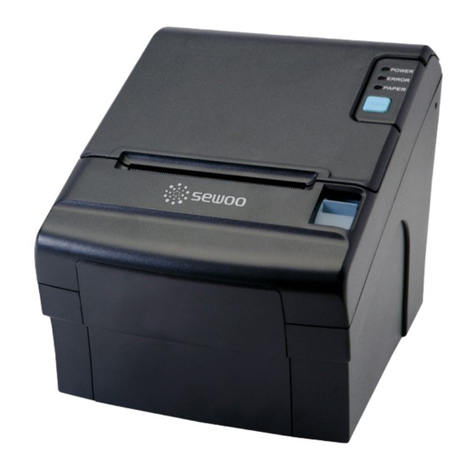

SEWOO LK-P22 User manual

All specifications are subject to change without notice

MOBILE PRINTER

J. STEPHEN Lab., Ltd.

374-2, Gajang-dong, Osan-si, Gyeonggi-do, 447-210, Korea

TEL : +82-31-459-8200 FAX : +82-31-459-8880

www.miniprinter.com

P22 Rev. C 11/16

MODEL : LK-P22

Wi-Fi & Bluetooth

1

23

Table of Contents

1. Safety Caution

4

2.

Unpacking

6

3. Product overview

7

4. Usage and Installation 8

4-1. Control panel usage

8

4-2. Battery Installation

9

4-3. Battery removal

10

4-4. Battery charging

11

4-4-1. Charging usage

11

4-4-2. Charging set cradle (Optional)

12

4-5. Set Cradle usage (Optional)

13

4-6. Belt clip & Strap

14

4-6-1. Belt Strap+Bracket usage

14

4-6-2. Belt clip usage (Optional)

16

4-7. Roll paper installation

17

4-8. Leather case usage (Optional)

18

4-9. Self test

19

4-10.

MSR usage (Optional)

21

4-11.

IC CARD usage (Optional)

22

5.

Peripherals connection 23

5-1. Bluetooth connection (Optional)

23

5-1-1. NFC connection (Optional)

24

5-2. Wi-Fi connection (Optional)

25

5-3. Interface cable connection

26

6.

Roll media specication 27

7.

Black Mark 28

8.

Printer cleaning 29

9.

Printer specication 30

9-1. Specication

30

10. Emulation Command Compatibility 32

11.

Certication 44

45

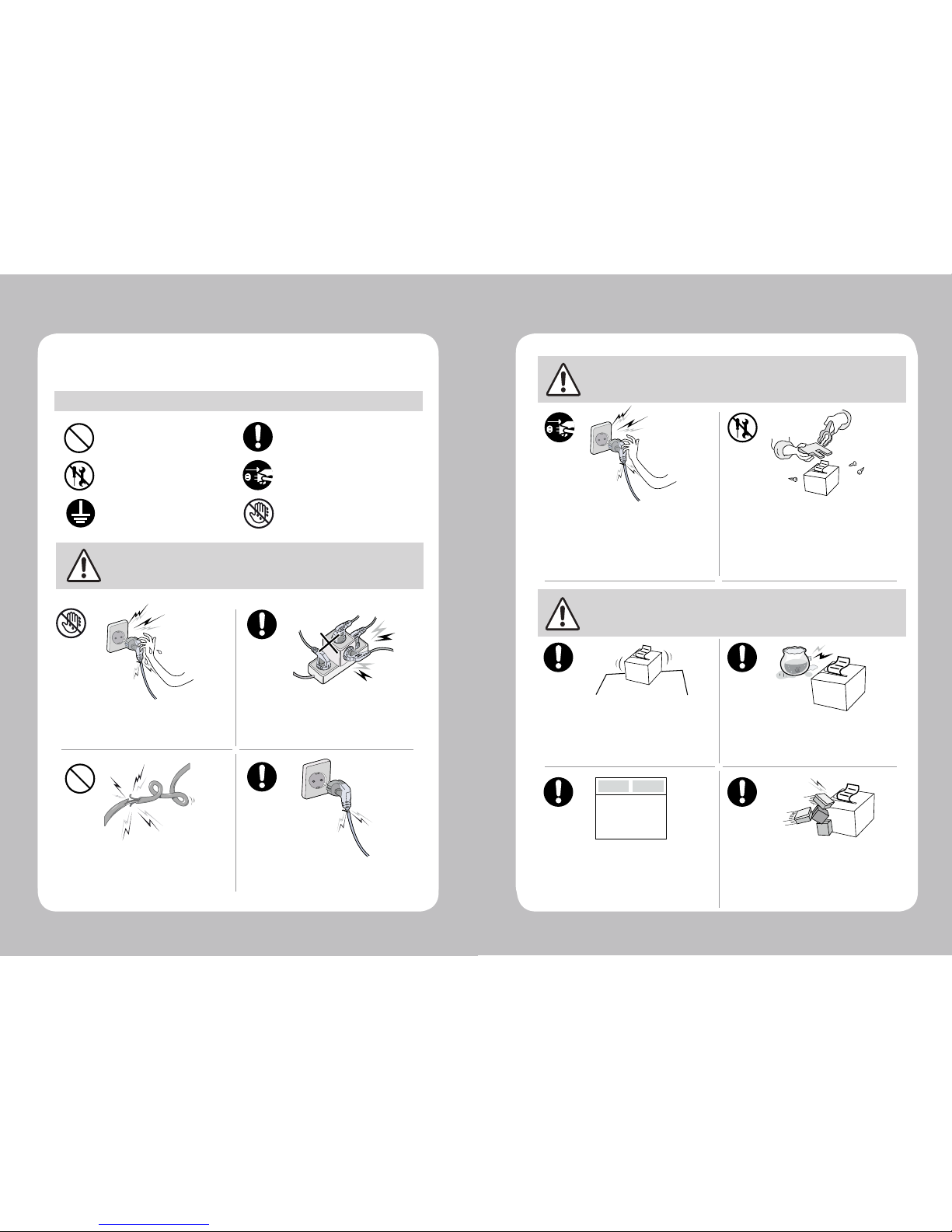

For higher reliability and safety, consider the following precautionary measures.

Read and follow the instructions carefully before running of the product.

1. Safety Caution

WARNING

Failure to follow these instructions could result in re, electric shock,

or other injuries, or property damage

Indication

Prohibition

(Potential risk of electric shock or re)

(Potential risk of electric shock or re) (Potential risk of electric shock or re)

(Potential risk of electric shock or re)

Must follow

Do not disassemble Unplug the power from the

outlet

Grounding to prevent electric

shock

Do not handle the product

with wet hands

Do not pull or touch the power plug with

wet hands.

Do not bend the wire and do not allow the

wire to be pressed by heavy object.

If a power plug is broken or a plug is cut or

worn, do not use it.

Do not overload the power plug into one

outlet.

WARNING

Failure to follow these instructions could result in re, electric shock,

or other injuries, or property damage

Failure to follow these instructions could result in re, electric shock,

or other injuries, or property damage

(Turn off the power at installation,

transportation, wiring and inspection.)

(You may get hurt and it can be broken

when it falls)

(Potential risk of re or unit malfunction)

(Potential risk of re or unit malfunction)

(Potential risk of discoloration or

electric shock)

(Potential risk unit malfunction, electric

shock or re. When the product needs

to be repaired, please contact in place

where you ordered.inspection.)

Dealer

Do not pull out the power plug to turn off

the product.

Do not install the product in uneven or

inclined surface.

If the product that needs to be repaired,

please contact in place where you ordered.

Please do not give excessive shock.

Keep product away from the water and

other material.

Do not disassemble, repair or modify the

product.

