Prime Controls LH200H User manual

LH200H, SL100H End Leak Detection System

Operating Instructions

202867 Revision H

03/13/2023

Prime Controls, Inc.

DESCRIPTION

The LH200H, SL100H End Leak Detection System uses Prime Controls Eclipse Leak Detection

Technology to provide state-of-the-art light-based end leak detection for conversion presses.

The system can operate at up to 1000 ends per minute while detecting holes as small as 0.5µm.

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 i Revision H

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 ii Revision H

Revision History

Revision

Date

Description

Author

A

2020-08-31

Initial Release

RMC

B

2020-09-10

Document clean up.

RMC

C

2020-12-16

Fixed missing references to drawings.

RMC

D

2021-05-26

Revised drawings 202798, 202866

RMC

E

2021-06-22

Revised with LH200H 2.4 firmware related changes

JDD

F

2021-11-02

Revised with LH200H-202 and LH200H-200

RMC

G

2022-08-10

Changed incorrect part number for CBL146-10

BP

H

2023-03-13

Added LH200H-2 Eight Wire Variant

Revised with LH200H 2.5 firmware related changes

RMC,

JDD

©Prime Controls, Inc.

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 iii Revision H

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 iv Revision H

Table of Contents

1INTRODUCTION .................................................................................1

2SYSTEM COMPONENTS....................................................................2

2.1 LH200H or LH200H-opt Light Detector..............................................................2

2.2 SL100H LED Illuminator ....................................................................................3

2.3 SQ200................................................................................................................4

2.4 PS506 Power Supply.........................................................................................4

2.5 CAP001 Power Filter .........................................................................................4

2.6 Cable Set...........................................................................................................5

2.7 Sensors and Actuators.......................................................................................5

3INSTALLATION...................................................................................6

3.1 LH200H/LH200H-opt, LH200H-2 Mounting .......................................................6

3.2 SL100H Mounting..............................................................................................6

3.3 SQ200 Mounting................................................................................................6

3.4 PS506 Mounting ................................................................................................6

3.5 CAP001 Mounting..............................................................................................6

3.6 Wiring and Cabling.............................................................................................6

3.6.1 Introduction................................................................................................6

3.6.2 AC Power...................................................................................................6

3.6.3 LH200H/LH200H-opt Connections ............................................................7

3.6.4 LH200H-2 Connections..............................................................................8

3.6.5 SL100H Connections.................................................................................8

3.6.6 Input/Output Connections..........................................................................8

Input Logic Signals ........................................................................................ 9

Output Logic Signals...................................................................................... 9

4Operation............................................................................................9

4.1 Power-Up Sequence..........................................................................................9

4.2 Indicators.........................................................................................................10

4.2.1 PS506......................................................................................................10

4.2.2 LH200H and LH200H-2 ...........................................................................10

4.2.3 SL100H....................................................................................................10

4.3 Measurement Cycle.........................................................................................10

4.4 IO Configuration...............................................................................................11

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 v Revision H

4.4.1 Default Configuration...............................................................................11

4.4.2 IO Enable/Disable Switch ........................................................................12

4.4.3 IO Polarity................................................................................................12

4.4.4 IO Override..............................................................................................12

4.4.5 IO Drive Type...........................................................................................13

4.5 Rejector Configuration.....................................................................................13

4.5.1 Initial Set-Up............................................................................................13

Parameters...................................................................................................13

Electrical Test...............................................................................................13

4.5.2 Timing Adjustment...................................................................................13

4.5.3 Final Parameter Adjustment ....................................................................14

5User Interface...................................................................................14

5.1 Console Serial Port Settings............................................................................14

5.2 Console Output................................................................................................14

5.3 Console Operation...........................................................................................16

5.4 Operator Commands .......................................................................................16

5.4.1 1: Trigger One Measurement...................................................................17

5.4.2 B: Bias .....................................................................................................17

5.4.3 A: Auto-Adjust..........................................................................................17

5.4.4 C: Calibrate..............................................................................................17

5.4.5 G: Signal Gain .........................................................................................17

5.4.6 L: Leak Limit ............................................................................................17

5.4.7 F: Clear Fault...........................................................................................17

5.4.8 P: Phase..................................................................................................18

P: Lane Phase..............................................................................................18

A: Auto Lane Phase......................................................................................18

5.4.9 V: Version................................................................................................18

5.4.10 I: Installer.................................................................................................18

5.4.11 Q: Quit .....................................................................................................18

5.4.12 ?: Menu....................................................................................................18

5.5 Installer Commands.........................................................................................18

5.5.1 M: Modbus...............................................................................................19

A: Address....................................................................................................19

E: Enumerated Address................................................................................19

M: Manual Address.......................................................................................19

X: Use Enumerated ......................................................................................19

R: Enumeration ADC ....................................................................................19

5.5.2 T: Trigger.................................................................................................19

E: Enable......................................................................................................19

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 vi Revision H

P: Polarity.....................................................................................................20

5.5.3 W: Strobe.................................................................................................20

S: Start .........................................................................................................20

W: Width.......................................................................................................20

P: Polarity.....................................................................................................20

E: Enable......................................................................................................20

O: Override...................................................................................................20

V: Value........................................................................................................20

5.5.4 H: Strobe Good........................................................................................20

P: Polarity.....................................................................................................20

E: Enable......................................................................................................21

O: Override...................................................................................................21

V: Value........................................................................................................21

5.5.5 R: Rejector...............................................................................................21

P: Polarity.....................................................................................................21

