Sharp VC-780E User manual

Other Sharp VCR System manuals

Sharp

Sharp VC-A560UA User manual

Sharp

Sharp VC-MH713HM User manual

Sharp

Sharp VC-GH611GM User manual

Sharp

Sharp VC-A560UA User manual

Sharp

Sharp VC-M35SM User manual

Sharp

Sharp VC-H726X User manual

Sharp

Sharp DV-NC55U User manual

Sharp

Sharp VC-MH780BM User manual

Sharp

Sharp VC-H725X User manual

Sharp

Sharp VC-M311AHM User manual

Sharp

Sharp VC-A413U User manual

Sharp

Sharp VC-6300G User manual

Sharp

Sharp VC-H730X User manual

Sharp

Sharp VC-S101U User manual

Sharp

Sharp VC-H726X User manual

Sharp

Sharp VC-H670X User manual

Sharp

Sharp VC-H705X User manual

Sharp

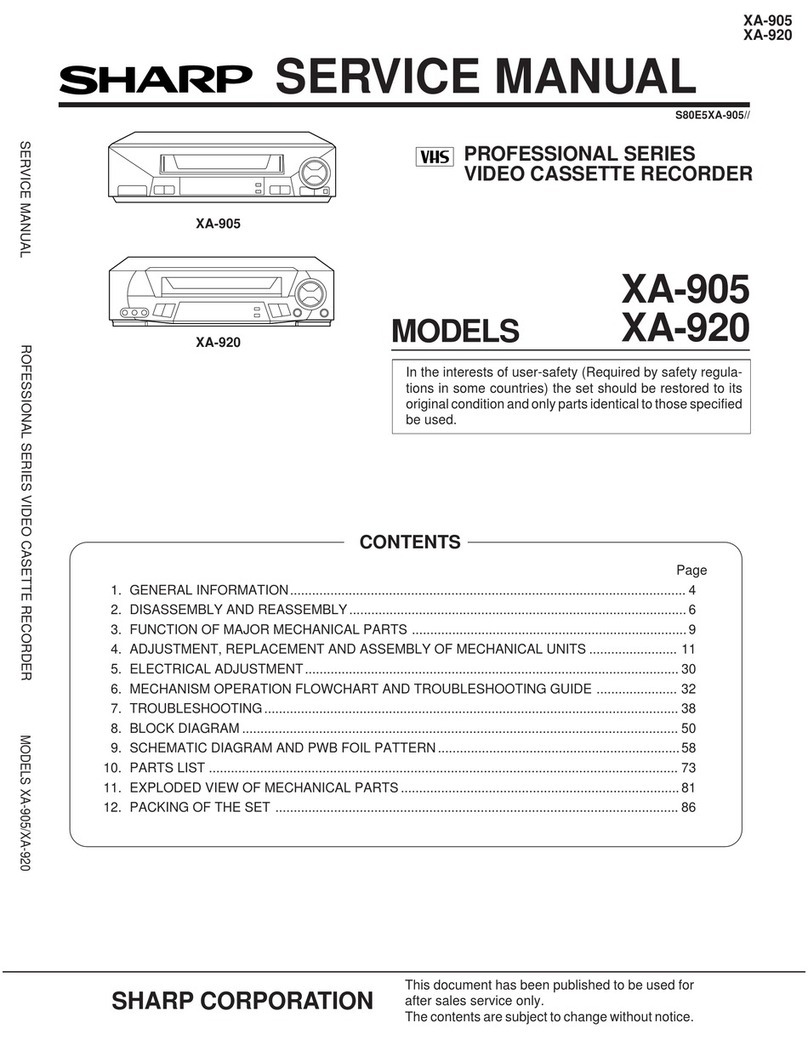

Sharp XA-920 User manual

Sharp

Sharp VC-M303HM User manual

Sharp

Sharp VC-FH30SM User manual