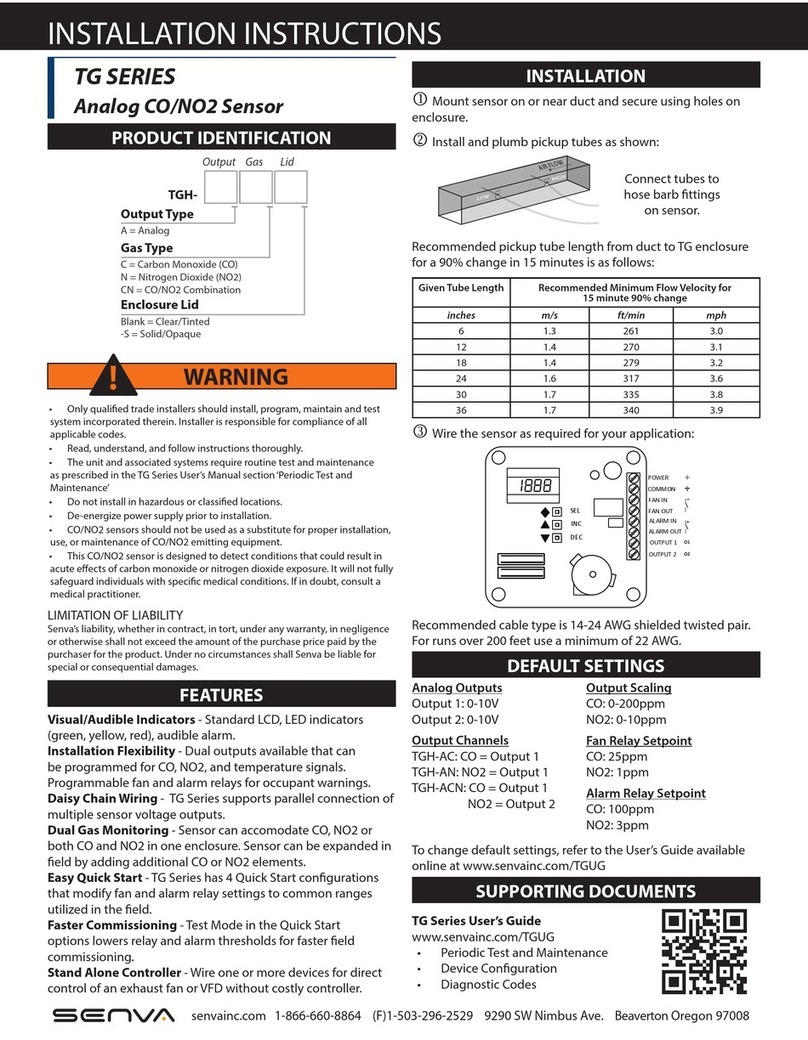

senva TG Series User manual

INSTALLATION INSTRUCTIONS

senvainc.com 1-866-660-8864 1825 NW 167th Place Beaverton Oregon 97006

TG SERIES

Toxic Gas Sensor

BACnet/Modbus/Analog

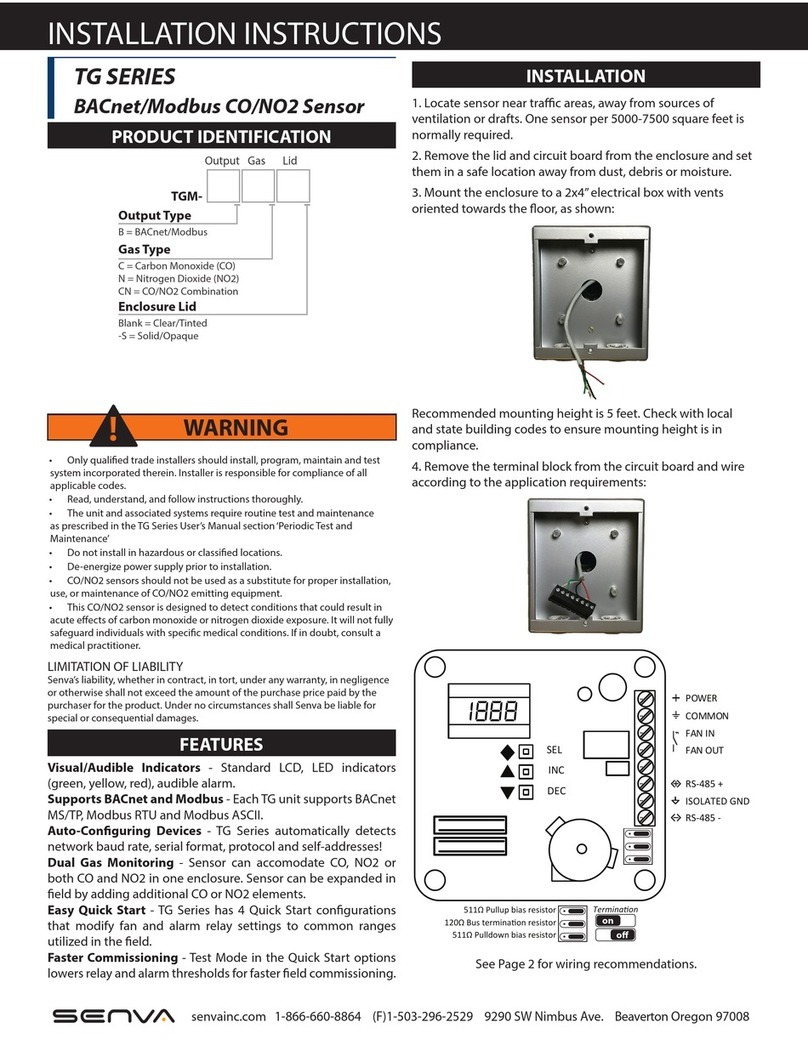

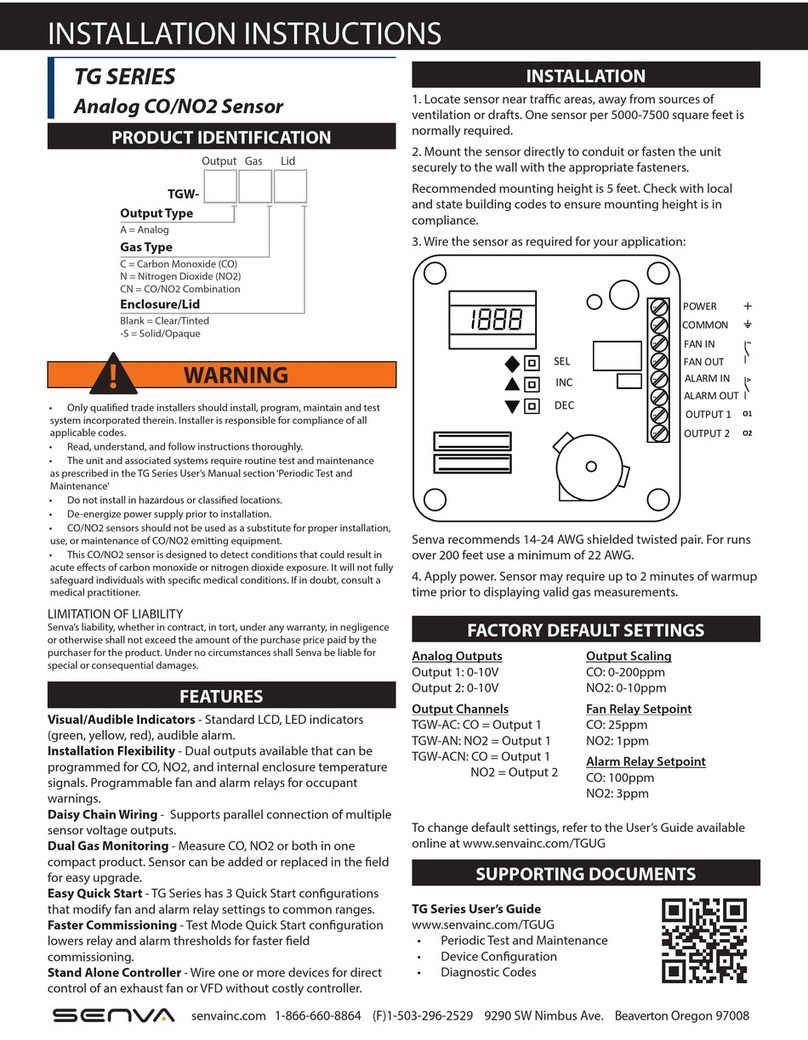

PRODUCT IDENTIFICATION

• Use installation wires rated for 75C and above.

• Only qualied trade installers should install, program,

maintain and test system incorporated therein. Installer is

responsible for compliance of all applicable codes.

• Read, understand, and follow instructions thoroughly.

• The unit and associated systems require routine test and

maintenance as prescribed in the TG Series User’s Manual

section ‘Periodic Test and Maintenance’

• Do not install in hazardous or classied locations.

• De-energize power supply prior to installation.

• Gas sensors should not be used as a substitute for proper

installation, use, or maintenance of gas emitting equipment.

• This device is designed to detect conditions that could

result in acute eects of gas exposure. It will not fully safeguard

individuals with specic medical conditions. If in doubt,

consult a medical practitioner.

• Conduit is prone to condensation if it passes from one

temperature zone to another, such as from indoors to outdoors

or from one part of a building to another. This condensation

may actually drip into the sensor if mounted below, causing

damage and/or poor readings.

In order to prevent condensation and water egress, seal

both the top and bottom of the conduit with a suitable

expanding foam product (such as PolywaterTM ZipsealTM ZIP-

50KIT1) to prevent warm air from entering cold conduit.

Alternatively, berglass insulation may be inserted in the

conduit between the cold and warm sections using a rigid wire

or other method if both ends cannot be sealed. Sealing is the

preferred method.

• Conduit air ow entering sensor may prevent sensor from

reading ambient air properly, resulting in under measurement

of gases. Plug sensor conduit in all installations with a foam

plug or seal as noted above in order to prevent airow from

the conduit.

DANGER

WARNING

!

LIMITATION OF LIABILITY

Senva’s liability, whether in contract, in tort, under any

warranty, in negligence or otherwise shall not exceed the

amount of the purchase price paid by the purchaser for the

product. Under no circumstances shall Senva be liable for

special or consequential damages.

