Shelbourne Reynolds Powermix Pro Express User manual

9-25m3

OPERATORS MANUAL

ORIGINAL INSTRUCTIONS

MAN-05005

POWERMIX PRO

Issue 9 15/10/2020

SHELBOURNE PRODUCT

Issue 2

12.04.18

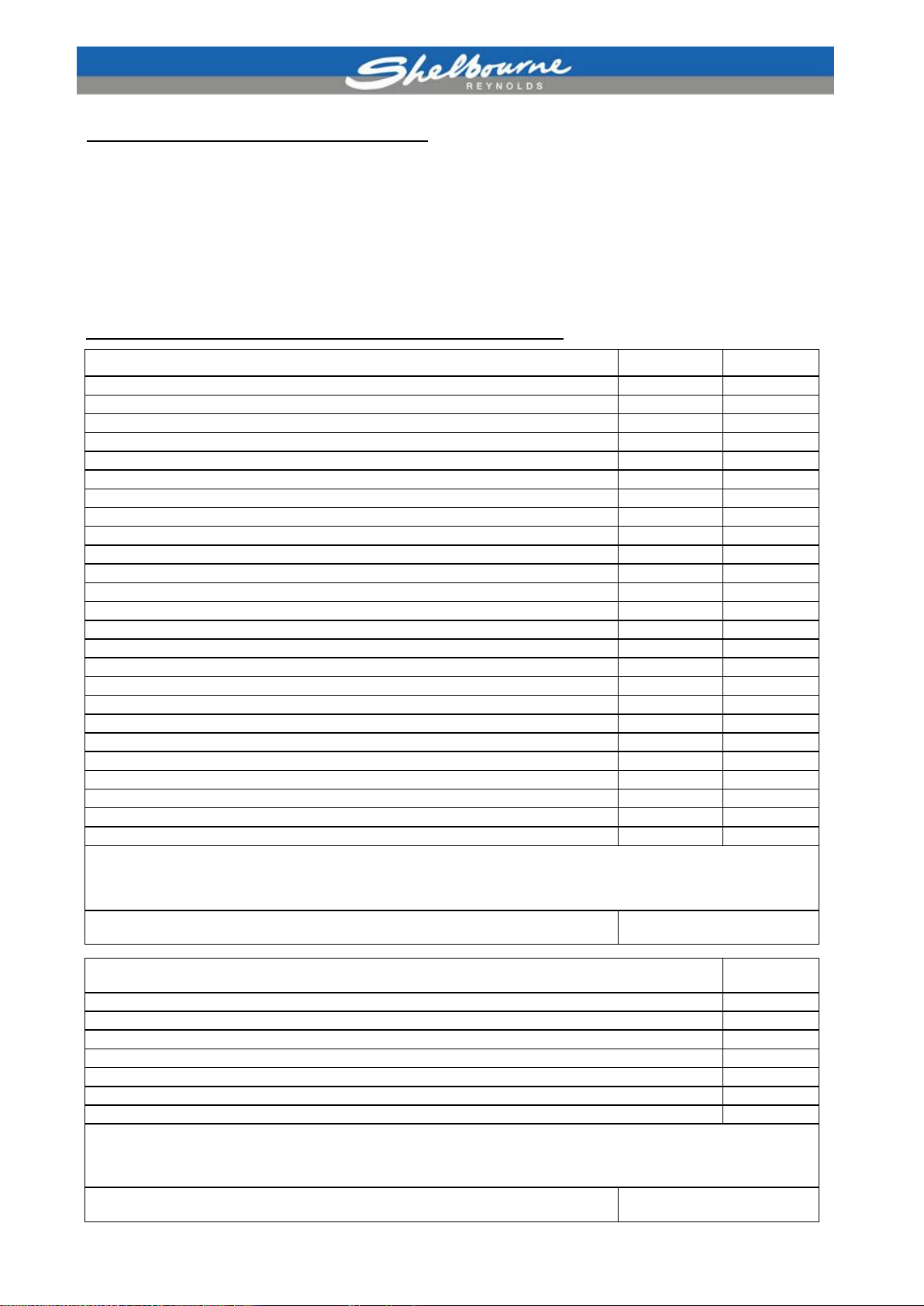

DEALER PRE-DELIVERY / INSTALLATION CHECK AND WARRANTY REGISTRATION –POWERMIX PRO

DEALERS PRE-DELIVERY / INSTALLATION CHECK

IMPORTANT⚠

All items listed below must be checked, and adjusted if necessary. The person conducting the inspection should tick each

item in the space provided, indicating whether or not adjustments were required. In the event of additional work being

needed, details should be given in the additional work / discrepancy box, located at the bottom of this sheet, or on a

separate sheet if required. When the inspection is complete, THIS FORM MUST BE COPIED & RETURNED TO: -

Shelbourne Reynolds within 30 days of delivery to customer, otherwise the invoice date to the dealer will be deemed to

be the start date for the warranty period.

SERIAL NUMBER: ......................................................... MACHINE NUMBER: ..........................................................

MODEL: .........................................................................

PLEASE TICK APPROPRIATE COLUMN FOR EACH ITEM UNDERTAKEN

Dealer Pre Customer Delivery / Installation / Commissioning

Checks OK

Adjusted

Check the PTO shaft length is compatible with the tractor. (see section 5.2)

Rotate the auger & check there is no unusual scratching or knocking sounds.

Check the drawbar height is adjusted to suit the tractor. (see section 5.1)

Check configuration of auger blades, and remove the blade guards. (see section 5.5)

Ensure the hoses are not taught when connected to the tractor.

Check planetary & 2-speed gearbox oil levels.

Check operation of all hydraulic services.

Check hydraulic system for leaks.

Check tyre pressures. (see section 8.2)

Check wheel nuts for correct torque setting. (see section 8.3)

Check brake ram operation & adjustment.

Check braking system for oil leaks.

Check operation of handbrake.

Lubricate all grease points.

Check in general that nuts & bolts are tight.

Check paintwork & finish.

Ensure that all safety guards & decals are fitted.

Ensure that an operator’s manual is supplied with the machine.

Additional Comments:

...........................................................................................................................................................................................

..........................................................................................................................................................................................

Dealer Representative’s Name: ..............................................................................................

Date: .........................................

Customer Instruction

Actioned

Explain the correct setting & operation of the machine to the customer.

Ensure the machine is correctly attached to the customer’s tractor.

Ensure the maintenance schedule is explained to the customer.

Ensure the lubrication & grease points are indicated to the customer.

Ensure all safety precautions & warning decals are explained to the customer.

Ensure the warranty policy is explained to the customer.

Ensure that the operator’s manual is handed to the customer.

Additional Comments:

...........................................................................................................................................................................................

...........................................................................................................................................................................................

Dealer Representative’s Name: .............................................................................................

Date: .........................................

