Safety

10

Who is allowed to

operate the

machine?

Qualified machine operators

Only qualified persons who have been informed of the dangers

associated with handling the machine are permitted to operate,

service or repair the machine. The necessary knowledge can be

gained in the course of agricultural vocational training, professional

training or intensive instruction.

General safety

information

The general safety information and warning signs apply to every

phase of the life cycle of the machine and to every application.

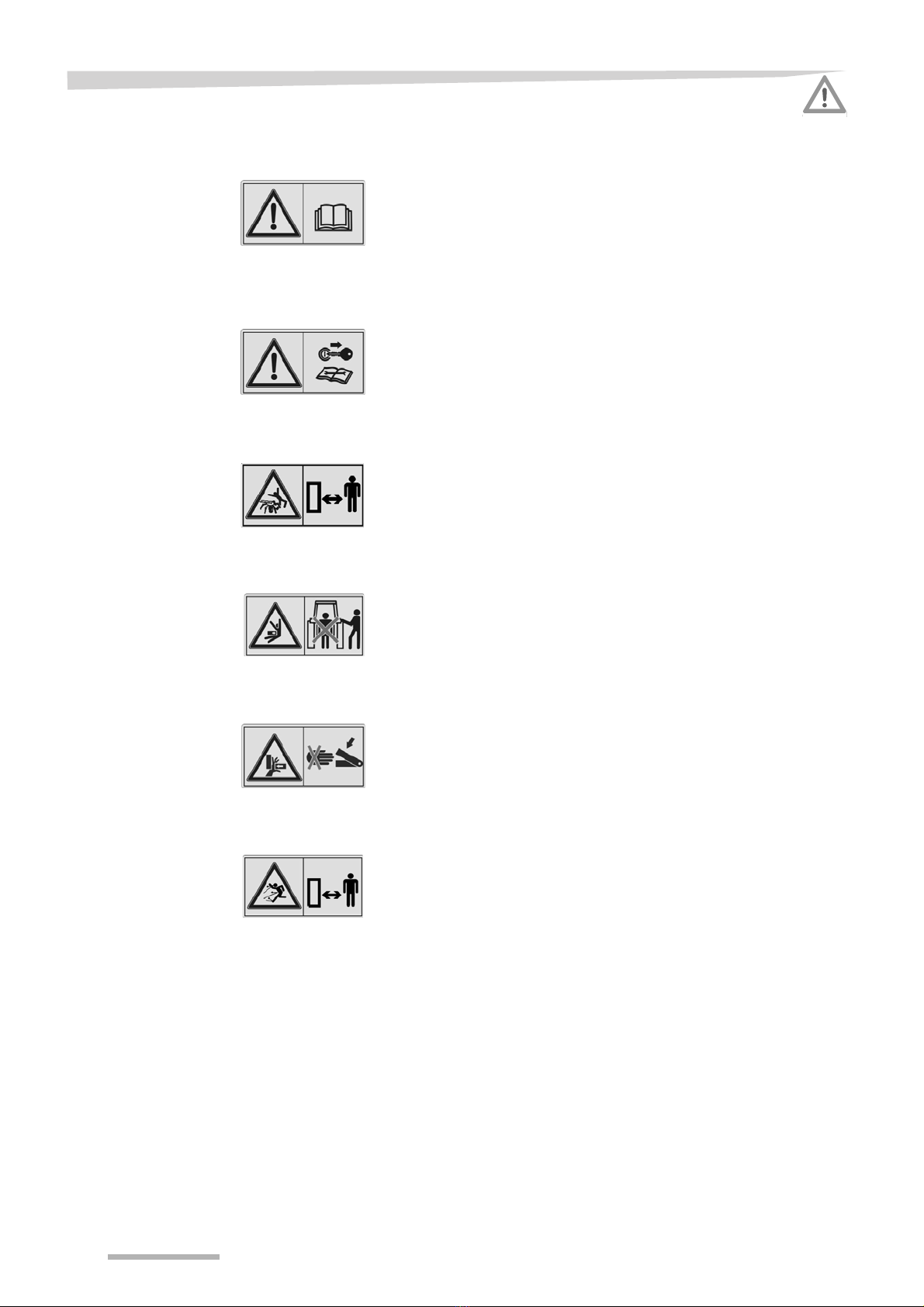

Switch off the tractor and secure it

Before you dismount:

Switch off the tractor.

Remove the ignition key.

Secure the tractor against rolling away.

An unsecured tractor can run you over or trap you. Otherwise, serious

or fatal injury may be caused as a result.

Operate for the first time only after proper training

The machine may only be put into operation after proper training has

been provided by an employee from a dealership or the manufacturer,

or by a factory representative. Operation without proper training can

lead to damage to the machine due to incorrect operation, or may

cause accidents.