TG -

Gas1

Pkg Gas2

Out

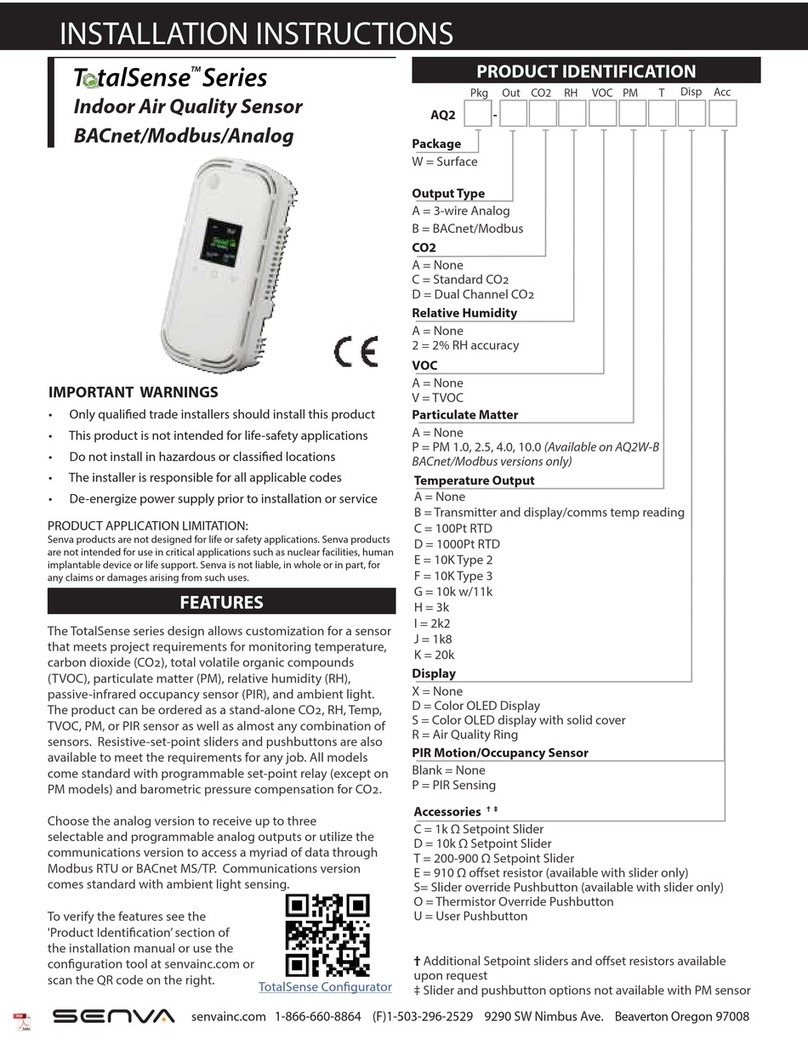

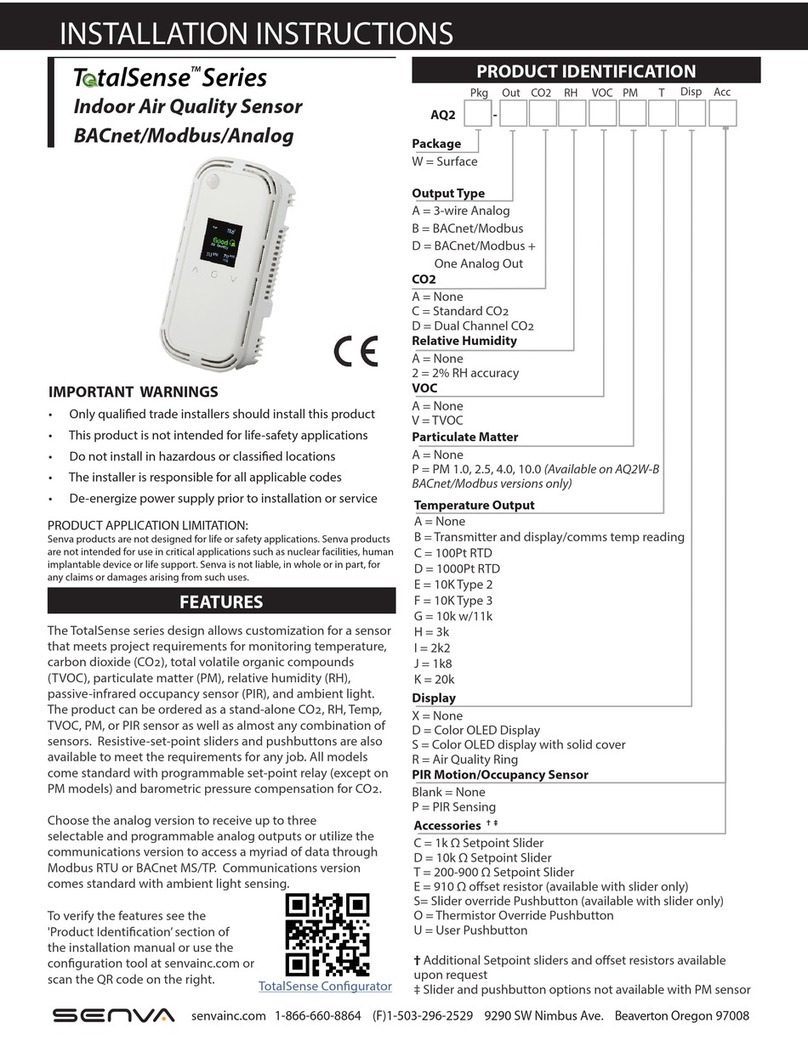

Package

R = Recessed Mount

Output Type

A = Analog

B = BACnet/Modbus

Gas Type 1*

C = Carbon Monoxide (CO)

