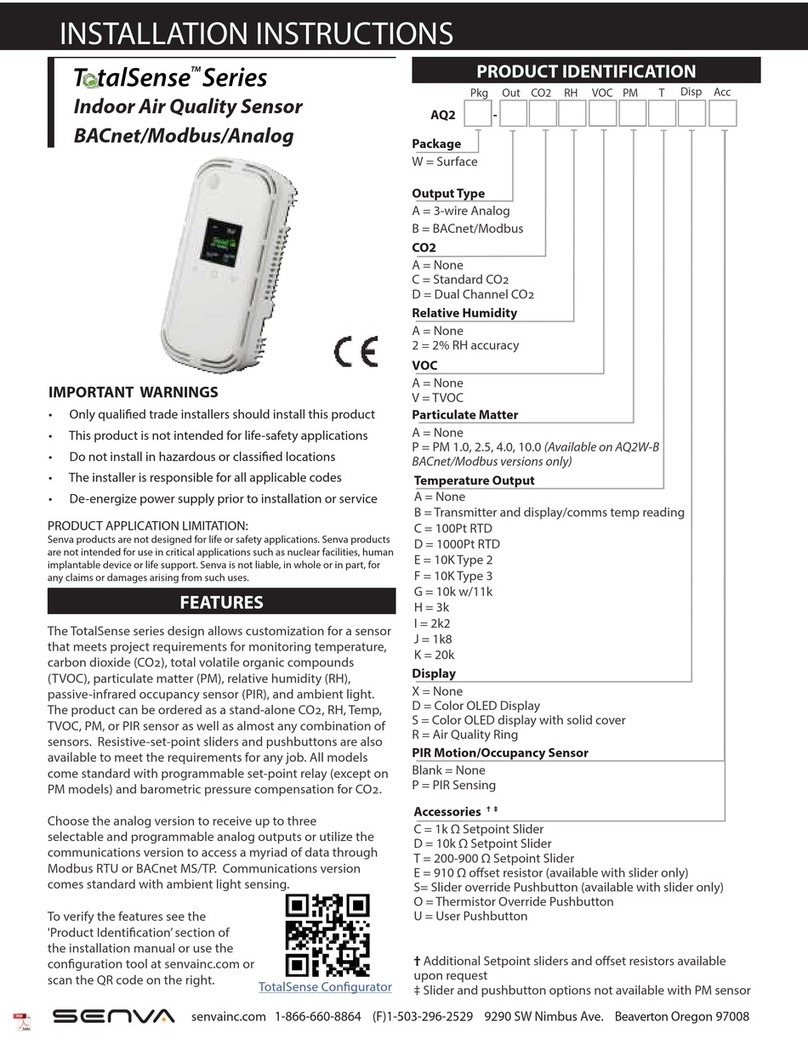

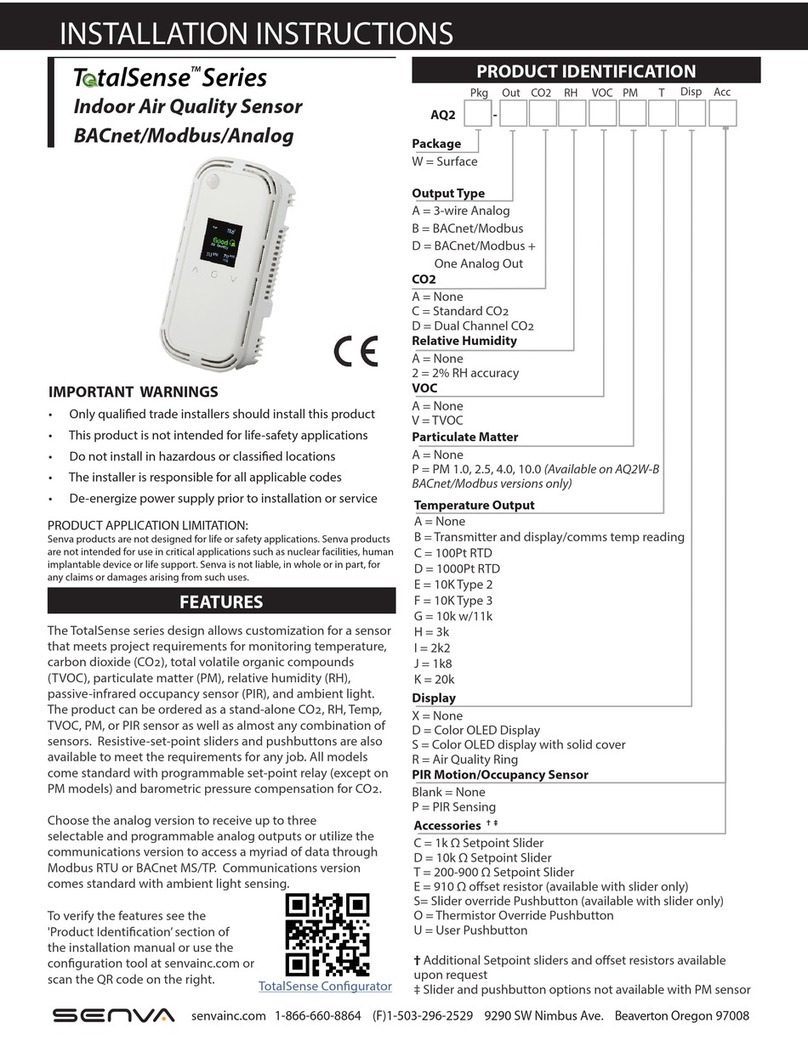

FEATURES

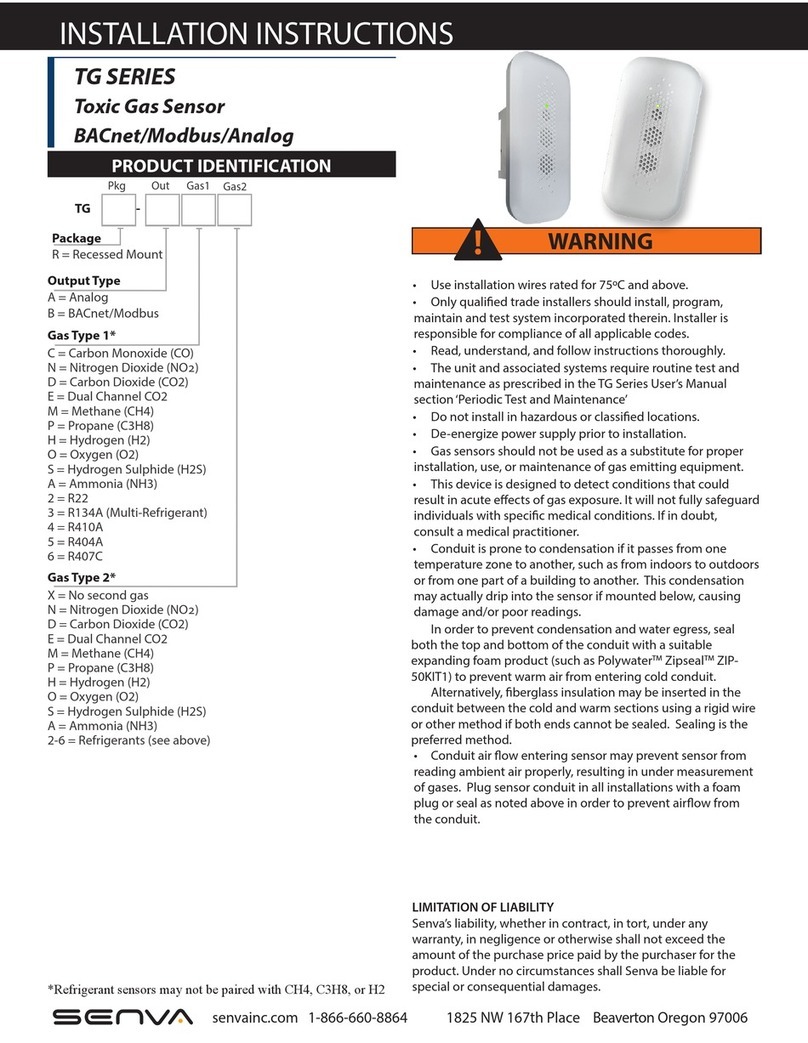

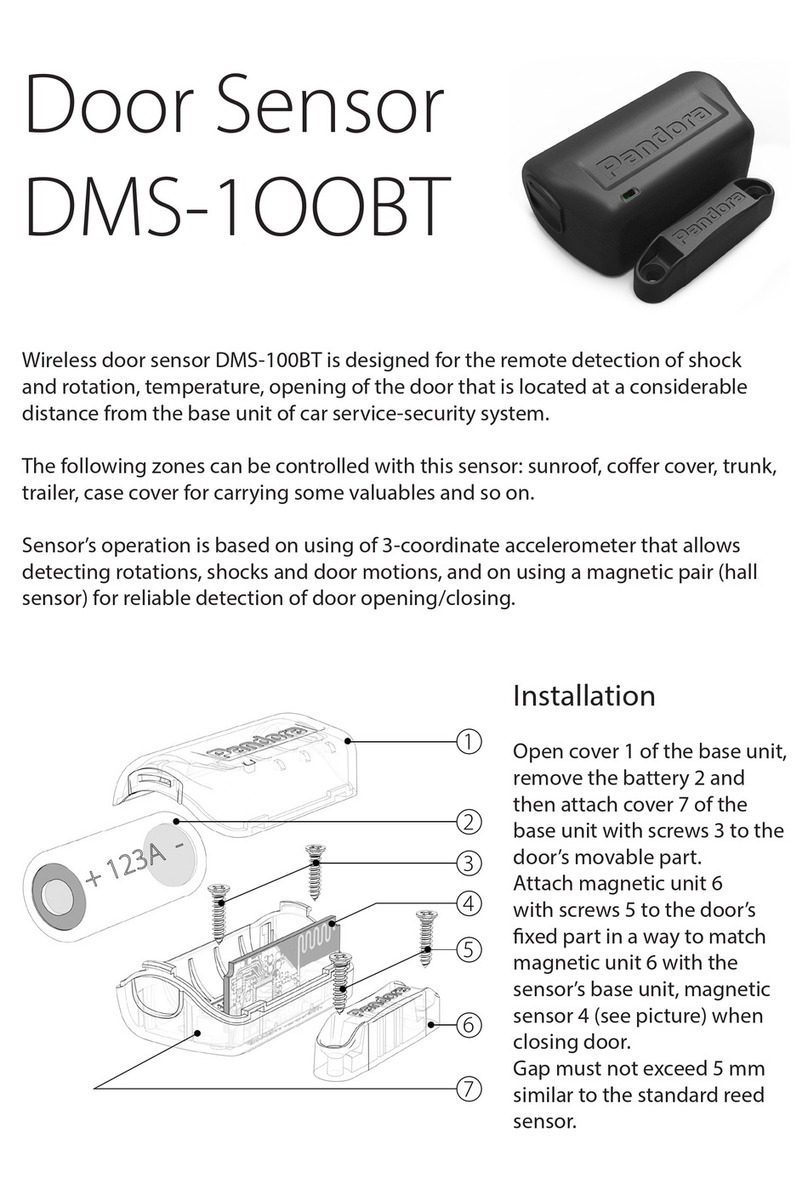

The Senva TG Series sensor is a dual-sensor toxic gas detector.

There are two versions to select from; the Analog version and

the Communications version(BACnet MS/TP and Modbus

RTU). Each version has Fan and Alarm relays for controls/

indication. The Analog version has two congurable 0-5V/10V

or 4-20mA analog outputs that represent gas concentrations.

The communications version has a physical RS-485 connection

for communications over either BACnet MS/TP or Modbus RTU.

These sensors can be mounted in an indoor application. In

addition, each sensor has the following features:

Visual/Audible Indicators - Standard LCD, LED indicators

(green, yellow, red), audible alarm.

Supports BACnet and Modbus(BACnet/Modbus Version) - TG

units with output type of BACnet/Modbus supports BACnet MS/

TP, Modbus RTU and Modbus ASCII.

Auto-Conguring Devices (BACnet/Modbus Version) - TG

Series automatically detects network baud rate, serial format,

protocol and self-addresses.

Dual Gas Monitoring - Sensor can accommodate CO, NO,

Methane, Propane, Hydrogen, Oxygen, Refrigerants or any dual

combination in one enclosure. Sensor can be expanded in eld

by adding additional elements.

Lockable Door- TG Series has a hex keyed screw that can be

used to secure the sensor’s door in the closed state. This should

be used to keep the sensor door locked to prevent/limit the

ability to tamper or misuse the sensor.

Streamlined Installation- TGM and TGW units are designed to

allow wire through the center, making installation simple and

reducing the need to run wires around a circuit board.

