SGS electronic TVC-TRF-10-MBT V2 User manual

TVC-TRF-10

(MBT V2)

Full option module with sound for RC-battle tanks

in 1 16th to1 25th scale

This module was developed to enable complete control of battle tanks.

This revised second edition of the module has been extended by the

following features:

–integrated battleunit

–polyphonic sound

–random sounds

–model change (up to three models can be controlled with one

transmitter)

–light control can the switched by RC

–automatic turn off

For different tanks there are versions available with sounds for::

#258120 HT1: Tiger 1 #258121 HT2: T-34

#258122 HT3: Panther #258123 HT4: Stug III

#258125 HT5: Panzer III

#258126 HT6: Walker Bulldog

#258102 MT1: Leopard 1 #258103 MT2: Leopard 2

#258107 MT6: Abrams #258110 MT9: T-55

instructions TVC-TRF-10-MBT_V2.odm Seite 1 von 29 Stand 13.10.11

Note:

Installation of the module requires intermediate to advanced

modeling skills Soldering skills are required to connect the wiring

Inexperienced modelers and persons under 16 should seek the

assistance of an experienced modeler

instructions TVC-TRF-10-MBT_V2.odm Seite 2 von 29 Stand 13.10.11

Overview:

This module will provide the following functions:

•proportional drive motor control with mixing

•proportional turret rotation with servo output and speed control

•proportional barrel elevation with servo output and speed control

•cannon fire and recoil with strobe LED flash and servo output

•MG LED

•polyphonic sounds for all functions (engine start stop idle,14 drive

stages, main gun, MG, turret turn, barrel elevation)

•automatic control of brake light, flashing light, rotating flasher

•battle-function

•model selection for up to three models

•automatic control of smoke pump and heating element

The controller is rated for an input of 7.2V to 12V. A 10A fuse protects

the module and the battery from over current. The module has 2

microprocessors with fail safe functions to prevent unintended operation

of the model.

The modul is equipped with a BEC circuit, that supplies the modul itself,

the receiver and the servos with a regulated 5V voltage.

scope of delivery:

–9 servo leads for X10 to X17 and/or X20 to X21

–speaker connection cable for X70

–connectors for X01, X02 and X60

–servo patch cable to connect the modul to the receiver

–10 resistors to connect LE

instructions TVC-TRF-10-MBT_V2.odm Seite 3 von 29 Stand 13.10.11

Function:

A proportional radio transmitter is required. It needs at least four

channels and max. six channels. The channels 5 and 6 can be plugged

optional. The functions of the channels are as follows:

Channel 1 - Proportional left right with integrated V-mixer. The

integrated mixer slows the inside track to a full stop. Deflection of the

stick while stopped causes the vehicle to pivot steer. (This channel

provides turn signal information)

Channel 2 - Proportional forward reverse. This channel also provides

the information for brake and reverse lights, and smoke generator.

Channel 3 - Proportional cannon elevation. With rapid stick operation to

full deflection the MG (upper limit) or the primary weapon (lower limit) is

fired. For the MG a lamp LED flickers to the sound, for the main gun an

LED is flashed. For the main gun a motor output is switched, and an

LED flashes. Recoil is also simulated with rapid retreat and slow return

of a servo output.

Channel 4 Proportional turret rotation

Channel 5 Controlling the light mode

Using this channel, the rotating flasher and the flasher can be controlled.

In addition there are two lamp outputs that can be used for individual

switch functions, e.g. light or beamers lamps.

If this channel leaves unplugged, all outputs are turned off. The rotating

flasher outputs are only active if a BattleUnit hit happens and the outputs

for the flashers become active when turning the model left right.

Channel 6 turn model of change model

Case the model is switched off by leaving the neutral position, the model

stops acting when channels 1 to 5 are controlled and the engine off

sound is played.

This feature can be used to play the engine start stop sound by the RC.

But it can the used to switch between up to three different models. To

archive that, the appropriate model must be switched on, when the

channel 6 switch is positioned in a unique position. The modul stores

this position as „turn on“ position. Leaves the switch this position, the

model becomes passive and can not be moved. However, in this state it

can still be fired by other tanks and model reacts to this by rumbling, hit

indicator and the hit counter increments.

instructions TVC-TRF-10-MBT_V2.odm Seite 4 von 29 Stand 13.10.11

To to this it is obvious, that you need receivers with the same channel

crystals. When using 2.4GHz receivers, they must be bound to the same

transmitter.

The use of this channel is optional.

Connection of the servo wires at the receiver

channe

l

connector optional Function

1 X50 no steering

2 X51 no throttle

3 X52 no cannon elevation and firing

4 X53 no turret rotation

5 X54 yes light mode control

6 X55 yes model select

channels 1 to 4 must be connected to the receiver, channel 5 and 6 can

be used optional.

instructions TVC-TRF-10-MBT_V2.odm Seite 5 von 29 Stand 13.10.11

Automatic functions:

Cannon:

When the cannon is fired, the following actions take place:

–the sound of the main gun is played

–the gun flash LED output is switched for about. 200milliseconds

–the gun motor output is switched for about. 800Milliseconds. This

output can be used to trigger a barrel recoil unit with stop switch.