E: Enable......................................................................................................21

R: Rate .........................................................................................................21

L: Location....................................................................................................22

B: Before.......................................................................................................22

A: After .........................................................................................................22

O: Override...................................................................................................22

V: Override Value .........................................................................................22

T: Type.........................................................................................................22

5.5.6 O: Result..................................................................................................22

M: Result Mode.............................................................................................22

P: Polarity.....................................................................................................24

S: Start .........................................................................................................24

F: Finish........................................................................................................24

E: Enable......................................................................................................24

O: Override...................................................................................................24

V: Override Value .........................................................................................24

T: Type.........................................................................................................24

5.5.7 K: System OK..........................................................................................24

P: Polarity.....................................................................................................25

E: Enable......................................................................................................25

O: Override...................................................................................................25

V: Override Value .........................................................................................25

T: Type.........................................................................................................25

5.5.8 U: Utility ...................................................................................................25

D: Default Settings........................................................................................25

F: Freerun.....................................................................................................25

5.5.9 D: Display ................................................................................................25

1: Samples Ch 1...........................................................................................26

2: Samples Ch 2...........................................................................................26

3: Samples Ch 3...........................................................................................26

4: Samples Ch 4...........................................................................................26

P: Plot Signals ..............................................................................................26

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 vii Revision H

M: Settings....................................................................................................26

5.5.10 S: Statistics..............................................................................................28

F: Statistics...................................................................................................28

G: Gain.........................................................................................................28

M: Gain M.....................................................................................................29

6MODBUS COMMUNICATION...........................................................30

6.1 Serial Interface.................................................................................................30

6.2 Commands ......................................................................................................30

6.2.1 Discrete Coil Outputs (000001)................................................................31

6.2.2 Discrete Inputs (100001)..........................................................................33

6.2.3 Register Inputs (300001) .........................................................................34

6.2.4 Holding Registers (400001).....................................................................35

7MAINTENANCE ................................................................................36

8TROUBLESHOOTING.......................................................................37

8.1 Basic Guide .....................................................................................................37

8.2 Status Messages .............................................................................................37

8.3 Detailed Instructions ........................................................................................38

8.3.1 Strobe NOK .............................................................................................38

8.4 Factory Assistance...........................................................................................39

9OPERATING SPECIFICATIONS.......................................................40

9.1 LH200H, LH200H-opt ......................................................................................40

9.2 LH200H-2 ........................................................................................................40

10 ELECTRICAL SPECIFICATIONS .....................................................41

11 LIMITATIONS AND EXCLUSION OF WARRANTIES.......................42

12 Drawings...........................................................................................43

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 viii Revision H

Table 1 - Cable Set.................................................................................................................... 5

Table 2 - LH200H/LH200H-opt Connection List ......................................................................... 7

Table 2 - LH200H/LH200H-opt Connection List ......................................................................... 8

Table 3 - SL100H Connection List.............................................................................................. 8

Table 4 - Signal Drive Types...................................................................................................... 9

Table 5 - Status LED Interpretation...........................................................................................10

Table 6 - Status LED Interpretation...........................................................................................10

Table 7 - Default IO Configuration.............................................................................................11

Table 8 - Output Polarities ........................................................................................................12

Table 9 - IO Drive Overrides .....................................................................................................12

Table 10 - IO Drive Type...........................................................................................................13

Table 11 - Console Output........................................................................................................15

Table 12 - Enumerated Addresses............................................................................................19

Table 13 - System Settings and Commands.............................................................................26

Table 14 –LH200H Modbus Connections.................................................................................30

Table 15 - Modbus Command Codes........................................................................................30

Table 16 - Modbus Discrete Coils .............................................................................................31

Table 17 - Modbus Discrete Inputs............................................................................................33

Table 18 - Modbus Register Inputs ...........................................................................................34

Table 19 - Modbus Holding Registers.......................................................................................35

Table 20 - Console Measurement Flags....................................................................................37

Table 21 –Flag Interpretation...................................................................................................38

Figure 1 - LH200H, LH200H-2 ................................................................................................... 2

Figure 2 - LH200H-opt ............................................................................................................... 3

Figure 3 - SL100H...................................................................................................................... 3

Figure 4 - SQ200 ....................................................................................................................... 4

Figure 5 - PS506........................................................................................................................ 4

Figure 6 - CAP001..................................................................................................................... 5

Figure 7 - Measurement Timing Phase 2 ..................................................................................11

Figure 8 - Measurement Timing Phase 5..................................................................................11

Figure 9 - Measurement Timing Phase 7 ..................................................................................11

Figure 10 - Result Mode 0.........................................................................................................23

Figure 11 - Result Mode 1.........................................................................................................23

Figure 12 - Result Mode 2.........................................................................................................23

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 1 Revision H

1 INTRODUCTION

The LH200H, SL100H End Leak Detection System detects defects as small as 0.5µm in ends

while operating at up to 1000 ends per minute. It utilizes all-solid-state illumination and detection

components for maximum system reliability and lifetime. The system accepts a single trigger

input and provides leak/no-leak, rejector control, and system ok outputs with programmable

polarity and drive. Factory automation is supported via built-in RS-232 and Modbus

communications. The system may be used with the SQ200 sequencer to automatically phase

measurement timing to reduce inter-lane crosstalk between strobe units. The PS506 power

supply and CAP001 power filter along with cables complete the system. A minimum installation

requires only a signal trigger pulse from the PLC to initiate measurement during press dwell. A

full system can take advantage of the system’s measurement output, built-in rejector control,

lane measurement phasing, system OK output, and optional Modbus.