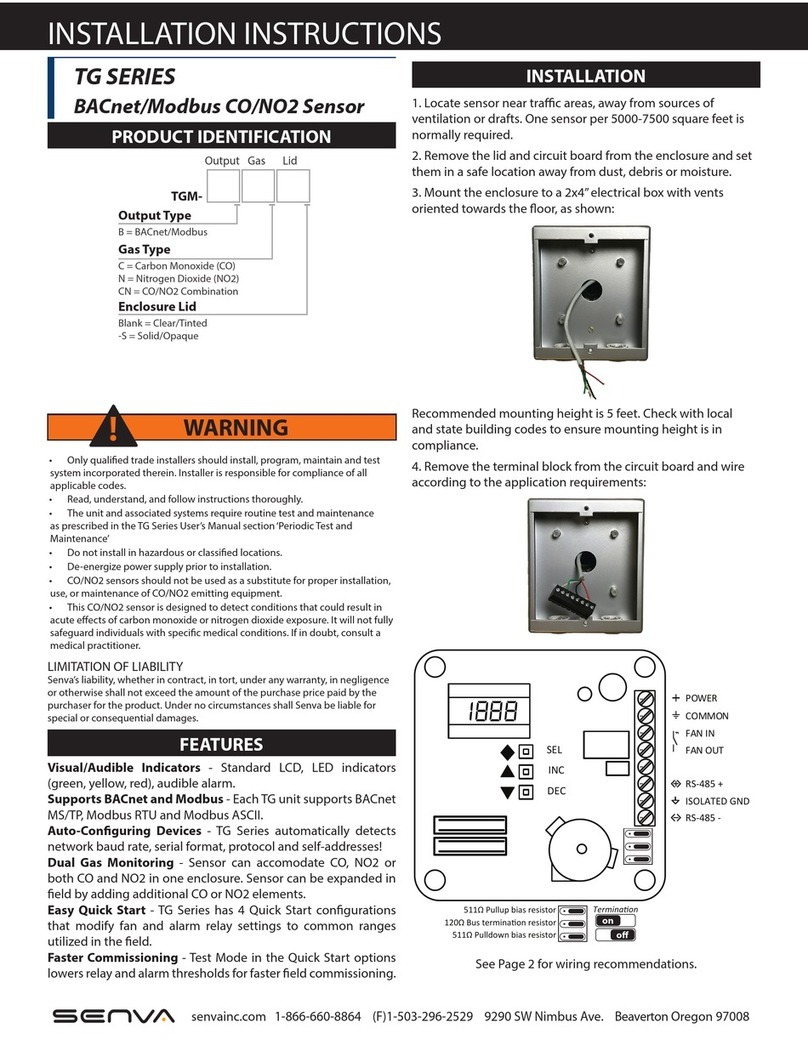

INSTALLATION

1. Identify the package type (wall/metal or duct) of the

TG Series sensor. Follow the‘Wall Mount’or‘Duct Mount’

installation instructions accordingly:

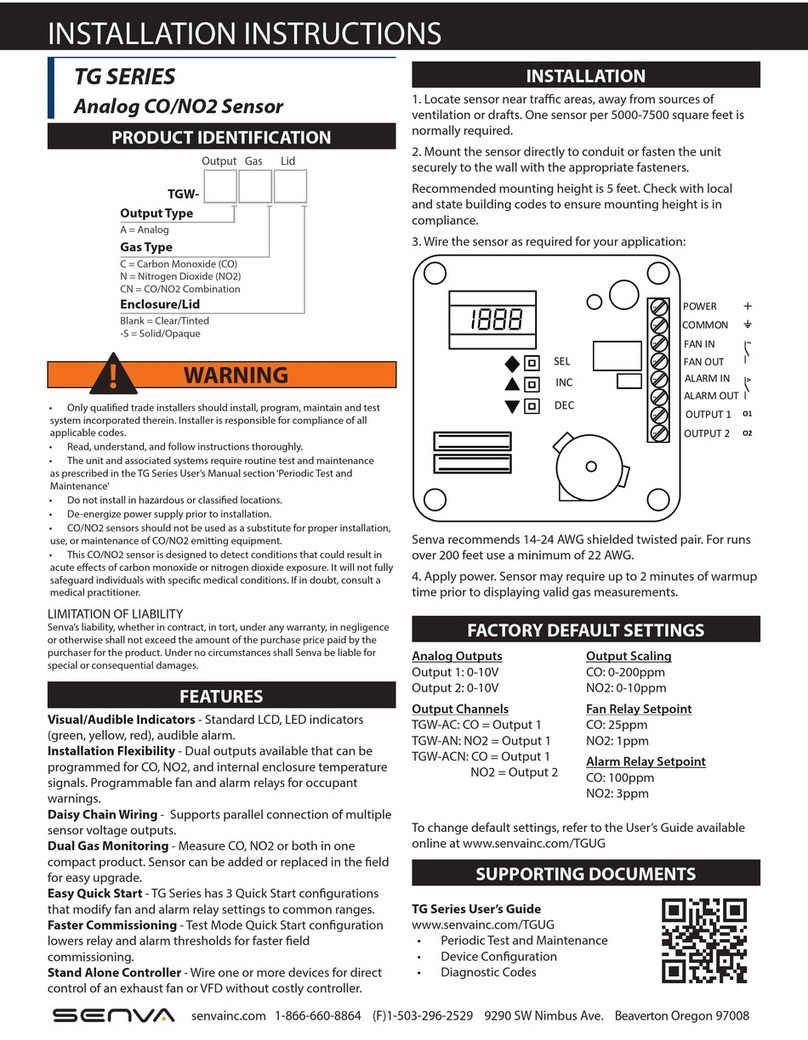

Wall Mount (TGM or TGW)

Locate sensor near trac areas, away from sources of

ventilation or drafts. One sensor per 5000-7500 square feet is

normally required (applies to CO, NO, Methane, Hydrogen).

