INSTALLATIEHANDLEIDING – P13 VERSION 0129NM02INT01INSTRUCTION MANUAL – P13 | P13 06A2NM20ENG05

Thank you for installing this charge point. Make sure

there is enough space to properly do the work.

Ensure to work safely and take the safety of others into

consideration as well, always work according to local

safety regulations. Ask the owner if there is anything

of signicant importance that requires electricity in the

house, before you turn of the electricity.

When selecting the mounting location of the charge point,

ensure that future maintenance work can be carried out

safely without obstruction.

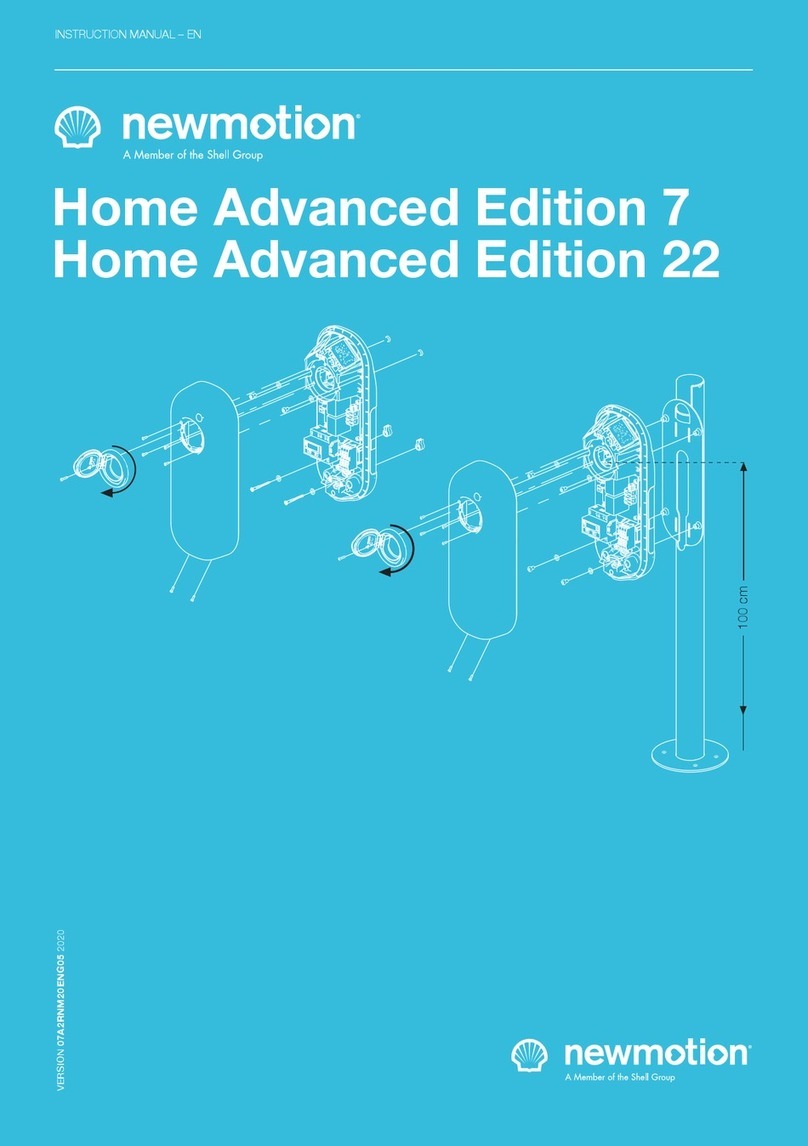

5.1 PREPARATION

Step 1: Prepare the cabling & RCD and MCB (conform to

local rules & regulations);

Step 2: Indicate which circuit(s) the charge point is

connected to in the distribution board;

Step 3: Turn the socket lid anti-clockwise and out of the

cover of the charge point;

Step 4: Then pull the cover from the rear edge to open

the charge point. Do not use any objects or tools to do

this.

5.2 MECHANICAL MOUNT

Step 1: Put the charge point back plate on the wall

to check its placement (charge poin is leveled and

connector at +/- 1 m height). On the wall, mark the

positioning of the top two and bottom two attachment

points of the charge point and select the appropriate

xtures (plugs, screws and washers).

Step 2: Drill all four holes and put the plugs in place.

Step 3: Place the two provided plastic spacers at the

backside of the bottom two attachment points. Secure

the charge point to the wall using the top two and

bottom two attachment points. Ensure that the rubber

and stainless steel washers are used and placed on the

back of the charge point at the bottom two attachment

points.

5.3 POWER CONNECTION

Step 1: Select the appropriate grommet that suits the

cable thickness and place it in the opening of the power

cable inlet. Lubcirate if necessary to make it easier to

feed the power cable through;

Step 2: Secure the power cable using the cable clamp;

Step 3: Connect the power to the terminal blocks, as

indicated in ‘3.4.1 Overview of Connections | 7,4 kW’ or

‘3.4.2 Overview of Connections | 22 kW Version’.

5.4A DYNAMIC POWER MANAGEMENT

- CT FOR 7,4 KW MODEL

The Current Transformer for Dynamic Power

Management (included in box) must be connected to the

phase used by the charge point at the most upstream

point of the house grid, closest to the house grid

connection.

Step 1: Install the CT on the same phase used by the

charge point, measuring the whole household. Place the

terminal block on a DIN-rail in the fusebox;

Step 2: Place a standard cable of 2x 1,5mm2(not

supplied) and connect two wires on both terminal blocks

in the charge point as indicated in the ’3.4.3 Overview

Installing Accessories’ section. Then place the cable of

2x 1,5mm2to the CT on the side of the grid connection.

The maximum length of the cable is 100m.

5.4B DYNAMIC POWER MANAGEMENT

MODULE FOR 22 KW MODEL

The Dynamic Power Management Module package

contains one Dynamic Power Management module, one

power adapter and three current transformers (CT’s).

The CT’s must be connected at the most upstream point

of the house grid, closest to the grid connection. Arrows

are shown on the CT, but direction is not important.

The connections for the CT’s are located at the bottom

of the Dynamic Power Management module, and are

labelled with L1, L2 and L3 on the front label. L1, L2 and

L3 must be connected to the rst, second and third

phase of the house grid in the correct order.

Although each measuring head is provided with two

dierent coloured threads, the polarity of connection is

not important.

The power cable connection on the terminal block of

the charge point should match the L1, L2 and L3 in the

charge point.

For a 1 phase installed charge point the L1 measurement

head should match the conduction which is connected

to the L1 of the terminal block.

Installation procedure

Step 1: Install the Dynamic Power Management module

on the DIN Rail in the fuse box;

Step 2: Connect the CT(’s) to the Dynamic Power

Management module, as described in the beginning of

this paragraph;

Step 3: Apply the CT(’s) to the grid connection(s). Make

sure to apply the CT(’s) so that the total power usage of

the household is measured on each phase;

5. INSTALLATION PROCEDURE