CAUTION

67

2. Unpacking

Printer Battery

AC Cord

Roll paper

Belt Strap+Bracket

USB Cable

Charger CD (Manual)

Quick Manual

Set Cradle Leather case

(Standard or MSR & IC Card) Belt Clip

Adaptor

Optional

Standard

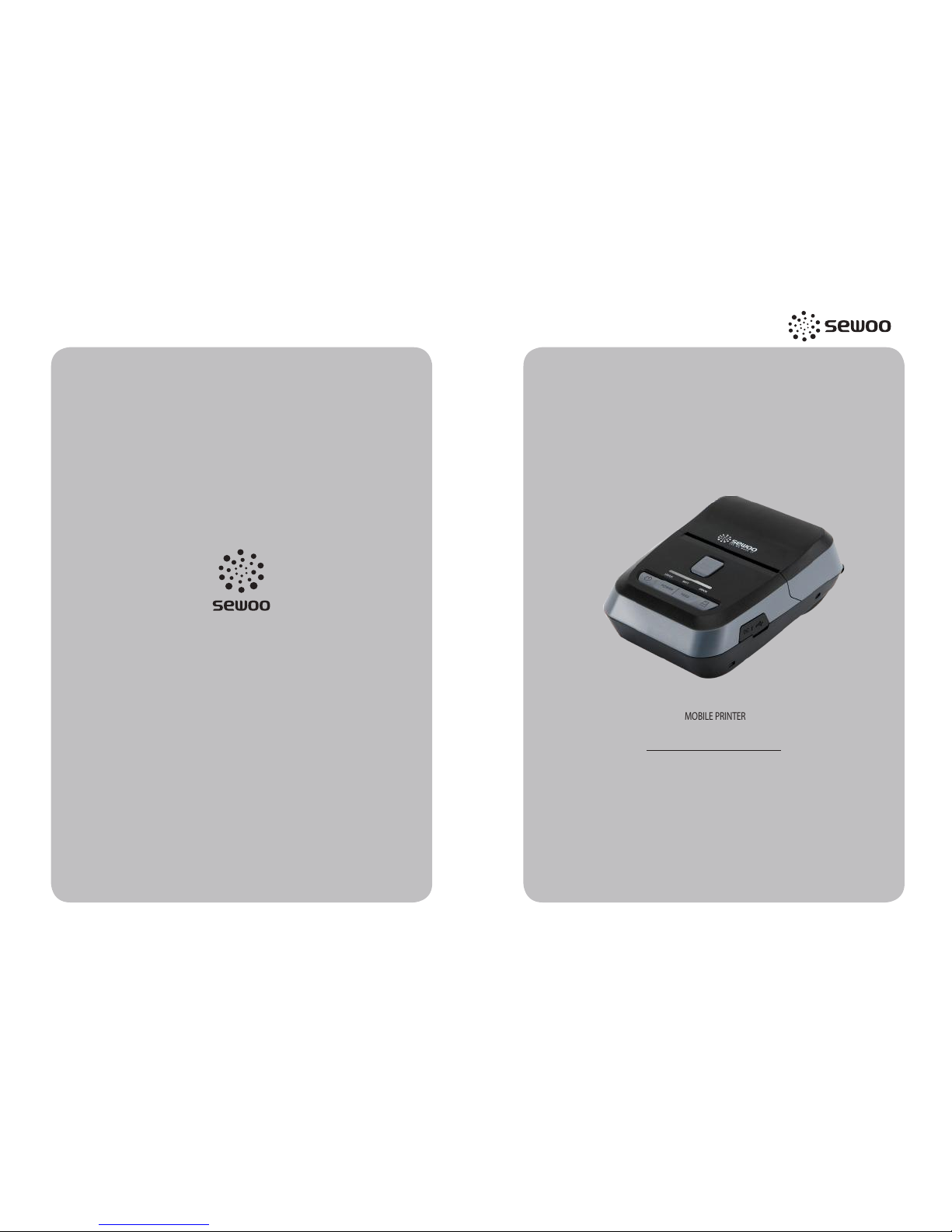

3. Product overview

Paper feed

Button

Open Button

Power

Button

Control

Panel

DC Power

USB

Belt clip hole

Battery

Front

Rear

MSR & IC CARD (Optional)

MSR

ICR

89

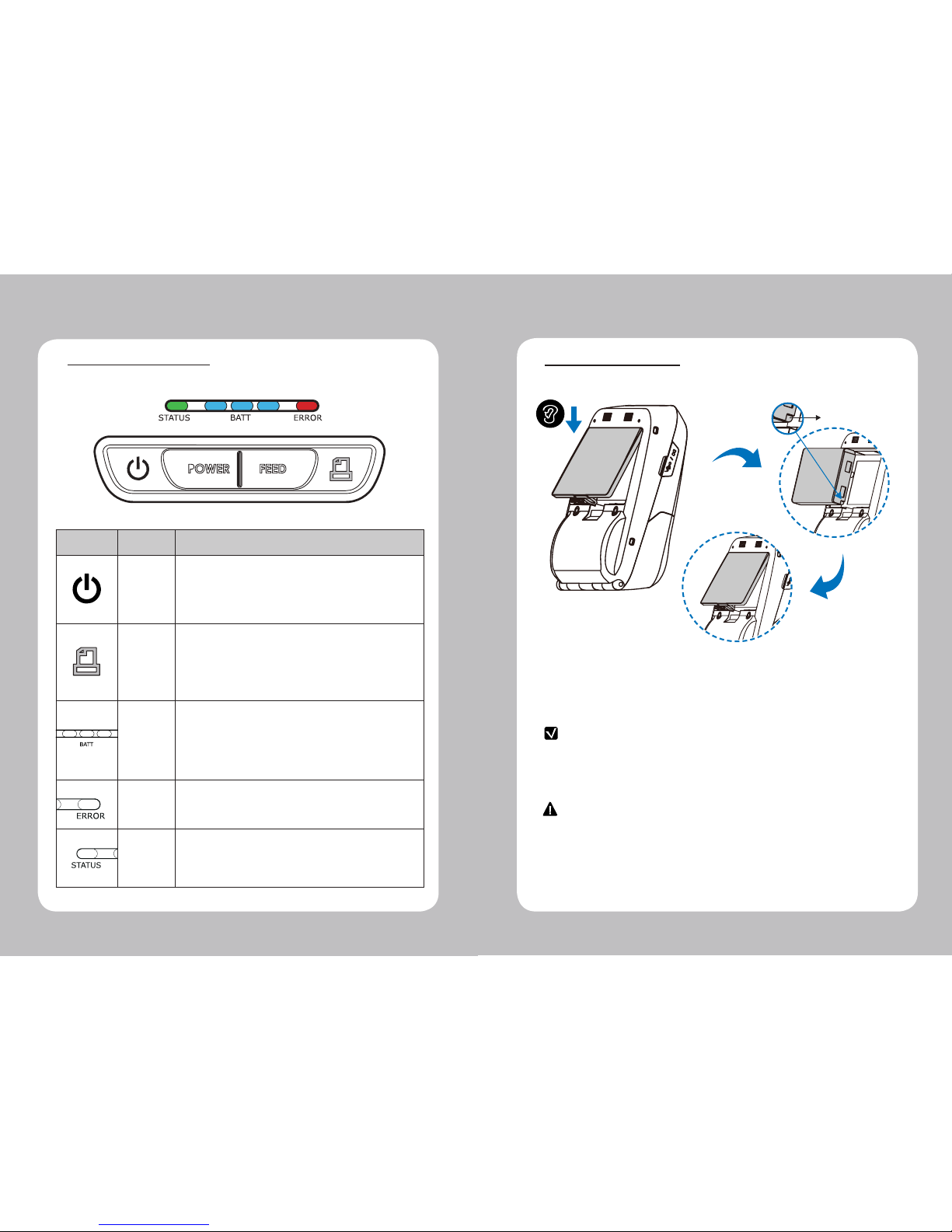

Button

Name

function

Power

Button

This button is used to turn the printer on and off.

When the printer is off,press this button for approximately 3 seconds

and it will turn on the power.When you press this button in a state

that the printer is on, the printer will turn off.

Paper

Feed

Button

Paper output can be done manually by pressing this button.

Additionally, self-testing and Hexadecimal Dumping can be

processed..

