General Information

Combined PIR + glass break detector «Orlan-D» (hereinafter, the Detector)

is designed for application as a component of security systems.

The Detector has the following two independent detection channels:

- Glass break channel (hereinafter, GB channel);

- Passive infrared channel (hereinafter, PIR channel).

GB channel is intended for detecting destruction of engineering structures

made of plate glasses, double- and triple-pane glasses with an area of not less

than 0.1 m2(with any side length not less than 0.3 m), as well as glass bricks.

PIR channel is assigned for detecting intrusion into protected area of closed

premises. PIR channel provides wide angle detection zone. The Detector is

resistant to movement of pets with weigh up to 20 kg with temperature contrast

∆t = 8 оC (smooth-coated cats and dogs) and pets with weigh up to 40 kg with

temperature contrast ∆t = 6 оC (long-hair cats and dogs).

The Detector generates Tamper message at it’s cover opening by an alarm

loop (AL) or microswitch contacts opening.

The Detector is resistant to the impacts of ambient light, radio noise, as well

as disturbance from small animals: mice, rats, birds in cages if a distance to

them is not less than 2.5 m.

The Detector can be installed on the wall or in the corner of the room. Wall or

ceiling mounting by means of swivel bracket (supplied) is also possible.

Features

Sensing element of detection channels:

- PIR channel – dual-element pyrodetector;

- GB channel – microphone.

- Microprocessor-based signal processing.

- Spherical lens ensures high detectability level.

- Self-test mode.

- Alarm at PIR and GB channels memorization (Alarm memory).

- Possibility of PIR and GB channels sensitivity modes choosing.

- Possibility of LED indication disabling.

- Pet movement resistance.

- Protection against ingress of insects to the pyrodetector.

- Possibility of swivel bracket using for the detection zone position alignment.