For specific details please refer to the operator’s manual. Page 1 of 2

Issue 2

12.04.18

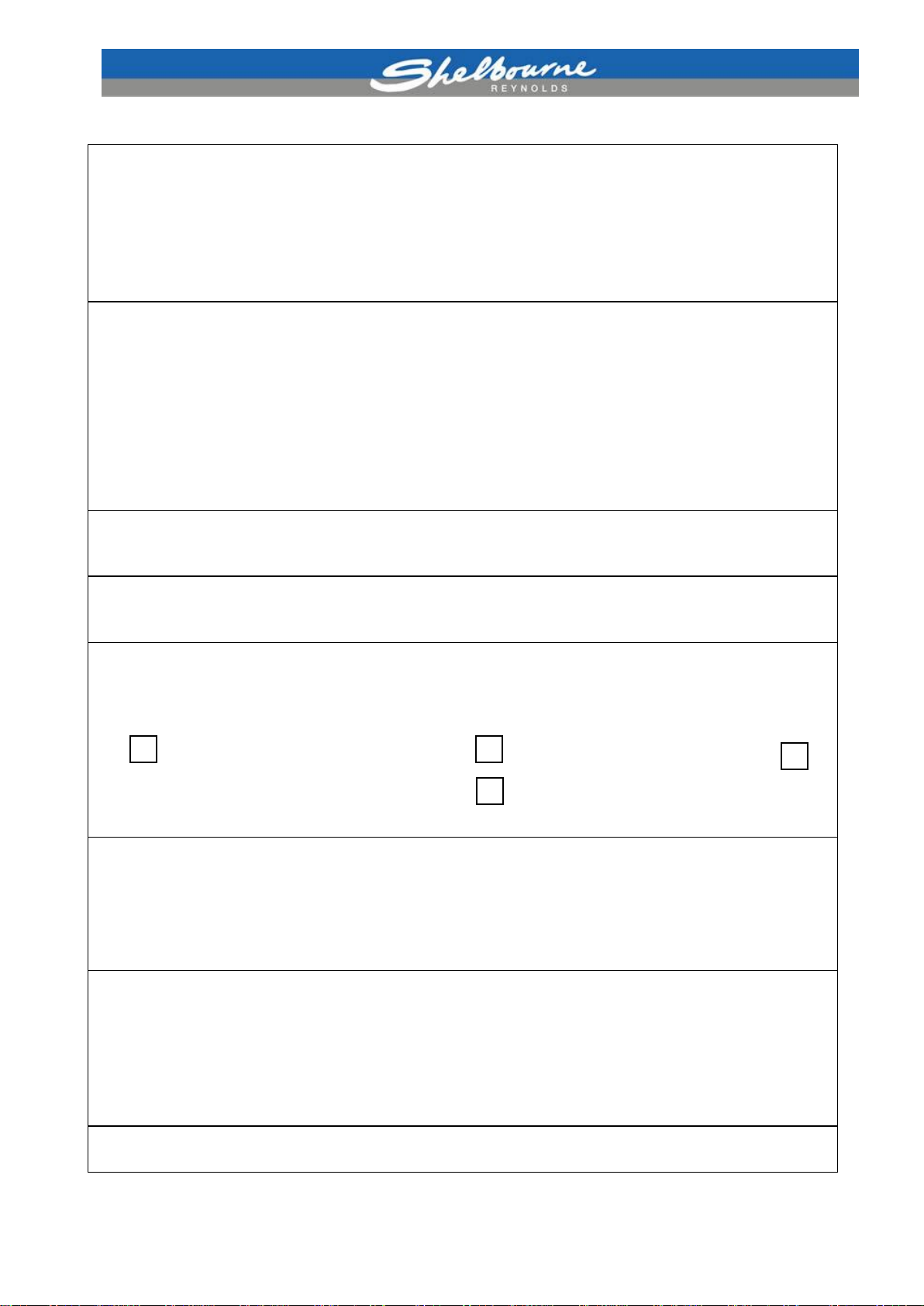

DEALER PRE-DELIVERY / INSTALLATION CHECK AND WARRANTY REGISTRATION –POWERMIX PRO

Dealer Name: ............................................................................

Address: .........................................................................................................................................................................

.........................................................................................................................................................................

Post / Zip code: .........................................................................

Dealer Salesman Name: ............................................................

Customer Name: ......................................................................

Business Name (if different from above): ............................................................................................................................

Address: .........................................................................................................................................................................

.........................................................................................................................................................................

Post / Zip code: ........................................................................

Email Address: ........................................................................

Tel No. Home / Office: ............................................................... Cell / Mobile:...................................................................

SERIAL NUMBER: ....................................................................MACHINE NUMBER: ......................................................

MODEL: ..................................................................................

Dealer Signature: ...................................................................

Print Name: .......................................................................... Date:.................................................................................

Privacy Notice

Here at Shelbourne Reynolds Engineering Ltd we take your privacy seriously and will only use your personal information to administer your account and

provide the products and services you have requested from us.

We would occasionally like to contact you with details of other products you may be interested in, special offers we provide and details/invitations to

shows, working demonstrations and open days, however this would be no more than once or twice per year. If you consent to us contacting you for this

purpose please tick a box or boxes to say how you would like us to contact you.

Post Email Telephone/SMS

If you prefer not to be contacted, then please tick this box

For further information please refer to our Privacy Policy at www.shelbourne.com

Customers Signature: .............................................................

Print Name:........................................................................... Date:.............................................................

The customer’s signature certifies that the machine was delivered in a satisfactory condition and that adequate instruction was received as to

its correct operation, safety requirements, and maintenance as stated in the operator’s manual, and that the customer has read, understood,

and agrees to the Terms and Conditions of Sale and Warranty (including the disclaimers and limitations) contained in Section 1.5 of the

operator’s manual.

Additional work / discrepancies:

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

...........................................................................................................................................................................................

This page must be faxed or emailed to Shelbourne Reynolds Engineering Ltd.

