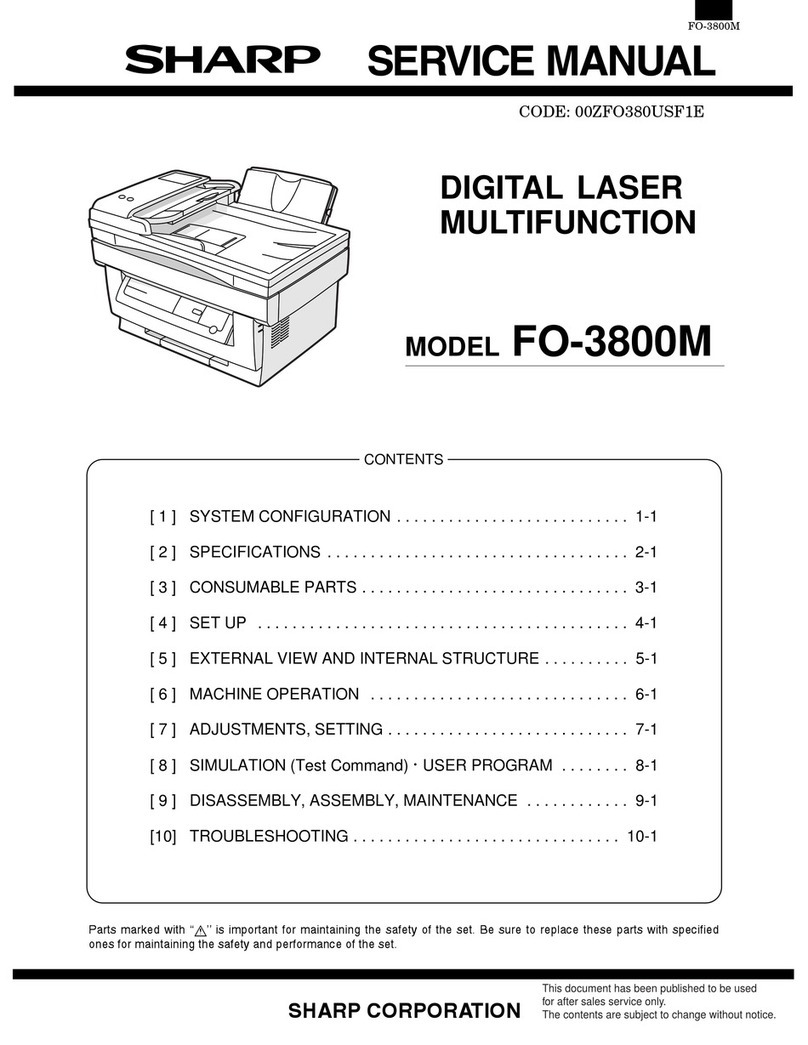

CONTENTS

[1] GENERAL

1. Major functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS

1. Basic Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Operation specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. Copy performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

4. GDI Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

5. Scan function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

6. SPF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

[3] CONSUMABLE PARTS

1. Supply system table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2. Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3. Production control number (lot No.) identification . . . . . . . . . . 3-2

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Internal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

3. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4. Motors and solenoids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

5. Sensors and switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

6. PWB unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

7. Cross sectional view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

[5] UNPACKING AND INSTALLATION

1. Copier installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. Cautions on handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

3. Checking packed components and accessories . . . . . . . . . . . 5-1

4. Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5. Removing protective packing materials. . . . . . . . . . . . . . . . . . 5-2

6. Installing the TD cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

7. Loading paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

8. Power to copier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

9. Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

10. Connecting the interface cable . . . . . . . . . . . . . . . . . . . . . . . . 5-4

11. Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

A. USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

B. RJ45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

12. Moving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

[6] COPY PROCESS

1. Functional diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

2. Outline of print process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

3. Actual print process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

[7] OPERATIONAL DESCRIPTIONS

1. Outline of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. Scanner section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