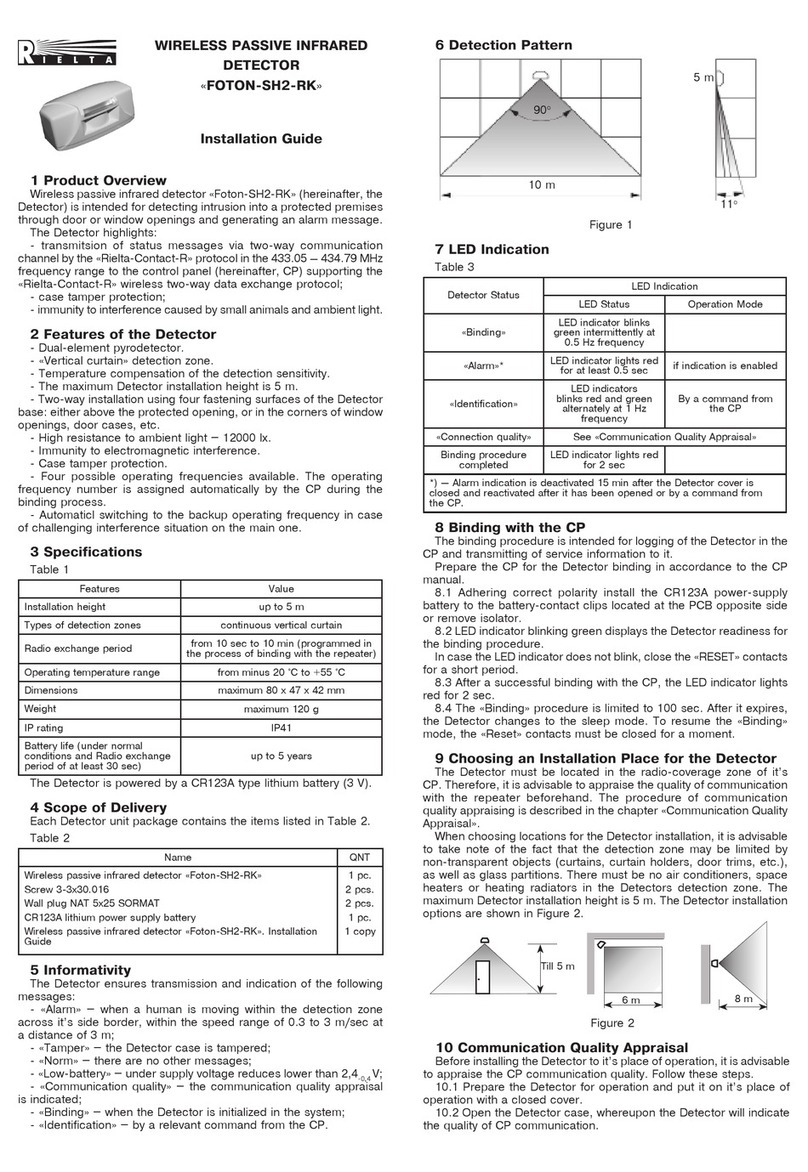

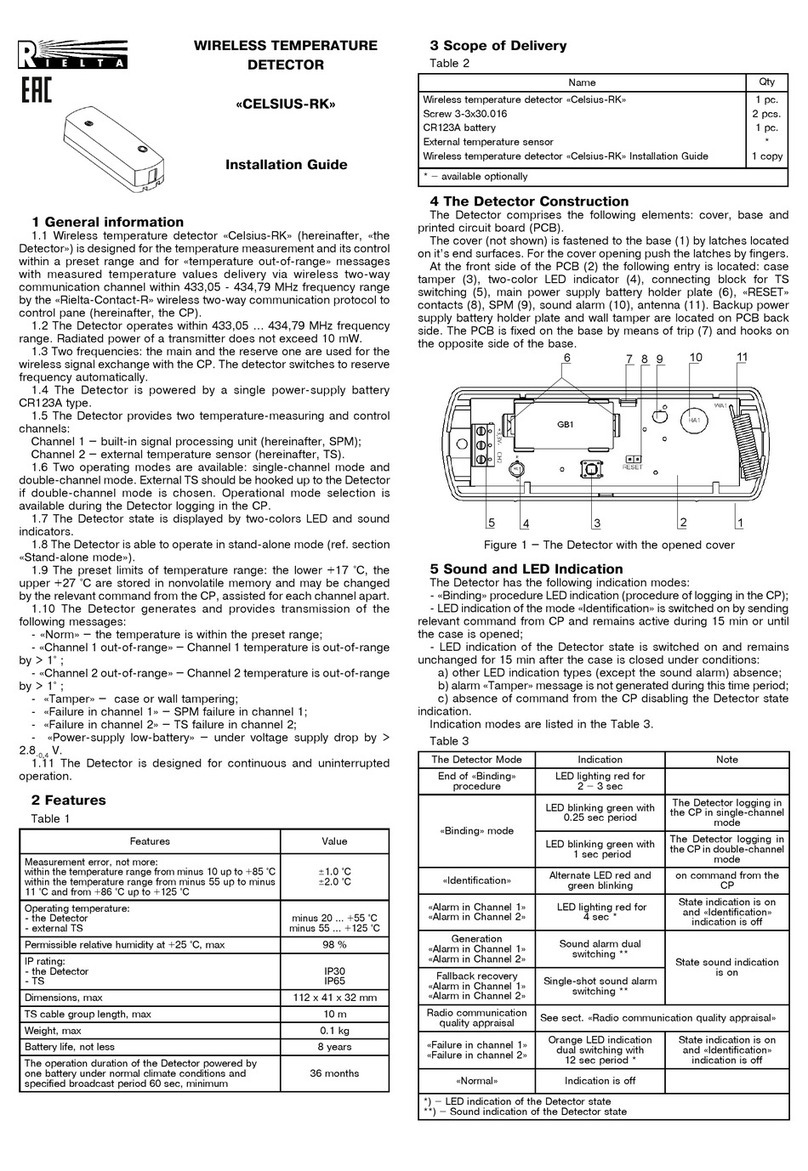

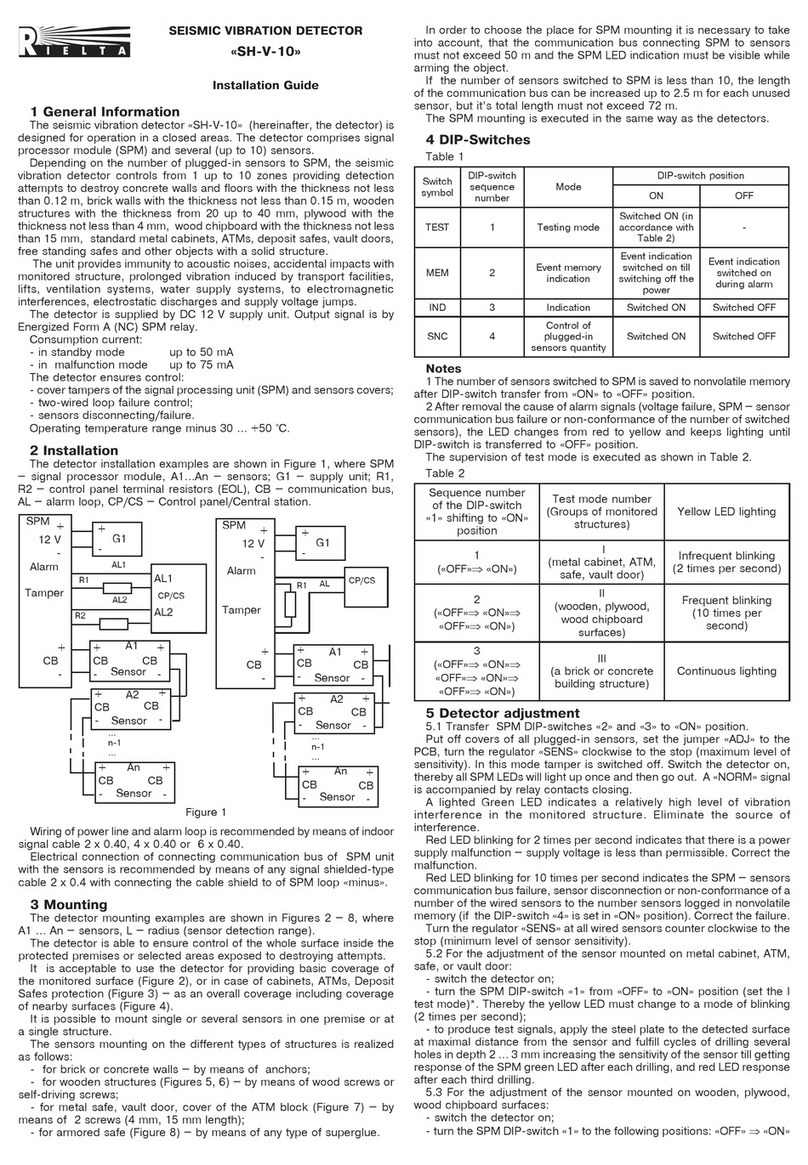

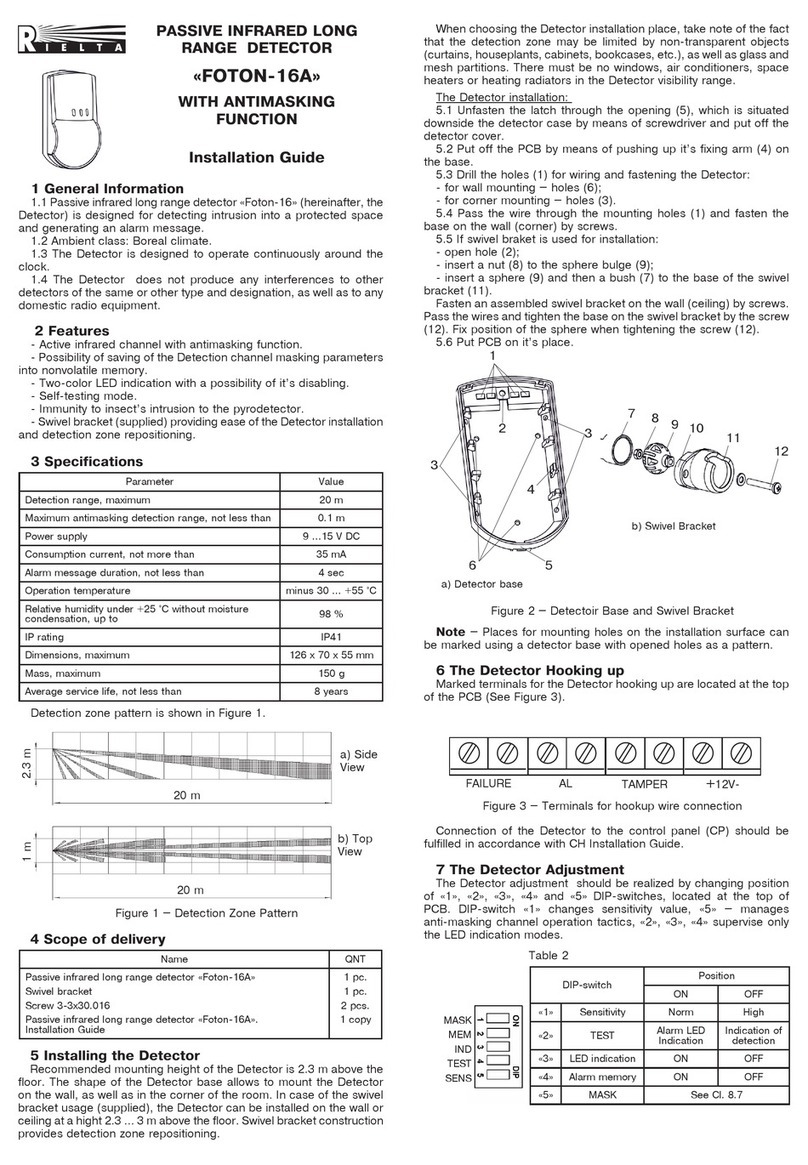

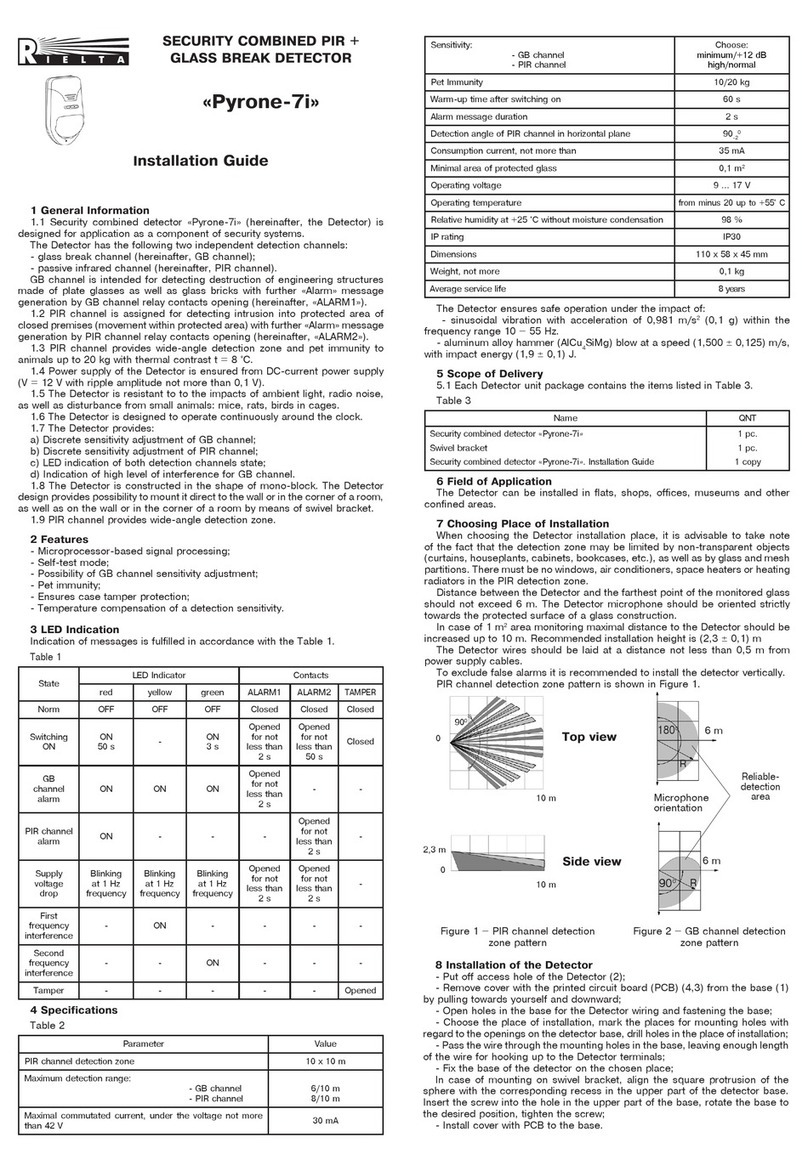

