responsible for compliance of all

applicable codes.

• Read, understand, and follow instructions thoroughly.

• The unit and associated systems require routine test and maintenance

as prescribed in the TG Series User’s Manual section ‘Periodic Test and

Maintenance’

• Do not install in hazardous or classied locations.

• De-energize power supply prior to installation.

• CO/NO2 sensors should not be used as a substitute for proper installation,

use, or maintenance of CO/NO2 emitting equipment.

• This CO/NO2 sensor is designed to detect conditions that could result in

acute eects of carbon monoxide or nitrogen dioxide exposure. It will not fully

safeguard individuals with specic medical conditions. If in doubt, consult a

medical practitioner.

DANGER

WARNING

!

ONE SENSOR PER CONTROL LOOP

OPERATION

The following section details daisy chain wiring support, fan/

alarm relay functions, LCD function, LED function, and the

sensor element lifetime clock.

Daisy Chain Wiring

Both voltage outputs are internally equipped to permit parallel

connection of multiple sensor voltage outputs. Resulting

voltage will be the greater of all connected sensors.

Fan/Alarm Relay

Both the fan and alarm relays are tied to the function of the

LED indicators on each TG Series sensor. If a device has both the

CO and NO2 elements populated on the board, then the relay

functions will activate if either of the gases reach their fan or

alarm threshold.

Status LED Fan Relay Alarm Relay Buzzer

O - Closed Closed Silent

Below Fan Setpoint Green Open Open Silent

Above Fan Setpoint Yellow Closed Open Silent

Above Alarm Setpoint Red Closed Closed Silent

Above Alarm Setpoint

for 30 minutes Red Closed Closed On

The duration of the fan/alarm relays and alarm buzzer

operation are as follows. These values can also be modied

from their default settings via the TG Series User’s Guide(1).

Relay Activation Timing

Fan/Alarm Relays Value

Minimum ON time 60 seconds

Minimum OFF time 60 seconds

Maximum OFF time 0 (inactive)

Audible Alarm Activation Timing

Buzzer Value

Delay 30 minutes

Minimum ON time 0 seconds

Minimum OFF time 0 seconds

LCD Function

The LCD is factory defaulted to toggle between readouts

for each gas type populated on the board. Toggling can be

modied using the TG Series User’s Guide(1).

LED Function

The LED indicators function in sync with the fan and alarm relay

thresholds. LEDs will change state if either of the gases reach

their fan or alarm setpoint.

Green Normal readings below the fan setpoint

Yellow Warning level above the fan setpoint and below the

alarm setpoint

Red Alarm level above the alarm setpoint

Sensor Element Lifetime Clock

With 30 days remaining on the element lifecycle, the green

LED will blink once every 10 seconds. This timer can be

viewed using the TG Series User’s Guide(1). Contact factory for

replacement elements.

(1) TG Series User’s Guide available at www.senvainc.com/TGUG

Diagram shows a standard connection between a single TG

sensor, alarm and controller or variable frequency drive:

SENVA TG SENSOR

POWER

COMMON

FAN RELAY

ALARM RELAY

OUTP UT 1

OUTP UT 2

ALARM

DDC Analog Inputs

or

Variable Frequency

Drive

DAISY CHAIN OF OUTPUTS

Diagram shows connection between multiple TG sensors

wired in a daisy chain to a controller or variable frequency

drive using analog outputs. See below for requirements and

recommendations for output and scaling settings.

There is no limit to the number of sensors that can be daisy

chained, but wire resistance on long runs should be taken into

account.

SENVA TG SENSOR

POWER

COMMON

FAN RELAY

ALARM RELAY

OUTP UT 1

OUTP UT 2

SENVA TG SENSOR

POWER

COMMON

FAN RELAY

ALARM RELAY

OUTP UT 1

OUTP UT 2

DDC Analog Inputs

or

Variable Frequency

Drive

Additional

TG Sensors

Analog Outputs

The analog outputs (0-5/10V) must be uniform on each TG

sensor in the daisy chain. The 4-20mA is not compatible with

daisy chain wiring.