A. Scanner unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

B. Optical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

C. Drive system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

3. Laser unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

A. Basic structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

B. Laser beam path. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

C. Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

4. Fuser section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

A. General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

5. Paper feed section and paper transport section . . . . . . . . . . . 7-4

A. Paper transport path and general operations . . . . . . . . . . . 7-4

6. Process unit new drum detection mechanism . . . . . . . . . . . . . 7-7

7. SPF section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

A. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

B. Document transport path and basic composition . . . . . . . . 7-7

C. Operational descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

D. SPF open/close detection (book document detection) . . . . 7-8

[8] DISASSEMBLY AND ASSEMBLY

1. High voltage section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

B. Disassembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

C. Assembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

D. Charger wire cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

E. Charger wire replacement . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

2. Operation panel section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

B. Disassembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

C. Assembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

3. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

A. List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

B. Disassembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

4. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

A. List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

B. Disassembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

5. Tray paper feed/transport section . . . . . . . . . . . . . . . . . . . . . . 8-7

A. List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

B. Disassembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

6. Manual paper feed section. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

A. List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

B. Disassembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

D. Pressure plate holder attachment . . . . . . . . . . . . . . . . . . . 8-14

7. Rear frame section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

A. List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

B. Disassembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-14

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-15

8 Power section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

A. List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

B. Disassembly procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

C. Assembly procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

9. SPF section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

A. SPF motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

B. Pick-up roller, paper feed roller . . . . . . . . . . . . . . . . . . . . . 8-17

C. Paper exit roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

D. Set sensor, scan front sensor . . . . . . . . . . . . . . . . . . . . . . 8-18

E. Transport roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

10. 2nd cassette section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

A. Paper sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

B. Cassette detection switch . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

C. Paper feed solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

D. Transport roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

E. Paper feed clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

F. 2nd paper feed roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

[9] ADJUSTMENTS

1. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

A. Copy magnification ratio adjustment. . . . . . . . . . . . . . . . . . 9-1

B. Image position adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

2. Copy density adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

A. Copy density adjustment timing . . . . . . . . . . . . . . . . . . . . . 9-4

B. Note for copy density adjustment . . . . . . . . . . . . . . . . . . . . 9-4

C. Necessary tool for copy density adjustment . . . . . . . . . . . . 9-4

D. Features of copy density adjustment . . . . . . . . . . . . . . . . . 9-4

E. Copy density adjustment procedure . . . . . . . . . . . . . . . . . . 9-4

3. High voltage adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

A. Main charger (Grid bias) . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

B. DV bias check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

4. Duplex adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

A. Adjusting the paper reverse position in memory

for duplex copying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

B. Adjusting trailing edge void in duplex copy mode . . . . . . . . 9-6

5. SPF scan position automatic adjustment . . . . . . . . . . . . . . . . . 9-7

6. SPF mode sub scanning direction magnification ratio

adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

7. Automatic black level correction. . . . . . . . . . . . . . . . . . . . . . . . 9-8

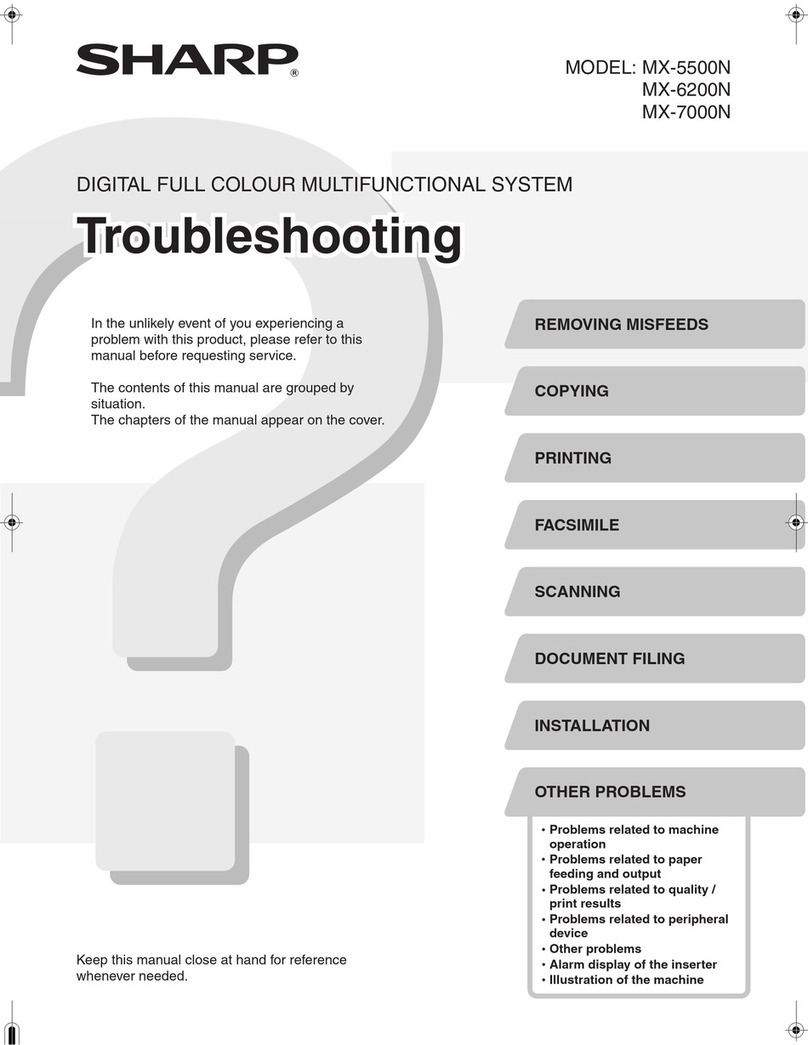

[10] SIMULATION, TROUBLE CODES

1. Entering the simulation mode. . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. List of simulations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

3. Contents of simulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

4. Trouble codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

A. Trouble codes list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

B. Details of trouble codes. . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

[11] USER PROGRAM

1. Functions that can be set with user programs . . . . . . . . . . . . 11-1

2. Toner save mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

3. User programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] ELECTRICAL SECTION

1. Block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

A. Overall block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

2. Actual wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

A. AL-2030. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

B. AL-2040CS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-4

3. Signal name list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6