Sharp GF-9090H User manual

Other Sharp Stereo System manuals

Sharp

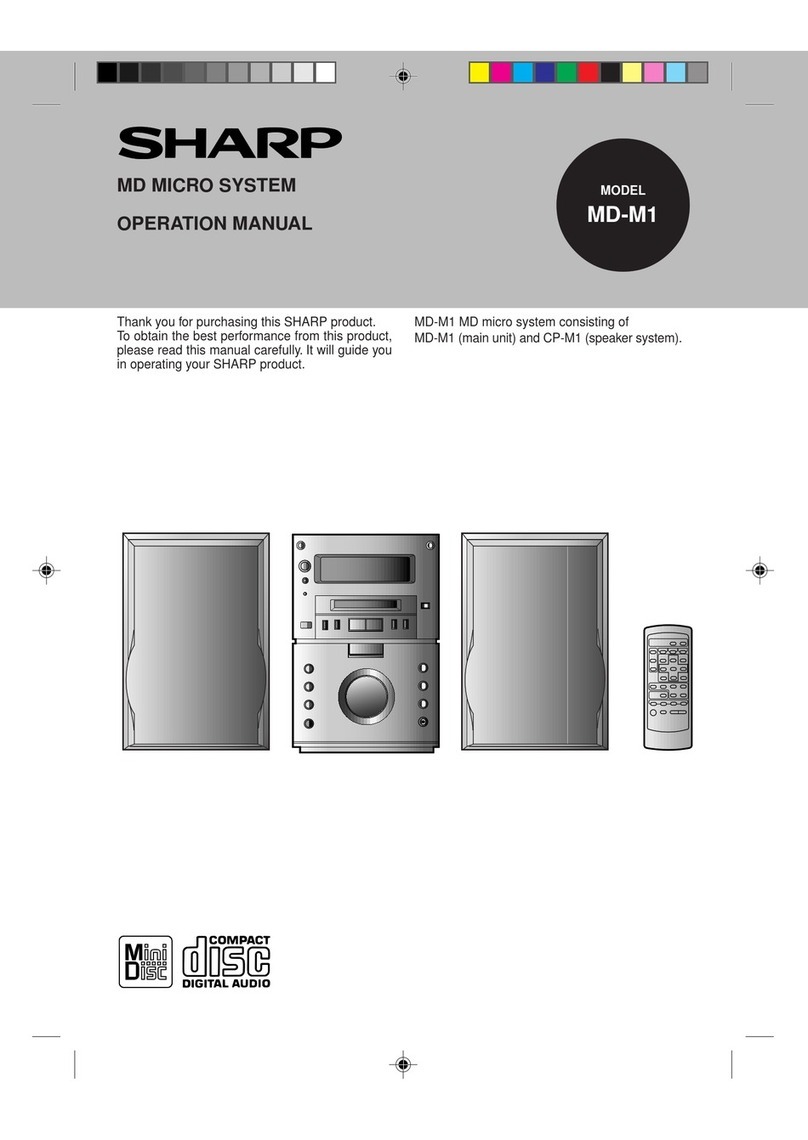

Sharp MD-M1 User manual

Sharp

Sharp QT-CD180 User manual

Sharp

Sharp CD-BK300W User manual

Sharp

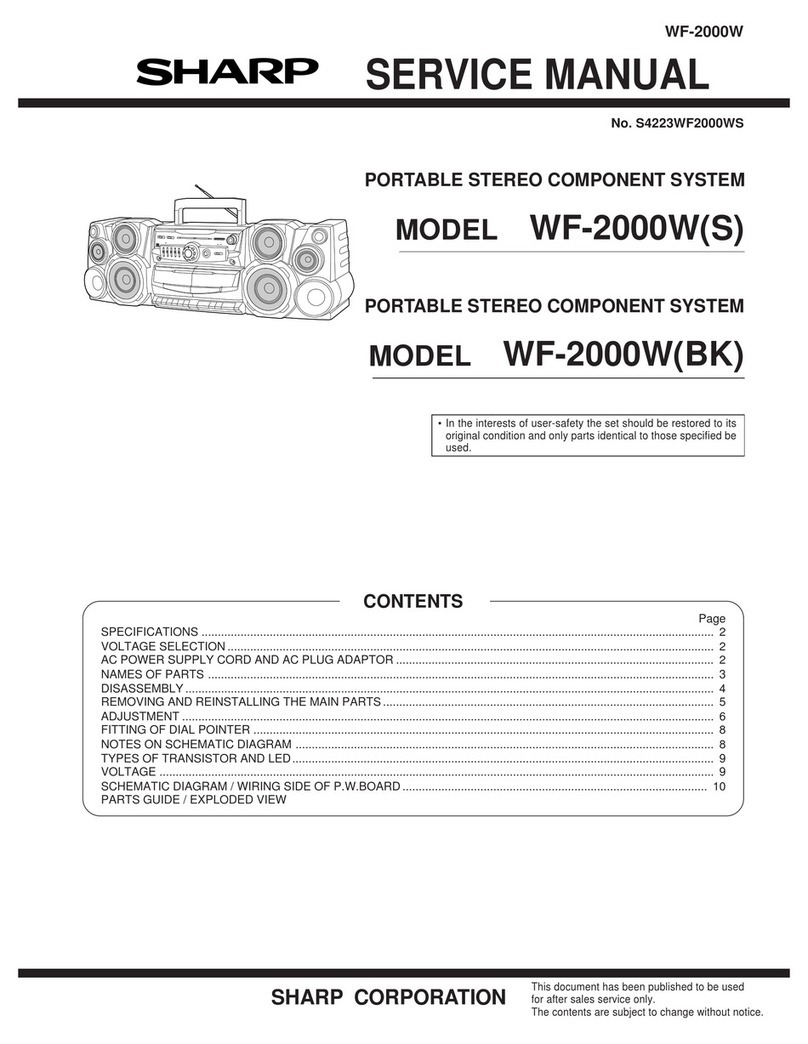