1. Refer to “MANUAL” for self test information.

2. Refer to the service manual regarding Hexadecimal Dumping.

Battery

Status

Lamp

1. If the Batt, LED are Lit,the battery is fully charged.

2. If you can hear beeping sound and LED light is turned off, it means

that the battery is at the lowest level.

3. If the battery is not charged at all, the printer turns off

automatically.

Error

Lamp

If the red light is turned on, it means there is no paper roll or the

paper cover is open.

LINK/

Power

Light

- LINK : LED BLINK

- POWER ON :BULE LED ON

- POWER OFF : LED OFF

4. Usage and Installation

4-1 Control panel usage

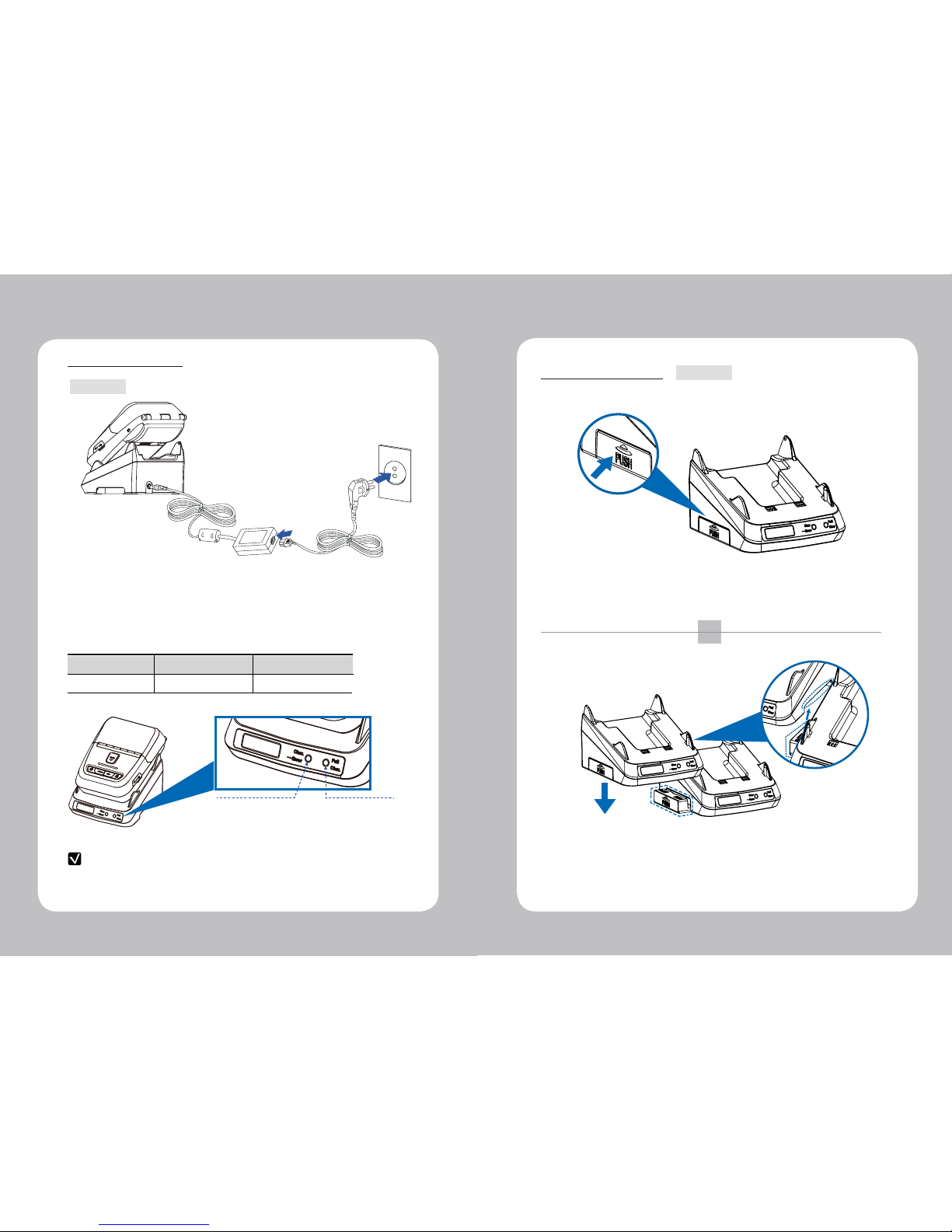

1. Align battery hook as shown in the picture

2. Push the battery into the printer until it locks in place.

NOTE

As the battery is not charged at the time of your purchase, charge the

battery prior to using the printer

(Battery charger or Cradle can be used to charge)

Hook

4-2 Battery Installation

CAUTION

Risk of explosion if battery is replaced by an incorrect type.

Dispose of used batteries according to the instructions

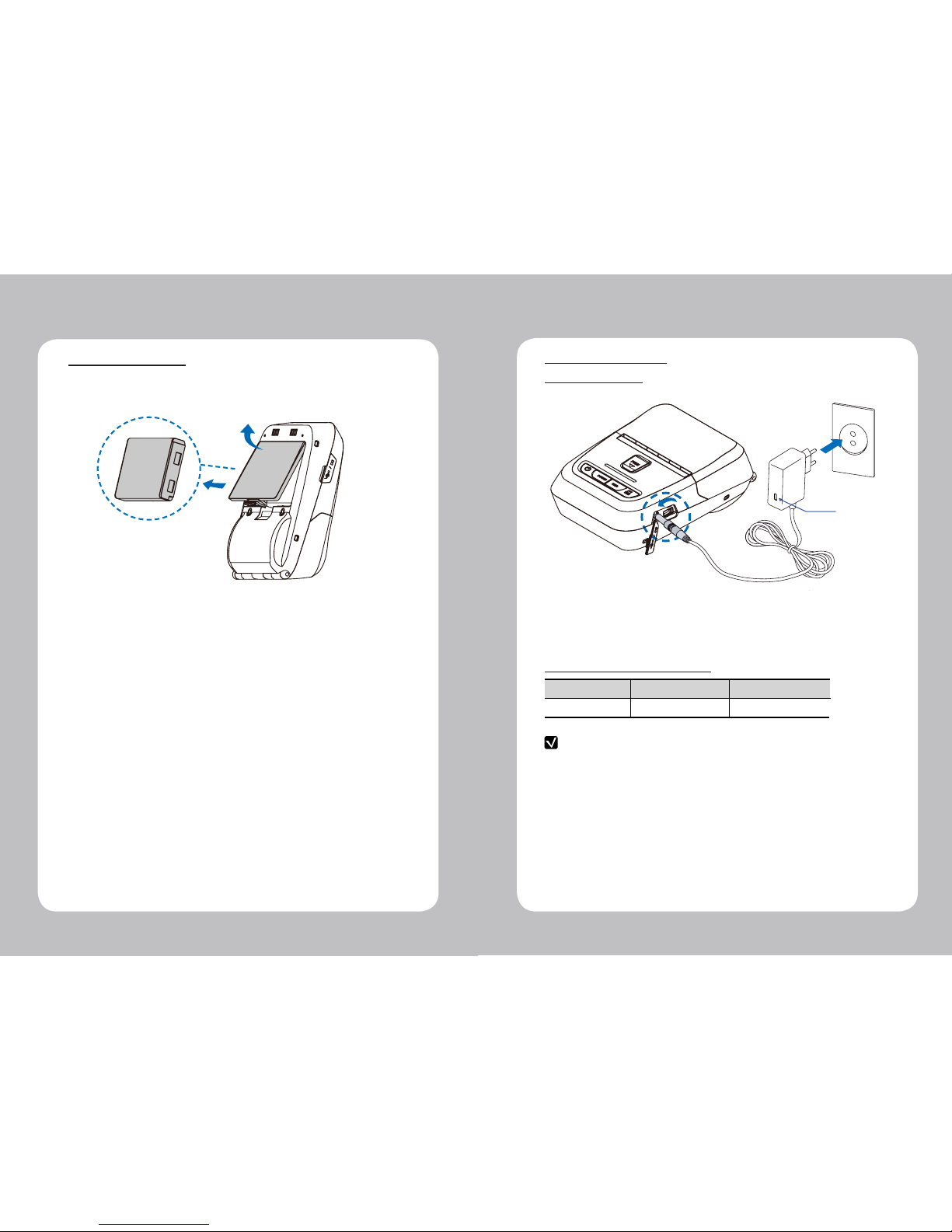

10 11

4-3 Battery removal

NOTE

1. Unless the exclusive charger is used provided by the manufacturer, the printer

can be damaged, and the manufacturer is not liable for the consequential damage.