Fax No: +44 (0)1359 250464 Email: warranty@shelbourne.com

Page 2 of 2

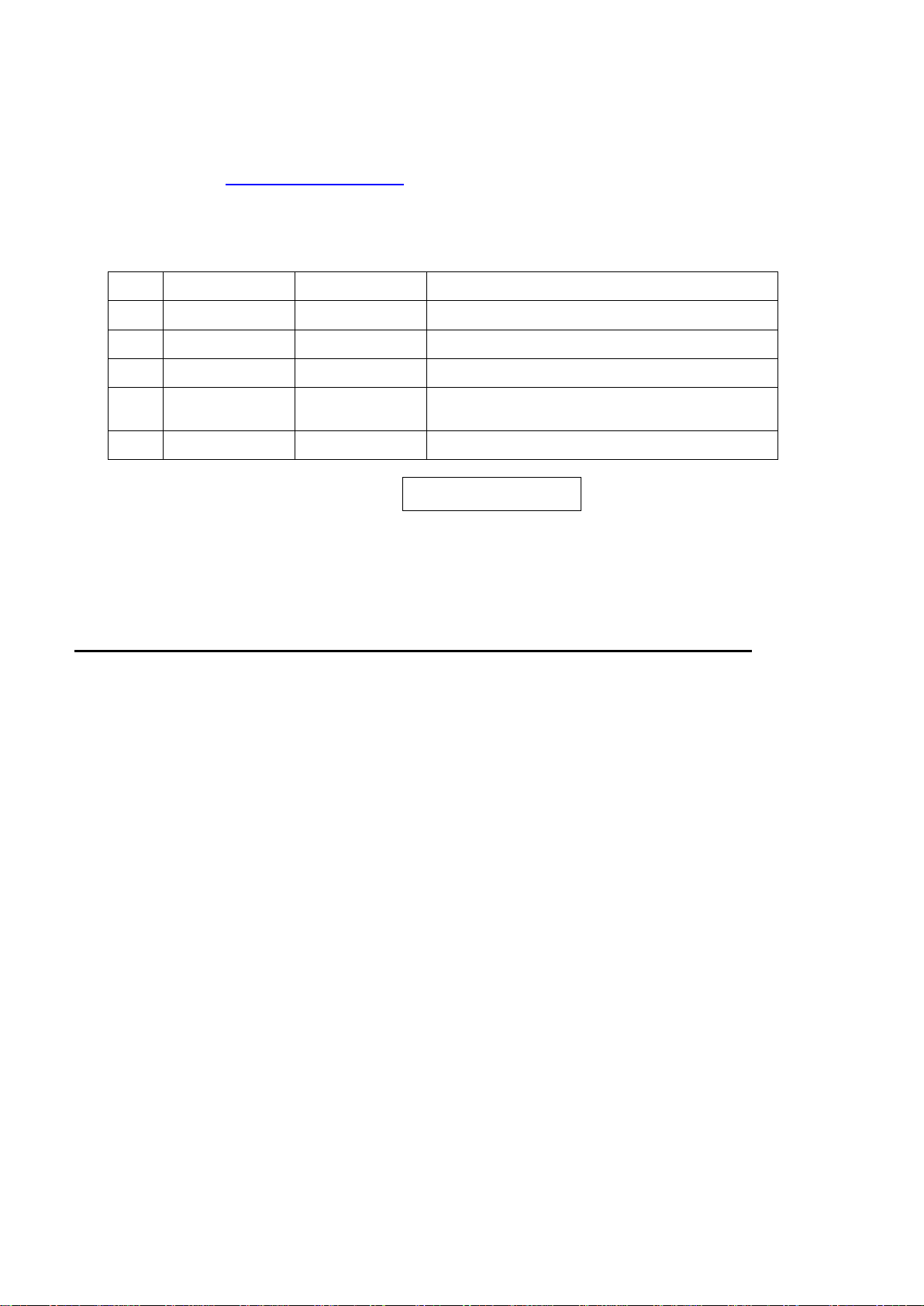

Dear Customer,

Parts manuals are not supplied with this machine, but they can be ordered from your

Shelbourne Reynolds dealer. Alternatively they can be downloaded from the Shelbourne

Reynolds website www.shelbourne.com by clicking on the Parts and Service section of the

website, and then selecting manuals followed by Powermix Manuals.

The Machine and Parts Manual Number for your machine is -

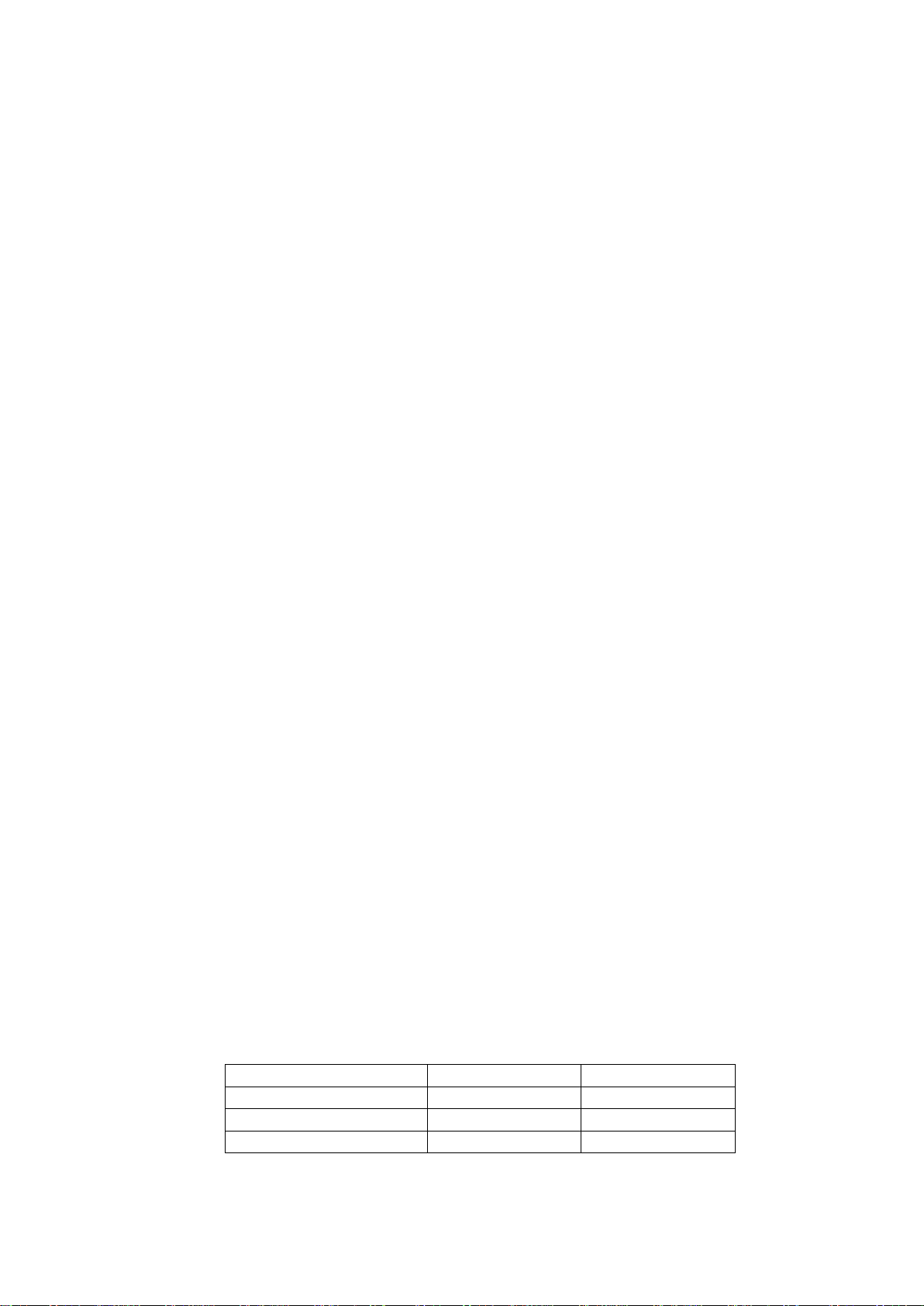

Tick

Machine No.

Manual No.

Machine Description

619928 02

MAN-05105

Powermix Pro 9m3 Express

619930 01

MAN-05106

Powermix Pro 9m3 Popular

619929 01

MAN-05107

Powermix Pro 16m3 Twin Express

619929 04

MAN-05107

Powermix Pro 16m3 Twin Express C/W

rear door

619932 01

MAN-05108

Powermix Pro 9m3 2 rear door Popular

Powermix Pro Serial Number

ORDERING SPARE PARTS

To ensure that you order the correct part from your SRE dealer please use the following

procedure.

ALWAYS QUOTE THE MACHINE AND SERIAL NUMBERS WHEN ORDERING.

Refer to the Parts Manuals front page/s, listing the machine numbers. Select the correct

machine number which is printed in the top left corner of the page (starting with 6199_ _01).

The machine number is listed above or can be found printed on the identification plate, which is

located on the LH side of the chassis member.

Scan down the page, and select the relevant sub assembly your required part falls within. Sub-

assemblies start from 6190_ _ 01. Note the year or serial number of the machine may

determine a correct sub assembly if more than one is listed.

Continue through the manual and find the relevant sub assembly parts listing. Again the number

will be printed in the top left corner; the sub-assemblies are in numerical order.

Having found the correct parts list, you will find the corresponding drawing by either looking at

the facing page or progressing through the manual to the next drawing.

The drawings indicate the components by item numbers, which you will find, are repeated in the

left-hand side of your parts listing, and therefore referring to the correct part.

Please note that if certain parts cannot be found listed below the sub-assembly numbers, they

are likely to form part of a specific optional kit. These kits will be found in numerical order further

through the manual and start with KIT- _ _ _ _ _.

The lists shown on the following pages highlight the optional build kits that also make up

your exact configuration of machine.