Propane and refrigerant sensors should be limited to 5000

square feet or less.

Recommended CO and NO2 Sensor Mounting Height is 3-6 feet

above nished oor. Methane or Hydrogen sensors should be

mounted within 1 foot of the ceiling. Propane sensors should

be mounted 1-3 feet above the oor. Refrigerant sensors

should be mounted 6 inches above oor. Check with local and

state building codes to ensure sensor mounting height is in

compliance.

Mount the sensor directly and securely to the wall with the

fasteners best suited to your construction. Use the factory

provided #8 x 3/4”Pan self tapping screws or equivalent.

• There are two mounting tabs for securing/mounting the

sensor. Mount/secure sensor to desired position on the

wall with screws while being careful not to over-tighten.

• The sensor has a hole in the back for mounting into a wall

or a junction box. If a top mounted conduit connection

is desired, drill out either of the top knockouts and install

appropriate conduit tting/connector.

ATTENTION: For conduit installations, remove

circuit board from enclosure prior to drilling holes to

ensure product is not damaged.

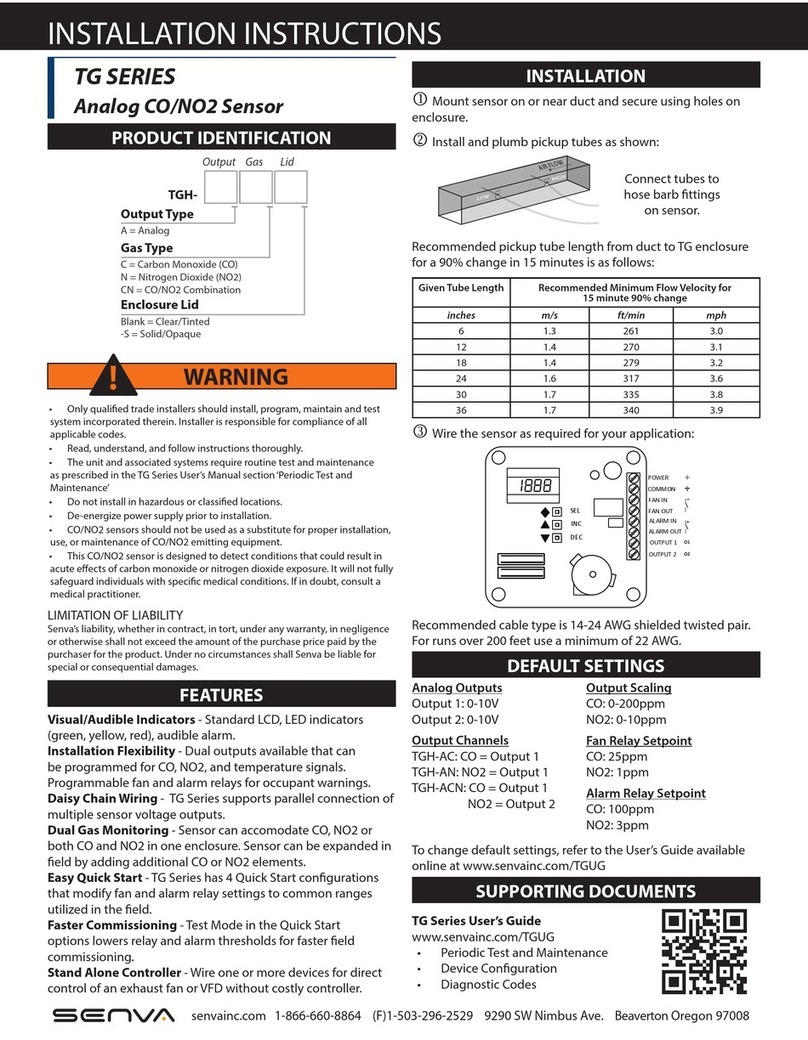

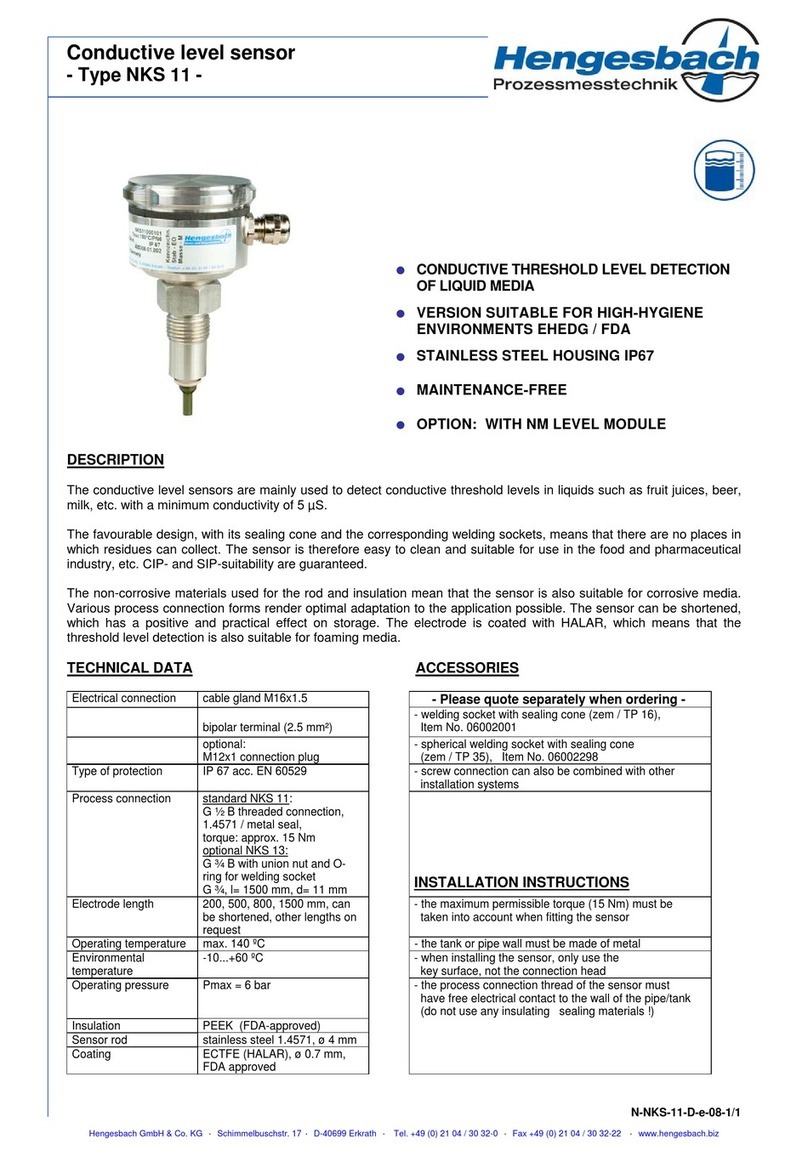

Duct Mount (TGD)

Drill a 3/4”hole in duct. Install sensor using gasket and screws

provided. The pickup tube will ensure adequate air ow

regardless of air ow direction.

Mount unit to duct with supplied screws.