2. Before removing the battery, make sure that power is turned o.

3. Printer does not work in the status of being connected with charger only.

4. The battery should be installed to operate printer.

5. While charging, do not turn on the power.

6. Do not operate the print while charging the battery.

7. Do not connect the charger while the printer is operated.

4-4 Battery charging

1. Be sure that the printer is turned o.

2. After open the DC JACK cover, insert DC JACK into the printer.

3. Plug the power cord to electrical outlet.

Lamp

4-4-1 The status of lamp in charging

Status charging charging complete

Charging Lamp Red

Green

Remove the battery as shown

OPEN

4-4-1 charging usage

12 13

4-4-2 charging set cradle

Status charging charging complete

Charging Lamp Red

Green

NOTE

In the case the printer is not xed properly in the set cradle, the red lamp will

be blinking, Then, extract and reinsert the battery.

4-5 Set Cradle usage

1. Place the printer into the set cradle as shown above.

2. Connect the DC JACK to the set cradle.

3. Plug the power cord into the electrical outlet.

4. Once the charging is completed, remove the printer from the set cradle.

Optional

Optional

CHARGING (RED ON)

ERROR (RED Flicker)

CHARGING COMPLETE

(GREEN ON)

1

2

Press the PUSH button to pop

the cradle slide out.

Align the second cradle to the slide of existing cradle,

and connect each other by pressing down.

(To disassemble, repeat these steps in a reverse order)

14 15

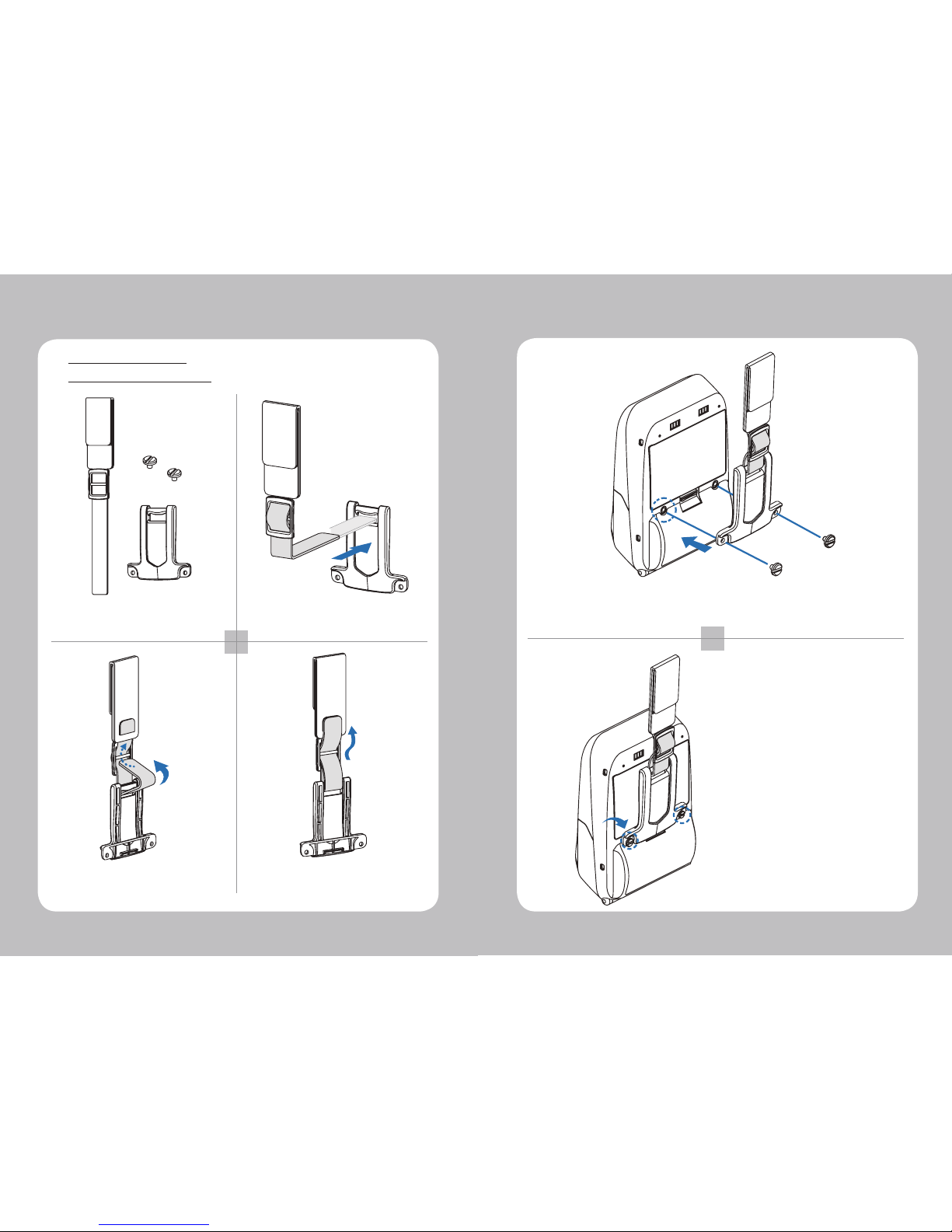

1 2

34

Prepare a belt strap, bracket

and 2 screws.

Slide the strap into the loop on

the back side.

Put the strap into the hole on the

top of the belt bracket.

Make sure the strap is fastened

enough to use.

4-6 Belt Clip & Strap

5

6

After connecting the strap and bracket, insert the screws

in the bracket xed hole.

Use a screw driver to tighten

the bracket.

4-6-1 Belt Strap+bracket usage

16 17

1 2

34

Press the PUSH button to open

the paper cover.

Pull a short length of paper out of

the printer and close the cover.

Insert the paper in the right

direction.

Tear o the additional paper using

tear bar.

4-7 Roll Paper installation

1

2

As shown in the picture, tighten the screw with a screw driver.

Insert the belt clip screw into the hole of Belt clip.