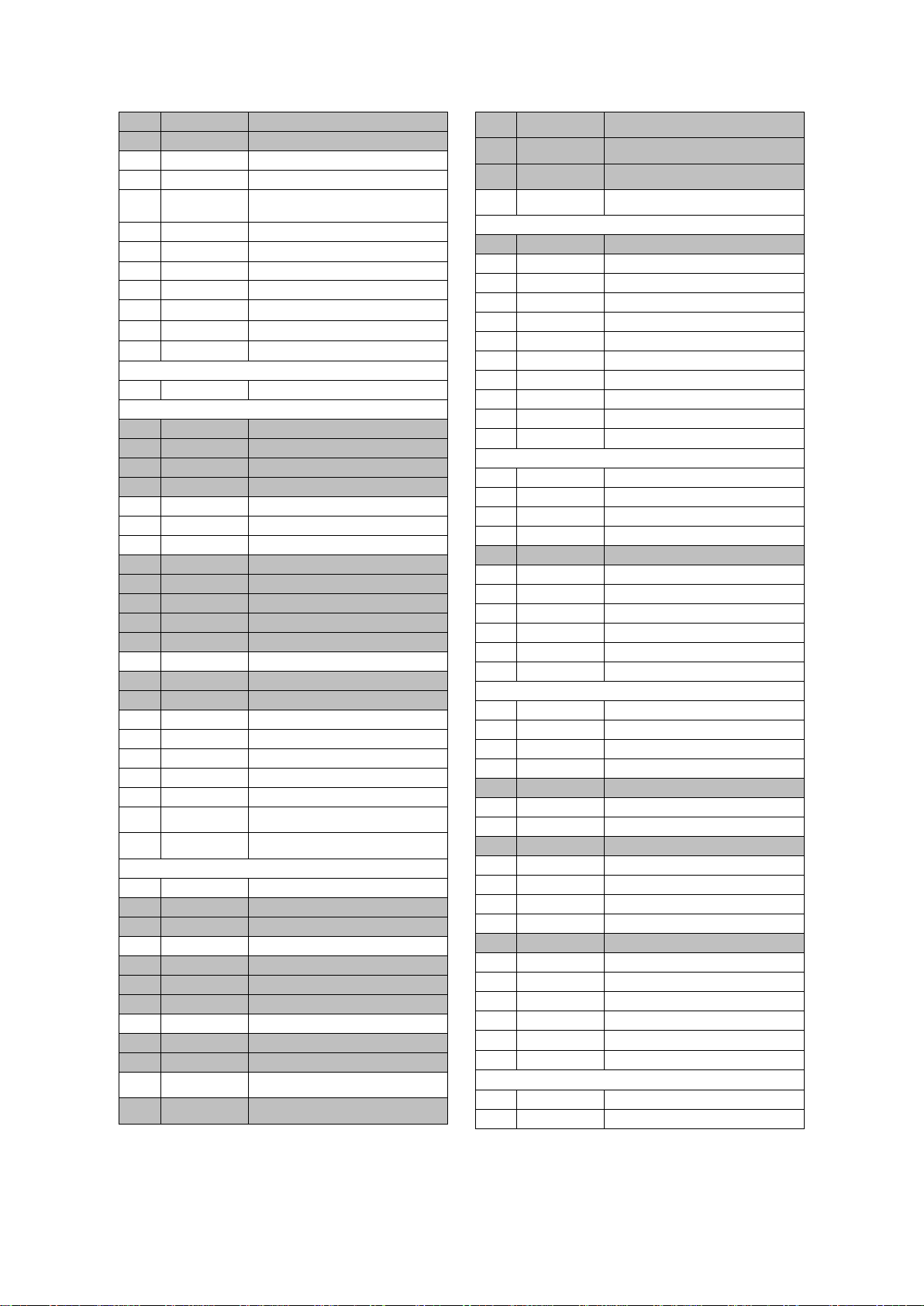

Non-current production highlighted

Tick

Part No.

Description

Drive Options

KIT-03594

Single speed drive kit (Popular)

KIT-03580

Single speed drive kit (Express)

KIT-03693

Single speed drive kit (Twin Express)

KIT-03683

2 Speed drive kit (Express)

KIT-03608

2 Speed drive kit (Popular)

KIT-03585

2 Speed drive kit (Twin Express)

KIT-03586

Gear change lever arm kit (cable)

KIT-03838

Gear change lever kit (fixed)

PTO Shaft Options

KIT-03595

W-A PTO (Comer) (Popular)

KIT-03595b

W-A PTO (Walt) (Popular)

KIT-03657

STD PTO (Comer) (Popular)

KIT-03657a

STD PTO (Weasler) (Popular)

KIT-03657b

STD PTO (Walt) (Popular)

KIT-03588

W-A PTO(Comer) (Exp Single)

KIT-03588b

W-A PTO (Walt) (Exp Single)

KIT-03647

STD PTO (Comer) (Exp Single)

KIT-03647a

STD PTO (Weasler) (Exp Single)

KIT-03647b

STD PTO (Walt) (Exp Single)

KIT-03609

W-A PTO (Comer) (2 speed Single)

KIT-03658

STD PTO (Comer) (2 speed Single)

KIT-03658b

STD PTO (Walt) (2 speed Single)

KIT-03618

W-A PTO 21 spline (2 speed Twin)

KIT-03659

STD PTO 21 spline (2 Speed Twin)

KIT-03587

W-A PTO (Comer) (2 Speed Twin)

KIT-03587a

W-A PTO (Weaslerr) (2 Speed Twin)

KIT-03587b

W-A PTO (Walt) (2-Speed Twin)

KIT-03660

STD PTO (Comer) (2 Speed Twin)

KIT-03660a

STD PTO (Weasler) (2 speed Twin)

KIT-03660b

STD PTO (Walt) (2 speed Twin)

KIT-03692a

W-A PTO (Single speed Twin)

KIT-03692

STD PTO (Single speed Twin)

Towing Eye Options

KIT-03439

Continental towing eye

KIT-03741

Heavy duty UK towing eye

KIT-03740

UK swivel towing eye

KIT-03422

UK towing eye

KIT-03513

Scharmuller hitch fixing kit

Ladder Options

KIT-03714

Standard rear ladder

KIT-03715

Ladder extension (11 & 19m³)

KIT-03715a

Ladder extension (13 & 22m³)

KIT-03715b

Ladder extension (15 &25m³)

KIT-03723

Platform option

Conveyor Options

KIT-03767

PVC web conveyor system

KIT-03964

PVC web conveyor spring tensioner

KIT-60009

PVC web conveyor spring tensioner

KIT-03761

PVC web conveyor system

KIT-03691

PVC web conveyor system

KIT-03644

Web conveyor system

KIT-03579

Conveyor mounting kit (Single)

KIT-03582

Conveyor mounting kit (Twin)

KIT-03634

3m web conveyor (Single)

KIT-03634a

3m web conveyor (twin)

KIT-03699

Fixed front conveyor (Single)

KIT-03650

Fixed front conveyor (Twin)

KIT-03612

1m side conveyor (RH popular door)

Transfers Kit

KIT-03598

Transfers for Single Express

KIT-03596

Transfers for Popular

KIT-03597

Transfers for Twin Express

Blade Options

KIT-03710a

Standard blade kit

KIT-03710

Tungsten coated blade kit

KIT-03577

Blade kit (up to 21.11.08)

KIT-03578

Large blade kit (up to 21.11.08)

KIT-03735

600mm auger extension std blades

KIT-03716

300mm auger extension std blades

KIT-03716a

300mm auger extension tungsten

KIT-03735a

600mm auger extension tungsten

KIT-03826a

Standard blade kit

KIT-03826

Tungsten coated blade kit

KIT-03827a

600mm auger extension tungsten

KIT-03827

600mm auger extension std blades

KIT-03828a

300mm auger extension tungsten

KIT-03828

300mm auger extension std blades

Weigher Options

KIT-03470

Dummy weigh cell kit

KIT-03470a

Dummy weigh cell kit (Twin)

KIT-03537

Weigh cell system

KIT-03538

Weigh cell system (Twin)

KIT-03456

Basic level display (EZ2000V)

KIT-03456a

Basic level display (EZ2000V remote)

KIT-03759

Basic level display & radio link

KIT-03717

Basic level display (EZ2400V)

KIT-03442

Mid level display (EZ3200V)