The Detector specifications are listed in Table 1. PIR detection zone pattern

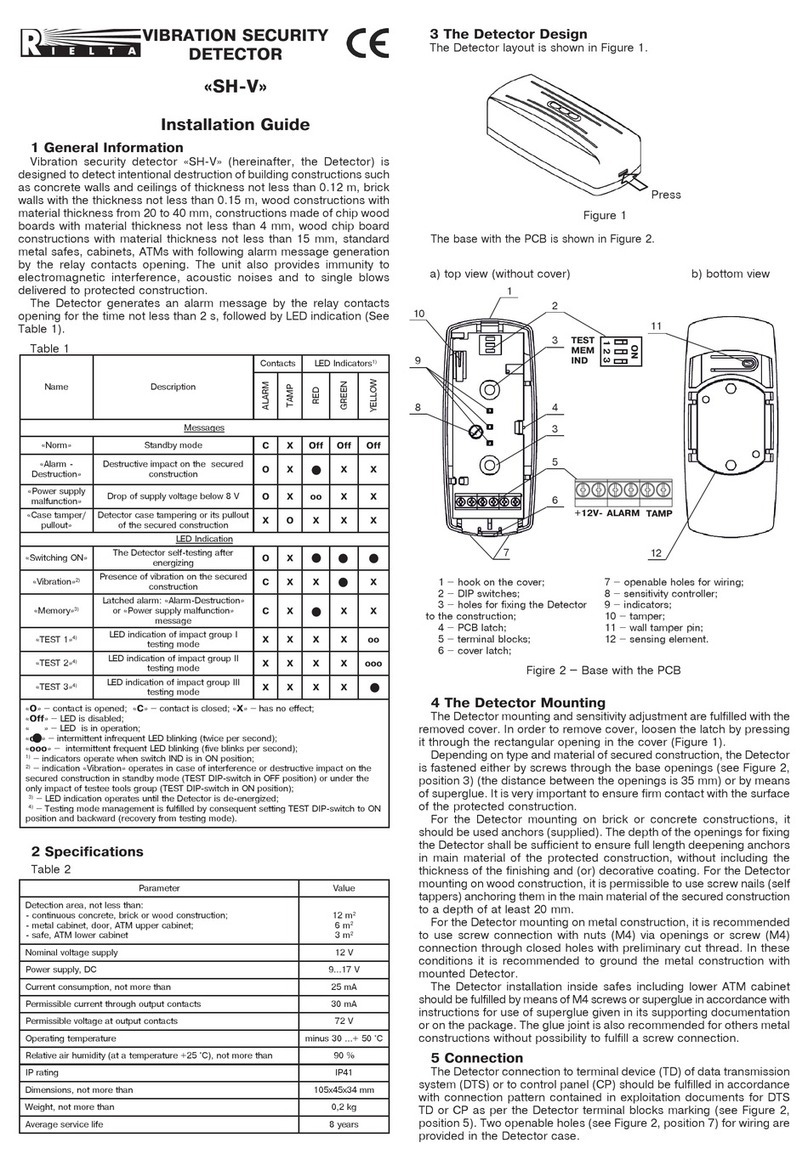

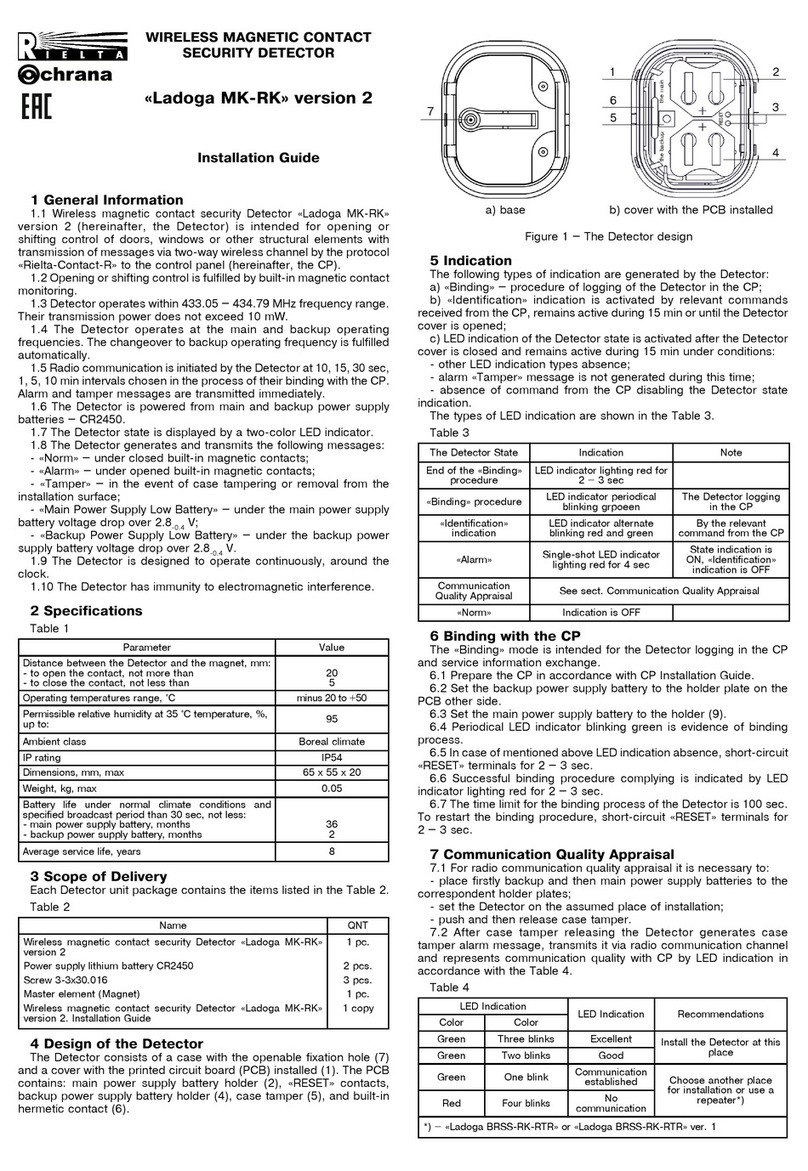

is shown in Figire 1. GB detection zone pattern is shown in Figure 2.

Table 1

Parameter Value

PIR channel detection zone

12 х 10 m

8 long-range zones, 7 middle-range,

4 short-range, 2 anti-sabotage

GB channel maximum detection range, not

less than 6 m

Output GB and PIR channels contacts:

- voltage, maximum

- current, maximum

72 V

30 mА

Sensitivity:

- GB channel (High Sens)

- PIR channel

selactable:

minimal/+7 dB/+14 dB/+21 dB

high/normal

Alarm message duration, not less than 2 sec

Minimum area of protected glass 0.1 m2

Warm-up time after energizing, not more than 60 sec

Operating temperature minus 20 оС ... +45 оС

Relative humidity at +25 оC without moisture

condensation 90 %

IP rating IP30

Dimensions, maximum 126 х 70 х 55 mm

Weight, maximum 150 g

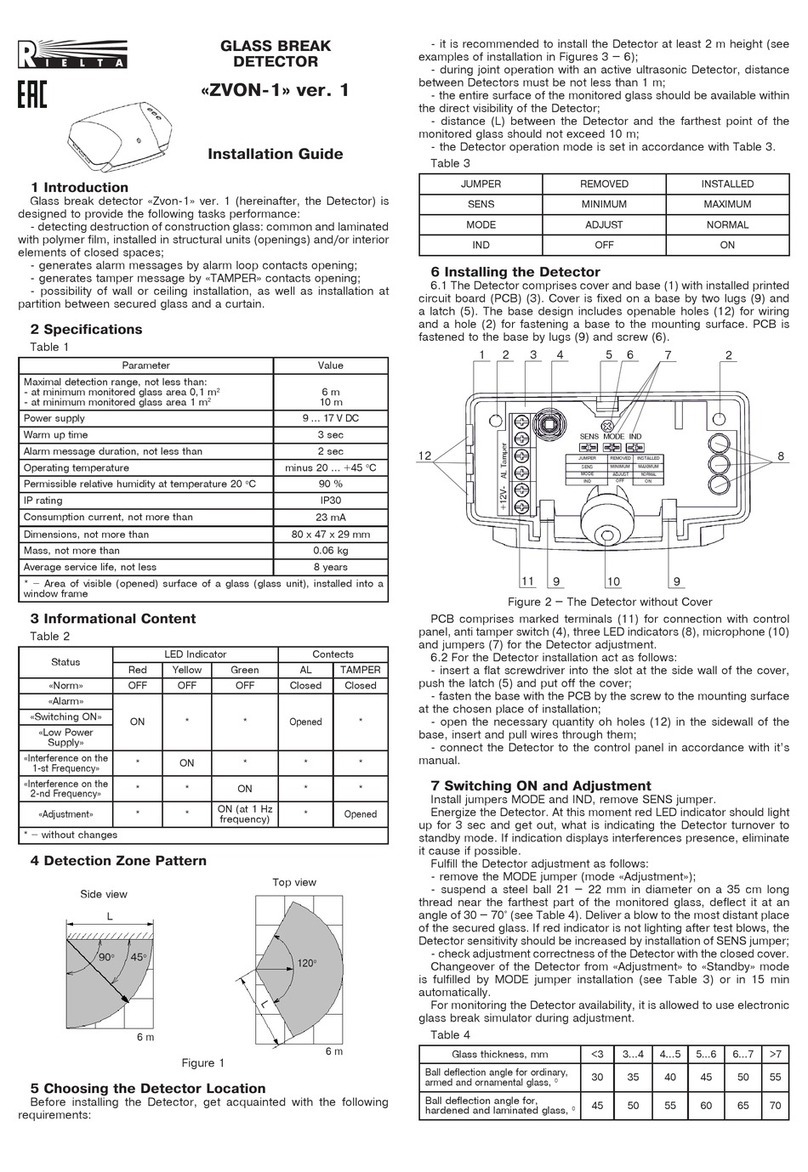

COMBINED PIR + GLASS

BREAK DETECTOR

«ORLAN-D»

Figure 2 – GB Channel Detection Zone Pattern

Field of Application

The Detector can be installed in flats, shops, museums, offices and other

closed premises.

Choosing Place of Installation

When choosing the Detector installation place, it is advisable to take note of

the fact that the detection zone may be screened by non-transparent objects

(curtains, houseplants, cabinets, bookcases, etc.), as well as by glass and mesh

partitions. There must be no windows, air conditioners, space heaters or heating

radiators in the PIR detection zone.

Recommended installation height is 2.3 m. Distance between the Detector and

the farthest point of the monitored glass should not exceed 6 m. The Detector

microphone should be oriented strictly towards the protected surface of a glass

construction. In case of 1 m2area monitoring, maximal distance to the Detector

should be increased up to 9 m.

The Detector wires should be laid at a distance not less than 1 m from power

supply cables.

Scope of Delivery

Each Detector unit package contains items listed in Table 2.

Table 2

Name QNT

Combined PIR + glass break detector «Orlan-D»

Accessories set:

Swivel bracket

Screw nut «SORMAT» 5х25

Screw 3-3х30.016

Testing ball

Combined PIR + glass break detector «Orlan-D». Installation Guide

1 pc.

1 pc.

2 pcs.

2 pcs.