4-6-2 Belt clip usage Optional

18 19

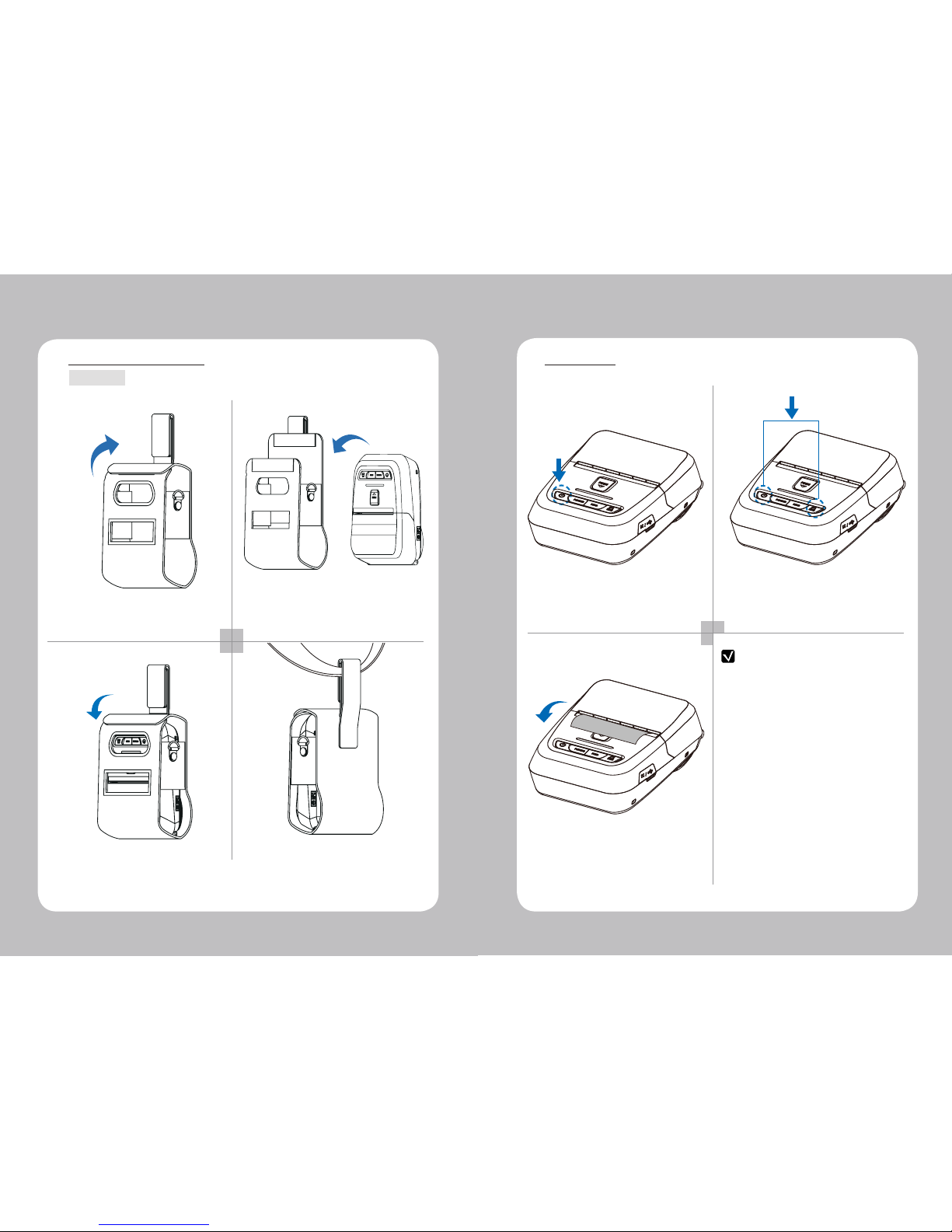

1 2

34

Open the leather case.

Close the Velcro and stick the

cover.

Place the printer into the leather

case.

Fasten to the belt by using the strap

at the rear of the leather case.

4-8 Leather case usage

Optional

1 2

3

NOTE

Turn o the power pressing the

power button for approximately

3 seconds.

The printout is produced.

While you are pressing the FEED

button, press the power button.

4-9 Self Test

1. To enter hex dump mode, press the Feed

button once more

2. If the Feed button is not pressed,

self test will be nished automatically

after 3 seconds

20 21

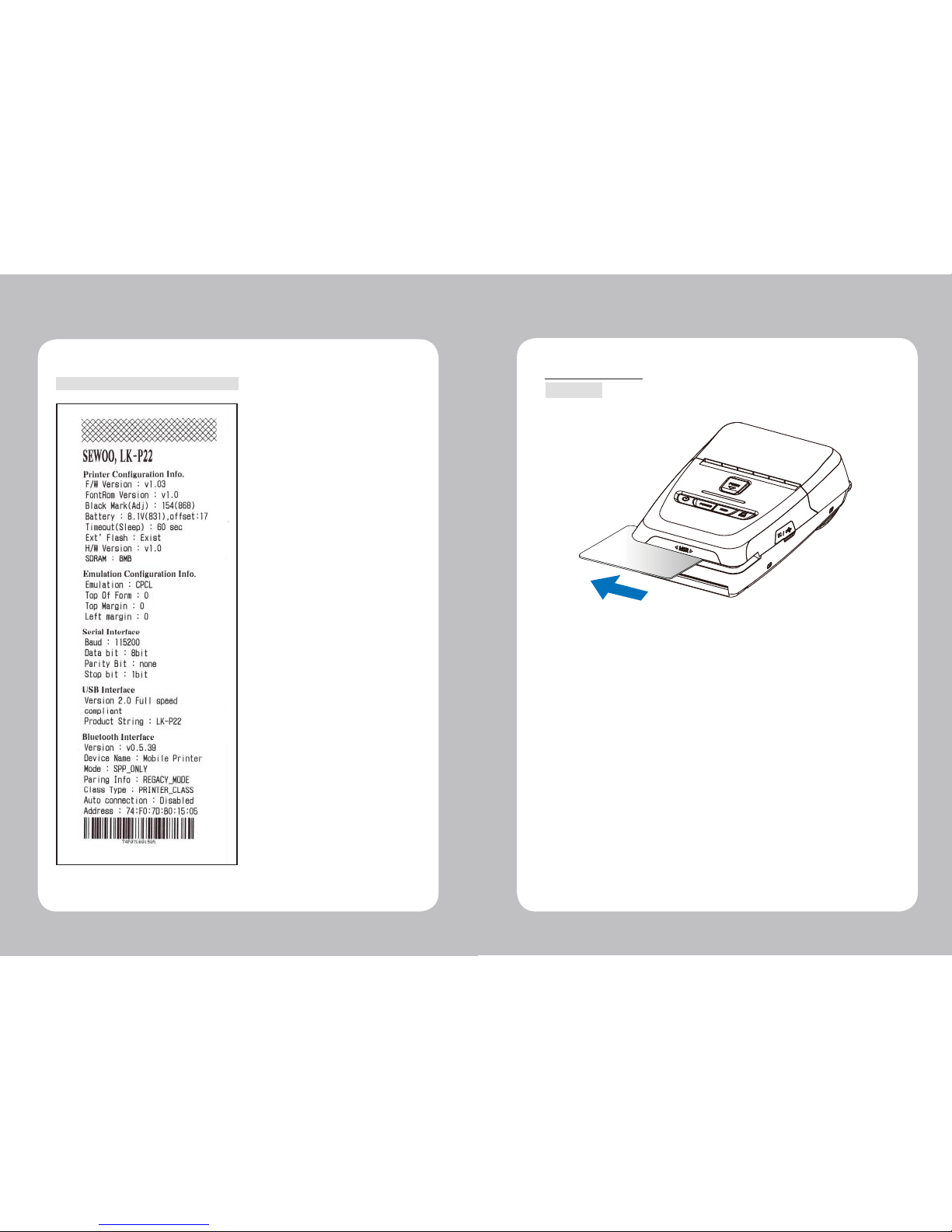

When the printer is installed initially or

when you face a problem, you can run the

self test and check the information about

-Control Circuit, Mechanism, Print Quality,

ROM Version

After checking with self-test and no issues

are found, you can examine other

devices and software. This function is

working independent of devices and

software.

●

Motor protection from being overheated

The motor should be stopped and cooled

about more than 30 seconds after

continuous printing 1.5 meter

The sample of self test printout

Insert and swipe the card in the direction of the arrow as shown in the picture.

Optional

4-10. MSR usage

22 23

Optional

Insert the card in the direction of the arrow as shown in the picture.

4-11. IC CARD usage

5. Peripherals connection

This product can communicate with other devices via

Bluetooth communication and cable.

5-1. Bluetooth connection

1. The Printer can be connected to devices equipped with Bluetooth communication

capacity (PDAs, PCs, etc.)

2. Use the Bluetooth connection function supported by the device to connect

to the printer.

NOTE

Refer to the

Bluetooth

Manual for more details on connection.