–a servo output provides a rapid recoil and slow return to fire

position. The complete cycle must operate before firing the

weapon again.

–there is a rumble in the drives

–the modul transmits an infrared battle unit signal

MG:

The MG light flashes at approximately two times per second when

shooting and the sound module plays the recorded MG sounds.

instructions TVC-TRF-10-MBT_V2.odm Seite 6 von 29 Stand 13.10.11

automatic engine stop:

In case the radio is unoperated for about 2 minutes, the modul turns off

the engine and plays the engine stop sound. Additional the exhaust

simulation is switched off. (parking mode)

To wake the modul, just move the throttle stick, then the engine startup

sound will be played and all functions are available again.

When the modul is parking mode, random sounds are played. E.g. this

can be sound from construction machines, music or walkie talky noise.

These sounds, like all others on the modul, can be changed.

You can also change to the parking mode by turning off the radio. When

doing this, no random sound is played.

TIP:

If you use a failsafe receiver, the receiver delivers signal output when the

radio is turned off. For that reason the modul can not detect the

unpowered radio. Please turn off failsafe function or use a normal

receiver.

instructions TVC-TRF-10-MBT_V2.odm Seite 7 von 29 Stand 13.10.11

Automatic functions:

Exhaust simulation module:

The module will control a liquid smoke heater and pump fan . The

smoke liquid heater is switched on when the model receives a valid radio

signal. The outputs for the blowers and pump are operated as a function

of acceleration and speed. At idle the smoke is inactive. As the model

accelerates,smoke increases proportional to setting and duration of the

throttle. During steady throttle travel the output is reduced by 50% (by

means of PWM)

Reverse light:

The reverse light output is linked to channel 2 and is automatic. When

the throttle lever (channel 2) is in neutral or straight-ahead position the

reverse light circuit is turned off.

“Rotating” flasher light:

The flasher runs constantly at close to 1.5 cycles per second. The

flasher can be controlled by light mode 2.

Turn signals:

Starting from a minimum of 10% throttle the signal lights will flash left or

right as required. In lifting and clearing mode the light operate as hazard

lights. Because turn signal is not reasonable when digging, this

automatic function can be turned off, controlled by light mode 2.

Brake light:

The brake light is automatic. Lights go out automatically with resumed

throttle.

instructions TVC-TRF-10-MBT_V2.odm Seite 8 von 29 Stand 13.10.11

Installation:

Before installing the model it is best to connect the components on the

workbench. Familiarize yourself with the operation of the components.

Pay particular attention to the maximum travel of the servos.

You do not have to connect all loads. For basic operation it is sufficient

to power the modul and to connect all servo inputs that are not „optional“

to the receiver.

It is recommended to connect the speaker in this early state, because

you can hear the action that should be activated.

In the following section the position and orientation of the connectors are

explained. The exact function of each connector is described later in

detail.

