Shell newmotion Home Advanced Edition 7 User manual

100 cm

Home Advanced Edition 7

Home Advanced Edition 22

INSTRUCTION MANUAL – EN

VERSION 07A2RNM20ENG05 2020

INSTALLATIEHANDLEIDING – P3 VERSION 0129NM02INT01INSTRUCTION MANUAL – P3 | P3 07A2NM20ENG05

1.1 PRODUCT DESCRIPTION &

INTENDED USE

Thank you for choosing a NewMotion Electric Vehicle

(EV) Charge Point.

This charge point is intended to charge the batteries within

EVs compatible with IEC-61851 MODE3 denition and

requirements. Dedicated EV specic plugs will need to be

utilised. No adaptors, conversion adaptors or extension

sets for cables are allowed to be used. EVs and cables

used with this charge point should always be undamaged

and in their original state.

1.2 SAFETY WARNING + CAUTION!

The electrical system must be voltage-free during the

entire installation procedure. Failing to do so can lead to

serious injury or even death. The installation procedure

must be carried out by a trained installer who works in

accordance with all relevant local laws and regulations.

Do not install in potentially explosive atmospheres and/

or zones with high electromagnetic radiation and/or in

ood-prone areas.

The charge point is connected to the electricity grid and

even if the equipment is switched o, hazardous voltag-

es may be present at the input terminals. Always switch

o the AC supply before starting any work on the charge

point and/or its installation. Do not carry out any work

in rainy conditions or when the humidity is above 95%.

The safety guidelines are intended to ensure correct in-

stallation and usage. Any failure to comply with the valid

safety guidelines or instructions provided in this manual

may result in re, electrocution or severe injury.

The charge point is a product in Safety Class I and is

supplied with an earth terminal for protection purposes.

The AC input clamps must be tted with an uninterruptible

earth for protection purposes. Ensure that the connection

cables are tted with fuses and circuit breakers. Never

replace a protection component with another type. First

check the full installation to determine if that component

can be used with the existing installation components.

Before you switch on the charge point, check that the

available power source matches the conguration set-

tings of the product, as described in this manual.

Tripping of the RCD could be caused by an earth fault

or a defect relay. If, after resetting the RCD, the device

cannot be activated or immediately trips again; please

contact your installer.

1.3 LEGAL DISCLAIMER

This manual is created for you with care.

We however do not guarantee that all information is

complete, accurate and correct.

If you nd any unclarities or mistakes in this installation

manual, or if you have any feedback or suggestions in

general about this manual, please inform us at

installationmanualfeedback@newmotion.com and men-

tion the document version in the subject.

Please check our website

go.newmotion.com/installationmanuals

for the latest version of this manual.

NewMotion strongly advises to have the product

installed by EV-Ready certied professionals. How the

product should be installed and used depends on local

circumstances and local and national regulation, which

are not mentioned in our manual. NewMotion is not

responsible for any loss or damage whatsoever caused

– including without limitation, any indirect, personal

or consequential loss or damage – arising from or in

connection with the use of this manual. Nor does New-

Motion accept any liability for any such loss or damage

arising out of your reliance on any information contained

in this manual.

1. INTRODUCTION

INSTALLATIEHANDLEIDING – P4 VERSION 0129NM02INT01INSTRUCTION MANUAL – P4 | P4 07A2NM20ENG05

This selected charge point can be connected to a Charge

Point Operator (CPO) backoce via WiFi or ethernet.

In case of an error or issue, on site support is needed from

the installer.