Sharp WF-2000W User manual

Sharp

Sharp CP-BK137W User manual

Sharp

Sharp CD-ES777 User manual

Sharp

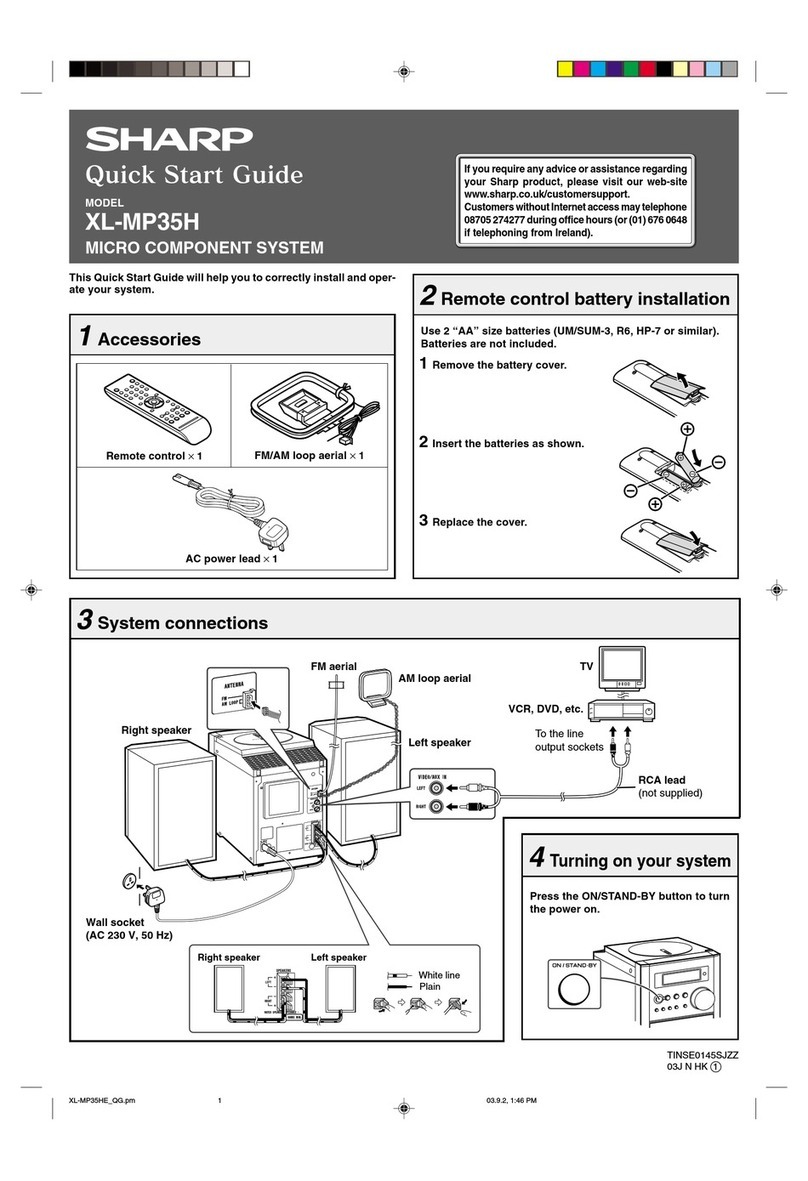

Sharp XL-MP35H User manual

Sharp

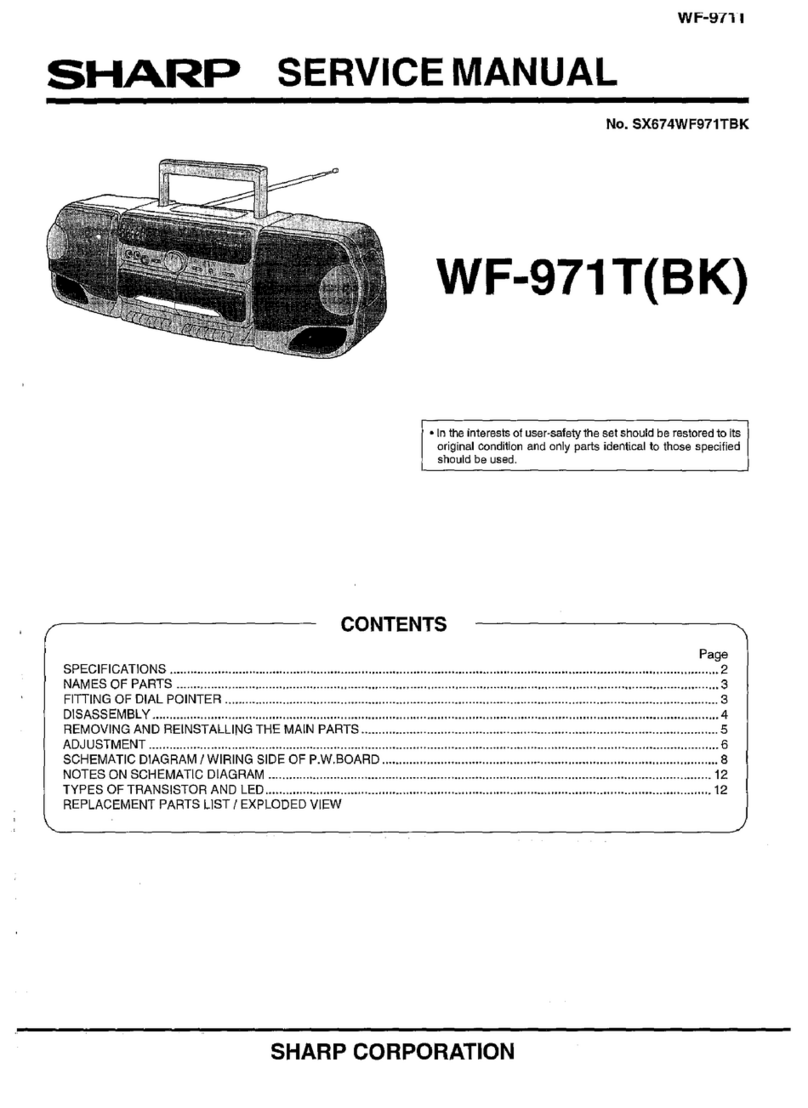