instructions TVC-TRF-10-MBT_V2.odm Seite 9 von 29 Stand 13.10.11

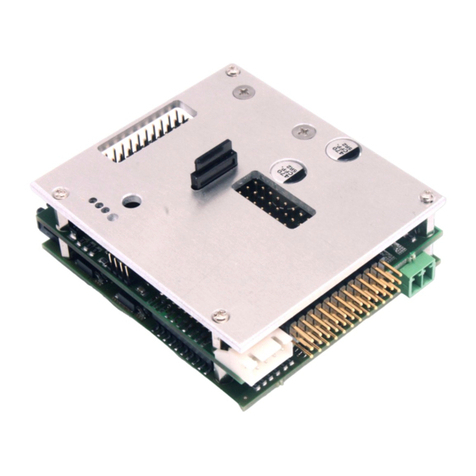

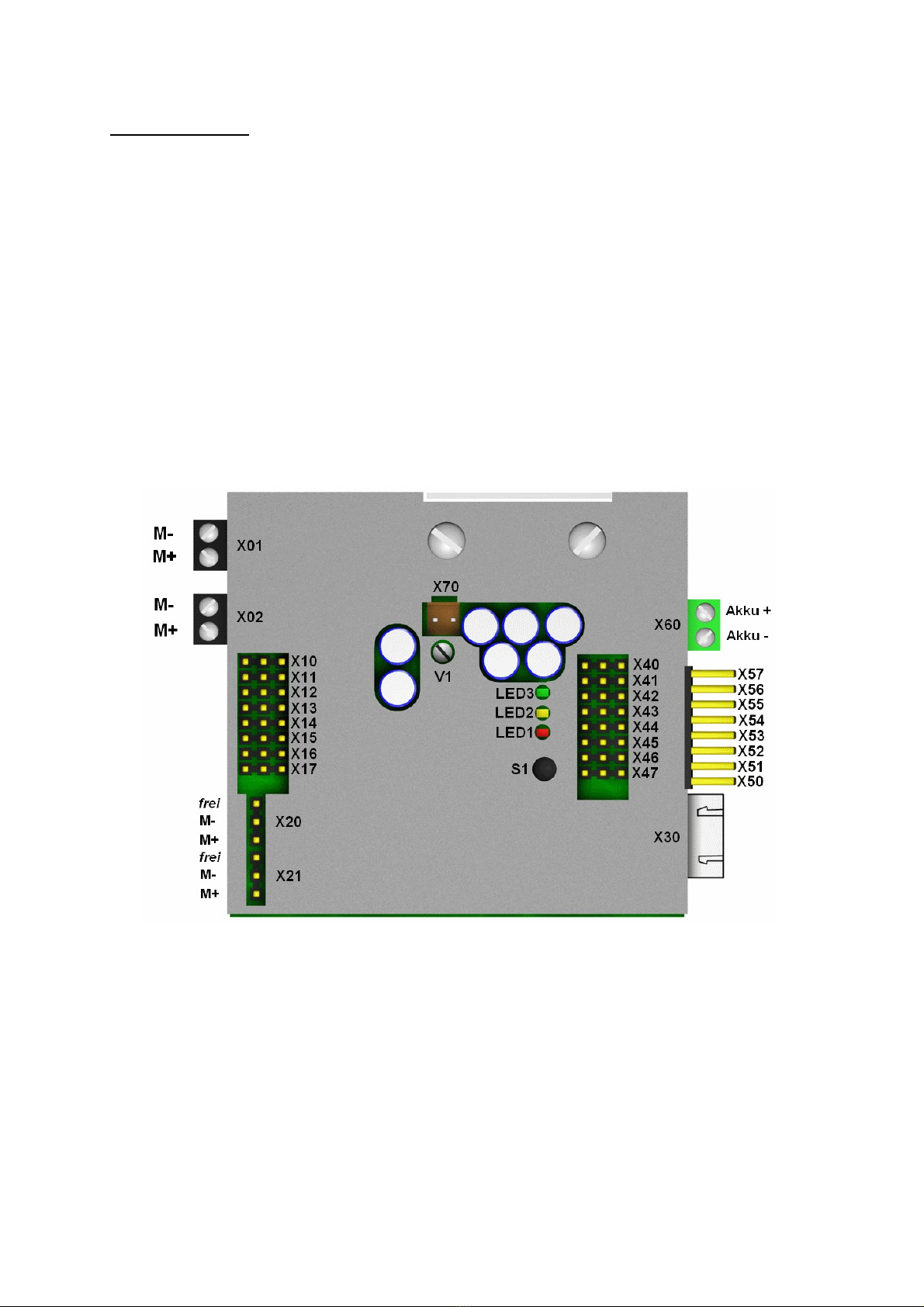

Abbildung 1: Connector Overview

connection of the servo inputs to the receiver (X50 to X57):

The connection to the receiver is

made using patch cables. One side

is plugged into the modul and one

side is connected to the receiver. If

the delivered cables does not match

the length needed, they can simply

be replaced by longer or shorter

versions.

The adjacent picture shows how the

connectors are plugged into the

modul.

The ground (black or brown line of

the servo cable) is closest to to the

bottom of the module.

connection of the servo outputs (X40 to X47):

The servos that are controlled by the

modul are connected to the

connectors X40 to X47.

Servos from Robbe Futaba or

Graupner JR can be connected

directly to the module. The ground

(black or brown line of the servo

cable) is closest to to the exterior of

the module.

The last servo position is stored with

the module memory. Because of that

you do not have to expect bis servo moves when powering the modul.

However, when powering the model, a short servo move may happen.

Make sure your servos can achieve the required position. When servo

travel is blocked current flow can be 300-500 mA instead of the usual

40mA at rest. This can lead to hight temperatures of the modul,

because the BEC has to deliver high currents.

instructions TVC-TRF-10-MBT_V2.odm Seite 10 von 29 Stand 13.10.11

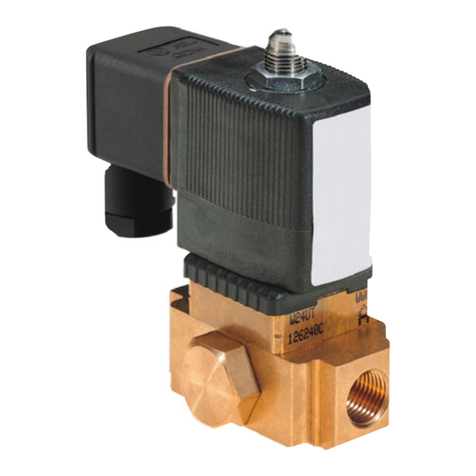

connection of the motors (X20 and X21):

The motors that are connected to X20

and X21 leave the upper contact

unconnected.