2. CHARGE POINT OPERATION

INSTALLATIEHANDLEIDING – P5 VERSION 0129NM02INT01INSTRUCTION MANUAL – P5 | P5 07A2NM20ENG05

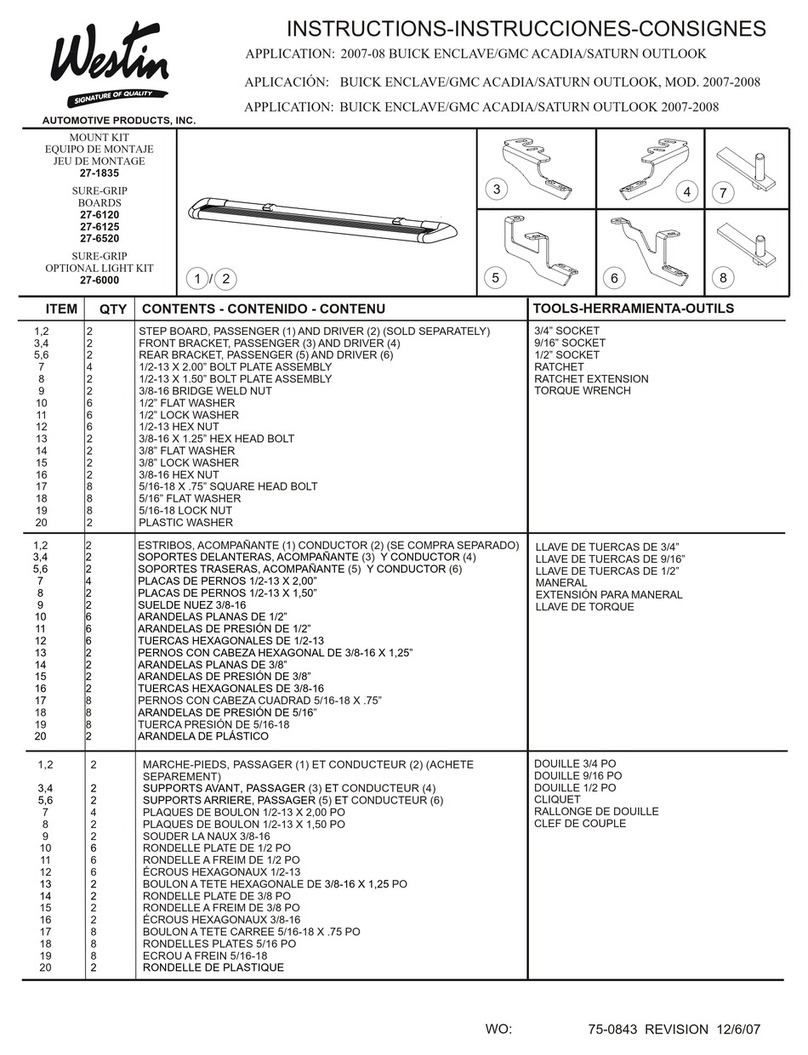

Wall mounting

Installation materials

& power setting

Installation &

conguration of

accessories

Required tools & additional materials

(not provided)

- 4x 6.3mm x 70mm Self Tapping pan

head Torx screws (DIN 7981C) stainless

steel (A4);

- 4x plugs;

- 4x Stainless steel (A4) washers;

- Drill and bit;

- Torx screwdrivers (T20);

- Voltage tester;

- Tape measure;

- Spirit level

- Power cable;

- Cable mount clips;

- RCD & MCB;

- For local conguration, smartphone with

Installer app

- UTP cable (CAT5 or CAT6);

- RJ45 UTP cable crimp tool;

- RJ45 connectors;

- Network cable tester;

- For Dynamic Power Management

functionality:

- UTP cable (CAT5 or CAT6);

- RJ11 UTP cable crimp tool;

- 2x RJ11/RJ12 connectors;

Package contents with charge point

- Charge point;

- Rubber grommets (various sizes);

- 2x Plastic spacers;

- 1x M4 x 20 mm bolt (Torx);

- 6x M4 x 12 mm bolts (Torx);

- 2x Power cable clamps;

- 2x UTP data cable inlet with rubber seal

- Dynamic Power Management module

for Dynamic Power Management

functionality;

- P1 dongle for Dynamic Power

Management functionality (black);

- QR code for WiFi connection

3. PRODUCT OVERVIEW

3.1 MOUNTING, PACKAGE CONTENTS AND REQUIRED TOOLS

INSTALLATIEHANDLEIDING – P6 VERSION 0129NM02INT01INSTRUCTION MANUAL – P6 | P6 07A2NM20ENG05

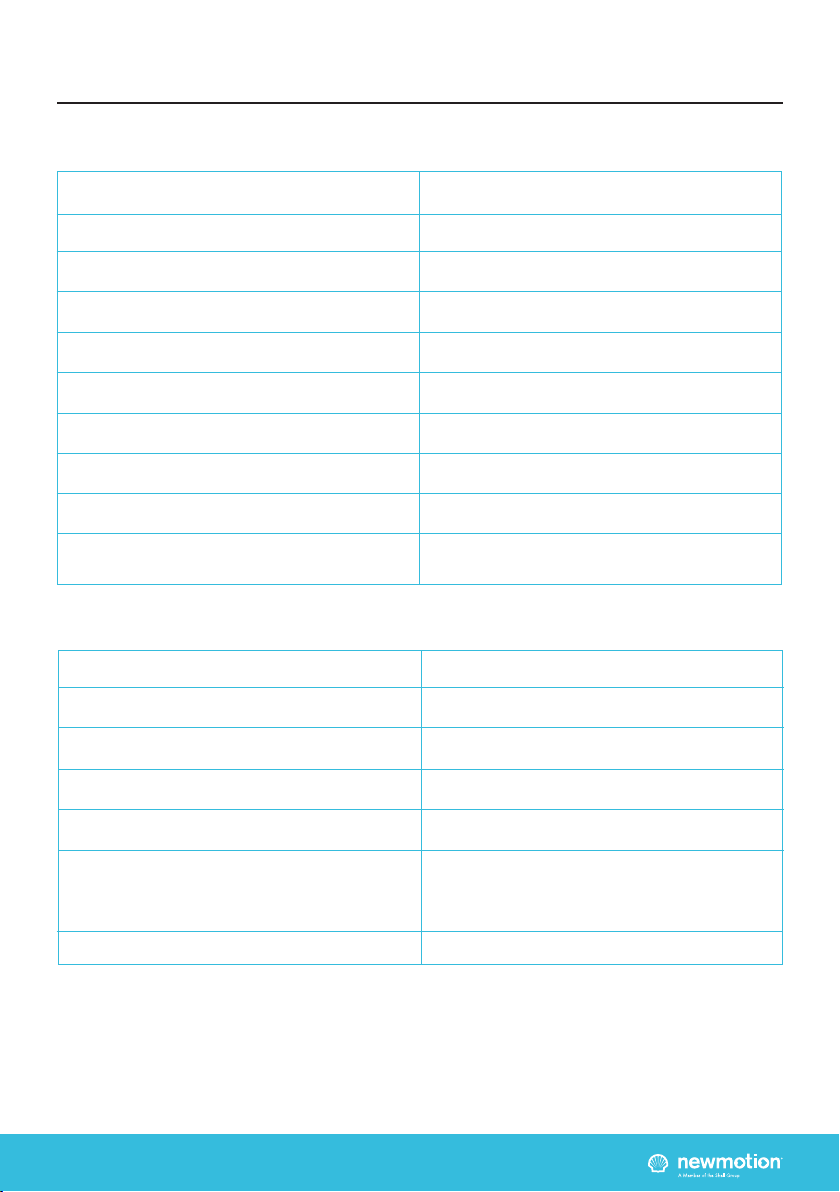

3.2 TECHNICAL SPECIFICATIONS

3. PRODUCT OVERVIEW

CONTINUED ON NEXT PAGE

Serial number format Home Advanced 7 kW

Serial number format Home Advanced 22 kW

Maximum charge capacity

Standard congured charge capacity

Electric safety category

Connector type

Dimensions (H x W x D)