KIT-03614

Mid level display (EZ3200V)

KIT-03442a

Mid level display (EZ3200V remote)

KIT-03751

Mid level display (EZ3400V)

KIT-03805

Basic display (EZ2500V)

KIT-03610

Top level display (3 pin plug wireless)

KIT-03471

Top level display (3 pin plug)

KIT-03471a

Top level display (European plug)

KIT-03728B

Top level display, Cab control, TMR tracker

LITE with USB flash drive

KIT-03728D

Top level display, TMR tracker LITE with

USB flash drive

KIT-03728E

Top level display, RD2400 remote display,

TMR tracker PRO with USB flash drive

KIT-03728F

Top level display, Cab control, TMR tracker

PRO+ with USB flash drive, RF data link

KIT-03467

Remote zero function

KIT-03616

Data down loader kit

KIT-03615

PROX sensor kit

KIT-03611

Cab control display kit

KIT-03567

Remote display

KIT-03483

Flashing light kit

KIT-03510

Alarm kit

KIT-03933

Weigh cell system (Single)

KIT-03941

Weigh cell system (DG) (Twin)

KIT-03943

Weigh cell system (DG) (Single)

KIT-03949B

TMR3610 Display C/W TMR tracker Lite

software + USB & cab control with wireless

modem.

KIT-03895

DG400 Basic display

KIT-03896

DG600 Mid level display

KIT-60015

DG8000IC Top level display

KIT-03904

Bluetooth Modem kit

KIT-03900

3-pin plug connection kit

KIT-03958

DINA TEL Remote display

KIT-03955

GPRS data transfer kit

Lights

KIT-03431

Lighting kit

Wheel & Tyre Options

KIT-03544

305/55R22.5 assy

KIT-03629

445/45R19.5 Wide option

KIT-03607

445/45R19.5 Wide option (Twin)

KIT-03672

435/50R19.5 Goodyear marathon

KIT-03672a

435/50R19.5 Doublecoin

KIT-03646

18R22.5 For single axle twin auger

KIT-03678

Axle packer plate kit for above

KIT-03628

18R22.5 Single axle twin (8 stud)

KIT-03671

385/55R22.5 assy (Twin)

KIT-03734

385/55R22.5 assy

KIT-03704

Axle spacer kit (for kit-03734)

KIT-03544a

305/55R22.5 assy (Twin)

KIT-03511

Super single tyre kit (385/65R22.5)

KIT-03757

355/55R22.5 Bandenmarkt

KIT-03757a

355/55R22.5 Bandenmarkt (Twin)

KIT-03671b

385/55R22.5 Longmarch

KIT-03512

Axle spacer kit (for KIT-03511)

KIT-03821

425/40B17 Delcora

KIT-03800

Super single (385/65R22.5) - Twin

KIT-03736

Axle spacer kit (for KIT-03800)

KIT-03934

385/55R19.5 Doublecoin (Single)

KIT-03934a

385/55R19.5 Doublecoin (Twin)

Axle Options

KIT-03433c

Hydraulic braked axle

KIT-03433b

Hydraulic braked axle

KIT-03433

Hydraulic braked axle

KIT-03446b

Unbraked axle

KIT-03446

Unbraked axle

KIT-03633

Braked single axle (twin 8 stud)

KIT-03627

Unbraked single axle (Twin 8 stud)

KIT-03809

Hyd braked single axle (Twin 10 stud)

KIT-03673

Hyd braked single axle (Twin 10 stud)

KIT-03645

Unbraked single axle (Twin 10 stud)

KIT-03811

Hyd braked axle tandem underslung

bogie rear steering

KIT-03624

Hyd braked axle tandem underslung

bogie rear steering

KIT-03583

Hyd braked axle tandem underslung

bogie

KIT-03694b

Hyd braked axle tandem underslung

bogie

KIT-03694

Hyd braked axle tandem underslung

bogie

KIT-03803

Hyd braked axle tandem underslung

bogie

Extension Side Options

KIT-03605

900mm extension (15m³)

KIT-03396a

600mm extension (13m³)

KIT-03642

450mm extension (12m³)

KIT-03681

250mm extension (10.5m³)

KIT-03395a

300mm extension (11m³)

KIT-03655

800mm extension (25m³)

KIT-03453

600mmm extension (22m³)

KIT-03651

450mm extension (21m³)

KIT-03674

250mm extension (18m³)

KIT-03452

300mm extension (19m³)

KIT-03845

800mm extension (15m³)

Rubber Retaining Ring Options

KIT-02651

Rubber retaining ring (9m³)

KIT-03622

Rubber retaining ring (11m³)

KIT-03641

Rubber retaining ring (12m³)

KIT-03620

Rubber retaining ring (13m³)

KIT-03604

Rubber retaining ring (15m³)

KIT-03461

Rubber retaining ring (16m³)

KIT-03623

Rubber retaining ring (19m³)

KIT-03652

Rubber retaining ring (21m³)

KIT-03619

Rubber retaining ring (22m³)

KIT-03654

Rubber retaining ring (25m³)

KIT-03847

Rubber retaining ring (15m³)

Others

KIT-03504

Rubber door flap (RH side door)

KIT-03505

Rubber door flap (LH side door)

KIT-03720

Rubber door flap (LH rear door)

KIT-03720a

Rubber door flap (RH rear door)

KIT-03632

Mud flap kit

PLG-0005

7 pin plug

KIT-02602

Brake relief kit

KIT-03576

300mm auger extension

KIT-03599

Hydraulic jack (hand pump/reservoir)

KIT-03514

Hydraulic jack (direct spool)

KIT-03449

Mechanical jack

KIT-03719

Auger magnet (15mm thick flights)

KIT-03300

Auger magnet kit (front auger only)

KIT-03617

Dummy ram kit

KIT-03837

Battery pack kit

Anti-rotation Plate Options

KIT-03448

Bolt in fixed anti-rotation plates

KIT-03447

Blade type anti-rotation plates

Hydraulic Options (up to 07/07/07)

KIT-03436

Direct tractor connection (LH)

KIT-03460

Direct tractor connection (LH Twin)

KIT-03507

2 station spool valve (2 door op)

KIT-03440

Direct tractor connection (RH)

KIT-03574

Direct coupled hydraulics (1m side)

KIT-03621

Manual lever spool valve (1m side)

KIT-03613

Electric solenoid hydraulics (1m side)

KIT-03434

Lever arm kit (spool valve - machine)

KIT-03455

Lever arm kit (spool valve - tractor)

KIT-03487

Direct coupled hyd (Web conv.)

KIT-03486

Manual lever spool valve (Web conv.)

KIT-03492

Electric solenoid (Web conv.)

KIT-03635

Electric solenoid (3m web conv.)

Hydraulic Options (Popular)

KIT-03666

1st stage hydraulics (LH side door)

KIT-03665

1st stage hydraulics (RH side door)

KIT-03722

1st stage hydraulics (rear door)

KIT-03667

Direct Coupled (side and rear door)

KIT-03670

Direct coupled (RH side door)

KIT-03668

Electric solenoid (RH side door)

KIT-03669

Manual lever (RH side door)

KIT-03434

Lever arm kit (Spool valve-machine)

KIT-03455

Lever arm kit (spool valve-tractor)

Hydraulic Options (Express)

KIT-03661

1st stage hydraulics (Front door)

KIT-03700

Direct coupled (Front fixed)

KIT-03662

Direct coupled (Web conv.)

KIT-03663a

Electric solenoid ( flow divider)

KIT-03664

Manual lever (Web conv.)