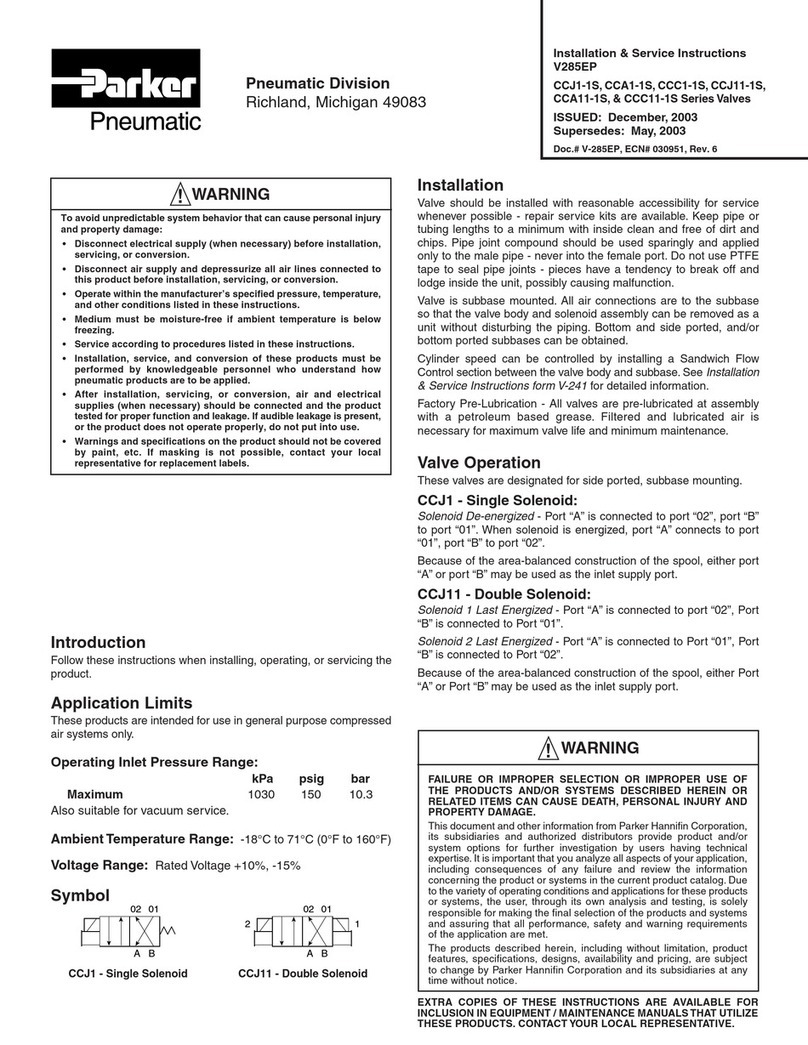

connection of the switch outputs X10 to X17:

The switch outputs are used for light-

and simple motor functions. The

outputs are switched to ground (blue

and grey).

The left connection (red) is connected

to battery +. This is the same voltage

provided to the green connector. It is

protected by a fuse.

TIP: The left connection (permanent +) is the same for all eight

connectors. To reduce lead count, you can use one + for several loads.

instructions TVC-TRF-10-MBT_V2.odm Seite 11 von 29 Stand 13.10.11

Connection of batteries cable:

The connection is made with the green contact block. The connector is

(X60). It is a good practice to install a switch between battery and the

power connector. For your convenience you can choose our cable set

3013.

On the bottom side of the pcb are four fuses.

They protect the groups:

–speed controller (X01 and X02)

–speed controller (X20 and X21), switch outputs (X10 to X17)

–audioamplifier and cpu

–servo outputs (X40 to X47)

instructions TVC-TRF-10-MBT_V2.odm Seite 12 von 29 Stand 13.10.11

battery cable shown with polarity

Connection of drive motors:

The drive motors are attached to X01 and X02 at the black plug in

connectors. The motors must be properly radio-interference-suppressed

(install capacitors if required).

The motor outputs are marked so that when connecting the motor to +,

the corresponding chain run in forward direction. The best way to

connect the motors is as follows:

•prepare the model-chassis and a battery

•jack up the chassis

•connect the battery direct to the right motor. Mark the motor lead,

that must be connected to the positive pole of the battery, to run

the track in forward direction. Mark the positive lead with M+ and

the negativ lead with M-.

•do it the same way with the left motor

•connect the leads of the right motor to X01 as shown in the picture

obove.

•connect the leads of the left motor to X02 as shown in the picture

obove.

Case you have done so and the direction is still not correct, use the

servo reverse setting of you transmitter to fix it. Same for the steer

channel.

Note:

please don't confuse the servo leads connected to the throttle and the

steer channel.

instructions TVC-TRF-10-MBT_V2.odm Seite 13 von 29 Stand 13.10.11

Connect the turret and cannon elevation motor servos:

the turret rotation motor can be plugged to X21

the cannon elevation motor can be plugged to X20

The motor must be connected to the indicated terminals as per the

illustration.

In addition to these 2 motor outputs the Module provides 2 servo outputs

for turret rotation (X42) and cannon elevation (X41). These operate in

parallel to the motor outputs The servo functions are damped for

realistic movement results.

The servo is supplied by the integrated BEC. Servos from Robbe Futaba

or Graupner JR can be connected directly to the module. The

ground(black or brown Line of the servo cable) points to the exterior of

the Module. The speed and direction are proportional to stick deflection.

