Shel lab SRI3 User manual

BOD INCUBATOR

110 – 120 Voltage / 220 – 240 Voltage

Installation - Operation Manual

SRI3 SRI3-2

2| Page

WARNING: Never use this unit for the growth, cultivation, incubation or storage of fruit flies

(drosophila melanogaster). This unit is not designed for use with fruit flies. Improper use of this

unit, including use with fruit flies, will void any warranty. Other units are specifically manufactured

for fruit fly applications, and you should consult your dealer or the manufacturer in order to

identify another model suitable for your application.

3| Page

BOD INCUBATOR

SRI3 110 – 120 Voltage

SRI3-2 220 – 240 Voltage

Part Number (Manual): 4861574

Revision: February 12, 2018

These units are compliant with the following standards for use within an ambient air pressure range

of 22.14 – 31.3 inHg (75 – 106 kPa), with no flammable, volatile, or combustible materials being

heated.

CAN/CSA C22.2 No. 61010-1:2012

CAN/CSA C22.2 No. 61010-2-010:2004 Reaffirmed: 2014-07

UL 61010-1:2012-05

UL 61010A-2-010:2002-03

EN 61010-1:2010

EN 61010-2-010:2014

Supplemented by: UL 61010-2-010:2015

4| Page

TABLE OF CONTENTS

INTRODUCTION ........................................................................................................................................................ 5

Read this Manual....................................................................................................................................................................5

Safety Considerations and Requirements ......................................................................................................................5

Contacting Assistance ..........................................................................................................................................................6

Engineering Improvements..................................................................................................................................................6

Reference Sensor Device .................................................................................................................................................... 7

RECEIVING YOUR UNIT ........................................................................................................................................... 9

Inspect the Shipment.............................................................................................................................................................9

Orientation Photo ................................................................................................................................................................. 10

Recording Data Plate Information.................................................................................................................................... 11

INSTALLATION .........................................................................................................................................................13

Installation Checklist ........................................................................................................................................................... 13

Required Ambient Conditions........................................................................................................................................... 14

Required Clearances........................................................................................................................................................... 14

Power Source Requirements ............................................................................................................................................ 15

Lifting and Handling ............................................................................................................................................................ 16

Leveling................................................................................................................................................................................... 16

Install Incubator in Location .............................................................................................................................................. 16

Adjust Shelves........................................................................................................................................................................17

Deionized and Distilled Water.......................................................................................................................................... 18

Installation Cleaning and Disinfection ........................................................................................................................... 18

GRAPHIC SYMBOLS ................................................................................................................................................19

CONTROL PANEL OVERVIEW ...............................................................................................................................21

OPERATION.............................................................................................................................................................. 23

Theory of Operation ........................................................................................................................................................... 23

Put the Incubator into Operation .................................................................................................................................... 24

Set the Temperature Set Point........................................................................................................................................ 25

Set the Over Temperature Limit...................................................................................................................................... 26

Loading Samples..................................................................................................................................................................27

Accessory Compatibility and Power Outlet ..................................................................................................................27

Condensation and the Dew Point .................................................................................................................................. 28

USER MAINTENANCE............................................................................................................................................. 29

Cleaning and Disinfecting................................................................................................................................................. 29

Minimizing Contamination Exposure ............................................................................................................................. 30

Electrical Components....................................................................................................................................................... 30

Refrigeration and Defrosting............................................................................................................................................. 31

Calibrate the Temperature display ................................................................................................................................ 34

UNIT SPECIFICATIONS .......................................................................................................................................... 39

Weight..................................................................................................................................................................................... 39

Dimensions............................................................................................................................................................................ 39

Capacity ................................................................................................................................................................................. 39

Shelf Capacity by Weight.................................................................................................................................................. 40

Temperature ......................................................................................................................................................................... 40

Power...................................................................................................................................................................................... 40

PARTS LIST................................................................................................................................................................41

5| Page

INTRODUCTION

Thank you for purchasing a SHEL LAB product. We know you have many choices in today’s competitive

marketplace when it comes to constant temperature equipment. We appreciate you choosing ours. We

stand behind our products and will be here for you if you need us.

READ THIS MANUAL

Failure to follow the guidelines and instructions in this user manual may create a protection

impairment by disabling or interfering with the unit safety features. This can result in injury or death.

Before using the unit, read the manual in its entirety to understand how to install, operate, and

maintain the unit in a safe manner. Keep this manual available for use by all operators. Ensure all

operators are given appropriate training before the unit begins service.

SAFETY CONSIDERATIONS AND REQUIREMENTS

Follow basic safety precautions, including all national laws, regulations, and local ordinances in your

area regarding the use of this unit. If you have any questions about local requirements, please

contact the appropriate agencies.