KIT-03780

Electric solenoid (Vari-Speed

controller)

KIT-03797

Electric solenoid (Vari-Speed

controller)

KIT-03779

Electric Solenoid ( manual speed

controller)

KIT-03798

Electric Solenoid ( manual speed

controller)

KIT-03434

Lever arm kit (spool valve-machine)

KIT-03455

Lever arm kit (spool valve-tractor)

KIT-03907

Hydrokit electric solenoid

KIT-03967

Hydrokit electric solenoid ( ¾” hoses)

KIT-03968

Hydrokit electric solenoid ( ¾” hoses)

KIT-03942

Wireless electric solenoid ( ¾” hoses)

Country Area Kits

KIT-03249

UK area kit

KIT-03959

UK area kit (2018 & on)

KIT-03251

USA area kit

KIT-03248

German area kit

KIT-03250

European area kit

Extras

LCL-04130

Sensor csble

LCL-01210

Power cable

MOTH16000

Conveyor motor (160cc)

EC Declaration of conformity for machinery

(Machinery Directive 2006/42/EC, Annex II., sub. A)

Manufacturer: Shelbourne Reynolds Engineering Ltd.

Address: Shepherds Grove Industrial estate,

Stanton,

Bury St Edmunds,

Suffolk.

England.

IP31 2AR

Name and address of the person (established in the European Community/EEA)

authorised to compile the technical file (to the authorities on request):

Name: Mr Neil Smith

Address: As stated above.

Herewith we declare that: DESIGNATION DIET FEEDER

MAKE: POWERMIX PRO

MACHINE No:

SERIAL No:

is in conformity with the relevant provisions of the Machinery Directive (2006/42/EC)

is in conformity with the relevant provisions of the EMC Directive (2004/108/EC)

Neil Smith

Director

Place : Stanton, England. Date :

1

CONTENTS

Section 1 INTRODUCTION

1.1 FOREWORD

1.2 IMPROVEMENTS AND CHANGES

1.3 SERVICE PARTS

1.4 MACHINE IDENTIFICATION

1.5 WARRANTY TERMS AND CONDITIONS TO THE PURCHASER

Section 2 SAFETY PROCEDURES

2.1 ACCIDENT PREVENTION

2.2 DANGER / WARNING SYMBOLS

2.3 ACCIDENT PREVENTION BEFORE STARTING THE MACHINE

2.4 ACCIDENT PREVENTION WHEN COUPLING TO THE TRACTOR

2.5 ACCIDENT PREVENTION WHEN USING THE HYDRAULIC SYSTEM

2.6 ACCIDENT PREVENTION WHEN USING THE PTO SHAFT

2.7 ACCIDENT PREVENTION WHEN OPERATING THE MACHINE

2.8 ACCIDENT PREVENTION WHEN TOWING ON PUBLIC ROADS

2.9 ACCIDENT PREVENTION WHEN LEAVING THE MACHINE

2.10 ACCIDENT PREVENTION WHEN CHANGING A WHEEL

2.11 ACCIDENT PREVENTION WHEN SERVICING OR WORKING ON THE

MACHINE

2.12 ACCIDENT PREVENTION WHEN CLEANING AND STORING THE MACHINE

2.13 NOISE EMISSIONS

2.14 PROPER USE

2.15 NO LIABILITY FOR CONSEQUENTIAL DAMAGE

Section 3 SPECIFICATION

3.1 DESCRIPTION

3.2 INTENDED USE

3.3 SPECIFICATION TABLE

3.4 SINGLE AUGER POPULAR MODEL OVERALL DIMENSIONS

3.5 SINGLE AUGER EXPRESS MODEL OVERALL DIMENSIONS

3.6 TWIN AUGER EXPRESS MODEL (TANDEM AXLE) OVERALL DIMENSIONS

3.7 TWIN AUGER EXPRESS MODEL (SINGLE AXLE) OVERALL DIMENSIONS

Section 4 HANDLING & TRANSPORTATION

4.1 HANDLING

4.2 TRANSPORTATION

Section 5 PREPARATIONS FOR USE

2

5.1 COUPLING AND UNCOUPLING

5.2 ADJUSTING THE DRAWBAR HEIGHT

5.3 CONNECTING THE HYDRAULIC SUPPLY

5.4 CONNECTING THE POWER SUPPLY

5.5 ADJUSTING THE PTO DRIVE SHAFT LENGTH

5.6 COUPLING THE PTO DRIVE SHAFT TO THE TRACTOR

5.7 ADJUSTING THE POSITION OF THE 2-SPEED GEAR CHANGE LEVER.

5.8 ADJUSTING THE POSITION OF THE MANUAL LEVER CONTROL VALVE.

5.9 RAISING / LOWERING THE PARKING STAND.

5.10 CHECK OPERATION OF WEIGH SYSTEM.

5.11 CONFIGURATION OF THE AUGER BLADES.

5.12 PRE OPERATION CHECK LIST.

Section 6 OPERATING THE MACHINE

6.1 LOADING THE MACHINE

6.2 MIXING / INGREDIENT LOADING SEQUENCE

6.3 CHOPPING ROOT CROPS

6.4 CHOPPING BALED FORAGE

6.5 OPERATING THE ANTI-ROTATION BLADES

6.6 USING THE FIXED ANTI-ROTATION PLATES

6.7 AUGER SPEEDS AND DRIVE CONFIGURATIONS

6.8 OPERATING THE 2-SPEED GEARBOX

6.9 FEEDING PROCEDURE.

6.10 OPERATING THE FRONT ELEVATING WEB CONVEYOR.

6.11 OPERATING THE CONVEYOR DEFLECTOR

6.12 OPERATING THE FIXED FRONT WEB CONVEYOR

6.13 SIDE DELIVERY OPTION

6.14 1M SIDE CONVEYOR OPTION

6.15 DIRECT COUPLED HYDRAULIC CONTROLS

6.16 MANUAL LEVER HYDRAULIC VALVE CONTROLS

6.17 SEMI-ELECTRIC HYDRAULIC VALVE CONTROLS.

6.18 ALL ELECTRIC HYDRAULIC VALVE CONTROLS.

6.19 CALIBRATING THE PROPORTIONAL CONTROLLER.

6.20 OPERATING THE HANDBRAKE.

6.21 USING THE INSPECTION LADDER

6.22 USING THE MINERAL CHUTE.

6.23 OPERATING THE BOGIE WITH A REAR STEERING AXLE.

6.24 SHEARBOLT REPLACEMENT

3

Section 7 MAINTENANCE AND STORAGE

7.1 CONNECTING THE DOOR SAFETY STRAP

7.2 REPLACING THE AUGER BLADES

7.3 CHECKING TYRE PRESSURES

7.4 TIGHTENING WHEEL NUTS

7.5 CHECKING THE AXLE HUB CAPS

7.6 CHECKING THE WHEEL BEARINGS

7.7 CHECKING BRAKE CLEARANCE AND WEAR.

7.8 BOGIE SUSPENSION MAINTENANCE.

7.9 STEERING AXLE MAINTENANCE AND ADJUSTMENT.

7.10 FRONT WEBBING CONVEYOR MAINTENANCE.

7.11 1M SIDE CONVEYOR MAINTENANCE.

7.12 GREASING SCHEDULE.

7.13 GEARBOX OIL CHANGES

7.14 STORAGE AND CLEANING

7.15 WELDING REPAIRS

7.16 RECOMMENDED PERIODIC MAINTENANCE.

4

5

SECTION 1: INTRODUCTION

1.1 FOREWORD

This manual will aid the user when setting, operating and servicing their Shelbourne

Reynolds Powermix Pro. Scheduled information is listed to ensure the operator follows

safe and efficient working procedures. It must be read & understood by all persons who

are required to carry out work either on or with the machine, and should be used in

conjunction with the operator’s manual of the tractor or prime mover.

1.2 IMPROVEMENTS AND CHANGES

Shelbourne Reynolds Engineering are continually improving their products to meet the

farmers needs and therefore reserve the right to make improvements and changes

when practical to do so, without incurring any obligation to make changes and additions

to equipment which has been sold previously.