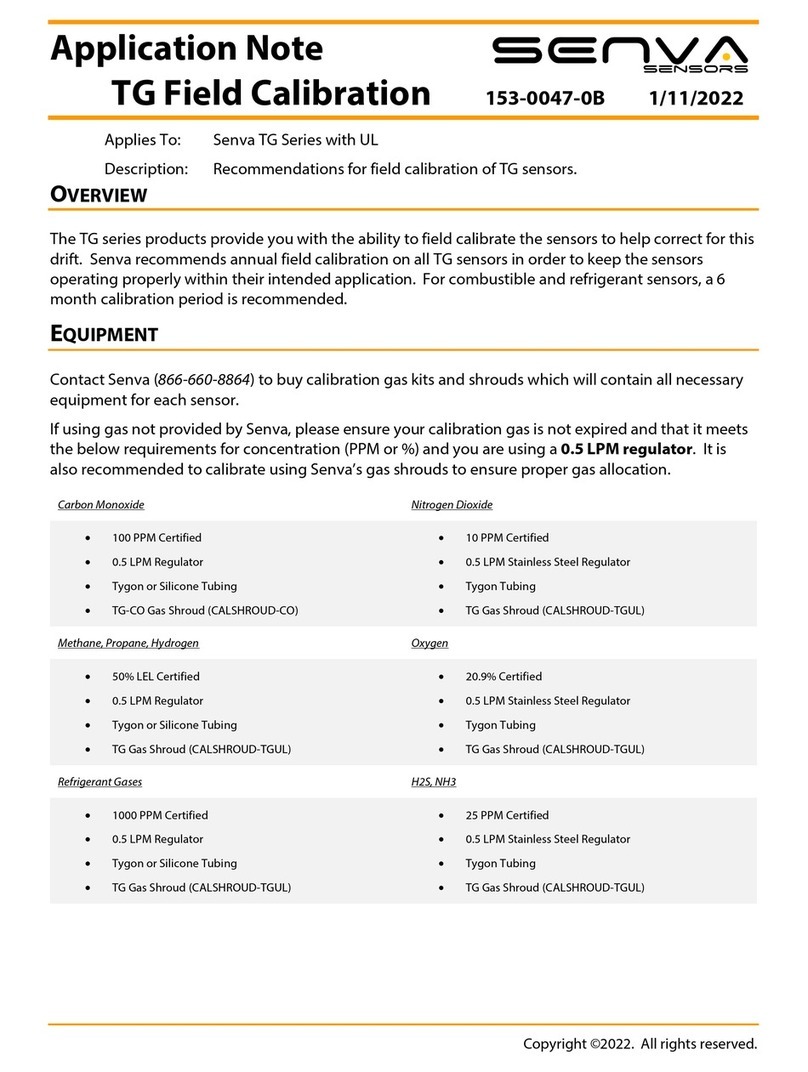

New Product Announcement

TG Toxic Gas Product Improvement Annoucement

NEW TG UL TOXIC GAS SENSOR

The new Senva TG toxic gas product line is now UL and cUL

Listed! Other product enhancements include an enhanced

through-the-back solution for wiring on the TGW, a new

duct-mountable option, temperature thermistor options,

and (coming soon!) additional toxic gases such as Methane,

Propane, Hydrogen, Hydrogen Sulde, Oxygen and

refrigerants.

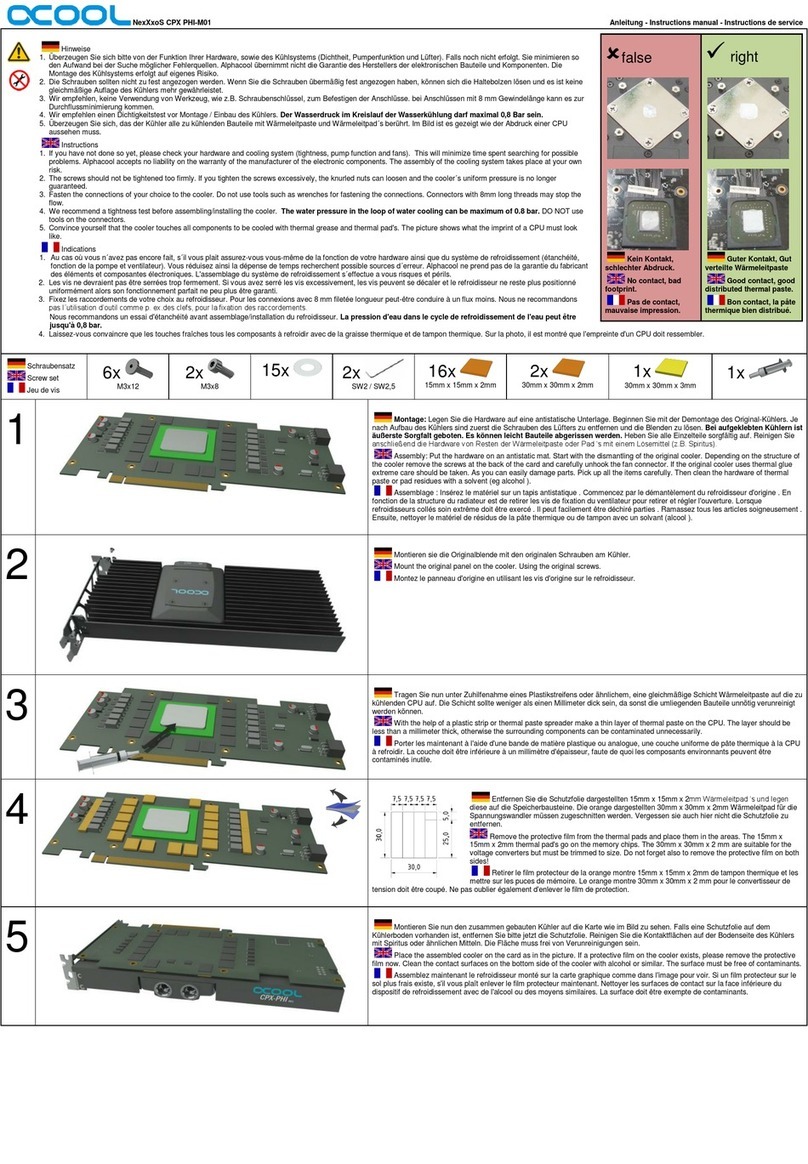

THROUGHTHEBACK SOLUTION FOR STREAMLINED

WALL MOUNTING

Installers have loved working with our TG product line for

years...except for one thing - it was dicult to run wires

for a junction box installation. Well, not anymore! Senva’s

new center-hole circuit board allows conductor entry

straight through the back for quicker, cleaner junction-box

installations.