N = Nitrogen Dioxide (NO)

D = Carbon Dioxide (CO2)

E = Dual Channel CO2

M = Methane (CH4)

P = Propane (C3H8)

H = Hydrogen (H2)

O = Oxygen (O2)

S = Hydrogen Sulphide (H2S)

A = Ammonia (NH3)

2 = R22

3 = R134A (Multi-Refrigerant)

4 = R410A

5 = R404A

6 = R407C

Gas Type 2*

X = No second gas

N = Nitrogen Dioxide (NO)

D = Carbon Dioxide (CO2)

E = Dual Channel CO2

M = Methane (CH4)

P = Propane (C3H8)

H = Hydrogen (H2)

O = Oxygen (O2)

S = Hydrogen Sulphide (H2S)

A = Ammonia (NH3)

2-6 = Refrigerants (see above)

*Refrigerant sensors may not be paired with CH4, C3H8, or H2

FEATURES

The Senva TG Series sensor is a dual-sensor toxic gas detector.

There are two versions to select from; the Analog version and

the Communications version(BACnet MS/TP and Modbus

RTU). Each version has Trouble and Alarm relays for controls/

indication. The Analog version has two congurable 0-5V/10V

or 4-20mA analog outputs that represent gas concentrations.

The communications version has a physical RS-485 connection

for communications over either BACnet MS/TP or Modbus RTU.

These sensors can be mounted in an indoor application. In

addition, each sensor has the following features:

Visual/Audible Indicators - LED indicator, audible alarm.

Supports BACnet and Modbus(BACnet/Modbus Version) - TG

units with output type of BACnet/Modbus supports BACnet MS/

TP and Modbus RTU.

Dual Gas Monitoring - Sensor can accommodate CO, NO,

CO, Methane, Propane, Hydrogen, Oxygen, HS, Ammonia,

Refrigerants or any dual combination in one enclosure. Sensor

can be expanded in eld by adding additional elements.

MOUNTING

IF MOUNTING INTO A JUNCTION BOX:

1. Remove drywall clamps by turning screw counter clockwise.

IF MOUNTING INTO DRYWALL:

1. Turn both mounting clamps all the way counter clockwise.

2. Insert into drywall cutout.

3. Turn screw clockwise to tighten drywall mounts until tight to

wall.

NFC Setup

To change device setting that are not available through the

dip switches, download the Senva Sensors app on your mobile

phone. The NFC capabilities will give you access to the internal

device settings for units that do not have screens.

*Refrigerant sensors may not be paired with CH4, C3H8, or H2

ANALOG SETUP

BACNET SETUP

WIRING CALL OUTS

PWR - Power

PWR - Power

GND - Common/Ground

GND - Common/Ground

TR - Trouble Relay

COM - Relay Common

AL - Alarm Relay

AL - Alarm Relay

PWR

GND

AL

AL

SW2

SW3

ON

ON

1 2

1 2 3 4 5 6 7 8

SW4

ON

1 2 3 4 5 6 7 8

SW1

ON

1 2

B

A

SG

GND

PWR

TR

PWR

GND

AL

AL

GND

PWR

TR

COM

S2

S1

GND

COM

SW1

ON

1 2

PWR

GND

AL

AL

GND

PWR

TR

COM

S2

S1

GND

PWR

GND

AL

AL

SW3

ON

1 2 3 4 5 6 7 8

SW4

ON

1 2 3 4 5 6 7 8

B

A

SG

GND

PWR

TR

COM

SW2

ON

1 2

1 2 3 4 5 6 7 8

PWR

GND

AL

AL

SW2

SW3

ON

ON

1 2

1 2 3 4 5 6 7 8

SW4

ON

1 2 3 4 5 6 7 8

SW1

ON

1 2

B

A

SG

GND

PWR

TR

PWR

GND

AL

AL

GND

PWR

TR

COM

S2

S1

GND

COM

SW1

ON

1 2

PWR

GND

AL

AL

GND

PWR

TR

COM

S2

S1

GND

PWR

GND

AL

AL

SW3

ON

1 2 3 4 5 6 7 8

SW4

ON

1 2 3 4 5 6 7 8

B

A

SG

GND

PWR

TR

COM

SW2

ON

1 2

1 2 3 4 5 6 7 8

S2 - Sensor 2 analog

output

S1 - Sensor 1 analog

output

GND - Common/Ground

PWR - Power

PWR - Power

GND - Common/Ground

GND - Common/Ground

TR - Trouble Relay

COM - Relay Common

AL - Alarm Relay

AL - Alarm Relay

B - -RS485(B(-))

SG - Isolated Shield

Ground

A - +RS485(A(+))