Weight

Standard colours

IEC-62262 IK code (robustness)

IEC-60529 IP code (protection class)

Certicates

kWh measurement & meter part number

User interface

Identication

Communication backoce

Communication Dynamic Power Management

module

07A _ _ _ _ _

07B _ _ _ _ _

Home Advanced 7: single phase 32A*

Home Advanced 22: triple phase 16A*

Home Advanced 7: 3,7 kW - single phase 16A**

Home Advanced 22: 11 kW - triple phase 16A**

Class I

Type 2

503.5 x 200 x 137 mm

± 4.5 kg

Rear side RAL 7031 (grey)

Front side RAL 9010 (white)

IK10

IP54*** (for indoor and outdoor use)

IEC-61851-1

IEC-61851-22

EV-Ready 1.4G1 & ZE-Ready 1.4G1

IEC-62262 -> IK10

IEC-60529 -> IP54

MID certied

LED

Plug & Charge (standard congured)

RFID (NFC) Mifare 13.56 MHz (via local conguration)

IEC 14443A

IEC 14443B

Ethernet connection (DHCP, TCP 443, TCP80, TCP21)

WiFi - 802.11 (2,4 GHz)

Straight wired RJ11 or RJ12 (6P6C) connectors on

CAT5 cable (max 100 mtr)

INSTALLATIEHANDLEIDING – P7 VERSION 0129NM02INT01INSTRUCTION MANUAL – P7 | P7 07A2NM20ENG05

* The maximum charge capacity of the charge point depends on several factors. This includes: local rules & regulations,

the type of EV, the grid connection at your location and the electricity usage of your building;

** Use the conguration software in order to change the charge capacity (only on site - locally - possible by an installer);

*** The charge point shall not be exposed to direct water jets or cleaned with high water pressure devices. The charge

point shall not be installed outdoors with a road proximity less then 5 meters.

