QT-CD180

– 2 –

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF THIS UNIT, PLEASE REFER

TO THE OPERATION MANUAL.

BEFORE RETURNING THE AUDIO PRODUCT

(Fire & Shock Hazard)

Before returning the audio product to the user, perform the

following safety checks.

1. Inspect all lead dress to make certain that leads are not

pinchedorthathardwareisnotlodgedbetweenthechassis

and other metal parts in the audio product.

2. Inspect all protective devices such as insulating materials,

cabinet, terminal board, adjustment and compartment

covers or shields, mechanical insulators etc.

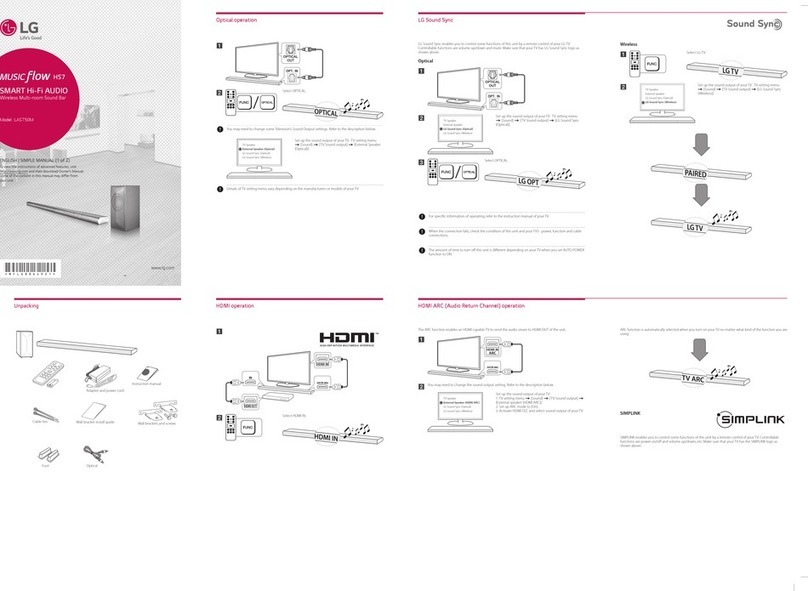

3. To be sure that no shock hazard exists, check for leakage

current in the following manner.

* Plug the AC line cord directly into a 120 volt AC outlet.

* Using two clip leads, connect a 1.5k ohm, 10 watt resistor

paralleled by a 0.15µF capacitor in series with all exposed

metal cabinet parts and a known earth ground, such as

conduit or electrical ground connected to earth ground.

* Use a VTVM or VOM with 1000 ohm per volt, or higher,

sensitivity to measure the AC voltage drop across the

resistor (See diagram).

* Connect the resistor connection to all exposed metal parts

havingareturnpathtothechassis(antenna,metalcabinet,

screw heads, knobs and control shafts, escutcheon, etc.)

and measure the AC voltage drop across the resistor.

IMPORTANT SERVICE NOTES (FOR U.S.A. ONLY)

AllcheckmustberepeatedwiththeAClinecordplugconnection

reversed.

Anyreading of0.3 voltRMS (thiscorresponds to0.2 milliamp.

AC.) or more is excessive and indicates a potential shock

hazard which must be corrected before returning the audio

product to the owner.

SPECIFICATIONS

Specifications for this model are subject to change without

prior notice.

AC SCALE

VTVM

1.5k ohms

10W

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

■Tape recorder

Frequency response

Signal/noise ratio

Wow and fiutter

Motor

Bias system

Erase system

50 - 14,000 Hz (Normal tape)

50 dB

0.25 % (WRMS)

DC 9 V electric governor

AC bias

Magnet erase

■Compact disc player

Type

Signal readout

Audio channels

Filter

D/A converter

Wow and flutter

Compact disc

Non-contact, 3-beam semi-conductor laser pickup

2

8-time oversampling digital filter

1-bit D/A converter

Unmeasurable (less than 0.001% W. peak)

■General

AC 120 V, 60 Hz

DC 9 V [“D” size (UM/SUM-1, R20 or HP-2) battery x 6]

11 W

3-1/8" (8 cm) full-range speaker x 2

5.5 lbs. (2.5 kg) without batteries

Power source

Power consumption

Output power

Speakers

Dimensions

Weight

FM; 87.5 - 108 MHz

AM; 530 - 1,720 kHz

■Radio

Frequency range

FTC; 2.0 W min. RMS per channel into 4 ohms from 150

Hz to 20 kHz, with no more than 10 % total harmonic

distortion.

RMS; 2.3 W/CH (DC operation, 10 % T.H.D)

Width; 14-6/8" (376 mm)

Height; 5-7/8" (150 mm)

Depth; 9" (230 mm)