Connect the recoil servo:

The servo for the recoil is connected to X40

It is supplied by the integrated BEC. Servos from Robbe Futaba or

Graupner JR can be connected directly to the module. The ground(black

or brown Line of the servo cable) points to the exterior of the Module.

instructions TVC-TRF-10-MBT_V2.odm Seite 14 von 29 Stand 13.10.11

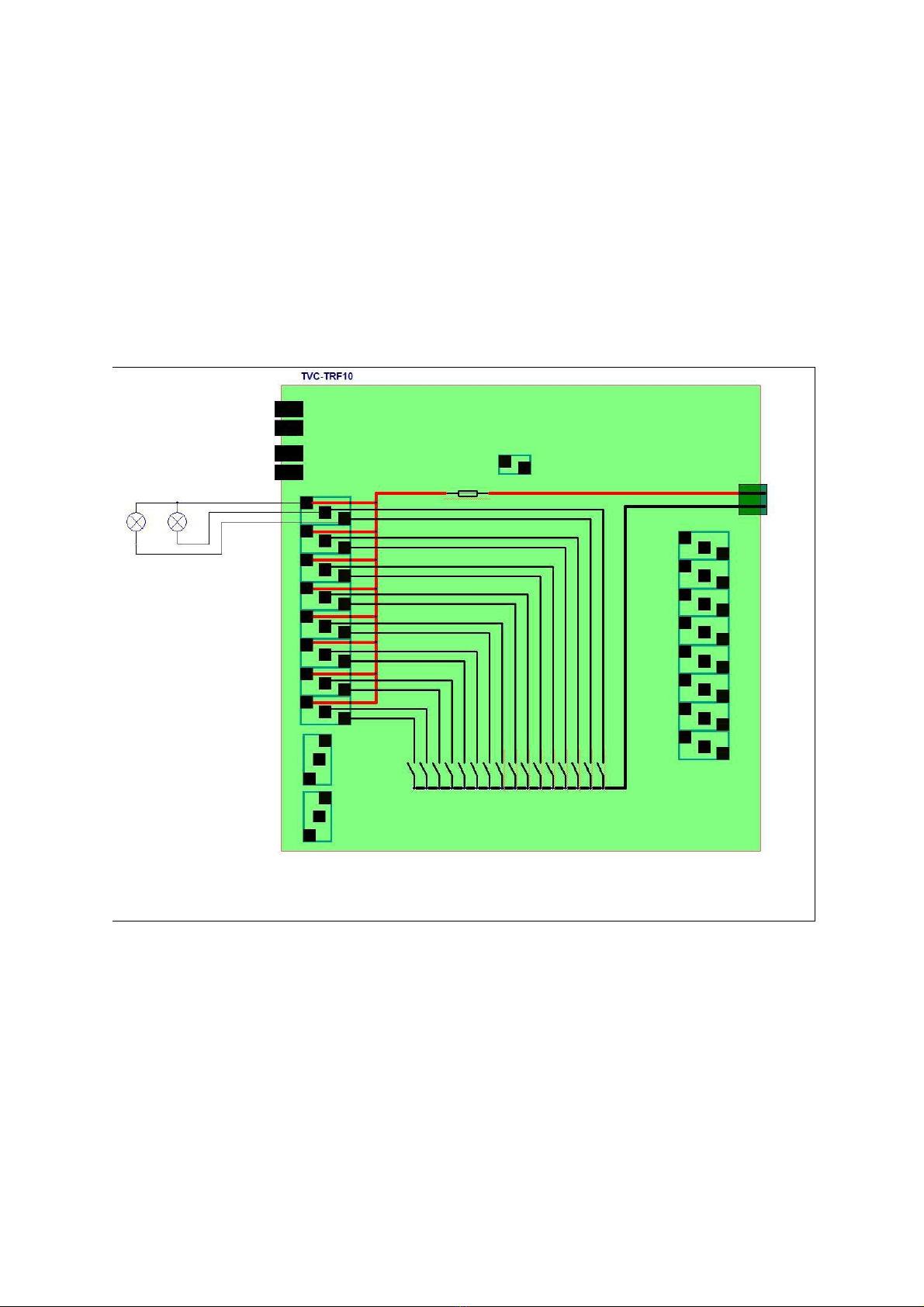

Abbildung 2: example for a recoil and elevation servo in one mechnical unit

Connecting the speaker:

The speaker connects at the brown 2 pole connector (X70) in the center

of the board. We recommend a 4 ohm speaker. An 8 or 16 ohm speaker

may be used but this will result in reduced sound volume. The volume

may be adjusted at the potentiometer (V1) directly below the connector.

The speaker needs to be installed in a box to prevent a feedback loop.