3.2 TECHNICAL SPECIFICATIONS (CONTINUED)

3. PRODUCT OVERVIEW

P1 DONGLE SPECIFICATIONS

Backoce protocol

Stand-by consumption

Operating temperature range

Operating humidity range

Operating air pressure range

Maximum mounting height socket

Advised mounting height socket

Mounting position

Function for ventilation according to IEC-61851

Conguration

OCPP protocol

3-5W

-30℃ to +50℃

5% to 95%

860 hPa to 1060 hPa

1.5 meter above ground

1 meter above ground

Vertical and upright postion only

Not supported

Local conguration using the Installer App on a

smartphone

Dimensions

Weight

Required input

Operating humidity range

Operating temperature range

Certicates

Enclosure of the electrival cabinet requirement

55x25x30 mm

27 gr

5V DC - 100mA

5-95%

5-55 °C

CE

IEC6236 8-1:2014

Immunity according to EN 61326-1:2013

Must be able to resist a force of 250N

INSTALLATIEHANDLEIDING – P8 VERSION 0129NM02INT01INSTRUCTION MANUAL – P8 | P8 07A2NM20ENG05

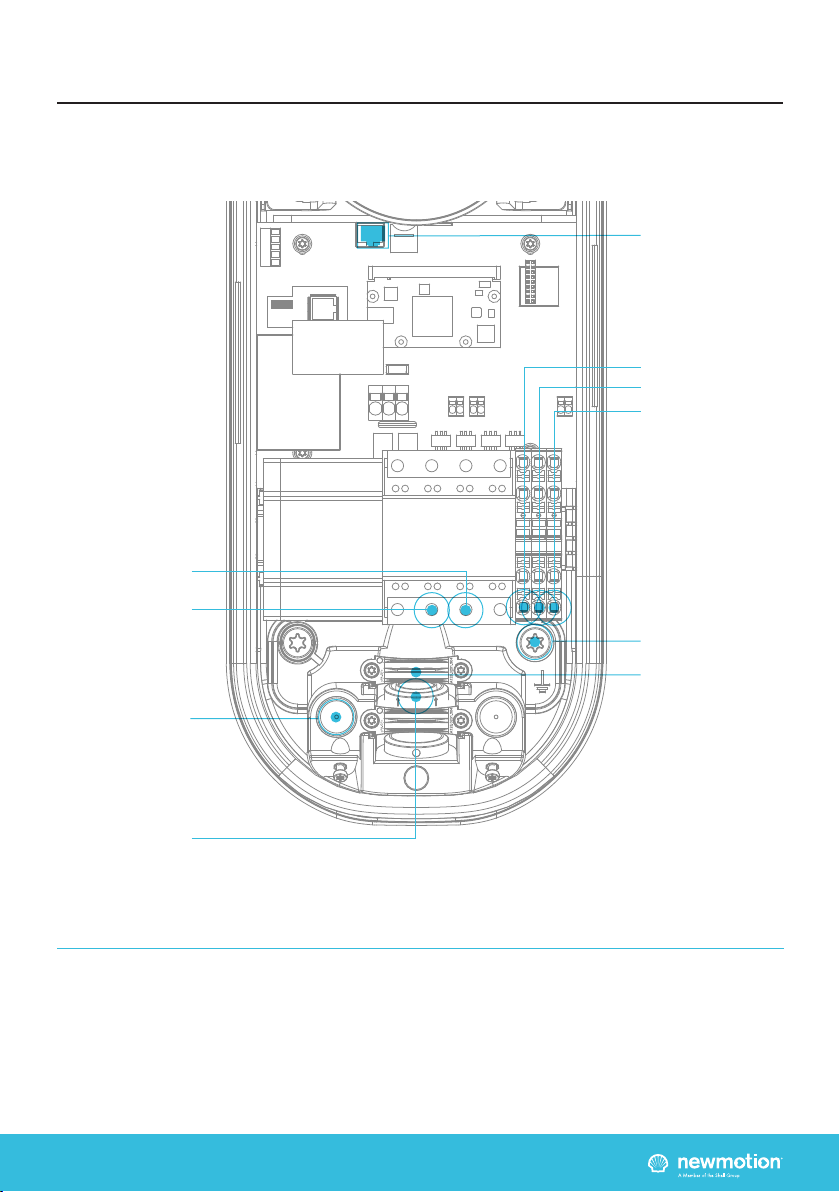

3.3 OVERVIEW OF PRODUCT

3. PRODUCT OVERVIEW

Type 2 EV Plug

socket & cover lid

RFID Reader

Identication label

with serial number

LED Status indicator

INSIDE

INSTALLATIEHANDLEIDING – P9 VERSION 0129NM02INT01INSTRUCTION MANUAL – P9 | P9 07A2NM20ENG05

3. PRODUCT OVERVIEW

3.4.1 OVERVIEW OF CONNECTIONS

Ethernet port

Earthing pole

UTP data cable inlet

with rubber seal

Inlets for

power cables

Power cables

clamps

Phase 2

Phase 3

Phase 1

Neutral

Earthing

INSIDE

INSTALLATIEHANDLEIDING – P10 VERSION 0129NM02INT01INSTRUCTION MANUAL – P10 | P10 07A2NM20ENG05

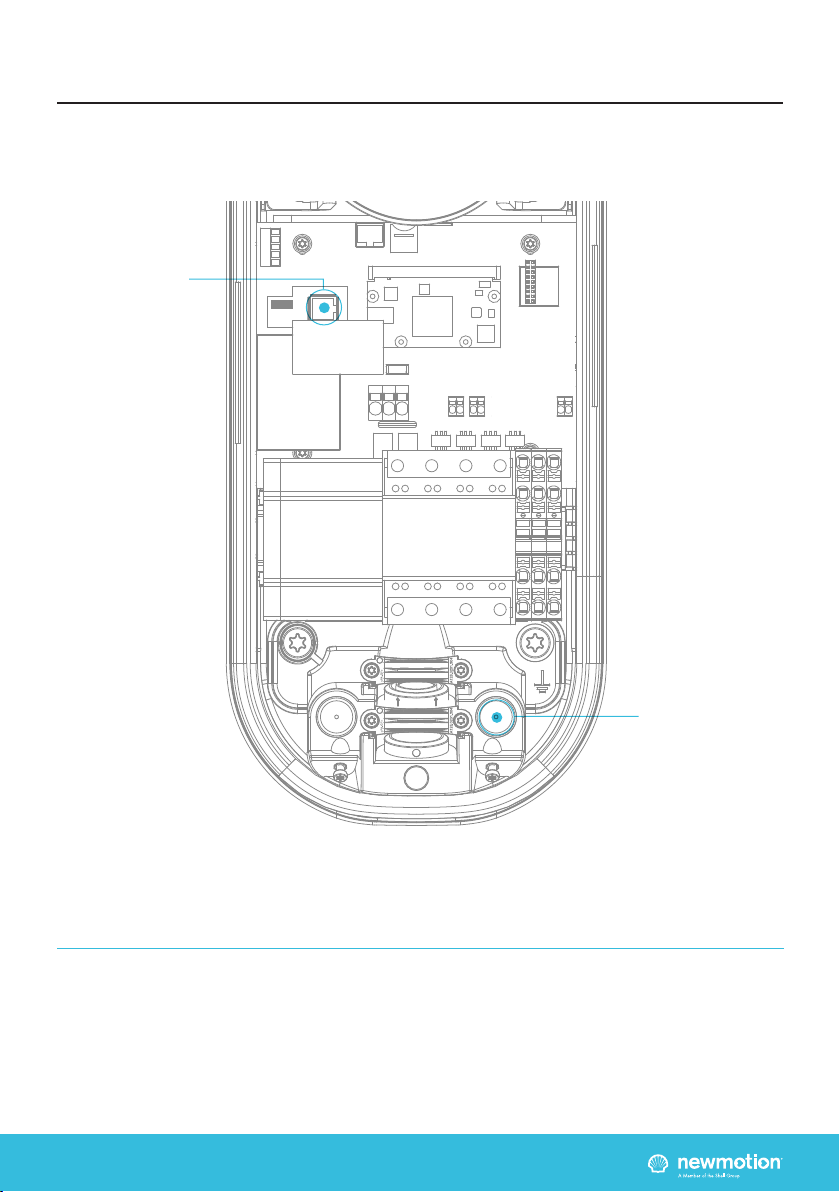

3. PRODUCT OVERVIEW

3.4.2 OVERVIEW INSTALLING ACCESSORIES

P1 Port

for Dynamic Power

Management

UTP data cable inlet

with rubber seal for

Dynamic Power

Management

INSTALLATIEHANDLEIDING – P11 VERSION 0129NM02INT01INSTRUCTION MANUAL – P11 | P11 07A2NM20ENG05

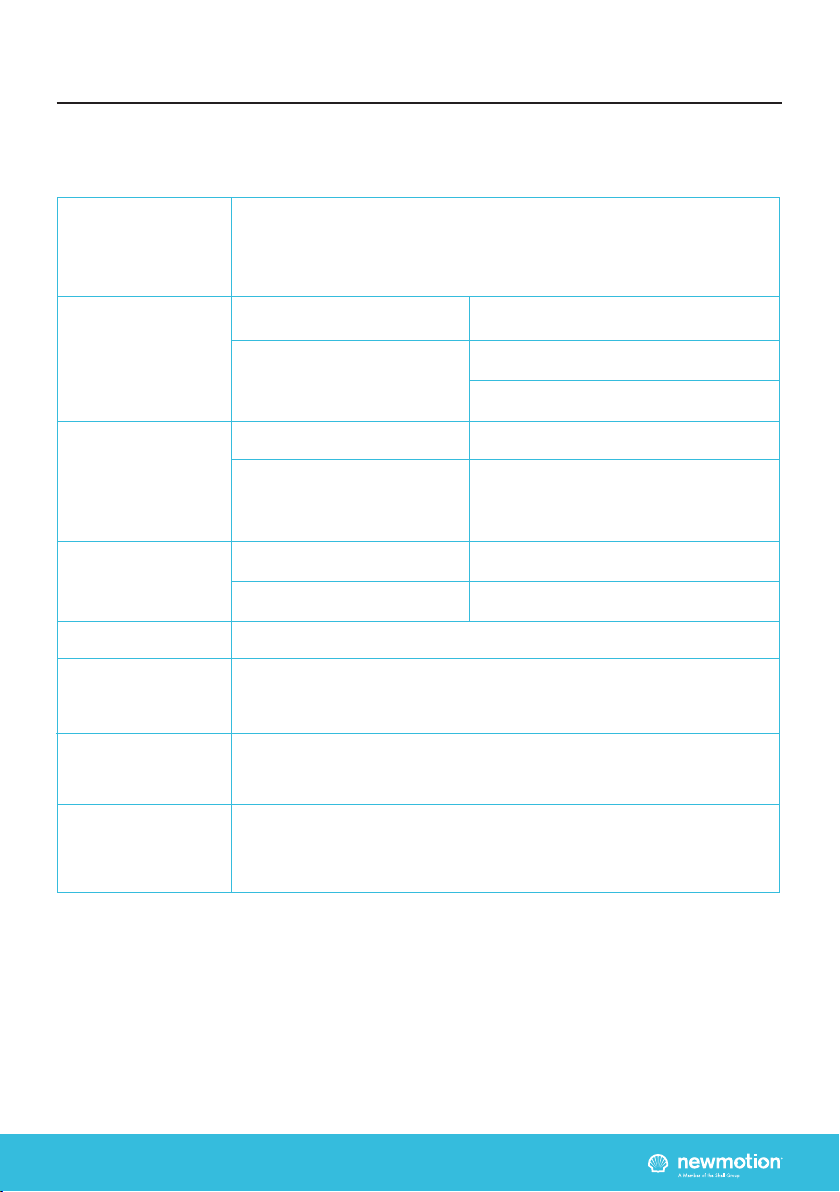