Optional

24 25

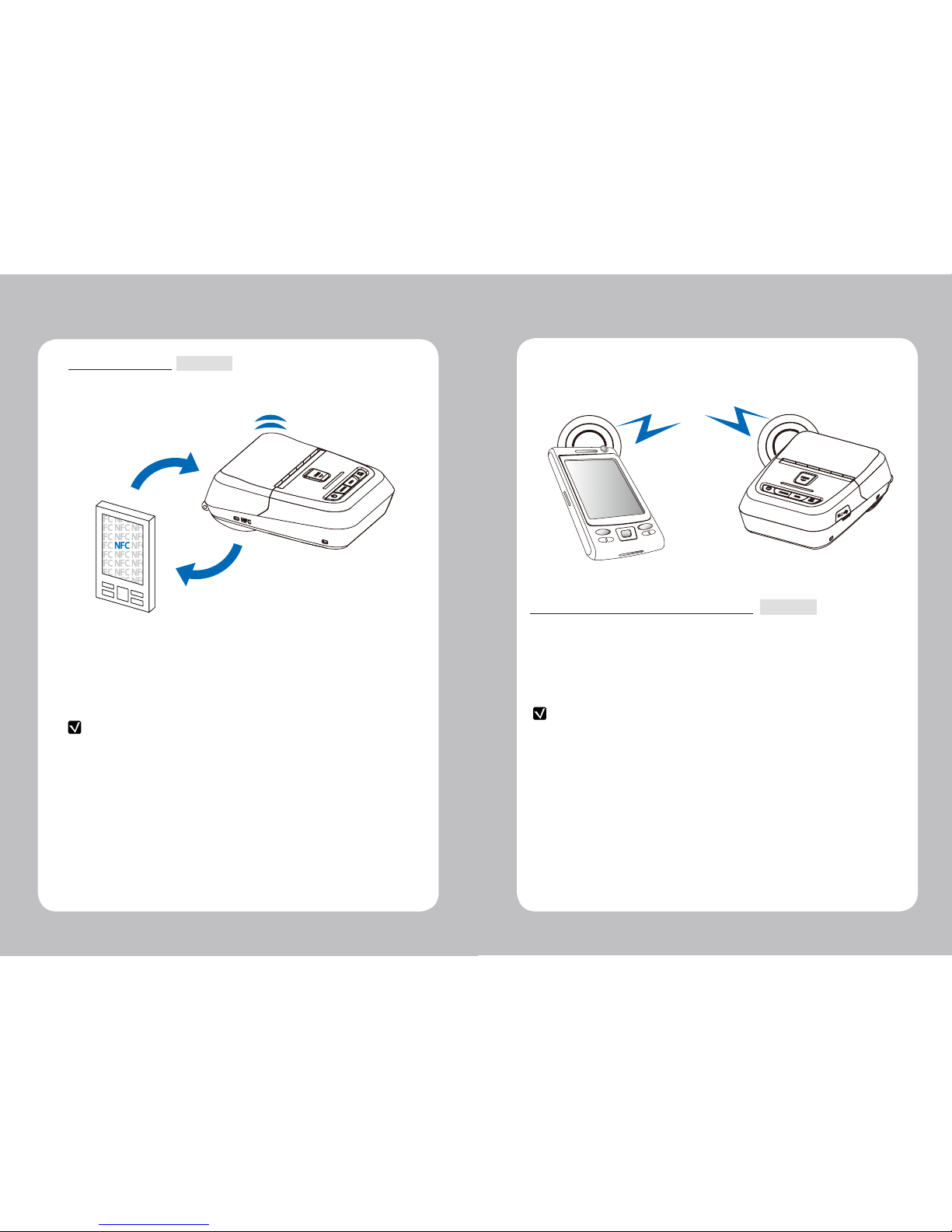

5-1-1. NFC connection

1. The printer can be connected to devices equipped with NFC

communication capacity.

2. Use the NFC connection function supported by the device to connect

to the printer.

This product can communication with other devices via NFC communication.

NOTE

-refer to the NFC Manual for more details on connection.

-NFC is compatible with only Bluetooth.

This product can communicate with other devices via

Wi-Fi communication and cable.

5-2. Wi-Fi(802.11 a/b/g/n) connection

1. The Printer can be connected to devices equipped with Wi-Fi(802.11a/b/g/n)

communication capacity (PDAs, PCs, etc.)

2. Use the Wi-Fi(802.11a/b/g/n) connection function supported by the device to

connect to the printer.

NOTE

Refer to the Wi-Fi(802.11a/b/g/n) Manual for more details on connection.

Optional

Optional

26 27

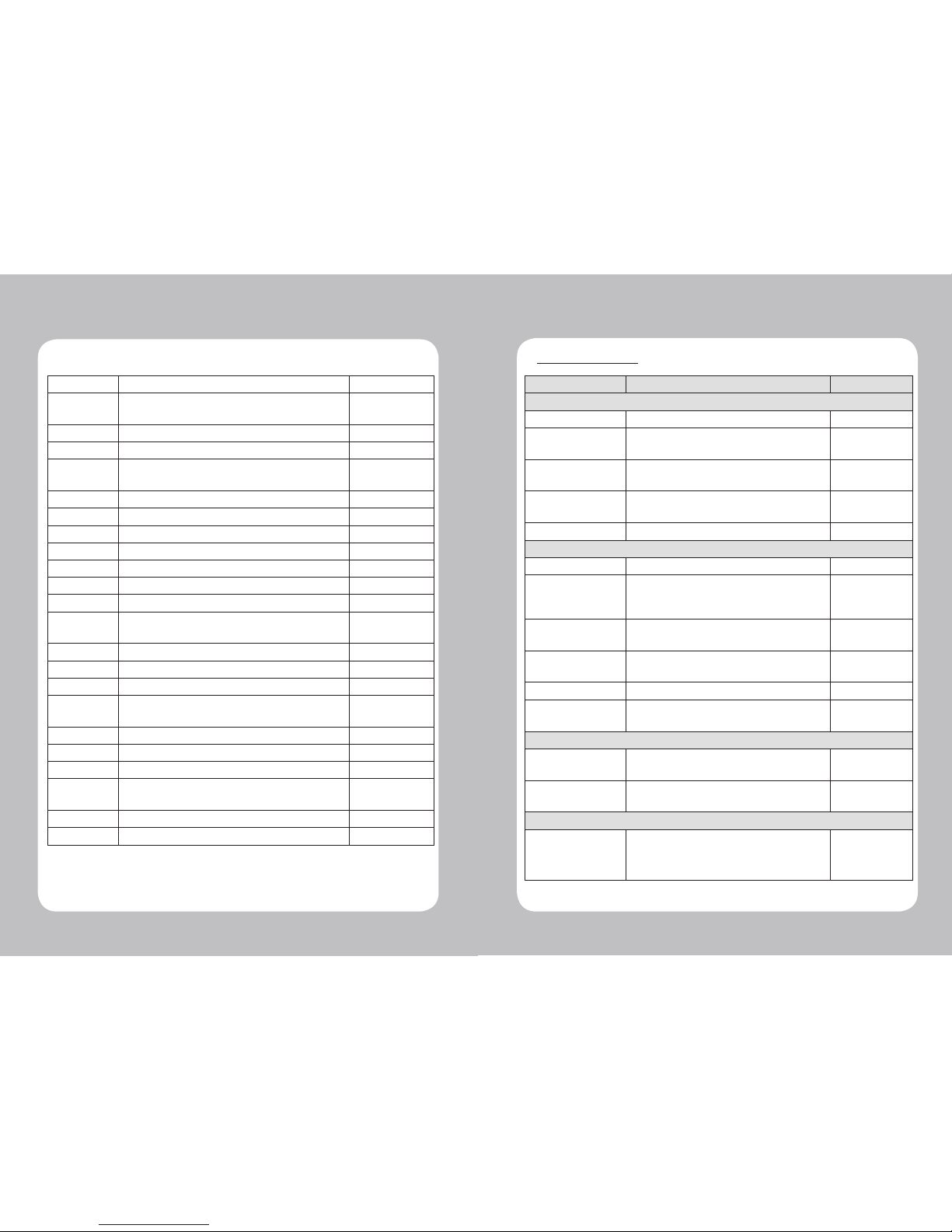

6. Roll media specification

Core

Diameter(A) 12.5mm +/-0.5mm

Roll

Max.diameter(B) Max. Φ40mm

Max.Media Width (C) Max. 58 ± 0.5mm

Min.media Thickness 0.06mm

Protect the media against sand, grit, and other hard particles during printing

and storage. Keep the cover closed. Even very small foreign particles may cause

severe harm to the delicate printhead.