Output Scaling

Senva recommends that each TG sensor’s output scale are

uniform between all devices in the daisy chain for all gas

sensing elements that are populated on the board.

DAISY CHAIN OF FAN RELAYS

Diagram shows connection between one or multiple TG

sensors wired to an exhaust fan using the fan setpoint relay(s).

This function can be performed by a single TG sensor or a

sequence of multiple TG sensors wired in parallel.

If wiring in a daisy chain, ensure that the fan relay setpoints are

uniform for each sensor. The fan relays will activate if one or

more of the sensors reach warning thresholds.

Device also features a maximum o time for the fan relay. See

TG Series User’s Guide to enable this feature.

SENVA TG SENSOR

POWER

COMMON

FAN RELAY

ALARM RELAY

OUTPUT 1

OUTPUT 2

SENVA TG SENSOR

POWER

COMMON

FAN RELAY

ALARM RELAY

OUTPUT 1

OUTPUT 2

Coil

Coil

Main Fan Power

Starter

Relays

Exhaust Fans

Additional

TG Sensors

DAISY CHAIN OF ALARM RELAYS

Diagram shows connection between one or multiple TG

sensors wired to an alarm using the alarm relay(s).

If wiring in a daisy chain, ensure alarm relay setpoints are

uniform for each sensor. Alarm relays will activate if one or

more of the sensors reach alarm thresholds.

ALARM

SENVA TG SENSOR

POWER

COMMON

FAN RELAY

ALARM RELAY

OUTPUT 1

OUTPUT 2

SENVA TG SENSOR

POWER

COMMON

FAN RELAY

ALARM RELAY

OUTPUT 1

OUTPUT 2

Additional

TG Sensors

This section will focus only on the following items:

• ‘Quick Start’ options for changing fan/alarm settings

• Altering output type for Outputs 1 and 2.

Device will timeout back to normal operation after 10 seconds

of no activity, so it is recommended to fully read through

this section before proceeding into the LCD menu. (This is an

abbreviated section of the TG Series User’s Guide. Do not attempt

to change any other parameters without utilizing the full TG Series

User’s Guide found online at www.senvainc.com/TGUG)

SEL

INC

DEC

POWER

COMMON

FAN IN

FAN OUT

ALARM IN

ALARM OUT

OUTPUT 1

OUTPUT 2

F A

O1

O2

Quick Start

Quick Start allows the user to quickly select from four

precongured parameters for the fan and alarm settings for CO

and NO2. This includes a ‘test mode’ for commissioning.

Press the select button uuntil QStArt, scrolls across the LCD.

Press the select button uagain and LCD will read A. This

corresponds to the default fan/alarm settings. Choose from

the table below which quick start parameter best ts your

application and scroll to the setting using pand q. Press the

select button uwith your desired Quick Start displayed and

proceed to‘Output Type options’ section below.

LCD CO Fan CO Alarm NO2 Fan NO2 Alarm Buzzer Delay

A25ppm 100ppm 1ppm 3ppm 30 minutes

815ppm 50ppm 0.7ppm 2ppm 30 minutes

C35ppm 100ppm 1ppm 5ppm 30 minutes

tSt 5ppm 10ppm 0.5ppm 1ppm 2 minutes

ESC Exits back to main User Menu screen

Output Type

After selecting the Quick Start parameter, device will display

10U which corresponds to the default 0-10V output type for

Output 1 and Output 2. Choose from the table below which

output type parameter best ts your application and scroll to

the setting using pand q. Press the select button uwith your

desired output type displayed.