* The installer is always responsible for selecting a cable thickness appropriate for the specic situation and

according to local regulations;

** 3-phase charge point can also be connected to 1-phase. In this case the charge point can only charge on

1-phase;

*** The installer must select a suitable MCB with C-characteristic to match the amperage setting of the charge point,

taking into account MCB manufacturer specications;

NOTE: The charge point can be set between 16 A / 20 A / 25 A and 32 A (depending on version)

Wiring advice*

Power cable size

Earthing advice*

Required nominal

input voltage at

charge point

MCB

RCD

Ethernet connection

cable requirements

Dynamic Power

Management cable

requirements

Ø 10mm - Ø 22,5mm

10 mm2solid wire

6 mm2stranded wire with ferrules

PE-cable (PEN conductor is not allowed)

Separately installed grounding electrode

< 100 Ohm spreading resistance

230V+N +/-10% 50Hz

400V (3 x 230V+N) +/-10% 50Hz

Cable grommets sizes

Maximum cable terminal block

TN-system

TT-system

Single phase**

Triple phase**

4. INSTALLATION DETAILS

The installer is responsible for selecting a cable thickness & safety components appropriate for

the specic situation and according to local regulations

- Wire for the maximum hardware amperage under continuous load;

- Calculate with a COS-Phi of 0.8;

- Calculate with a max allowed voltage drop over the cable of 2%;

- Use shielded cable for underground wiring

C-characteristic***

30mA Type B, or 30mA Type A (Hi, Hpi, Si) in combination with appropriate

equipment that guarantees shutdown of power when a DC leakage of more than 6mA

occurs

Standard CAT5 or CAT6 Ethernet cable (UTP cable with RJ45 connectors)

Straight wired RJ11 or RJ12 (6P6C) connectors on CAT5 UTP cable (max 100m)

INSTALLATIEHANDLEIDING – P12 VERSION 0129NM02INT01INSTRUCTION MANUAL – P12 | P12 07A2NM20ENG05

Thank you for installing this charge point. Make sure

there is enough space to properly do the work.