DIP

1

2

OFF

LOW

LOW

ON

HIGH

HIGH

Function

S1 Alarm

S2 Alarm

Comms DIP Settings

Analog DIP Settings

OFF

N/A

Modbus

0

0

0

Modbus

N/A

DIP

1

2

3

4

5

6

7

8

Function

BAUD0

BAUD1

BAUD2

D/P/S0

D/P/S1

NO USE

Protocol

EOL

ON

120 OHM

BACnet

1

1

1

BACnet

120 OHM

Function

MAC Address/

Modbus Address

0-127 (binary)

Baud Rate

0(000)=9600

1(001)=19200

2(010)=38400

3(011)=57600

4(100)=76800

5(101)=115200

Data/Parity/Stp

0(00)=8N1

1(01)=8N2

2(10)=8O1

3(11)=8E1

1 2

DIP

1

2

OFF

Current

0-5V

ON

Voltage

0-10V

1 2

OFF

0

0

0

0

0

0

0

DIP

1

2

3

4

5

6

7

8

Function

MAC0

MAC1

MAC2

MAC3

MAC4

MAC5

MAC6

NO USE

ON

1

1

1

1

1

1

1

SW4

SW3

DIP

SW3

1-7

SW4

1-3

SW4

4-5

SW2

ON

1 2

SW1

ON

1 2

SW3

ON

1 2 3 4 5 6 7 8

SW4

ON

1 2 3 4 5 6 7 8

SW2

SW1

DIP

1

2

OFF

LOW

LOW

ON

HIGH

HIGH

Function

S1 Alarm

S2 Alarm

Comms DIP Settings

Analog DIP Settings

OFF

N/A

Modbus

0

0

0

Modbus

N/A

DIP

1

2

3

4

5

6

7

8

Function

BAUD0

BAUD1

BAUD2

D/P/S0

D/P/S1

NO USE

Protocol

EOL

ON

120 OHM

BACnet

1

1

1

BACnet

120 OHM

Function

MAC Address/

Modbus Address

0-127 (binary)