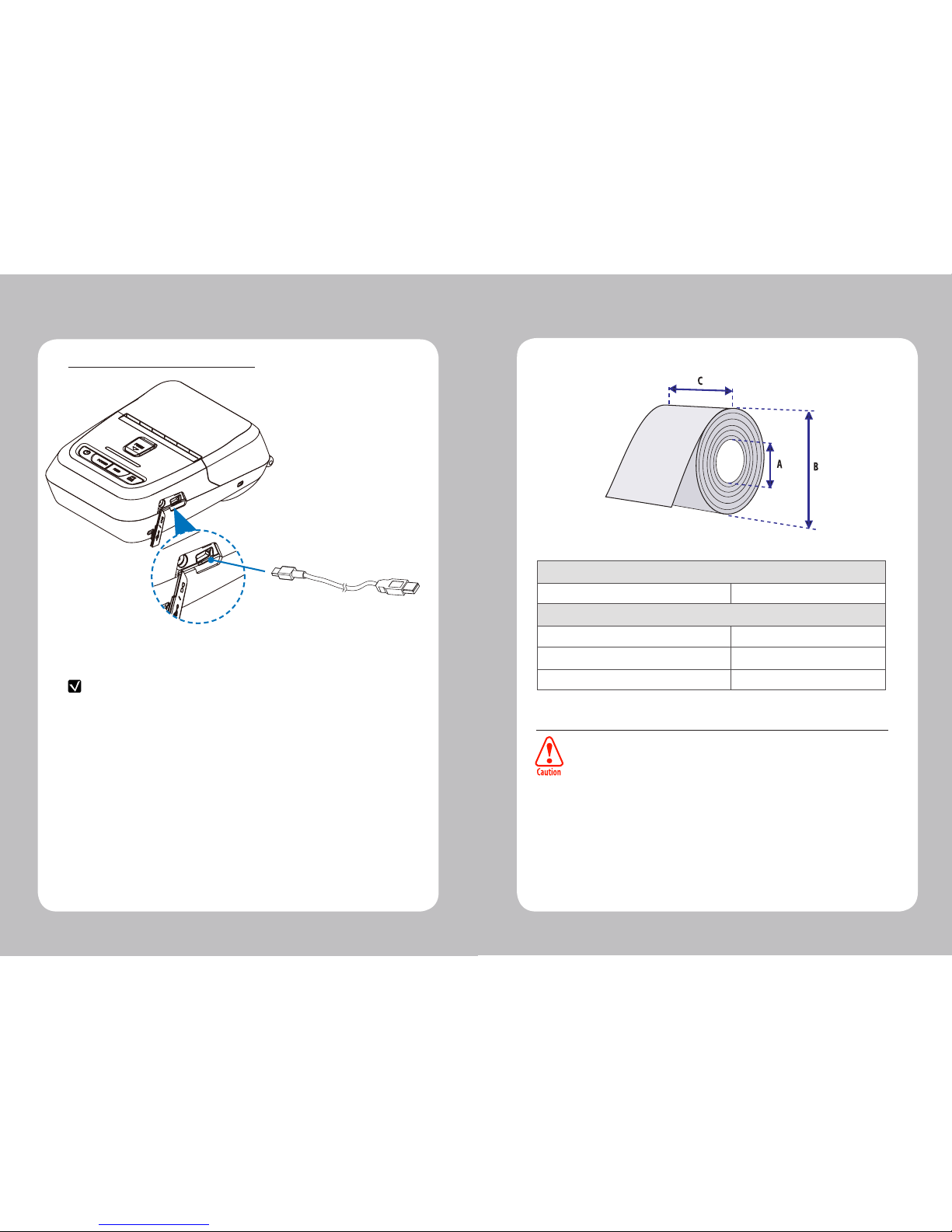

USB

5-3. Interface Cable connection

1. Connect USB cable into the cable connector on the printer.

2. Connect the interface cable into the USB port of the device

(PDA, PC, etc.)

NOTE

Use the cable oered by the manufacturer (USB)

28 29

8. Printer cleaning

If the interior of the printer is dusty, printing quality can lowered.

In such a case, follow the instructions below to clean up the printer.

NOTE

1. Make sure to turn the printer power o prior to cleaning

2. Regarding print head cleaning, as the print head sets very hot during

printing, turn o the printer power and wait approximately 10 minute before

commencement.

3. When cleaning the print head, take care not to touch the heated portion of the

print head. The print head subject to be damaged by static electricity.

4. Take care not to allow the print head to become scratched and /or

damaged in any way.

1. Use an applicator swab moistened with an alcohol solution to clean the print

head and remove any dusts.

2. Once the cleaning is completed, insert paper roll into the printer few minutes

later and close the printer cover.

Preventing Overheating

To prevent the motor from overheating, continuous driving of the printer

should be 1.5 m or less in print length. Set the pause time for 30 seconds

or more after driving the printer.

HEAD

7. Black Mark

58 (MAX PAPER WIDTH)

48 (PRINT WIDTH)

55

1.8 ~ 8.3

10 ~ 58

1.8 ~ 8.3

2.5

20 ~ 300

15

5

PAPER FEEDING DIRECTION

30 31

9. Printer Specification

9-1 Specication

Printing Method Direct Thermal

Printing Speed Max. 100mm/s

Resolution 203 DPI

Character ESC/POS FontA(12x24), FontB(9x17), Asian Font(KOR,

JPN,CHN_GB2312,CHN_BIG5)

CPCL Font0/1/2/4/5/6/7, 24x24 Asian Font(KOR,

JPN,CHN_GB2312,CHN_BIG5), Resident TTF,

Downloadable TTF

ZPL FontA~H, FontGS,Resident TTF(Font0), Download-

able TTF

Barcode ESC/POS 1D: EAN-8, EAN-13, Code39, ITF, UPC-A, UPC-E,

Codabar, Code93, Code128

2D: QR, PDF417

CPCL 1D: LUPC-A(+2,+5), UPC-E(+2, +5), EAN13(+2, +5),

EAN8(+2,+5), Code39 etc. (CPCL)

2D: QR, PDF417, MicroPDF417, Maxicode,

Datamatrix, Aztec, TLC39, RSS14

ZPL 1D : Code11, ITF, Code39, Planet, EAN-8, UPC-E,

Code93, Code128 etc. (ZPLII)

2D: QR, PDF417, MicroPDF417, Maxicode,

Datamatrix, Aztec, TLC39, RSS14

Emulation ESC/POS, CPCL, ZPL

Driver Window Printer Driver(10, 2012, 8.0/8.1, 7, 2008,

Vista, 2003, XP, 32 & 64bit),

Windows (CE 4.2 & 5.0 & 6.0 & 7.0 / Mobille 5.0 & 6.0)

Sensor Paper End Sensor, Cover Open

Sensor, Black Mark Sensor

Paper Paper type Thermal Paper

Width Max. 58±0.5mm

Thickness 0.06mm

External Diameter Max. Φ40mm

Internal Diameter 12.5mm +/-0.5mm

Reliability TPH 50km

PulseActivation 50,000,000 pulse or more(12.5% Print Ratio)

Interface Standard USB

Option Bluetooth Smart Ready Ver 4.2

or Wi-Fi(802.11a/b/g/n)

Battery Charger Input AC100~240V, 50/60Hz

Output 8.4V , 800~1400mA

Battery Battery type Li-ion

Output 7.4V, 1510mAh

Charging time 2 Hrs (MSR+ICR : 2.5 Hrs)

EMV II

(Optional) MSR Card Standard ISO 1&2&3 or ISO 1&2&JIS-II

Track ISO Track 1&2&3

Magnetic Head Life 500,000 Passes(minimum)

ICR Card Standard ISO 7816

Head Life Cycle 100,000 Passes(minimum)

Size

[W x D x H (mm)] Standard 80 x 119.4 x 44

MSR+ICR 80 x 135.8 x 44

Weight Standard 242.5g (With Battery)

MSR+ICR 280.8g (With Battery)

Temperature Operation -10~50℃

Storage -20~60℃

Humidity Operation 35 ~ 80%

Storage 10 ~ 90%

32 33

NOTE

Compatible Partially

Compatible

Not

Compatible

○●△x

Compatible with only

commanders provided

by the manufacturer.