For brevity, the LH200H, LH200H-202 and LH200H-300 shall be referenced as the LH200H in

this manual. The units are functionally and electrically equivalent except for packaging and the

absence of power and status LEDs on the LH200H-202 and LH200H-300. The term LH200H-

opt shall be used to refer to the LH200H-202 or LH200H-300.

The LH200H-2 unit is designed as a drop-in replacement for the LH200 light detector. This unit

features an 8 wire cable compatible with the LH200 eight wire cable. Due to the reduced

number of wires to the unit, certain signals and functionalities are not available. Refer to other

portions of this text for details.

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 2 Revision H

2 SYSTEM COMPONENTS

The End Leak Detection System consists of five major components as described below:

2.1 LH200H or LH200H-opt Light Detector

The system uses a LH200H or LH200H-opt light detector based on Prime Control’s proprietary

Eclipse Leak Detection Technology. One detector is used per lane. These detectors are

designed to work in the hostile industrial environment of a conversion press while detecting

leaks down to 0.5µm. The LH200H, and LH200H-2 are packaged to mechanically match the

Prime Controls LH200 light sensor, while the LH200H-opt is packaged to mechanically match a

common mounting interface used in the industry.

Figure 1 - LH200H, LH200H-2

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 3 Revision H

Figure 2 - LH200H-opt

2.2 SL100H LED Illuminator

The SL100H LED Illuminator is an all-solid-state LED-based illumination system designed

specifically to work with the LH200H detector. It provides constant current drive to the LEDs for

detection consistency and pulse confirmation to the LH200H ensuring correct leak detection

operation.

Figure 3 - SL100H

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 4 Revision H

2.3 SQ200

The SQ200 sequencer automates the sequencing of measurements across multiple lanes to

reduce inter-lane crosstalk due to adjacent SL100H illuminators turning on at the same time. It

also automatically assigns Modbus addresses for up to six LH200H detectors.

Figure 4 - SQ200

2.4 PS506 Power Supply

The PS506 power supply of the system is a high current, +27V power supply selected for its

current handling capability and reliability. It can support up to four lanes. The supply is adjusted

to produce 27VDC. It is DIN rail mounted for ease of service.

Figure 5 - PS506

2.5 CAP001 Power Filter

CAP001 provides current smoothing for the PS506 and up to four lanes of SL100H illuminators.

It is DIN rail mounted for ease of service.

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 5 Revision H

Figure 6 - CAP001

2.6 Cable Set

The following cables are used in the system:

Table 1 - Cable Set

Name

Part Number

Description

Note

CBL108-10

CBL108-10

Connector/Cable, 8 pole, F PUR,

Shielded, 10M

to LH200H-2 only

CBL144-10

202807-10

Connector/Cable, 12 pole, F PUR,

Shielded, 10M

to LH200H or

LH200H-opt only

CBL146-10

202853-10

Connector/Cable, 6 pole, F PUR,

Shielded, 10M

to SL100H

The customer is responsible for cables to the reject solenoids, PLC, and power source. Only

one of CBL108-10 or CBL144-10 is required. Select the appropriate cable to match your

LH200H version.

2.7 Sensors and Actuators

In addition to the LH200H or LH200H-opt and SL100H mounted on the machine, the customer

may supply a relay, and reject solenoid (actuator) to reject failed can ends from the product flow

by using a blast of air to remove the end from the outfeed conveyor.

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 6 Revision H

3 INSTALLATION

Prior to installation of any component, verify that power is off to the unit and lock-outs are in

place per workplace safety policies.

3.1 LH200H/LH200H-opt, LH200H-2 Mounting

The LH200H or LH200H-2 is mounted using four 6.75mm (0.266″) holes on a 69.85mm (2.75″)

bolt circle. The unit should be shock-mounted to reduce the vibration of the unit. See section 12

for drawing 202690 for details.

The LH200H-opt is mounted using four 6.75mm (0.266″) holes on a 117.48mm (4.625″) bolt

circle. Shim the unit to achieve proper contact with ends as they pass under the detector. See

section 12 for drawing 202798 for details.

3.2 SL100H Mounting

The SL100H is mounted using four single ¼-20 or ¼-28 shoulder bolts. See section 12 for

drawing 202720 for details.

3.3 SQ200 Mounting

The SQ200 terminal block array mounts onto a standard 35mm DIN rail. See section 12 for

drawing 202740 for details.

3.4 PS506 Mounting

The PS506 power supply mounts onto a standard 35mm DIN rail. See section 12 for drawing

202822 for details.

3.5 CAP001 Mounting

The CAP001 power supply filter mounts onto a standard 35mm DIN rail. See section 12 for

drawing 202850 for details.

3.6 Wiring and Cabling

3.6.1 Introduction

System wiring is described in the section. Refer to section 12 for wiring diagram 202866.

3.6.2 AC Power

The system uses 90-260 VAC, 47-63Hz power. The terminal blocks support wire gauges 26-12

AWG wire using Line1, Neutral (or Line 2), and Protective Earth (PE) ground. Select an

appropriate wire gauge within the allowable range consistent with system safety requirements.