SOPs

Because of the range of potential applications this unit can be used for, the operator or their

supervisors must draw up a site-specific standard operating procedure (SOP) covering each

application and associated safety guidelines. This SOP must be written and available to all operators

in a language they understand.

Intended Applications and Locations

These incubators are intended for professional, industrial, or educational BOD applications at a

constant temperature. The incubators are not designed for use in hazardous or household locations.

Power

Your unit and its recommended accessories are designed and tested to meet strict safety

requirements.

•The unit is designed to connect to a power source using the specific power cord type

shipped with the unit.

•Always plug the unit power cord into a protective earth grounded electrical outlet

conforming to national and local electrical codes. If the unit is not grounded properly, parts

such as knobs and controls can conduct electricity and cause serious injury.

•Do not bend the power cord excessively, step on it, or place heavy objects on it.

•A damaged cord can be a shock or fire hazard. Never use a power cord if it is damaged or

altered in any way.

•Use only approved accessories. Do not modify system components. Any alterations or

modifications to your unit not explicitly authorized by the manufacturer can be dangerous

and will void your warranty.

6| Page

INTRODUCTION

CONTACTING ASSISTANCE

Phone hours for Sheldon Technical Support are 6 am – 4:30 pm Pacific Coast Time (west coast of

the United States, UTC -8), Monday through Friday. Please have the following information ready

when calling or emailing Technical Support: the model number and the serial number (see page 11).

EMAIL: [email protected]

PHONE: 1-800-322-4897 extension 4, or (503) 640-3000

FAX: (503) 640-1366

Sheldon Manufacturing, INC.

P.O. Box 627

Cornelius, OR 97113

ENGINEERING IMPROVEMENTS

Sheldon Manufacturing continually improves all of its products. As a result, engineering changes and

improvements are made from time to time. Therefore, some changes, modifications, and

improvements may not be covered in this manual. If your unit’s operating characteristics or

appearance differs from those described in this manual, please contact your SHEL LAB dealer or

customer service representative for assistance.

7| Page

INTRODUCTION

REFERENCE SENSOR DEVICE

Optional

Must be purchased separately

A reference sensor device is required for calibrating the unit temperature display.

Reference devices must meet the following standards:

•Accurate to at least 0.1°C

The device should be regularly calibrated, preferably by a third party.

Temperature Probe

Use a digital device with a wire thermocouple probe that can be introduced into the unit chamber

through the door space. Select thermocouples suitable for the application temperature you will be

calibrating at.

Why Probes?

Reference readings taken outside the chamber using wire temperature probes avoid chamber door

openings. Openings disrupt the chamber temperature. Each disruption requires a minimum 1-hour wait

to allow the atmosphere to re-stabilize before continuing.

No Alcohol or Mercury Thermometers

Alcohol thermometers do not have sufficient accuracy to conduct accurate temperature calibrations.

Never place a mercury thermometer in the unit chamber. Always use thermocouple probes.

Temperature

Reference

8| Page

INTRODUCTION

9| Page

RECEIVING YOUR UNIT

INSPECT THE SHIPMENT

•When a unit leaves the factory, safe delivery becomes the responsibility of the carrier.

•Damage sustained during transit is not covered by the manufacturing defect warranty.

•Save the shipping carton until you are certain that the unit and its accessories function

properly.

When you receive your unit, inspect it for concealed loss or damage to its interior and exterior. If you

find any damage to the unit, follow the carrier’s procedure for claiming damage or loss.

1. Carefully inspect the shipping carton for damage.

2. Report any damage to the carrier service that delivered the unit.

3. If the carton is not damaged, open the carton and remove the contents.

4. Inspect the unit for signs of damage. See the orientation depiction on the next page as a

reference.

5. The unit should come with an Installation and Operation Manual.

6. Verify that the correct number of accessory items has been included.

7. Carefully check all packaging for accessory items before discarding.

10 | Page

Figure

1: SRI3/SRI3-2

RECEIVING YOUR UNIT

ORIENTATION PHOTO

Control Panel

Temperature Probe

Wire Shelf, 1 of 2

Chamber Door

Incubation

Chamber

Door Gasket

11 | Page

RECEIVING YOUR UNIT

RECORDING DATA PLATE INFORMATION

The data plate contains the unit model number and serial number. Tech Support will need this

information during any support call. Record it below for future reference.

•The data plate is located near the power cord on the back of the unit.

Model Number

Serial Number

12 | Page

RECEIVING YOUR UNIT

13 | Page

INSTALLATION

INSTALLATION CHECKLIST

For installing the unit in a new workspace location.