We also reserve the right to make changes to the illustrations, data and specifications

contained within this manual.

6

1.3 SERVICE PARTS

Use guaranteed and genuine Shelbourne Reynolds Engineering service parts on

Shelbourne Reynolds machinery to ensure maximum life and best performance.

These are available through your Shelbourne Reynolds Engineering dealer.

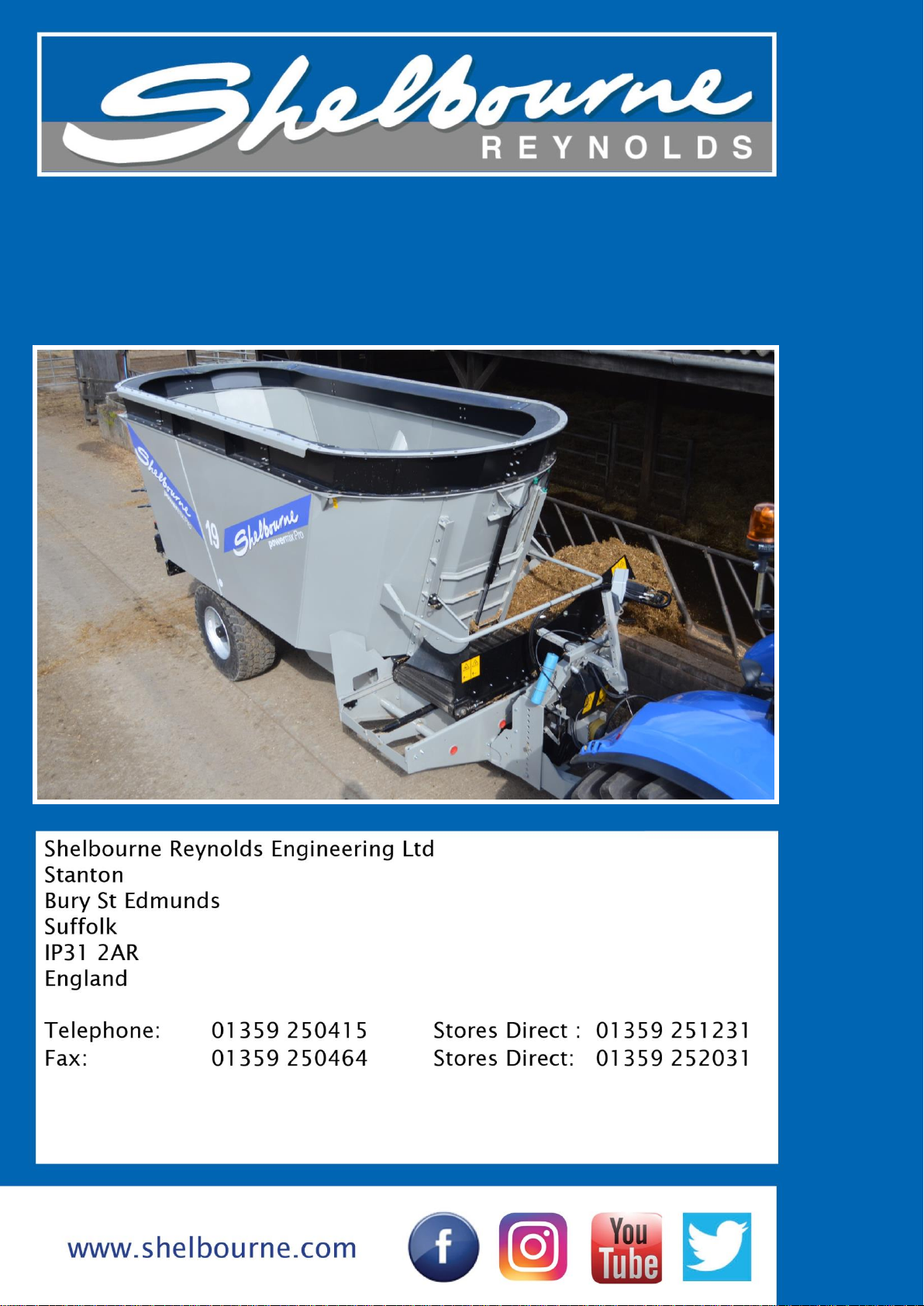

1.4 MACHINE IDENTIFICATION

The serial and machine numbers are printed on a plate (Fig. 1), attached midway along

the LH side of the chassis.

Fig. 1

1.5 POWERMIX WARRANTY POLICY

1.5.1 MACHINE REGISTRATION

To qualify for the full benefit of the warranty set out in clause 1.5.2 of this warranty

policy (the “Warranty”), it is the buyer’s responsibility to ensure that the selling dealer

has completed the warranty registration details and that they are submitted to

Shelbourne Reynolds Engineering Ltd. within 30 days from the date of delivery. Using

the machine implies the knowledge and acceptance of these warranty terms.

1.5.2 NEW MACHINE WARRANTY

All new machines supplied by Shelbourne Reynolds Engineering Ltd.

(“Shelbourne”), are warranted to the original purchaser, under normal use and

7

service, to be free from defects in material and workmanship for a period of 12 months

from the date of delivery to the original purchaser (the Warranty Period), subject to the

terms set out in this warranty policy.

No other warranty is given by Shelbourne regarding the machine, and no person has

any authority to give any such warranty for or on behalf of Shelbourne, other than

where given in writing signed by a director of Shelbourne.

1.5.3 WARRANTY CLAIMS

All claims must be submitted by a Shelbourne authorised dealer providing that the

original purchaser has;

1) given notice in writing with full information regarding the failure, to Shelbourne

(or the Shelbourne authorised dealer) during the Warranty Period, and within 15

days of the failure;

2) given Shelbourne (or the Shelbourne authorised dealer) a reasonable

opportunity of examining the machine or the damaged or defective parts;

3) if requested by Shelbourne, returned the damaged or defective parts (via the

original Shelbourne authorised dealer) within 30 days of notification of a defect;

then Shelbourne shall, at its opinion, repair or replace the defective parts, or refund the

price of the defective parts.

1.5.4 REPAIR COSTS

The original purchaser or Shelbourne authorised dealer shall not repair, or arrange for

a repair, of the machine without the prior written authority of Shelbourne. Such

authority may only be given by Shelbourne service personnel. Shelbourne will not be

liable for the cost of any repairs carried out without its prior written consent to

the work being done.

If Shelbourne authorises a repair of the machine, all claims for repair costs must be

submitted to Shelbourne by a Shelbourne authorised dealer within 15 days of the date

of repair on a Shelbourne Warranty Claim Form.

Repairs should be completed by a Shelbourne authorised dealer (or another repairer

with the prior written consent of Shelbourne).

The submission of a claim is not a guarantee of payment. Shelbourne will only

reimburse the reasonable costs and expenses incurred in connection with any repair.

The decision reached by Shelbourne is final.

1.5.5 EXCLUSIONS

Shelbourne will not be liable for the machine’s failure to comply with the Warranty in

any of the following circumstances:

1) damage due to improper use or abusive operation

8

2) damage or depreciation caused by normal wear and tear;

3) the machine has been subjected to alteration, modification or fitment of non-

genuine Shelbourne parts without the prior consent of Shelbourne;

4) accidental damage, including (but not limited to) damage caused by foreign

objects (e.g. stones, metals and any materials other than those suitable for the

machines intended use);

5) the machine has been neglected and not maintained and serviced fully in

accordance with the details and maintenance schedule set out in the Operators

Manual, and only using Shelbourne genuine parts. Proof of service work may be

requested prior to approval of any claim under the Warranty;

6) failure due to use of incorrect oil or lubricants, contamination of the oil, or oil

which has served its useful life or failure to carry out proper maintenance as

recommended in the Shelbourne Operators Manual;

7) where the original purchaser has continued to use the machine after they

became (or should reasonably have become) aware of the defect with the

machine.