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 7 Revision H

3.6.3 LH200H/LH200H-opt Connections

The light detector has a 12-wire male M12 connector. Pinout as indicated below:

Table 2 - LH200H/LH200H-opt Connection List

Pin

Signal

Color

Type

1

+27V Power

White

Power

2

Common

Brown

Power

3

Result

Green

Output

4

Serial Data In

Yellow

RS-232 Input

5

Serial Data Out

Gray

RS-232 Output

6

Strobe Trigger

Pink

Output

7

System OK

Blue

Output

8

Trigger

Red

Input

9

Rejector

Orange

Output

10

Strobe Good

Tan

Input

11

Modbus RS-485 B

Black

Bidirectional

12

Modbus RS-485 A

Violet

Bidirectional

Shield

Shield

Braid

Shield

Caution: Color codes vary for M12 12 pole cables. Verify the pin connections

according to pin numbers shown.

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 8 Revision H

3.6.4 LH200H-2 Connections

The light detector has an 8-wire male M12 connector. Pinout as indicated below:

Table 3 - LH200H/LH200H-opt Connection List

Pin

Signal

Color

Type

1

Result

White

Output

2

Power (+27V)

Brown

Power

3

Serial Data In

Green

RS-232 Input

4

Strobe Trigger

Yellow

Output

5

Test Cycle Enable

Gray

Input

6

Serial Data Out

Pink

RS-232 Output

7

Common

Blue

Power

8

Shield

Braid

Shield

The LH200H-2 light detector does not include System OK, Strobe Good, Rejector, and the

ModBus communication pairs. These functions are not available on this unit.

Caution: Color codes vary for M12 8 pole cables. Verify the pin connections

according to pin numbers shown.

3.6.5 SL100H Connections

The illuminator has a six-wire male M12 connector. Pinout as indicated below:

Table 4 - SL100H Connection List

Pin

Signal

Color/Label

Type

1

Common

Black 1

Power

2

Common

Black 2

Power

3

+27V Power

Black 3

Power

4

Strobe

Black 4

Input

5

Strobe Good

Black 5

Output

PE

Protective Earth

Green/Yellow

Safety

Braid

Shield

Braid

Braid

3.6.6 Input/Output Connections

Connections to the PLC are made individually to each LH200H. The Trigger input should be

paralleled to all LH200H units. The LH200H Result and System Ok outputs may be used by the

PLC to track rejects and individual lane status.

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 9 Revision H

The logic outputs of the LH200H are programmable for PNP, NPN, and Push-Pull drive. The

default is PNP. The polarity of the signals default to fail-safe values for PNP drive. This means

that fault conditions are signaled by a low or ground signal, and non-fault signals are signaled

by high or +24V (PNP driven signals).

Table 5 - Signal Drive Types

Drive Type

High Signal

Low Signal

Fail-Safe

Hi-Z

No Drive

No Drive

N/A

PNP

Pull Up

No Drive

Low

NPN

No Drive

Pull Down

High

Push-Pull

Pull Up

Pull Down

Low

Input Logic Signals

Each LH200H has a single input signal that triggers the measurement cycle. The detector can

be programmed to trigger on the rising or falling edge of this signal. The timing of the

measurement cycle is programmable. It is possible to have all lanes measure at once or to

sequence them in several ways using the SQ200. The default is for odd lanes measure together

and even lanes measure together 1mS later. Sequencing helps to reduce the possibility of light

interacting between adjacent lanes.

Output Logic Signals

All versions of the LH200H and the LH200H-2 have a result output. The LH200H and LH200H-

opt include System OK and Rejector outputs.

System OK signals the general health of the system and is used by the PLC to confirm each

lane is fully functional with no faults detected. Result is the resulting output from the

measurement cycle. The result output has three modes to assist the PLC in confirming that the

result signal is properly connected and received by the PLC.

The Rejector output may be used to drive a relay to control a rejection mechanism to eject

defective ends based on measurement results. This signal includes timing provisions to account

for the time lag between the measurement and the arrival of an end at the rejector blow-off

position along with the capability to reject ends before and after the suspect end to ensure

successful rejection of the end regardless of minor speed and handling variations between the

light detector and reject position.

4 Operation

4.1 Power-Up Sequence

Prior to powering on the unit, verify that all cables are properly connected to the LH200H or

LH200H-2 and SL100H units. The system is designed to be continuously powered. It is not

necessary to periodically cycle power other than as required for maintenance of the system.

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 10 Revision H

4.2 Indicators

4.2.1 PS506

PS506 contains a single LED to indicate that it is powered and operating.

4.2.2 LH200H and LH200H-2

The LH200H and LH200H-3 have two LEDs. One dedicated to indicating power is applied, and

the second, multiple color LED to indicate device status and measurement results.

Table 6 - Status LED Interpretation

Color

Meaning

Green

No Leak

Yellow

Measurement Fault Detected

Red

Leak Detected

4.2.3 SL100H

The SL100H has two LEDs. One dedicated to indicating power is applied, and the second,

multiple color LED to indicate device status.

Table 7 - Status LED Interpretation

Color

Meaning

Green

Strobe Good

Yellow

Strobe Too Fast

Red

Strobe Error

4.3 Measurement Cycle

A measurement cycle is initiated by the Trigger input to the LH200H. Once triggered the

LH200H delays for a period defined by the SQ200 or internal phase setting. Once the specified

period has elapsed, the LH200H triggers the SL100H to produce a flash of light used to detect

leaking ends. Data are captured during the flash and a determination is made if the end under

test is a leaker. The Result line is set according to the leak status of the end and along with the

rejector logic.

The timing of the strobe and Result output is controlled, in part, by the Phase setting of the

LH200H. By adjusting the Phase setting between 1 and 10, it is possible to cause each lane to

trigger its strobe and make its measurements at unique times. In the diagrams below, notice

how the time from the edge of the trigger pulse to the strobe pulse increases as the Phase

setting increases.