Sharp WF-971T User manual

Sharp

Sharp XL-HP550E User manual

Sharp

Sharp CD-DV650W User manual

Sharp

Sharp MD X5 User manual

Sharp

Sharp XL-DV100NH User manual

Sharp

Sharp QT-CD180H User manual

Sharp

Sharp CD-DP2500W User manual

Sharp

Sharp CD-BA1500H User manual

Sharp

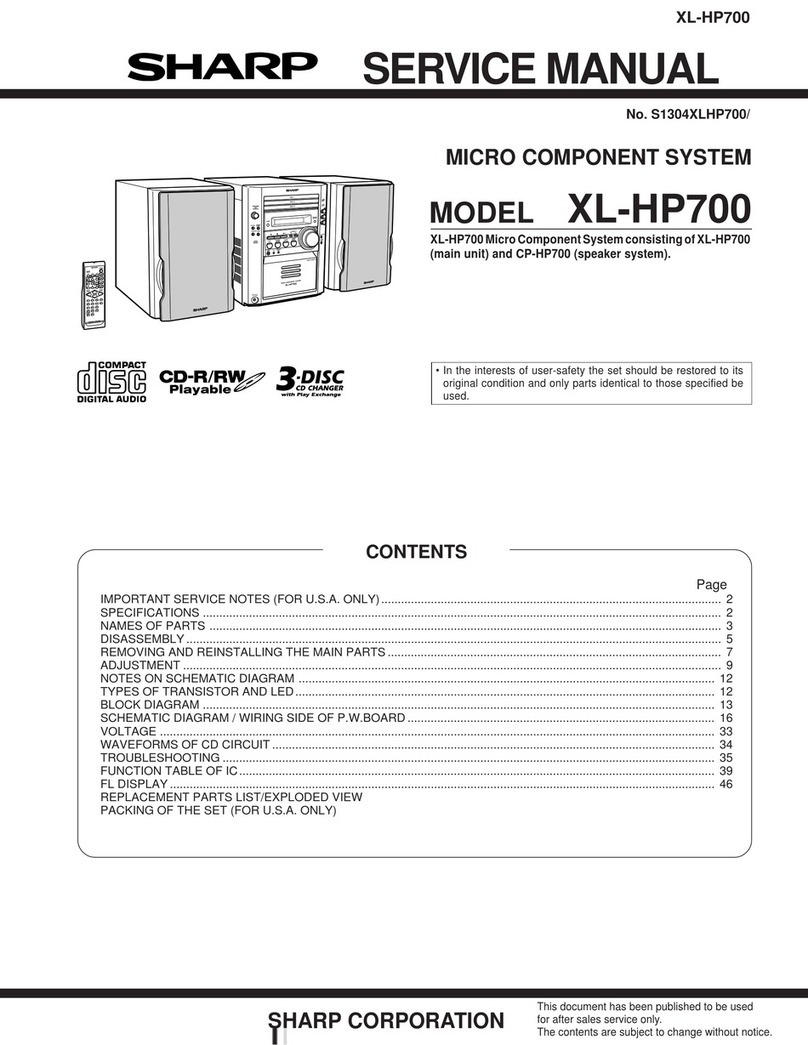

Sharp XL-HP700 User manual

Sharp

Sharp Illustration XL-HP535E User manual

Sharp

Sharp XL-UR5H User manual

Sharp

Sharp CD-XP200 User manual

Sharp

Sharp XL-HF201P User manual