Continued use of the machine after a defect is discovered could cause further

failures for which Shelbourne cannot be held liable and may also have safety

implications.

8) the Shelbourne serial number plate on the machine has been removed or

altered;

9) failure by the customer to release the machine for repair will not be accepted as

a reason for delay in repair or submitting warranty claims.

The Warranty shall not apply in respect of any:

1) wearing items which includes blades or any other items which are considered to

be a normal wearing or consumable items such as chains, bearings and belts;

2) hoses that have suffered external damage, unless the damage is a direct result

of poor routing during assembly. Complete hoses must be returned for warranty

within this period. Any which have been cut or repaired will be rejected;

3) repeat or additional repairs resulting from incorrect diagnostics, unless advised

by Shelbourne.

4) poor-quality previous repair work.

1.5.6 LIMITATIONS OF LIABILITY

Shelbourne and the Shelbourne authorised dealer shall not be liable to the original

purchaser under any circumstance for injuries, death, property damage or damages of

9

any kind whatsoever directly, consequential or contingent to any person or property

caused by the use of the machine.

Shelbourne shall not be liable for any consequential loss such as the following costs or

types of loss (whether direct or indirect):

1) Loss of profit;

2) Loss of or damage to goodwill;

3) Loss of sales or business;

4) Loss of agreements or contracts or business opportunity;

5) The cost of lost consumables (such as oil);

6) Any loss or costs arising from the inability to use the machine due to any defect

with the machine, and during the time taken to repair or replace the machine;

7) The cost of hire or purchase of any replacement machine;

8) Recovery of broken-down machine;

9) Damage to or loss of crops or vegetation;

10)Damage to the carrying tractor;

11)Damage caused by exceeding the tractor OEM (original equipment

manufacturers) specification for implement mounting and hitch capability;

12)Any other indirect or consequential loss.

In view of the Warranty given by Shelbourne, the terms implied by sections 13 to 15 of

the Sale of Goods Act 1979, and all other implied warranties or conditions regarding

the quality or suitability of the machine, are, to the fullest extent permitted by law,

excluded from this warranty policy and any contract or agreement between Shelbourne

and either the original purchaser or the Shelbourne authorised dealer.

Nothing in this warranty policy limits any liability which cannot legally be limited,

including liability for:

1) death or personal injury caused by negligence;

2) fraud or fraudulent misrepresentation;

3) breach of the terms implied by section 12 of the Sale of Goods Act 1979 (title

and quiet possession); and

4) breach of section 2 of the Consumer Protection Act 1987.

1.5.7 EXTENDED WARRANTY

Shelbourne will provide an extended Warranty on the Powermix for an additional 12

months on the weigh system components and 24 months for gearboxes on a parts only

basis, subject to all the other terms and conditions of this warranty policy. This is a

conditional extended warranty offered solely at the discretion of Shelbourne.

Powermix PRO

Powermix PLUS

Gearbox Planetary

2 Years

2 Years

Gearbox 2 Speed

2 Years

2 Years

Weigh System

1 Year

1 Year

10

1.5.8 WARRANTY ON SPARE PARTS

Shelbourne warrants that any spare part or component supplied by Shelbourne in

accordance with this limited warranty are free from defects in material or workmanship

from the date of sale to the original purchaser for 6 months, subject to the conditions

and limitations in clauses 1.5.4 to 1.5.7 of this warranty policy. Shelbourne will at its

option, either repair or replace the defective part free of charge providing that any

warranty claim is supported with a copy of the invoice to the end user for the failed part.

Original Purchaser shall be responsible for labour and all freight charges to and from

the place where the warranty work is performed.

Shelbourne Reynolds Engineering Ltd. cannot be held responsible for any

failures or safety implications arising from the use of non-genuine parts. Use of

non-genuine parts may seriously affect the machine’s performance and safety.

1.5.9 TRANSFER OF WARRANTY

Shelbourne may at its sole discretion allow this warranty to be transferred to a

subsequent owner of the machinery for the balance of the Warranty Period, subject to

all the warranty conditions being met and only with Shelbourne giving prior written

consent.

1.5.10 EXPORT CUSTOMERS

If you are based outside of the UK, warranty terms and conditions outlined above may

differ depending on your market. Please contact Shelbourne Reynolds Engineering Ltd.

for further information.

This manual suits for next models

7

Table of contents

Other Shelbourne Reynolds Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Anderson

Anderson TRB-2000 Operator's manual

SIP

SIP SILO 80 D manual

Vicon

Vicon Andex 764 operating manual

USC

USC AT500H DUAL PUMP STAND Operator's manual

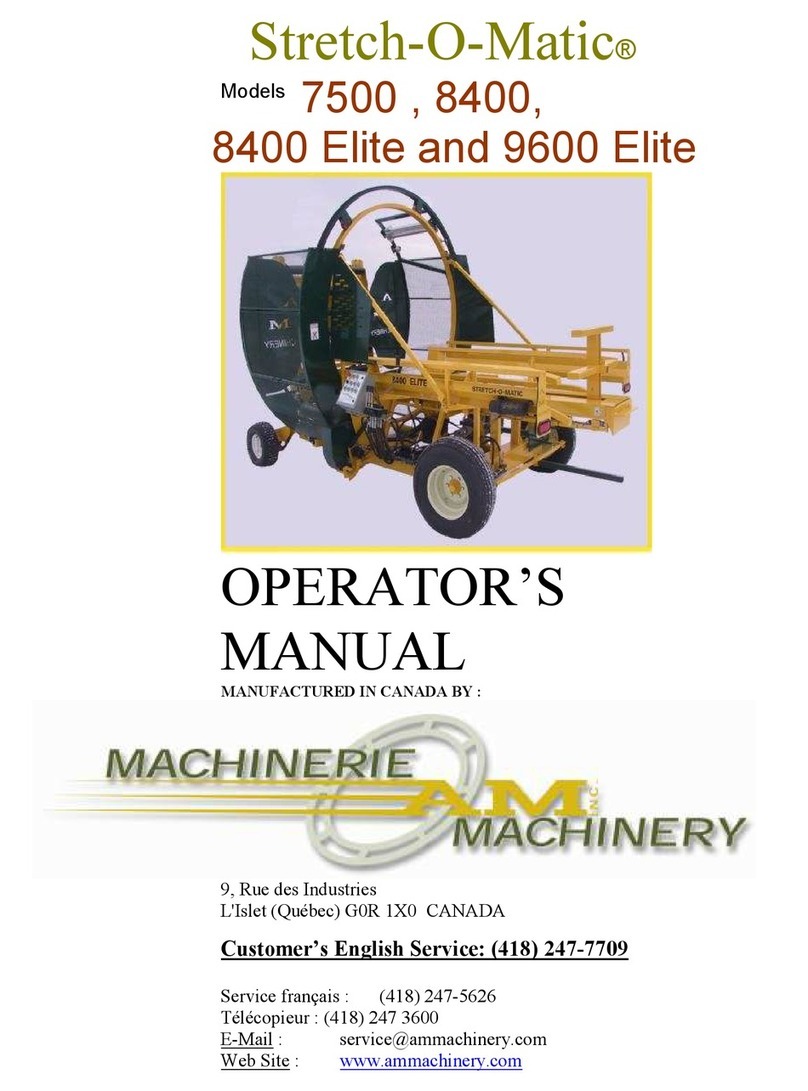

AM Machinery

AM Machinery Stretch-O-Matic 7500 Operator's manual

TTI

TTI WeedControl 12VSPT-TTI INSTRUCTIONS FOR ASSEMBLY, OPERATION, SERVICING & STORAGE