Ensure to work safely and take the safety of others into

consideration as well, always work according to local

safety regulations. Ask the owner if there is anything

of signicant importance that requires electricity in the

house, before you turn of the electricity.

When selecting the mounting location of the charge point,

ensure that future maintenance work can be carried out

safely without obstruction.

5.1 PREPARATION

Step 1: Prepare the cabling & RCD and MCB (conform to

local rules & regulations);

Step 2: Indicate which circuit in the distribution board is

connected to the charge point;

Step 3: Turn the socket lid anti-clockwise and out of the

cover of the charge point;

Step 4: Then pull the cover from the rear edge to open

the charge point. Do not use any objects or tools to do

this

5.2 MECHANICAL MOUNT

Step 1: Put the charge point back plate on the wall to

check its positioning (connector at +/- 1 m height). On

the wall, mark the positioning of the top two and bottom

two attachment points of the charge point and select the

appropriate xtures (plugs, screws and washers);

Step 2: Drill all four holes and put the plugs in place;

Step 3: Secure the charge point to the wall using the top

two and bottom two attachment points. Ensure that the

rubber and stainless steel washers are used and placed

on the back of the charge point at the bottom two

attachment points

5.3 POWER CONNECTION

Step 1: Select the appropriate grommet(s) that suits

the cable(s) thickness and place it in the opening of

the power cable inlet. Lubricate if necessary to make it

easier to feed the power cable through;

Step 2: Secure the power cable(s) using the cable

clamp(s);

Step 3: Connect the power to the terminal blocks, as

indicated in section ‘3.4.1 Overview of Connections’.

Warning: Keep charge point switched o during

installation!

5.4 DYNAMIC POWER MANAGEMENT

MODULE

The Dynamic Power Management Module package

contains one Dynamic Power Management module, one

power adapter and three current transformers (CT’s).

The CT’s must be connected at the most upstream point

of the house grid, closest to the grid connection. Arrows

are shown on the CT, but direction is not important.

The connections for the CT’s are located at the bottom

of the Dynamic Power Management module, and are

labelled with L1, L2 and L3 on the front label. L1, L2 and

L3 must be connected to the rst, second and third

phase of the house grid in the correct order.

Although each measuring head is provided with two

dierent coloured threads, the polarity of connection is

not important.

The power cable connection on the terminal block of

the charge point should match the L1, L2 and L3 in the

charge point.

For a 1 phase installed charge point the L1 measurement

head should match the conduction which is connected

to the L1 of the terminal block.

Installation procedure

Step 1: Install the Dynamic Power Management module

on the DIN Rail in the fuse box;

Step 2: Connect the CT(’s) to the Dynamic Power

Management module, as described in the beginning of

this paragraph;

Step 3: Apply the CT(’s) to the grid connection(s). Make

sure to apply the CT(’s) so that the total power usage of

the household is measured on each phase;

Step 4: Connect the power adapter to the Dynamic

Power Management module. One of the two power

adapter wires has a broken white stripe. This wire is the

power adapter GND and should therefore be connected

to the GND pin (right) on the module. The other wire is

the +5 Volts and should be connected to the +5V pin

(left) on the module. The middle pin is not used;

Step 5: Plug the power adapter of the Dynamic Power

Management Module into a power outlet. The PWR LED

must light up;

Step 6: The CS LED will (after a few seconds) indicate a

measured current after the power is on;

Step 7: Clamp a RJ12 connector straight to the UTP

cable for Dynamic Power Management;

Step 8: Feed the UTP cable(s) through the rubber stop(s)

on the data cable inlet of the charge point, as indicated

in section ‘3.4.1 Overview of Connections’;

5. INSTALLATION PROCEDURE

INSTALLATIEHANDLEIDING – P13 VERSION 0129NM02INT01INSTRUCTION MANUAL – P13 | P13 07A2NM20ENG05

Step 9: Clamp a RJ12 connector straight to the UTP

cable for Dynamic Power Management;

Step 10: Check if the RJ12 connectors are OKAY with a

network cable tester;

Step 11: Plug the RJ12 cable in the black P1 dongle,

which is included in the box. Plug the P1 dongle in the

Dynamic Power Management module.

Step 12: Connect it to the P1 port, as indicated in the

’3.4.2 Overview Installing Accessories’ section;

If both ends of the UTP cable are properly connected to

the charge point & Dynamic Power Management module

and powered, the P1 LED will indicate whether the

connection is correct. If the P1 LED does not show any

signal, please check if the RJ12 connectors are properly

connected using a network cable tester. If the led of the

P1 port of the charge point is blue, the Dynamic Power

Management is functioning. If it is red, the P1 dongle is

forgotten. If there is no led on the P1 port, the cable is

not correctly connected.

5.5 INTERNET CONNECTION

The Internet connection can be established via WiFi or

Ethernet. For WiFi connection, follow steps of chapter 6.

For Ethernet connection:

Step 1: Pass the UTP cable through the grey rubber

cable inlet and clamp a RJ45 connector to the cable.

Step 2: Check if the RJ45 connectors are OKAY with a

network cable tester;

Step 3: Connect the UTP cable to the Ethernet port of

the charge point, as described in section section ‘3.4.1

Overview of Connections’ and to the households router

with DHCP (or indirectly via a switch or hub).