Baud Rate

0(000)=9600

1(001)=19200

2(010)=38400

3(011)=57600

4(100)=76800

5(101)=115200

Data/Parity/Stp

0(00)=8N1

1(01)=8N2

2(10)=8O1

3(11)=8E1

1 2

DIP

1

2

OFF

Current

0-5V

ON

Voltage

0-10V

1 2

OFF

0

0

0

0

0

0

0

DIP

1

2

3

4

5

6

7

8

Function

MAC0

MAC1

MAC2

MAC3

MAC4

MAC5

MAC6

NO USE

ON

1

1

1

1

1

1

1

SW4

SW3

DIP

SW3

1-7

SW4

1-3

SW4

4-5

SW2

ON

1 2

SW1

ON

1 2

SW3

ON

1 2 3 4 5 6 7 8

SW4

ON

1 2 3 4 5 6 7 8

SW2

SW1

PWR

GND

AL

AL

SW2

SW3

ON

ON

1 2

1 2 3 4 5 6 7 8

SW4

ON

1 2 3 4 5 6 7 8

SW1

ON

1 2

B

A

SG

GND

PWR

TR

PWR

GND

AL

AL

GND

PWR

TR

COM

S2

S1

GND

COM

SW1

ON

1 2

PWR

GND

AL

AL

GND

PWR

TR

COM

S2

S1

GND

PWR

GND

AL

AL

SW3

ON

1 2 3 4 5 6 7 8

SW4

ON

1 2 3 4 5 6 7 8

B

A

SG

GND

PWR

TR

COM

SW2

ON

1 2

1 2 3 4 5 6 7 8

PWR

GND

AL

AL

SW2

SW3

ON

ON

1 2

1 2 3 4 5 6 7 8

SW4

ON

1 2 3 4 5 6 7 8

SW1

ON

1 2

B

A

SG

GND

PWR

TR

PWR

GND

AL

AL

GND

PWR

TR

COM

S2

S1

GND

COM

SW1

ON

1 2

PWR

GND

AL

AL

GND

PWR

TR

COM

S2

S1

GND

PWR

GND

AL

AL

SW3

ON

1 2 3 4 5 6 7 8

SW4

ON

1 2 3 4 5 6 7 8

B

A

SG

GND

PWR

TR

COM

SW2

ON

1 2

1 2 3 4 5 6 7 8

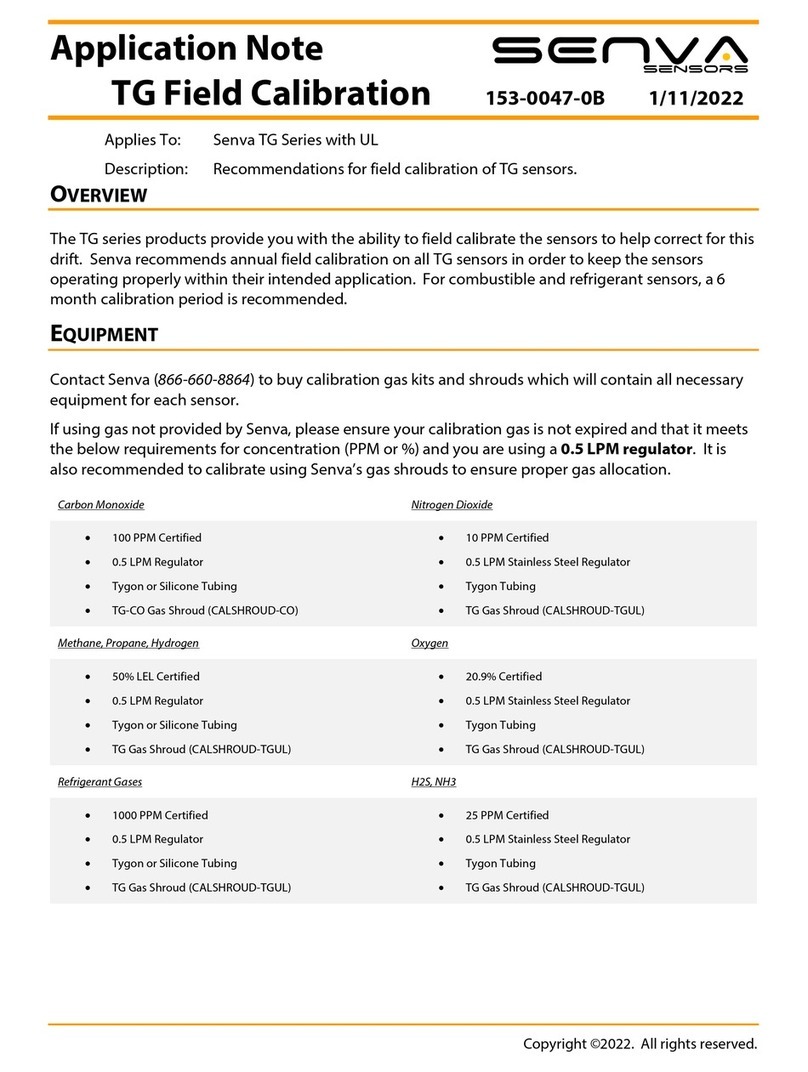

PERIODIC TEST AND MAINTENANCE

Periodic Maintenance

Though the frequency of inspection is typically aected by the

operating conditions and environment (extreme temperatures,

extreme humidity, exposure to contaminants, etc.), Senva

recommends the following maintenance and intervals. More

frequent maintenance may be required per local code by the

Jurisdiction Having Authority (JHA). An accurate log of all

maintenance and abnormal occurrences should be maintained

for the proper service of this product

Every 6 Months

• For Methane, Propane, Hydrogen, H2S, Ammonia NH3

or refrigerants retest and recalibrate the unit using NIST

traceable reference gas to ensure sensors remain accurate.

• Visually inspect to ensure optimal operating conditions (no

broken pieces/components, sensor lter not blocked or

discolored, visual indicators operational, etc.).

• Clean the exterior with a soft cloth to remove debris from

the sensor intake ports.

Annual

• For Oxygen, CO or NO2, retest and recalibrate the unit

using NIST traceable reference gas to ensure sensors

remain accurate.

• For sensor replacement be sure to power down the sensor

and remove element to be replaced and plug in new

element in its place and then re-apply power.

Do Not

• Expose the sensor and its elements to solvents.

• Immerse the sensor into liquids.

DEVICE OVERVIEW

2

1

3

4

56

1 - LED indicator

2 - Buzzer

3 - Sensor Element 1

4 - Sensor Element 2

5 - Capacitive touch button

6 - Capacitive touch button

1. For proper detector operation, ensure that the Senva TG is connected to a continuous source of power

(not controlled by a wall switch). The TG current draw gures represent worst-case conditions and will not

vary as the applied DC voltage varies. To meet the requirements of ANSI/UL 2075, Second Edition, the TG

Carbon Monoxide detector employs duplicate power leads (Red and Black) where the rst pair of power

leads goes into the rst Carbon Monoxide detector and the second pair of power leads goes to the next

detector on the loop.

2. The alarm control panel zone inputs must be terminated with end of line resistors (E.O.L.R.), which are

provided with the panel.

3. The relay of the TG is a dry contact and rated at 1A, 24VAC/30VDC. It shall not be used to directly drive a

fan. When connecting the units to other UL approved devices, make sure that the load does not exceed the

relay’s rating.

WIRING AND INSTALLATION

OPERATION

Green Normal readings below the low level set-point

Yellow Gas concentration above the low level set-point

and below the high level set-point

Red Gas concentration level above the high level set-

point

Alarm Set-points

The alarm set-points are applicable for elements populated on

the board by the factory, or added in the eld by the user.

Sensor LOW level (Default) HIGH level (Default)

CO 35 ppm 100 ppm

NO2 1 ppm 3 ppm

CO2 800 ppm 5000 ppm

Methane/

Propane/

Hydrogen

10% L.E.L. 25% L.E.L.

Oxygen Less than 19.5% Vol Greater than 23% Vol

H2S 25 ppm 75 ppm

Ammonia 20 ppm 40 ppm

Refrigerants 300 ppm 600 ppm

CO for Fire Alarm System

The sensors shall respond with the following Carbon Monoxide

concentration and time limits.