Pre-Installation

Check that the required ambient conditions and ventilation spacing for the incubator

are met, page 14.

•Unit dimensions may be found on page 39.

Check that a suitable electrical outlet and power supply is present, page 15.

Install the Incubator in a suitable location

Review the lifting and handling instructions, page 16.

Install the incubator in its workspace location, page 16.

Make sure the incubator is level, page 16.

Set up the Incubator for use

Verify that all packaging has been removed from the incubator shelving and

incubation chamber. Adjust the shelving positions if need be, page 17.

Clean and disinfect the incubator and shelving accessories that will be placed in

the incubation chamber, page 17.

14 | Page

INSTALLATION

REQUIRED AMBIENT CONDITIONS

When selecting a location to install the unit, consider all environmental conditions that can adversely

impact its temperature performance. These include:

•Proximity to ovens, autoclaves, and any device that produces significant radiant heat

•Heating and cooling vents or other sources of fast-moving air currents

•High-traffic areas

•Direct sunlight

These units are built for use indoors at room temperatures between 15°C and 30°C (59°F and 86°F), at

no greater than 80% Relative Humidity (at 25°C / 77°F). Operating outside these conditions may

adversely affect the unit temperature performance.

REQUIRED CLEARANCES

These clearances are required to provide air flows for ventilation and cooling.

4 inches (100 mm) of clearance is required on the sides and back.

2.5 inches (60 mm) of headspace clearance is required between the top of the unit and any

overhead partitions.

2.5” (60 mm)

4” (100 mm)

4” (100 mm)

Leave sufficient room in

front of the unit for the

door to swing freely.

15 | Page

INSTALLATION

POWER SOURCE REQUIREMENTS

When selecting a location for the unit, verify each of the following requirements is satisfied.

Power Source

The power source for the unit must match the voltage and the amperage requirements listed on the

unit data plate. These units are intended for 110 - 120V 50/60 Hz (SRI3) or 220 – 240V 50/60 Hz

(SRI3-2) applications at the following amperages:

SRI3 SRI3-2

5.0 Amps 3.5 Amps

•Supplied voltage must not vary more than 10% from the data plate rating. Damage to the

unit may result if the supplied voltage varies more than 10%.

•The wall power source must be protective earth grounded.

•Use a separate circuit to prevent loss of the unit due to overloading or circuit failure.

•The wall power source must conform to all national and local electrical codes.

Power Cord

The unit must be positioned so that all end-users can quickly unplug the power cord in the event of

an emergency.

•The SRI3 is provided with an integral 120V, 15 Amp, NEMA 5-15P, 8ft (2.5m) power cord.

•The SRI3-2 is provided with an integral 220V, 16 Amp, Euro CEE 7/7, 8ft (2.5m) power cord.

Circuit Breaker: The unit is provided with an integral circuit breaker to protect against overcurrent

conditions.

•Always determine the cause of an overcurrent event before resetting a tripped circuit

breaker.

16 | Page

INSTALLATION

LIFTING AND HANDLING

The unit is heavy. Use appropriate lifting devices that are sufficiently rated for these loads. Follow these

guidelines when lifting the unit.

•Lift the unit only from its bottom surface.

•Doors, handles, and knobs are not adequate for lifting or stabilization.

•Restrain the unit completely while lifting or transporting so it cannot tip.

•Remove all moving parts, such as shelves and trays, and lock doors in the closed position

during transfers to prevent shifting and damage.

LEVELING

The unit must be level and stable for safe operation.

INSTALL INCUBATOR IN LOCATION

Install the unit in a workspace location that meets the criteria discussed in the previous entries of the

Installation section.

17 | Page

INSTALLATION

ADJUST SHELVES

Note: The form factor of the shelves may vary slightly by year of production.

The unit ships with its shelves installed in the incubation chamber. Tape, foam, and other packing

dunnage is used to secure the shelves during transit and prevent damage to the chamber interior.

1. Remove all shipping materials from the shelving.

Optional: Shelf Adjustment

Move the shelves as needed for your application.

Figure 2: Shelf Installed

2. Install the right

side mounting

prongs first.

3. Install the left side

mounting prongs last.

1. Tilt the shelf at roughly

60° up or down when

moving to avoid

scraping the chamber

walls.

18 | Page

INSTALLATION

DEIONIZED AND DISTILLED WATER

Do not use deionized water to clean the chamber even if it is readily available in your laboratory

environment. Use of deionized water may corrode metal surfaces and voids the warranty. Sheldon

Manufacturing recommends the use of distilled water in the resistance range of 50K Ohm/cm to 1M

Ohm/cm, or a conductivity range of 20.0 uS/cm to 1.0 uS/cm, for cleaning applications.