In each diagram, the top row is a representation of the trigger pulse assuming rising edge

trigger, the second row represents the Strobe signal output. The third row represents the Result

output if a no leak is detected Result (No-Leak), and the bottom row represents the Result

output if a leak is detected Result (Leak). In the example, the Result output is set to High True.

Setting the Result output to Low True inverts the signals from those shown.

LH200H, SL100H End Leak Detection System

This document is confidential and proprietary. No part of this document may be disclosed in any manner

to a third party without the prior written consent of Prime Controls, Inc.

202867 11 Revision H

Figure 7 - Measurement Timing Phase 2

Figure 8 - Measurement Timing Phase 5

Figure 9 - Measurement Timing Phase 7

4.4 IO Configuration

The inputs and outputs of the LH200H are fully configurable. They can be enabled or disabled,

they can be overridden and set to a fixed value. Each output’s drive type can be set to one of

four options.

4.4.1 Default Configuration

The LH200H is shipped with a default configuration that is designed to be ready to run without

user adjustment. The default settings are as listed below. The Rejector and System OK signals

are not available on the LH200H-2 unit.

Table 8 - Default IO Configuration

Signal

Enabled

Polarity

Override

Output Type

Trigger

Yes

Rising Edge

No

N/A

Result

Yes

Low - Leak

No

PNP

Rejector

Yes

High - Reject

No

PNP

System OK

Yes

High - OK

No

PNP

This manual suits for next models

1

Table of contents

Other Prime Controls Security Sensor manuals

Prime Controls

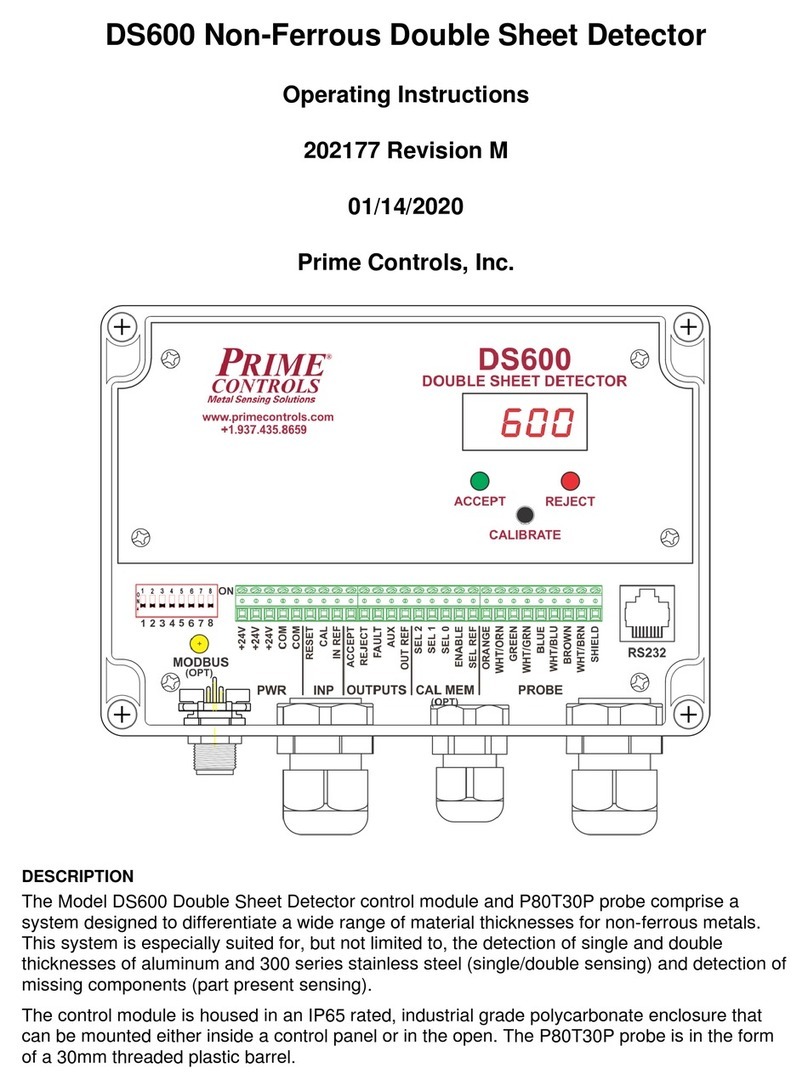

Prime Controls DS600 User manual

Prime Controls

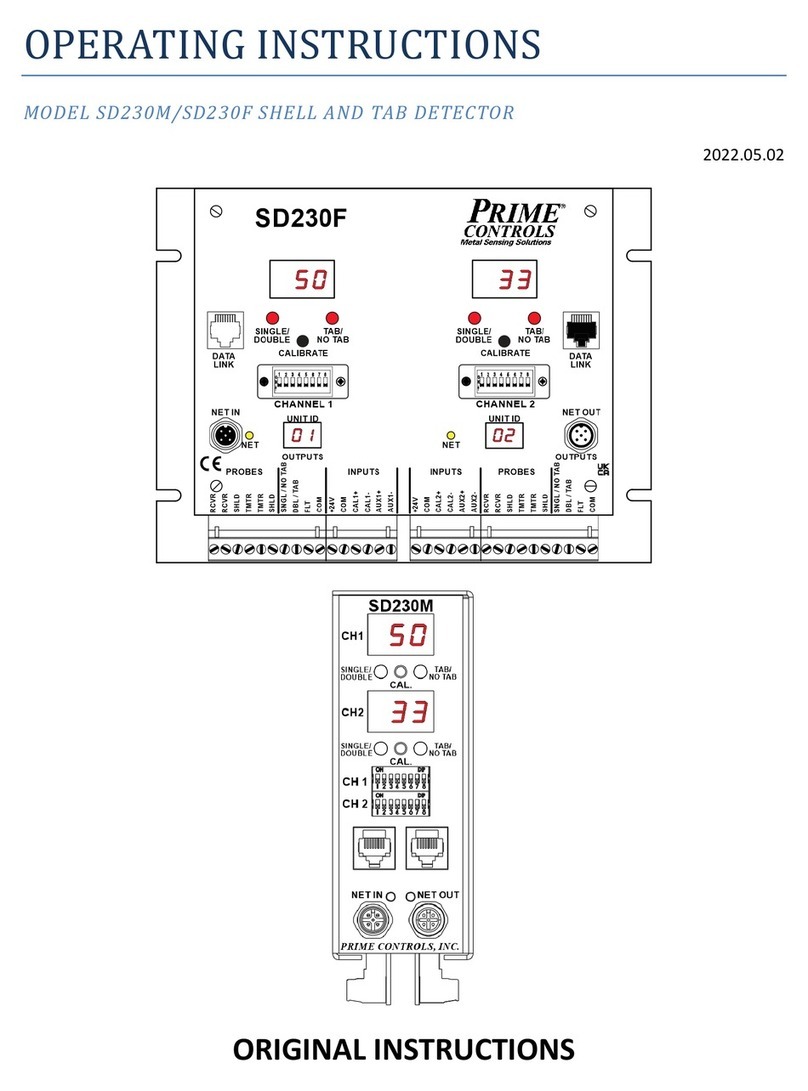