The presence of a box also improves bass response and sound

volume. The box should have as much volume as practical and should

not hinder airflow from the face of the speaker.

instructions TVC-TRF-10-MBT_V2.odm Seite 15 von 29 Stand 13.10.11

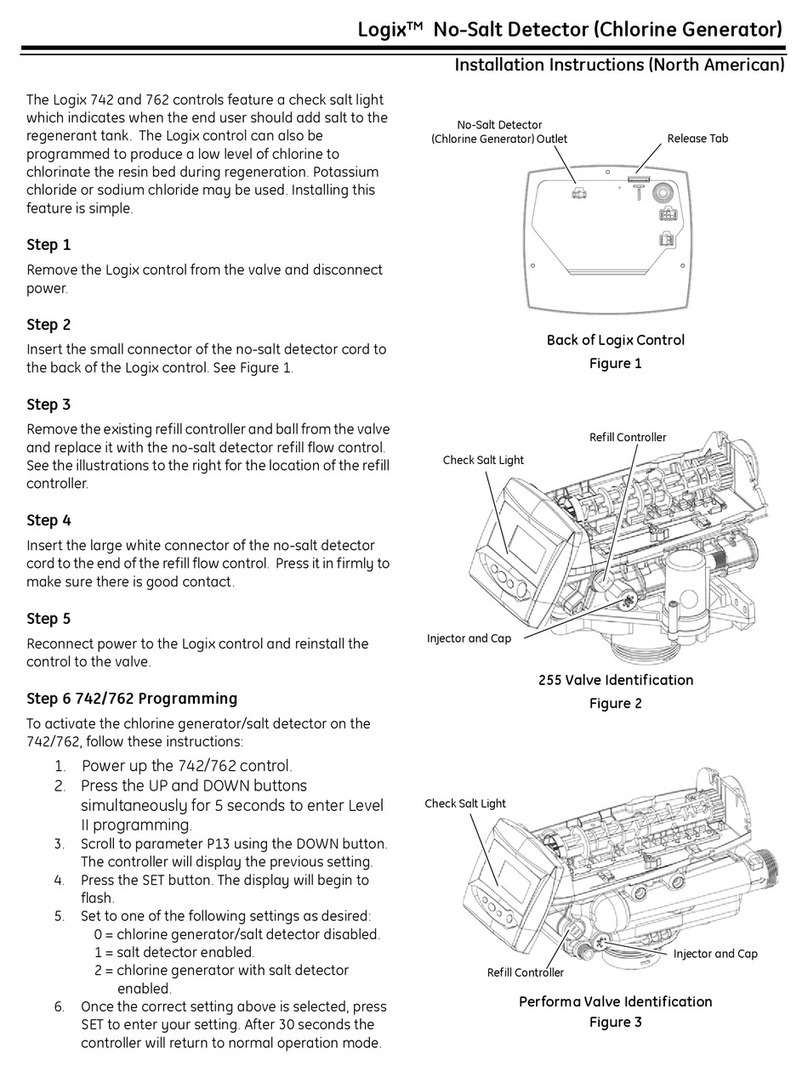

Connection of lighting and exhaust systems:

The lighting and exhaust system outputs are at battery voltage. evices

must be suitable for that voltage. If LE 's are used appropriate resistors

must be installed. These outputs can switch inductive loads such as

relays.