10. Emulation Command Compatibility

ESC Command

Command Function Compatibility

HT

Horizontal tab

○

LF

Print and line feed

○

CR

Print and carriage return

○

FF

Print end position label to start printing

○

CAN

Cancel print data in page mode

○

RS

Beep 0.3seconds

○

DLE EOT

Transmit real-time status

○

DLE ENQ

Send real-time request to printer

○

ESC FF

Print data in page mode

○

ESC SP

Set character right-side spacing

○

ESC !

Set print mode

○

ESC $

Set absolute print position

○

ESC %

Select/cancel user-defined character set

○

ESC &

Define user-defined characters

○

ESC *

Set bit image mode ○

ESC -

Turn underline mode on/off

○

ESC 2

Select default line spacing

○

ESC 3

Set line spacing ○

ESC ?

Cancel user-defined characters

○

ESC @

Initialize printer

○

ESC D

Set horizontal tab positions

○

ESC E

Turn emphasized mode on/off ○

ESC G Turn double-strike mode on/off ○

ESC J Print and feed paper ○

ESC L Select page mode ○

ESC M

Select character font ○

ESC R

Select international character set ○

ESC S Select standard mode ○

ESC T Select print direction in page mode ○

ESC V Turn 90° clockwise rotation mode on/off ○

ESC W Set printing area in page mode ○

ESC \Set relative position ○

ESC a Select justification ○

ESC c 5 Enable/disable panel buttons

ESC d Print and feed paper n lines ○

ESC t Select character code table ○

ESC v Transmit paper sensor status ○

ESC { Turn upside-down print mode on/off ○

ESC 0xFF Macro ○

GS ! Select character size ○

GS $ Set absolute vertical print position in

page mode ○

GS * Define downloaded bit image ○

GS / Print down-loaded bit image ○

GS B Turn white/black reverse printing mode

on/off ○

GS H Select printing position of HRI characters ○

GS I Transmit printer ID ○

GS L Set left margin ○

GS P Set horizontal and vertical motion units ○

34 35

GS W Set printing area width ○

GS \Set relative vertical print position in page

mode ○

GS ^ Execute macro ○

GS : Start/end macro definition ○

GS a Enable/disable Automatic Status

Back(ASB) ○

GS f Select font for HRI characters ○

GS h Set bar code height ○

GS k Print bar code ○

GS r Transmit status ○

GS v 0 Print raster bit image ○

GS w Set bar code width ○

GS S C Set Serial Baud rate ○

DLE EOT n Selects card read mode / Cancel card

read mode ○

GS S P Power Save Mode ○

FS ! Set print mode(s) for Kanji characters ○

FS & Select Kanji character mode ○

FS - Turn underline mode on/off for Kanji

characters ○

FS . Cancel Kanji character mode ○

FS 3 Select Kanji character code system ○

FS S Set Kanji character spacing ○

FS W Turn quadruple-size mode on/off for

Kanji characters ○

FS p Print NV bit image ○

FS q Define NV bit image ○

CPCL Command

Command Function Compatibility

PRINTER COMMANDS

PRINT Terminate and print the file. ○

FORM Instruct the printer to feed to top of

form after printing. ○

JOURNAL Disable this automatic media

alignment. ○

UNITS Specify a measurement system for

all subsequent command fields. ○

USING COMMENTS Comments. ○

TEXT

TEXT Place text on a label. ○

FONT-GROUP(FG)

Give a user the ability to group up

to 10 pre-scaled font files into a

single group.

○

TEXT

CONCATENATION

Assign different character styles to

strings. ○

MULTILINE(ML) Print multiple lines of text using the

same font and line-height. ○

COUNT Is used for printing multiple labels. ○

SETMAG Magnify a resident font to the

magnification factor specified. ○

SCALABLE TEXT

SCALE-TEXT Specify the point size of both the

width and height of the font. ○

SCALABLE

CONCATENATION

Assign different character styles to

strings. ○

LINEAR BARCODES

BARCODE

prints bar codes in both vertical and

horizontal orientations at specified

widths and heights.

○

36 37

BARCODE-TEXT

Is used to label bar codes with the

same data used to create the bar

code.

○

COUNT

Is used for printing multiple labels

where a numeric text field or

numeric data encoded in a bar

code is to be incremented or

decremented for each label.

○

TWO-DIMENSIONAL BARCODES

PDF417 Produce the PDF417 barcode. ○

MICROPDF-417 Produce the MICROPDF-

417barcode. ●

MAXICODE Produce the MAXICODE barcode. ○

QRCODE Produce the QRCODE barcode. ○

DATAMATRIX Produce the DATAMATRIX barcode. ●

GS1(RSS-14) Produce the GS1barcode. ○

AZTEC Produce the AZTEC barcode. ○

GRAPHICS

BOX Produce rectangular shapes of

specified line thickness. ○

LINE Produce the lines of any length,

thickness, and angular orientation. ○

INVERSE-LINE Black areas re-drawn white, and

white areas re-drawn black. ○

PATTERN

Is used with the LINE and SCALE-

TEXT commands to change the

patterns used to fill these shapes.

○

GRAPHICS Print bit-mapped graphics. ○

PCX Send “.PCX” graphics formatted

images to the printer. ○

ADVANCED COMMANDS

CONTRAST Specify the print darkness for the

entire label. ○

TONE Specify the print darkness for all

labels. ○

JUSTIFICATION Control alignment of field. ○

PAGE-WDITH Specify page width. ○

PACE Batch printing. ○

NO-PACE Cancel the PACE and AUTO-PACE

mode. ○

WAIT Introduce a delay after a label is

printed. ○

SPEED Set the highest motor speed level. ○

SETSP Change spacing between text

characters. ○

ON-FEED

Can be configured to ignore, form-

feed, or reprint the last label when

the feed key is pressed or when

it receives a form-feed character

(0x0c).

○

PREFEED Advance the media a specified

amount prior to printing. ○

POSTFEED Advance the media a specified

amount after printing. ○

COUNTRY/

CODE PAGE

Substitute the appropriate character

set for the specified country. ○

FORMAT FILES Identify format and data respectively. ○

BEEP Sound the beeper for a given time

length. ○

Other manuals for LK-P22

1

Table of contents

Other SEWOO Printer manuals

SEWOO

SEWOO SLK-TL122 User manual

SEWOO

SEWOO LK-P41W User manual

SEWOO

SEWOO LK-D10 User manual

SEWOO

SEWOO SLK-T20EB Series User manual

SEWOO

SEWOO SLK-T32EB Series User manual

SEWOO

SEWOO SLK-T21EB Series User manual

SEWOO

SEWOO STL202II User manual

SEWOO

SEWOO SLK-T12EB User manual

SEWOO

SEWOO SLK-TS400 Instruction Manual

SEWOO

SEWOO SLK-TE21 Series User manual

SEWOO

SEWOO LK-B10 User manual

SEWOO

SEWOO SLK-TL21 Series User manual

SEWOO

SEWOO SLK-TE20 Series User manual

SEWOO

SEWOO LK-P30 Installation instructions

SEWOO

SEWOO LK-P12W User manual

SEWOO

SEWOO LK-P300 User manual

SEWOO

SEWOO LK-P20II User manual

SEWOO

SEWOO LK-P43II User manual

SEWOO

SEWOO LK-P43 User guide

SEWOO

SEWOO LK-P30W User manual