Safety is your responsibility

Follow the safety regulations. Ensure that all operators comply with

the safety instructions. Prevent serious or fatal accidents by following

the safety instructions.

Instructions in the event of malfunctions

In the event of a malfunction, stop, shut down and secure the machine

immediately. Rectify the malfunction immediately yourself or seek the

assistance of a workshop. Operating a faulty machine can cause

accidents or damage.

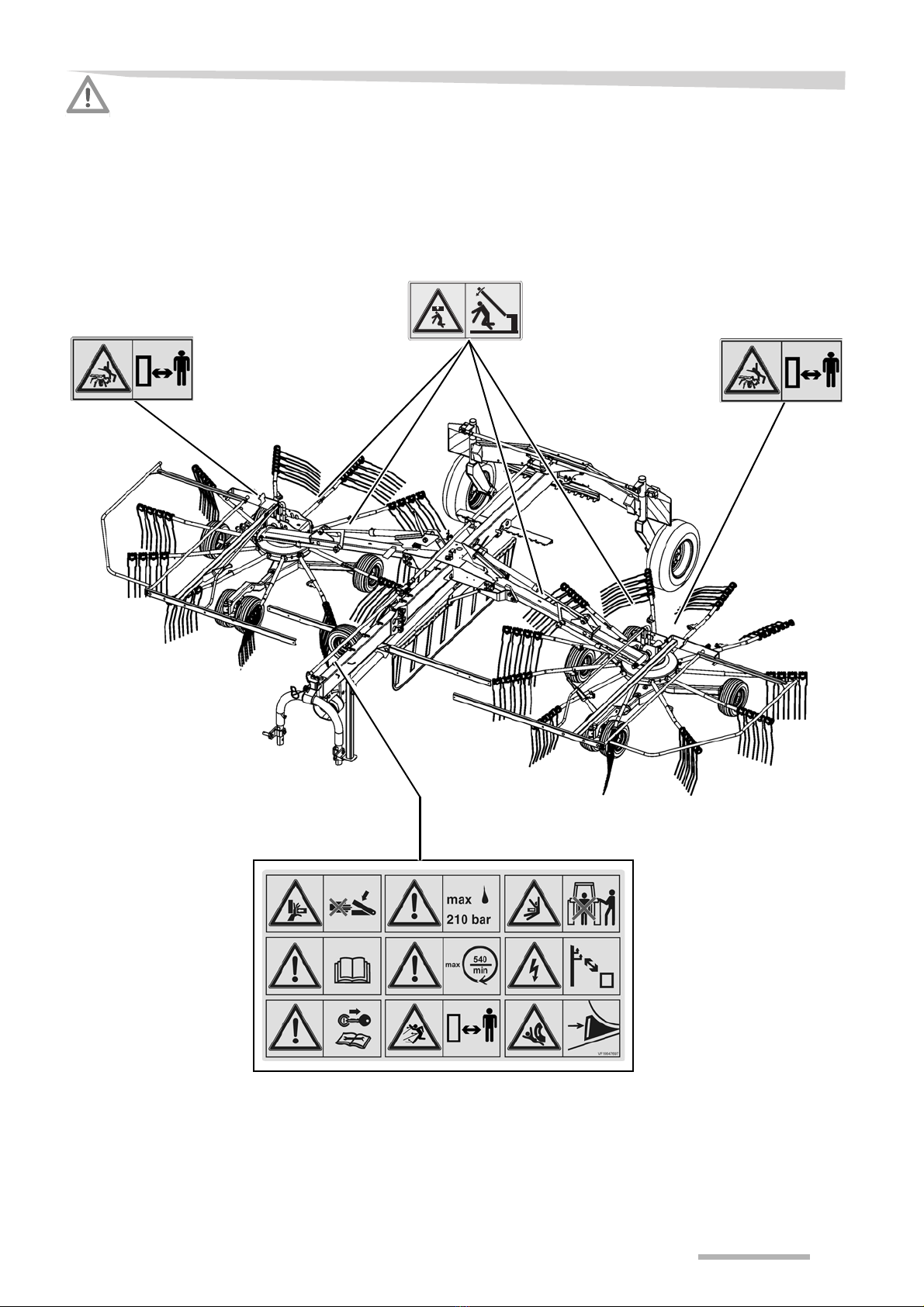

No persons in the working area

Ensure that no persons are present in the slewing and working area

of the machine. Persons could be caught by the machine within this

area. This could result in fatal injury.

Perfect working condition

Ensure that the tractor and the machine are always in perfect working

condition. Make sure that the tractor brakes work in conjunction with

the machine. Also follow the instructions in your tractor's operating

manual.