instructions TVC-TRF-10-MBT_V2.odm Seite 16 von 29 Stand 13.10.11

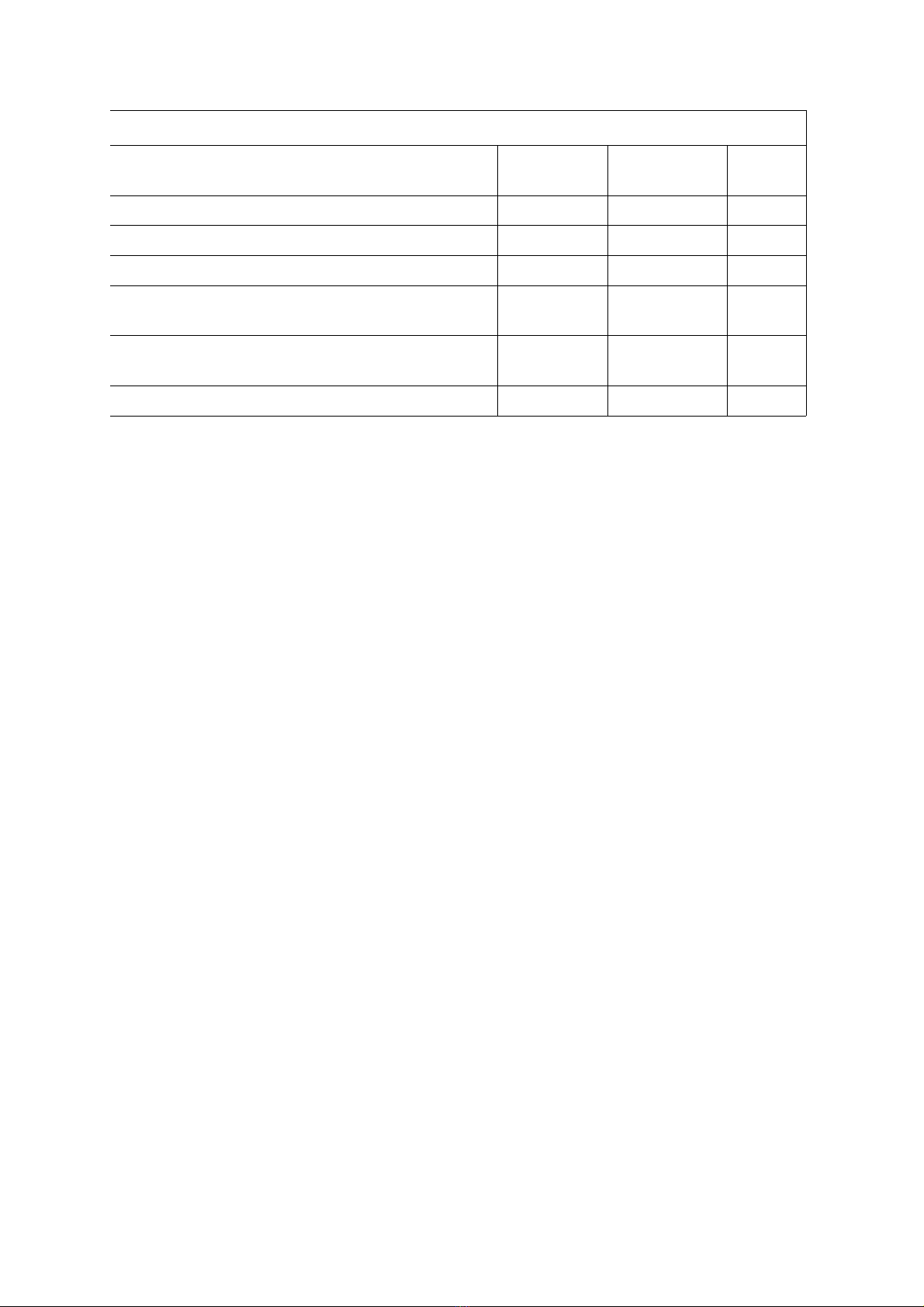

Illustration 3 connection diagram for lighting and smo e generator..

connector Left post Middle post Right post

X10 (+) MG LED (-)negative battery

terminal

(-) MG LED

X11 (+) rotating flasher 1+2 (-) rotating flasher 1 (-) rotating flasher 2

X12 (+) rotating flasher 3+4 (-) rotating flasher 3 (-) rotating flasher 4

X13 (+) cannon (-) cannon recoil (-) cannon LED

X14 (+) aux 1 and aux 2 (-) aux 1 (-) aux 2

X15 (+) reverse light and

brake light

(-) combat brake light (-) brake light

X16 (+) signal (-) signal left (-) signal right

X17 (+) Exhaust system (-)Exhaust system

heater

(-) Exhaust system

motor

Allocation of terminal posts for the lights, exhaust fan, and heater X10 to X17

instructions TVC-TRF-10-MBT_V2.odm Seite 17 von 29 Stand 13.10.11

Function of the light mode control

There are two light modes light mode 1 and light mode 2.

Lightmode 1 for auxillary output 1 and 2. They can be used for combat

light, beam light or any other consumer.

The lightmode 1 is changed by tipping the stick forward. The mode is

count up , 1 → 2 → 3 → 4 → 1, and so on.

When keeping the stick for about 2 seconds, the lightmode is reset to

1(all off).

light mode 1

state 1 2 3 4 1

auxlight 1 off On off On off

auxlight 2 off off On On off

The lightmode 2 controls the automatic functions of the warnblinker and

the rotating flasher. The lamp function is given by the table below.

The modes are called :

•road traffic 1

•road traffic 2

•road traffic 3

•combat 1

For example the turn flasher is not activated automaticly in combat

mode, while it is activated in road traffic 1 and 2 when steering.

The lightmode 2 is changed by tipping the stick backwards.The mode is

count up , road traffic1 → road traffic2 → road traffic3 → combat 1 →

road traffic1, and so on.

When keeping the stick for about 2seconds, the lightmode 2 is reset to

road traffic1.

instructions TVC-TRF-10-MBT_V2.odm Seite 18 von 29 Stand 13.10.11

light mode 2

state road traffic

1

road traffic

2

road traffic

3

combat

1

...

brake light auto auto auto off

combat brake light off off off auto

blinker left and

right

Auto

left right

Auto

left right

Warning

flasher

off

rotating light

off on

(rotating)

on (rotating) off

The light modes states are stored when changing the operation mode.

When the model is switched off by the model selector channel, all light

states are unchanged.

When the model is parked by turning of the transmitter, all light are

turned off.

TIP 1:

The four rotating lights are also activated in a random way for about

three seconds when the tank is hit by the battlesystem

TIP 2:

Typically, a three-stage switch is used on the transmitter.