INSTALLATION CLEANING AND DISINFECTION

The manufacturer recommends cleaning the shelving and unit chamber prior to installation of the

shelving in the chamber. The unit was cleaned at the factory but may have been exposed to

contaminants during shipping. Remove all wrappings and coverings from shelving prior to cleaning

and installation. Do not clean with deionized water.

Please see the Cleaning and Disinfection procedure on page 29 of the User Maintenance section

for information on how to clean and disinfect without damaging the unit and its components.

19 | Page

GRAPHIC SYMBOLS

Your incubator comes provided with graphic symbols on its exterior surfaces. These identify hazards

and the function of the adjustable components, as well as important notes in the user manual.

Symbol Definition

Consult the user manual.

Consulter le manuel d'utilisation

Temperature display

Indique l'affichage de la température

Over Temperature Limit system

Thermostat température limite contrôle haute

AC Power

Repère le courant alternatif

I/ON O/OFF

I indique que l'interrupteur est en position marche.

O indique que le commutateur est en position d'arrêt.

Protective earth ground

Terre électrique

Adjusts UP and DOWN

Ajuster le haut et vers le bas

Manually adjustable

Indique un réglage manuel

Potential shock hazard

Risque de choc électrique

Recycle the unit. Do not dispose of in a landfill.

Recycler l'unité. Ne jetez pas dans une décharge

20 | Page

GRAPHIC SYMBOLS

This manual suits for next models

1

Table of contents

Other Shel lab Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Fluke Biomedical

Fluke Biomedical INCU Operator's manual

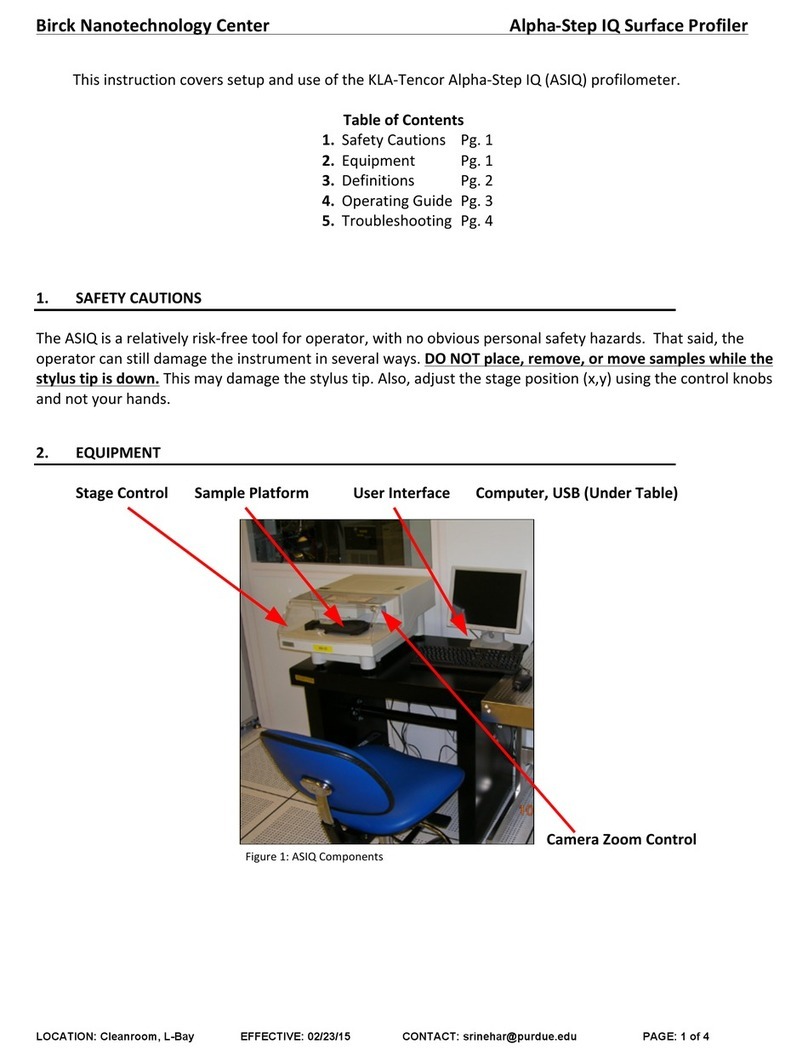

KLA Tencor

KLA Tencor Alpha-StepIQ operating guide

ASEG GALLONI

ASEG GALLONI MODULAR 6 Operating and maintenance manual

Laarmann

Laarmann LMFC250 user manual

REITEL

REITEL RETOCAST I operating instructions

Nippon Genetics

Nippon Genetics FastGene FAS-Digi PRO manual