5.7 FINISHING UP (CLOSE ENCLOSURE)

Step 1: Check and make sure that the rubber seal of the

casing is properly in place on the edge;

Step 2: Place the cover on the charge point;

Step 3: Hand-tighten the four M4 x 12mm T20 bolts

provided around the socket so that the cover closes on

the rubber seal but the rubber seal does not deform;

Step 4: Hand-tighten the other two M4 x 12 mm T20

bolts provided in the bottom of the cover;

Step 5: Turn the socket lid clockwise in the cover and

hand-tighten the M4 x 20 mm bolt provided;

Step 6: Switch on power to the charge point;

Step 7: Wait until charge point is fully started up (+/-10

minutes, the LED should be o)

5.8 CHARGE POINT CONFIGURATION

Charge point conguration should be done after the

charge point is powered on, using the Home Charging

by NewMotion app. To congure charge point features

such as Dynamic Power Management, please follow the

instructions as desribed in chapter 6 of this installation

manual.

5. INSTALLATION PROCEDURE

INSTALLATIEHANDLEIDING – P14 VERSION 0129NM02INT01INSTRUCTION MANUAL – P14 | P14 07A2NM20ENG05

The Home Advanced Edition can be congured locally

using the Home Charging by NewMotion app.

Three items are required for local conguration:

1. Charge point which is installed and on power

2. QR Code for WiFi connection

3. Home Charging by NewMotion app

Make sure that the charge point is powered on for at

least 5 minutes.

TIP: Make sure to have the Home Charging by

NewMotion app already installed on your smartphone,

before installing the charge point.

- Open the Home Charging by NewMotion app

on your phone

- Follow the steps as described in the Home Charging

by NewMotion app

- Use the QR Code for WiFi connection, which is

included in the charge point package, when the Installer

App requests to scan a QR Code

6.1 POWER SETTING

Select the maximum allowed current for the installed

circuit. Taking into account the MCB, RCD, grid

connection and local regulations.

6.2 DYNAMIC POWER MANAGEMENT

SETTING

Enable Dynamic Power Management if upstream

Dynamic Power Management module is installed.

When Dynamic Power Management is enabled, ll in

the maximum current of the grid connection as the

installation max current.

6.3 START CHARGING SETTING

Set whether the charge session will be started

automatically after connecting the cable and car (default)

or using an RFID charge card.

6. LOCAL CONFIGURATION

INSTALLATIEHANDLEIDING – P15 VERSION 0129NM02INT01INSTRUCTION MANUAL – P15 | P15 07A2NM20ENG05

7.1 REGULAR USE

The rst step is to connect your car to the charge

point by plugging in the charge cable. If you are using

Plug&Charge the session will start automatically. If you

have to identify rst; swipe your charge card above the

LED.

The LED will ash green to authenticate the card and

after acceptance, the session will start. If the LED

ashes red, the session has not been accepted.

When the car has delayed charging congured, the LED

will remain green until charging can start between the

car and charge point.

Start charging? Plug in & identify

Stop charging? Identify & unplug

Full or waiting to charge

Plug in or identify

Charging

Not accepted

Error

Flashing green or multi colors: starting procedure or

software update procedure for charge point.

7. USER MANUAL

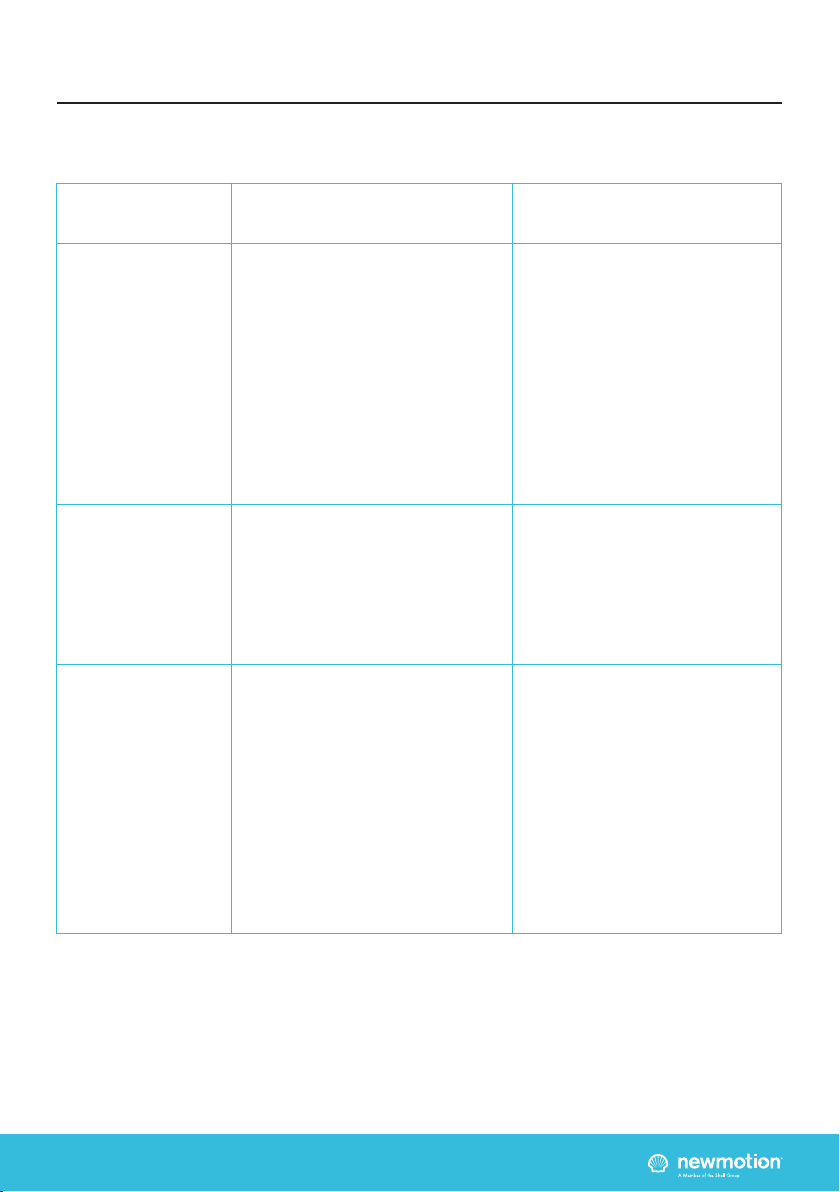

7.2 TROUBLESHOOTER

DO YOU SEE A RED LED LIGHT ON YOUR CHARGE

POINT?