Single and multiple-station CO alarms (UL Product code: CZHF)

Concentration of CO Maximum Alarm time response

100-5 ppm 90 minutes (not less than 16 minutes)

200-10 ppm 35 minutes (not less than 8 minutes)

400-20 ppm 15 minutes (not less than 4 minutes)

Trouble Signal

During a device failure mode the N.C. Trouble relay will open

and the Device LED indicator will then turn yellow and blink to

indicate one of the following events:

• Removal of a sensor

• Sensor is at end of life

• The pulse check function has detected a sensor failure

• The device has lost power

The following section details factory defaults for LED function,

Trouble and alarm set-points, Trouble relay and alarm status

functions, and the sensor element lifetime clock. These values

can be modied from their default settings via the TG Series

User’s Guide.

LED Function

The LED indicators function in sync with the Trouble relay and

alarm status thresholds. LED will change state if either of the

gases reach their Trouble or alarm set-point.

WIRING EXAMPLES

Gas Sensor 1

V+

V- (Gnd) A(+)

Agnd

B(-)

TR

COM

AL

AL

Gas Sensor 2

Building Automation Control Panel

Comms (BACnet or Modbus)

A(+)

B(-)

Note:

Colors are shown to

clarify node connections;

wire color shall be

determined by national

and local electrical codes.

V+

V- (Gnd)

V+

V- (Gnd)

TR

COM

AL

AL

V+

V- (Gnd)

A(+)

Agnd

B(-)

N.O. initiating

circuit

E.O.L.R.

Power Supply

15-30VDC/24VAC

50/60Hz, 4w max, 160mA max.

GND

Gas Sensor 1

V+

V- (Gnd) GND

S1

S2

TR

COM

AL

AL

Gas Sensor 2

Building Automation Control Panel

Analog (0-5/10V, 3 wire 4-20mA)

IN1

IN2

Note:

Colors are shown to

clarify node connections;

wire color shall be

determined by national

and local electrical codes.

V+

V- (Gnd)

V+

V- (Gnd)

TR

COM

AL

AL

V+

V- (Gnd)

N.O. initiating

circuit

E.O.L.R.

COMMON

GND

S1

S2

Power Supply

15-30VDC/24VAC

50/60Hz, 4w max, 160mA max.

GND

SPECIFICATIONS

Power supply Power 15-30VDC/24VAC (1), 50/60Hz, 4w max, 160mA max.

Wiring Conductor 14-24 AWG, Minimum 600V, 75°C

Terminal Torque 0.5 N•m

Outputs (Analog)

2 Programmable Outputs 0-10V (default), 0-5V, 4-20mA (selectable)

CO Output Scaling 0-200ppm (default), 0-500ppm (menu selectable)

NO Output Scaling 0-10ppm (default), 0-10ppm (menu selectable)

CO2 Output Scaling 0-10,000 ppm (default), 0-10,000 ppm (menu selectable)

Propane/Methane/Hydrogen Output Scaling 0-50% LEL (default), 0-50% LEL (menu selectable)

Oxygen Output Scaling 0-25% Vol (default), 0-25% Vol (menu selectable)

Refrigerant Output Scaling 0-1000 ppm (default), 0-1000 ppm (menu selectable)

H2S Output Scaling 0-100 ppm (default), 0-100 ppm (menu selectable)

Ammonia NH3 Output Scaling 0-100 ppm (default), 0-100 ppm (menu selectable)

Temp Output Scaling (optional) -20 to 85ºC

Output (BACnet/Modbus)

RS-485 BACnet MS/TP, Modbus RTU, Modbus ASCII

Baud Rates 9600, 19200, 38400, 57600, 76800, 115200

RS-485 Loading 1/4 unit

Trouble Relay Trouble relay characteristics N.C. 1A@24VAC/30VDC(50/60Hz)(No Mains Connection)

Alarm Relay Alarm relay characteristics N.O. 1A@24VAC/30VDC(50/60Hz)(No Mains Connection)

LED’s Green, Yellow, Red Green = Normal, Yellow = Relay, Red = Alarm

Audible exposure alarm 85dB@4” Piezo transducer 30 minutes above alarm set-point per UL2034 (menu selectable)

CO Sensor Performance

Type Electrochemical

Accuracy ±5% of Default Range, ±5% of Reading Above 200ppm

Resolution 1ppm

Life expectancy 7 years

Recommended Calibration Annual

Recommended Height 3 to 6 feet; coverage 5000-7500 sq ft.

NO Sensor Performance

Type Electrochemical

Accuracy ±5% of Default Range, ±5% of Reading Above 20ppm

Resolution 0.1ppm

Life expectancy 7years

Recommended Calibration Annual

Recommended Height 3 to 6 feet; coverage 5000-7500 sq ft.

CO Sensor Performance

Type Non-dispersive Infrared (NDIR)

Accuracy

±(30ppm +3% of reading) (400-2000ppm), @-10-50°C

±(50ppm +5% of reading) Standard (2000-5000ppm), @-10-50°C

±(50ppm+3% of reading) Dual Channel (2000-5000ppm), @-10-50°C

±(100ppm+10% of reading) (5000-10000ppm), @ 0-50C

Drift with ABC disabled 35ppm/month (6) (Standard) 5ppm/month (6) (Dual Channel)

Range 0-2000/5000ppm; Programmable up to 10,000ppm

Response time 30s

Sample rate 1s

Recommended Height 3 to 6 feet; coverage 5000-7500 sq ft.

(1) One side of transformer secondary is connected to signal common. Dedicated transformer is recommended. No mains circuit connection allowed. In addition,

it is required to use an isolated power supply that is certied by a national or international standard (i.e. UL). Use of a Class 2 LPS power supply or greater is

required.