Prime Controls SD230M User manual

Prime Controls

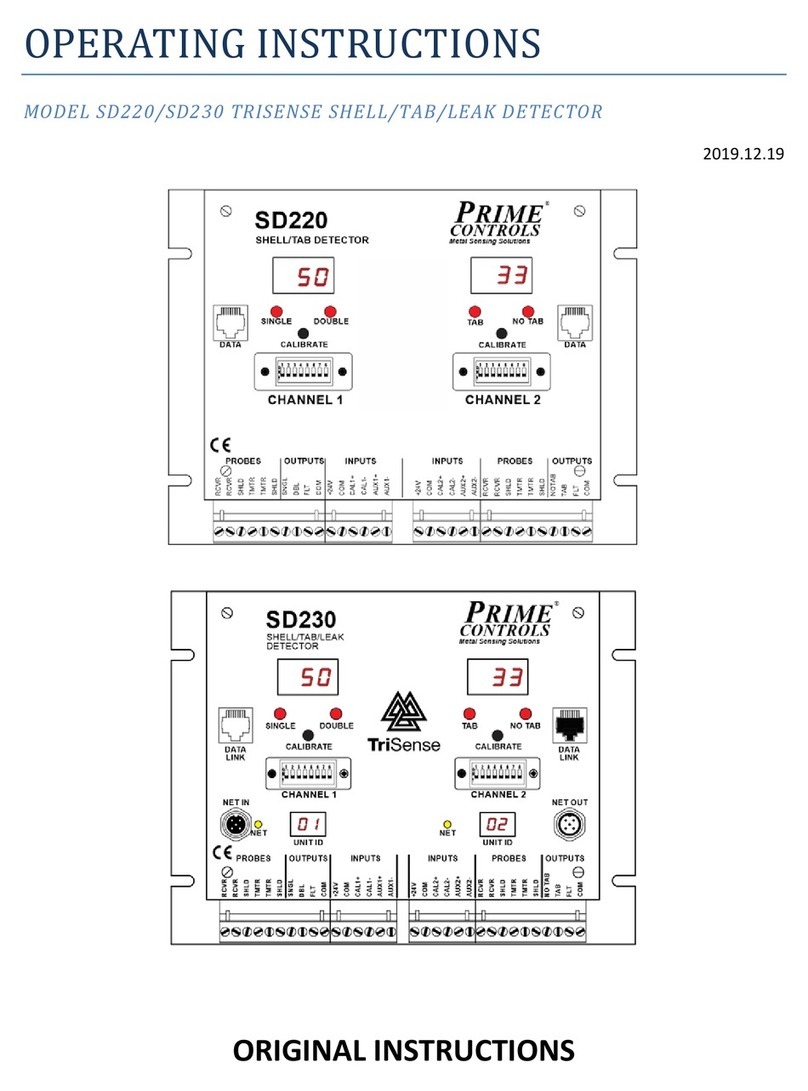

Prime Controls SD220 User manual

Prime Controls

Prime Controls SD220 User manual

Prime Controls

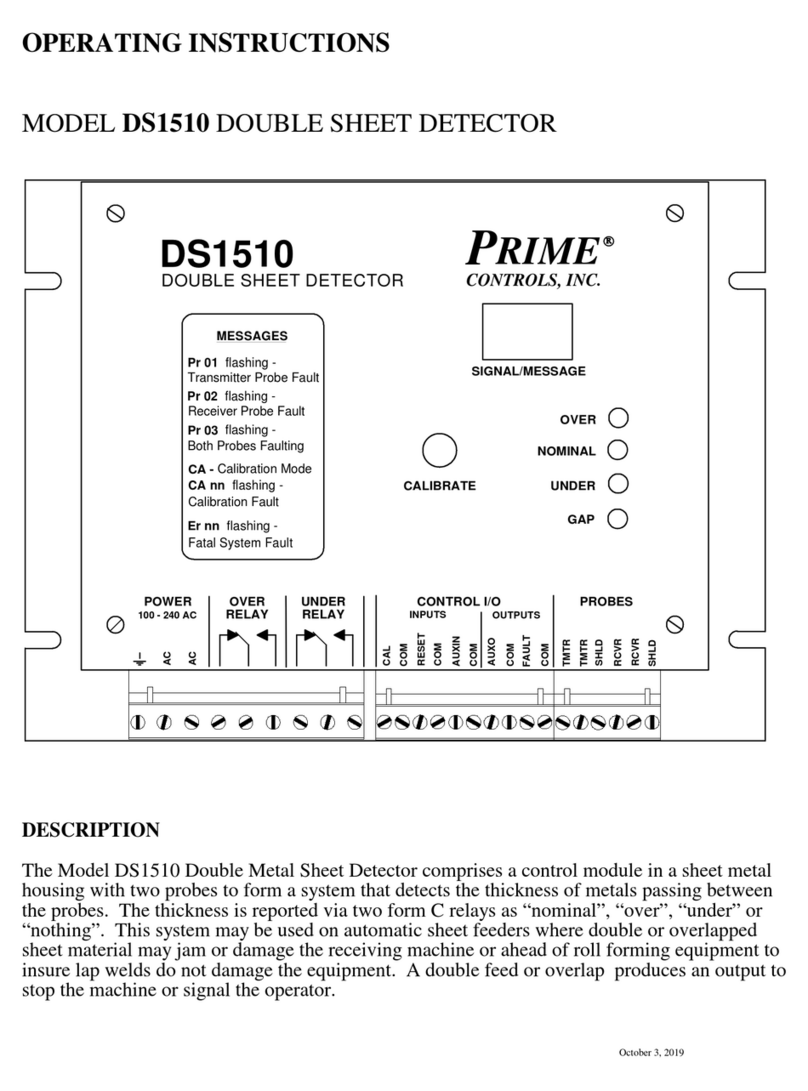

Prime Controls DS1510 User manual

Prime Controls

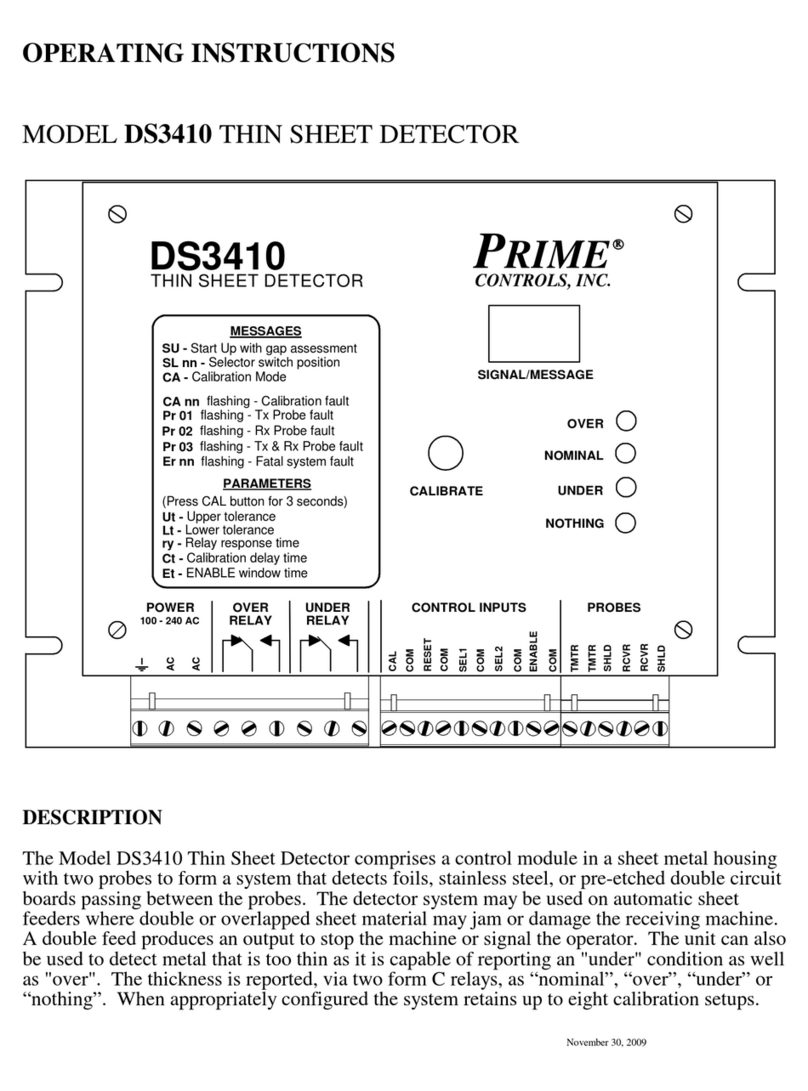

Prime Controls DS3410 User manual

Prime Controls

Prime Controls LH200 User manual

Prime Controls

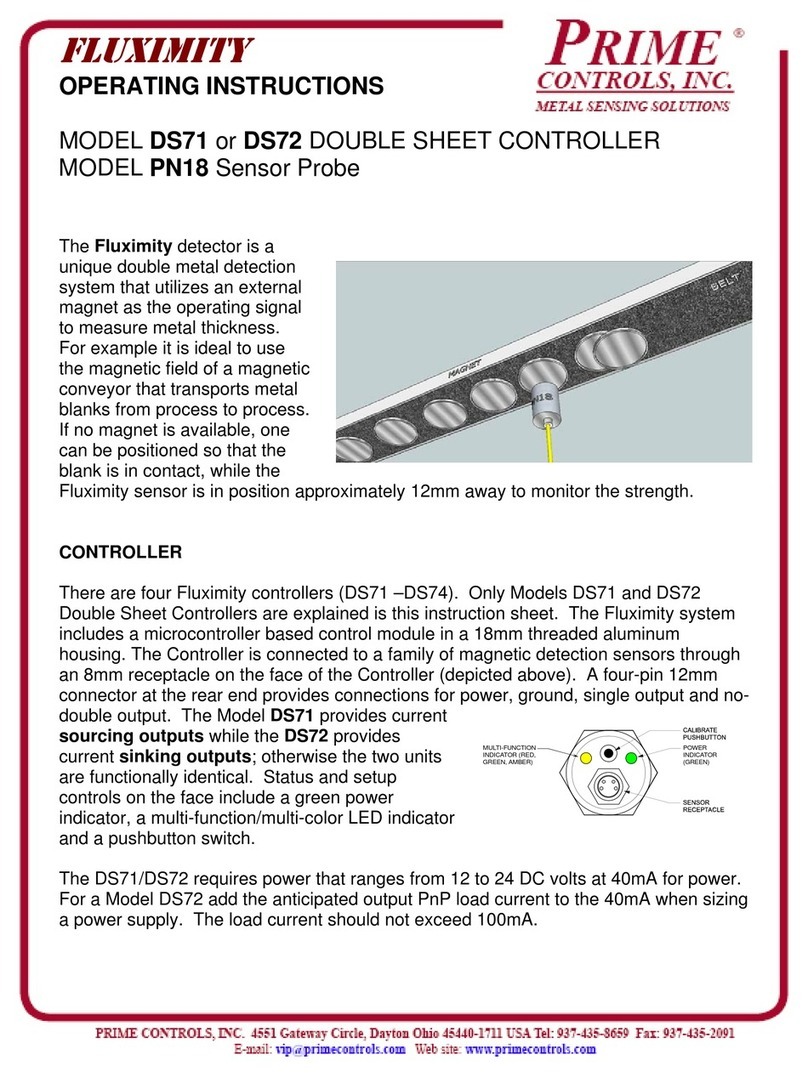

Prime Controls FLUXIMITY DS71 User manual

Prime Controls

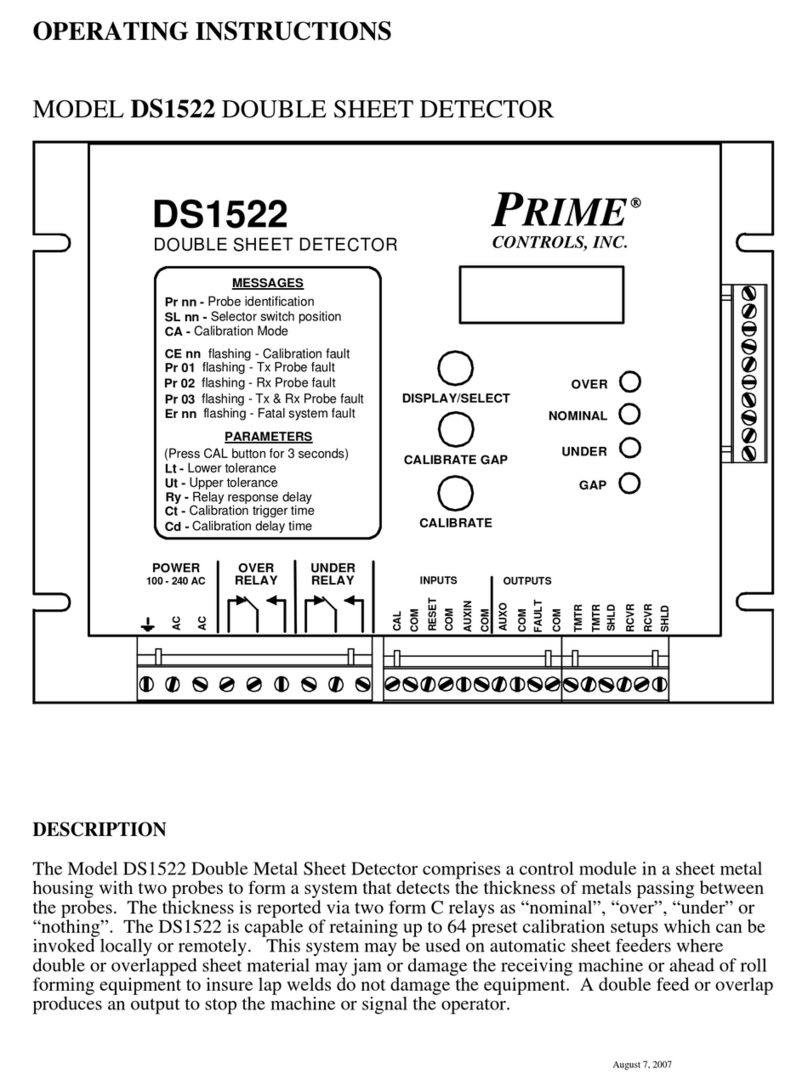

Prime Controls DS1522 User manual