If so, it means your car won’t charge when plugged in.

To x this issue, turn o the Mechanical Circuit Breaker,

wait 15 seconds, and turn it back on.

IS THERE A BLINKING RED LED LIGHT ON YOUR

CHARGE POINT?

If so, it means you are using a card which is not linked

to the charge point by your installer. To start and stop a

charging session, you have to use a card which is linked

to the charge point. To link a new card (with RFID) to

your charge point, please contact your installer.

HAVE YOU LOST YOUR CHARGE CARD?

If you are unable to release the cable from your car, turn

o the Mechanical Circuit Breaker and you will be able

to release the cable. After releasing your cable, you can

switch the power back on by turning the Mechanical

Circuit Breaker on.

DOES YOUR CAR CHARGE VERY SLOWLY WHEN

USING THE LOAD-SHEDDING FUNCTIONALITY?

Please check if your car charging speed is varying.

If it is varying, the charge point is balancing the total

electrical use with your household as Load-shedding is

an automatic function.

If the charge speed does not increase when most of

the devices in household are turned o, communication

between your charge point and the Load-Shedding

module may be lost. Turn o the Mechanical Circuit

Breaker, wait 15 seconds, and turn it back on.

If the issue remains, contact your installer to check that

the cable is working properly.

Other manuals for newmotion Home Advanced Edition 7

3

This manual suits for next models

1

Table of contents

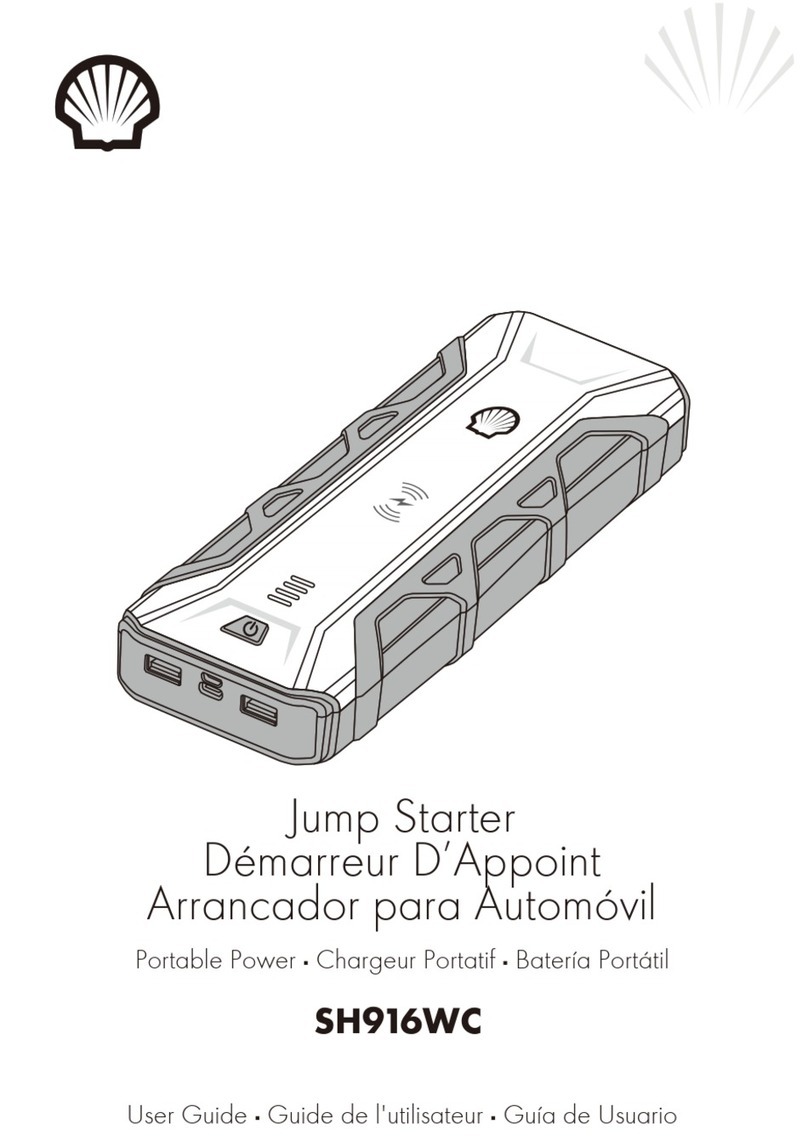

Other Shell Automobile Accessories manuals

Shell

Shell Recharge Basic User manual

Shell

Shell NewMotion Business Pro 2.1 User manual

Shell

Shell NewMotion Business Pro 2.1 User manual

Shell

Shell newmotion Home Advanced Edition 7 User manual

Shell

Shell SH916WC User manual

Shell

Shell NewMotion Home Advanced 2.1 User manual

Shell

Shell NewMotion Home Advanced 2.1 User manual