Proportional channels with linear knops may complicate the selection of

the light mode, because the indexing is done by briefly returning to the

center position. This may be difficult with linear knops.

instructions TVC-TRF-10-MBT_V2.odm Seite 19 von 29 Stand 13.10.11

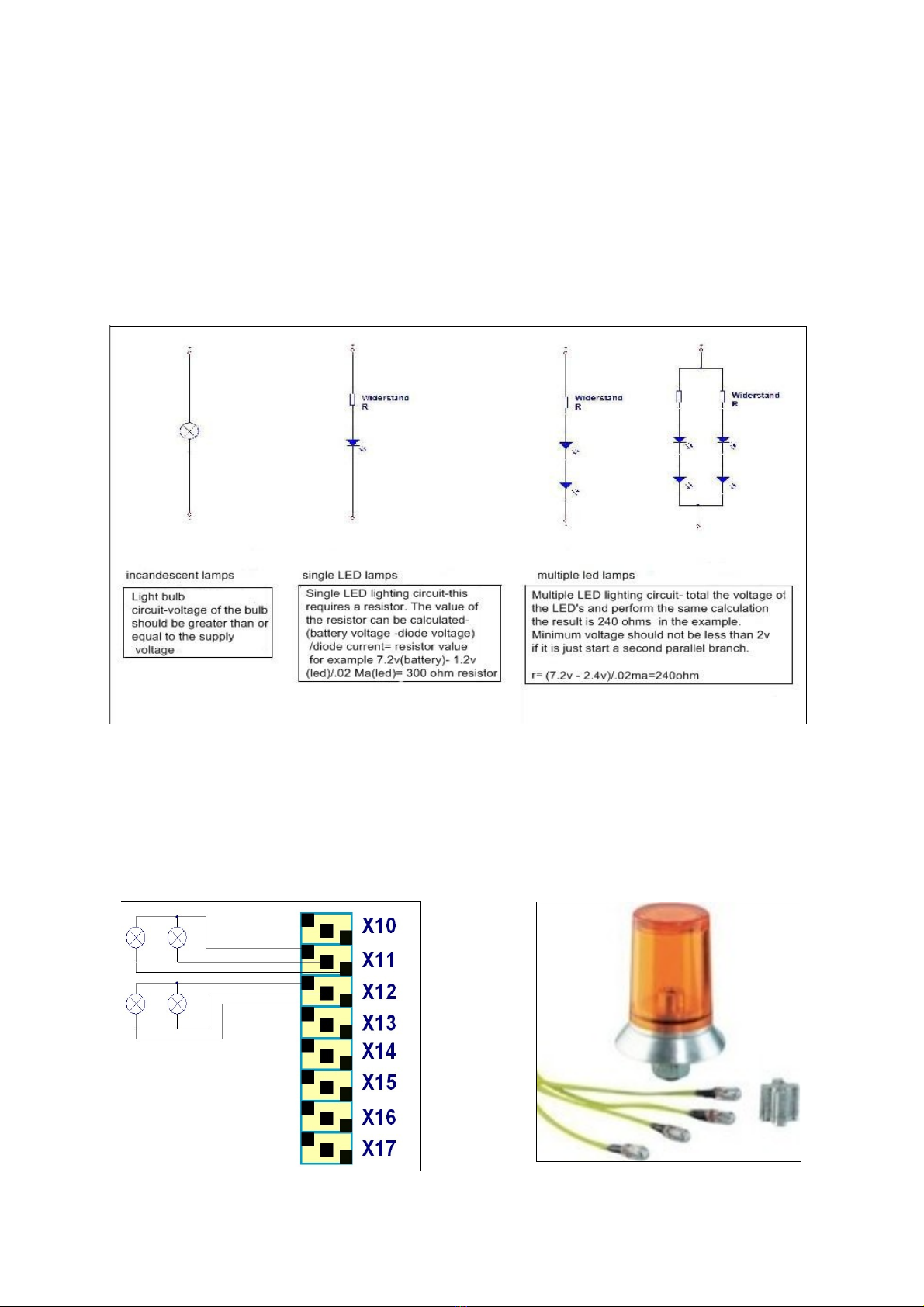

When connecting LED, please use suitable resistors. In the diagram

below the correct way to calculate the resistor value is show.

In any case you should connect the quite common resistors delivered

with the modul.

Note: Please never connect LED without resistor to the modul. This will

destroy the LED and or the modul.

Example: rotating flasher

The modul controls a rotating flasher with four lamps. Two lamps are

connected to X11 and two lamps are connected to X12.

Remember that the lighting outputs are at battery voltage. So when the

modul is powered with 12V the lamps must be rated for 12V.

l

instructions TVC-TRF-10-MBT_V2.odm Seite 20 von 29 Stand 13.10.11

Table of contents

Other SGS electronic Control Unit manuals

Popular Control Unit manuals by other brands

SMC Networks

SMC Networks VF1000 Series instruction manual

Parker Pneumatic

Parker Pneumatic CCJ1-1S Series Installation & service instructions

Pike

Pike RoboSign MK3 Operator's guide

Diehl

Diehl LoRaWAN CMi4160 user guide

Overland Tandberg

Overland Tandberg NEOxl 40 instructions

Elnec

Elnec DIL20W/PLCC20 ZIF manual