NEW DUCT VERSION

Senva’s duct is engineered to maximize airow throught he

sensing elements to ensure quick and accurate sensing. The

design allows for easy installation into any duct. See our

“Duct Mount Gas Sensing”application note to learn more!

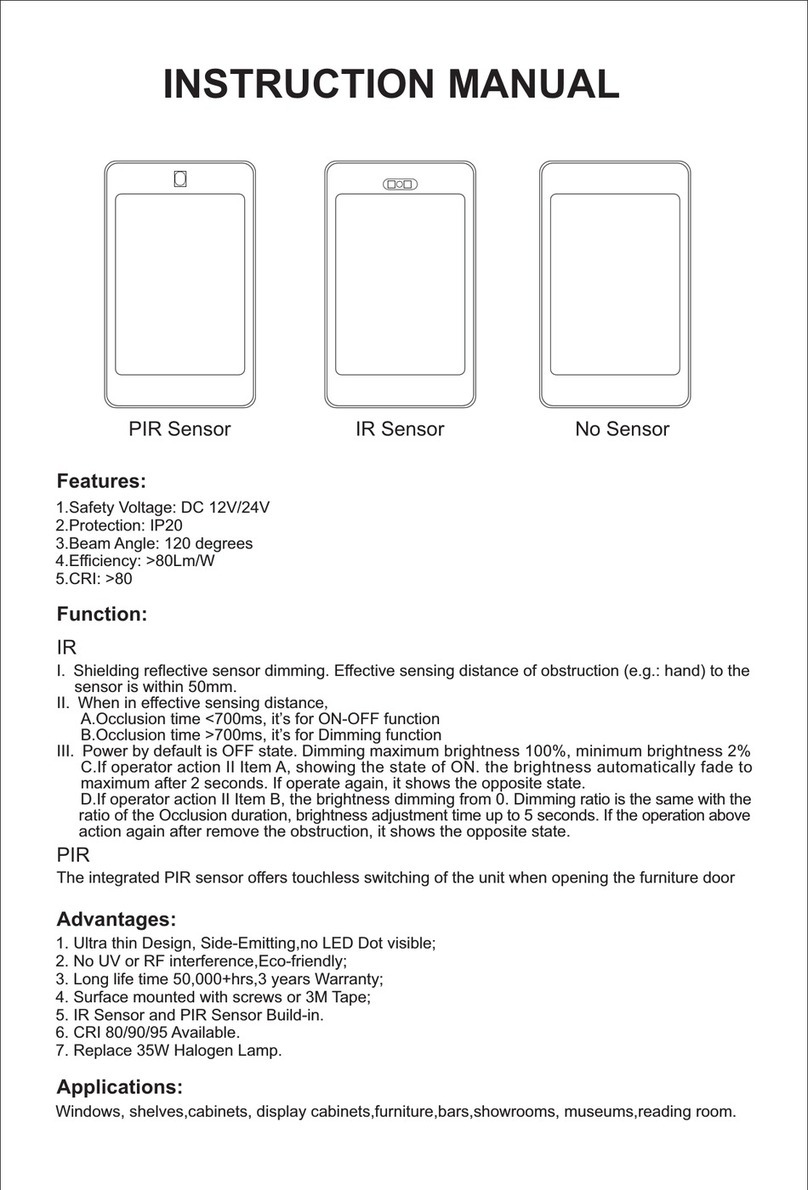

OTHER KEY FEATURES

▪NEW! O2, Methane, Propane, H2, VOC, H2S, and refriger-

ants coming soon

▪NEW! Self-Test feature periodically checks health and alerts

occupants of faulty sensors or end of lifespan

▪Temperature compensated, eld replaceable, 7 year life

expectancy on CO and NO elements

▪LCD with intuitive setup menu

▪Standard LED and audible alarm

▪Analog or RS485 Available

▪7-year limited warranty on electronics; 2-year on elements

ORDERING

To dierentiate from the non-UL product and allow for future

gas additions, the new TG product will have a dierent part

number naming convention than the previous product. Use

the following cross reference to choose the appropriate TG

product for your application.

Higher Reliability, Faster Installation, Superior Accuracy | Sense the dierence

7 year limited warranty

PROUDLY MADE IN USA

Step 1: Install mud plate in a

2x4” conduit junction box, or

skip this step if mouting TG

directly to wall

Step 2: Run wire(s) through

TG center; mount TG

Step 3: Wire to removable

terminal block, plug, and

play

UL LISTED

STREAMLINED WALL INSTALLATION

NEW DUCT VERSION FOR

UNDERGROUND GARAGES

COMING SOON! MORE

GASES