LCD Output Type (Output 1 & Output 2)

10U 0-10V Output

1_5 1-5V Output

420 4-20mA Output

0_5 0-5V Output

After selecting the output type, LCD menu will bounce back to

your selected Quick Start selection. Use the pand qto scroll

to ESC option and press the select button u. Display will now

show QStArt. Again, use the pand qto scroll to ESC option

and press the select button u,or allow the device to timeout

(approximately 30 seconds), to return to normal operation.

RELAY/OUTPUT TYPE MODIFICATIONS

LCD Menu Buttons

u‘Select’ button

p'Increase/Up' button

q‘Decrease/Down’ button

SPECIFICATIONS

Power supply 15-30VDC/24VAC (1), 4w max, 120mA max.

Analog Outputs

2 programmable outputs 0-10V (default), 0-5V, 1-5V and 4-20mA (menu selectable)

CO output scaling 0-200ppm (default), ranges up to 1000ppm (menu selectable)

NO2 output scaling 0-10ppm (default), ranges up to 20ppm (menu selectable)

Temperature output scaling -20 to 85oC

Fan Relay

Fan relay characteristics N.C. 10A@125VAC, 5A@30VDC

CO fan relay setpoint 25ppm (default), 0-1000ppm (menu selectable)

NO2 fan relay setpoint 1ppm (default), 0-20ppm (menu selectable)

Alarm Relay

Alarm relay characteristics N.C. 1A@30VDC

CO alarm relay setpoint 100ppm (default), 0-1000ppm (menu selectable)

NO2 alarm relay setpoint 3ppm (default), 0-20ppm (menu selectable)

Display 3-1/2 digit LCD Indicates CO ppm, NO2 ppm, Temp (menu selectable)

LED’s Green, Yellow, Red Green = Normal, Yellow = Relay, Red = Alarm

Audible exposure alarm 85dB Piezo transducer 30 minutes above alarm setpoint per UL2034 (menu selectable)

CO Sensor Performance

Type Electrochemical

Accuracy +/-10% of reading @ 20oC

Reproducibility +/-2% of reading

Response time <15 seconds(2)

Certications UL2034 recognized

Long term stability <+/-5% per year

Life expectancy >5 years

NO2 Sensor Performance

Type Electrochemical

Accuracy +/-10% of reading @ 20oC

Reproducibility <+/-3% of reading

Response time <15 seconds(2)

Long term stability <+/-5% per year

Life expectancy >5 years

Operating Environment

Temperature, continuous -20 to 40oC

Temperature, intermittent -30 to 55oC

Humidity 15-95% continuous, 0-95% intermittent

Enclosure Material Polycarbonate

Dimensions 3.7”h x 3.7”w x 2.24”d

(1) One side of transformer secondary is connected to signal common. Dedicated transformer is recommended.

(2) Reference‘Installation’ section on page 1 to account for time required to change enlosure air sample by 90% within 15 minute window based on pickup tube

length and airow velocity.

Symptom Solution

No output Check wiring. Ensure power supply meets requirements.

Slow Response Timing Verify tube length is within recommended length based on rate of airow in duct. See

‘Installation’ section on page 1.

CO reading error Verify control panel software is congured for correct output scaling.

Sensor contaminated or at end of 5-year life. Replace sensor.

NO2 reading error Verify control panel software is congured for correct output scaling.

Sensor contaminated or at end of 5-year life. Replace sensor.

Relay Function Verify setpoint. Verify test gas concentration. Cover sensor to prevent drafts and dilution during

test.

TROUBLESHOOTING

Revised 9/6/2017 Document # 152-0272-0C

Other manuals for TG Series

6

This manual suits for next models

1

Other senva Accessories manuals

senva

senva TG Series User manual

senva

senva TG Series User manual

senva

senva TG Series User manual

senva

senva TG Series Installation and operating instructions

senva

senva CHTWL Series User manual

senva

senva TG Series User manual

senva

senva TotalSense Series User manual

senva

senva TotalSense Series User manual

senva

senva AQ Series User manual

senva

senva TG Series User manual