(2) Carbon Monoxide full scale is 1000 ppm.

(3) Nitrogen Dioxide full scale is 30 ppm.

(4) Accuracy of CO reading may be reduced at temperatures below 14ºF (-10C).

(5) It is not recommended to de-activate ABC (auto-calibration) except for continuously occupied spaces or greenhouses. Drift ratings may vary based on

environment.

Methane/Propane/

Hydrogen Sensor

Performance

Type Catalytic

Detection Range 0-50% LEL (Lower Explosive Limit)

Accuracy ±5% of Range

Resolution 1% LEL

Life expectancy 5years

Recommended Calibration 6 months

Recommended Height Hydrogen/Methane: 0.5 to 1 foot from ceiling; coverage 5000-7500 sq ft

Oxygen Sensor Performance

Type Electrochemical

Detection Range 0-25% Volume

Accuracy ±5% of Range

Resolution 0.1%

Life expectancy 5 years

Recommended Calibration Annual

Recommended Height 3 to 6 feet; coverage 5000-7500 sq ft.

H2S Sensor Performance

Type Electrochemical

Detection Range 0-100 ppm

Accuracy ±5% of Range

Resolution 1 ppm

Life expectancy 5 years

Recommended Calibration 6 months

Recommended Height 3 to 6 feet; coverage 5000-7500 sq ft.

Ammonia NH3 Sensor

Performance

Type Electrochemical

Detection Range 0-100 ppm

Accuracy ±5% of Range

Resolution 0.1 ppm

Life expectancy 5 years

Recommended Calibration 6 months

Recommended Height 0.5 to 1 foot from ceiling; coverage 5000-7500 sq ft.

Refrigerant Sensors

Performance

Type MOS

Detection Range 0-1000 ppm

Resolution 1 ppm

R22, R134A, R410A, R404A, R407C Calibrated for respective gas

R134A Sensitivity @300ppm test gas: 450 ppm R410A, 425 ppm R407C, 400 ppm R404A, 370

ppm R22, 300 ppm R134A

Life expectancy 10 years (typical expectation for MOS sensors)

Recommended Calibration 6 months

Recommended Height 6 inches above oor; no more than 18 inches above lowest level of equip-

ment location for leak detection; coverage 5000-7500 sq ft.

Operating Environment

Temperature, continuous -20 to 50oC

Humidity 15-90% continuous, 0-99% intermittent

Max Elevation 2000m

Enclosure

Material ABS/Polycarbonate

Rating IP20

Dimensions 5.66”h x 3.0”w x 1.69”d

Agency Compliance CE

SPECIFICATIONS (Continued)

(6) Combination CO/Methane, CO/Propane, or CO/Refrigerant sensors should be mounted according to Propane/Methane/Refrigerant

recommendations. Consult factory for other combinations. Mounting height recommendations may be adjusted according to installation.

Ensure sensor is accessible for maintenance and target gas has unobstructed access to sensor. Mount in accordance with ANSI/NFPA 70 and NEC

or CEC.

(7) R134A sensor may be used as a general purpose refrigerant detection. The sensor’s response to other refrigerants will change proportionally

as shown in the following app note: https://www.senvainc.com/catalog/documents/downloadcenter/Refrigerant%20cross%20sensitivities.pdf

(or scan QR code). Actual response may vary depending on installation. For more accurate response to a specic gas, a unit may be eld

calibrated.

DIMENSIONS

Symptom Solution

No output Check wiring. Ensure power supply meets requirements.

Sensor reading error Sensor contaminated or at end of life. Replace sensor.

Relay Function Verify set-point. Verify test gas concentration. Cover sensor to prevent drafts and dilution during test.

TROUBLESHOOTING

BACnet/Modbus Quick Reference

The following section outlines some commonly utilized

Modbus registers and BACnet objects for quick reference. For a

complete list and description of each, please see the associated

protocol guides: TG BACnet Protocol Guide or TG Modbus

Protocol Guide.

Access Legend:

R=Readable

W-Write-able

W0 = Write-able with 0 only

NV = Saved in non-volatile conguration memory

Description BACnet

Object

Modbus

Register

Access

Gas 1 Concentration AI1 6/7 R/W0

Gas 2 Concentration AI2 8/9 R/W0

Gas 1 Warning Set-point AV1 101 R/W/NV

Gas 1 Alarm Set-point AV2 102 R/W/NV

Gas 2 Warning Set-point AV4 104 R/W/NV

Gas 2 Alarm Set-point AV5 105 R/W/NV

Supported Modbus Functions:

0x03 Read Multiple Holding Registers

0x04 Read Register Input

0x06 Write Single Register

0x10 Write multiple Registers

Revised 3/15/2021 Document #152-0386-0A

Other manuals for TG Series

6

Table of contents

Other senva Accessories manuals

senva

senva TG Series User manual

senva

senva TG Series User manual

senva

senva TG Series User manual

senva

senva TotalSense Series User manual

senva

senva CHTWL Series User manual

senva

senva AQ Series User manual

senva

senva TotalSense Series User manual

senva

senva TotalSense Series User manual

senva

senva TG Series User manual

senva

senva TG Series Installation and operating instructions