1 pc.*

1 copy

* Supplied optionally

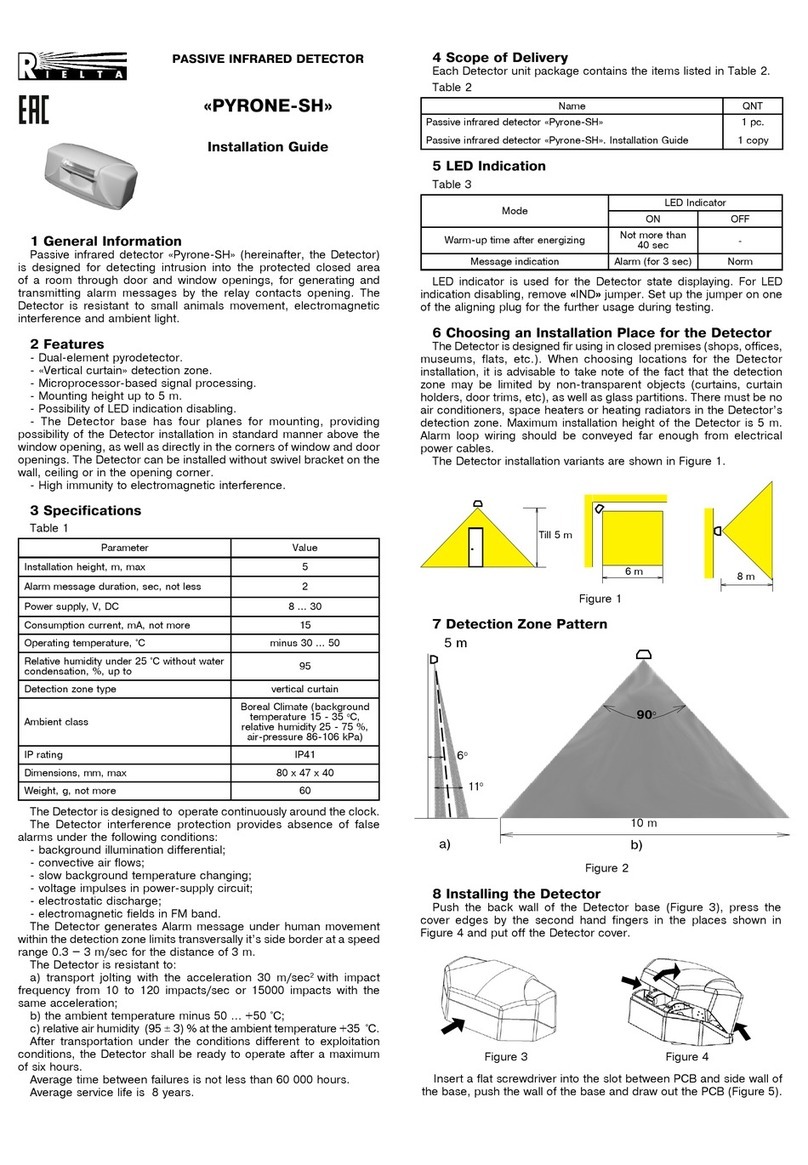

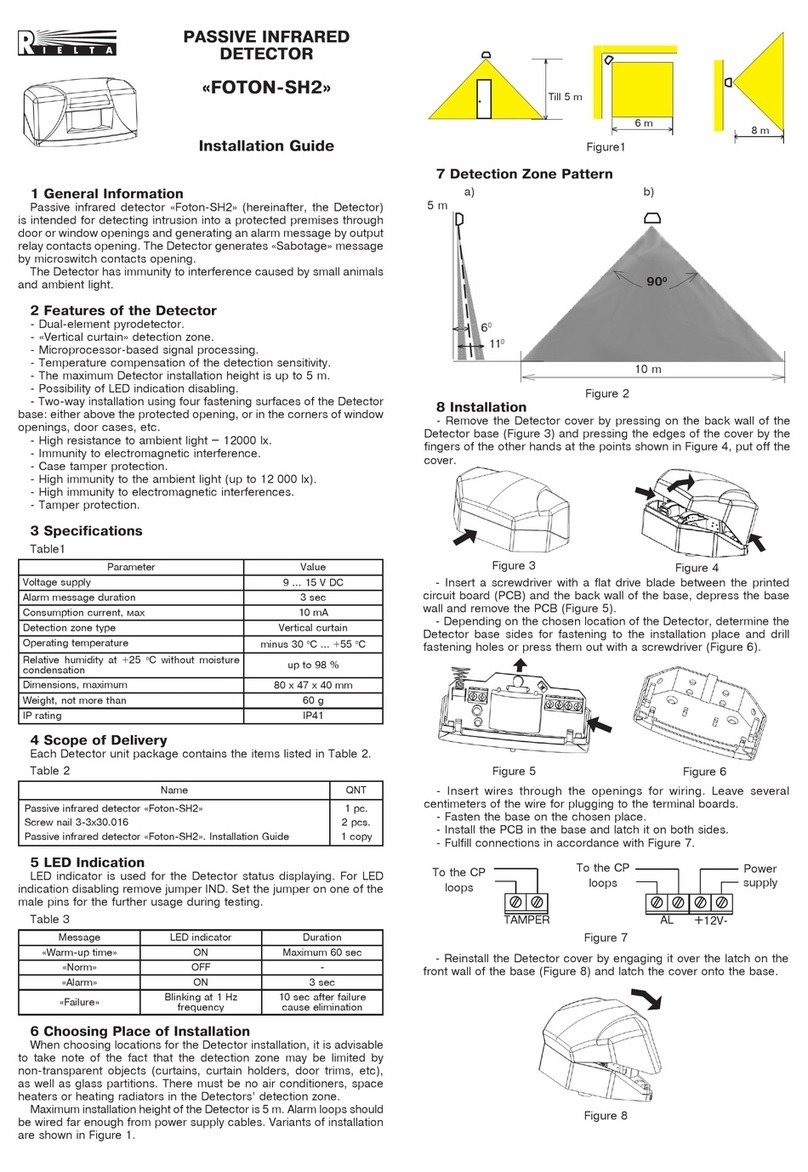

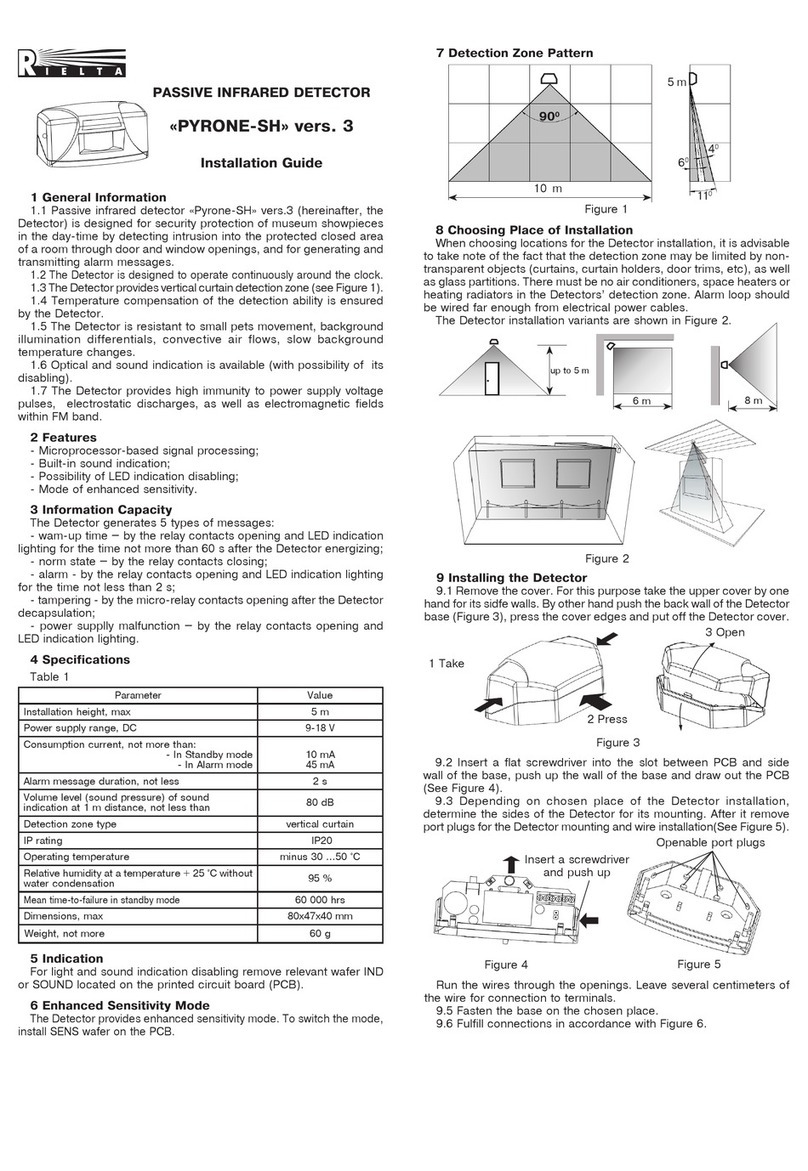

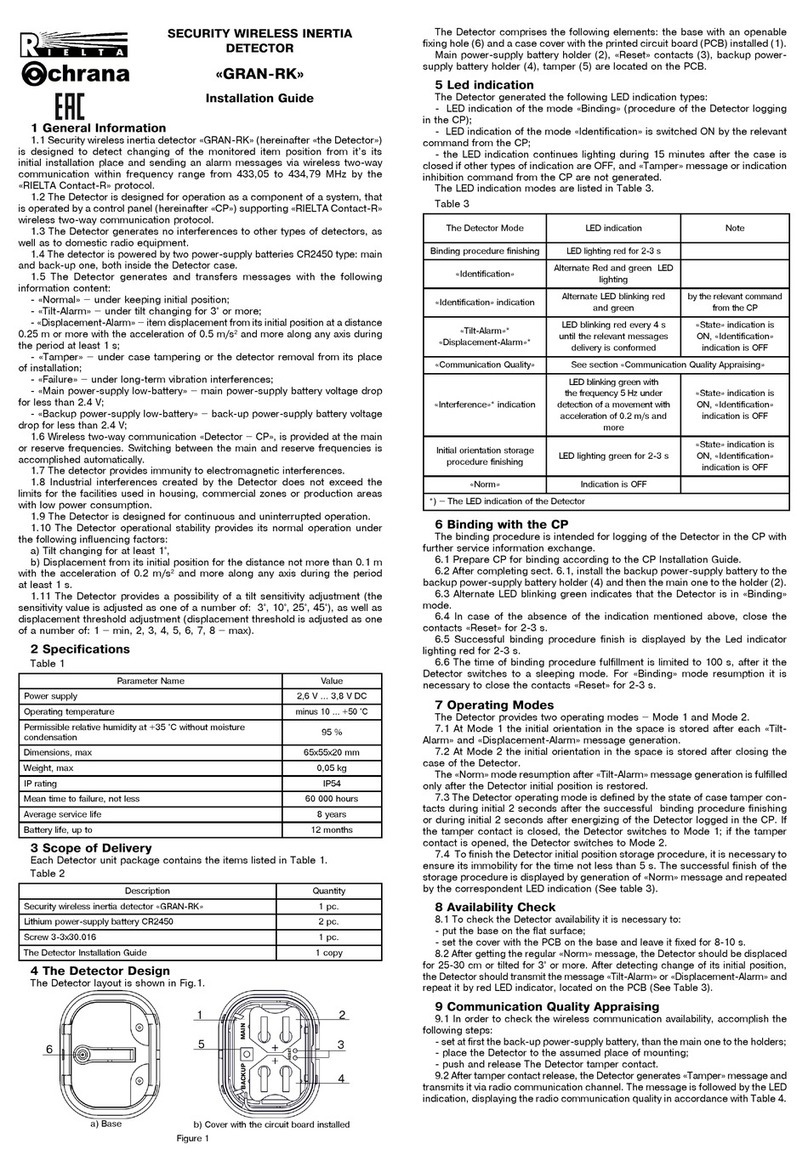

The Detector Installation

- Unfasten the latch through the opening, which is situated downside the

detector case by means of screwdriver and put off the detector cover (see

Figure 3).

- In case of mounting without swivel bracket, put off the PCB by means of

pushing up it’s fixing arm on the base.

- Drill the holes for wiring and fastening the detector (see Figure 3).

- Choose the place of installation, mark places for fastening holes in

compliance with fastening holes position on the Detector base (swivel bracket),

drill holes in the wall.

- Pass the wire through the mounting holes in the base leaving enough wire

inside the case for connection to the Detector terminals.

- Fasten the base (or swivel bracket) at the chosen place.

- In case of swivel bracket using, reverse the cap screw from the swivel

bracket sphere. Fit the square bulge of the swivel bracket external sphere with

the corresponded opening on the detector base (see Figure 3). Plug in the

screw to the opening in the top of the detector base and fix the connection by

the screw without tightening.

- Set the base in desired position and tighten the screw to ensure the base

stable fastening.

- Put the cover with PCB on the base by combining bulge on the PCB with

recess on the base, then click-up the PCB by fixing arm.

Installation Guide

010 m

Side view

Top view

900

2.3 m

010 m

Figure 1 – PIR Channel Detection Zone Pattern

Microphone

psitioning

90о

R

R

180о

Side view

Top view

Figure 3 –Detector Base and Swivel Bracket

For the wall

mounting

Openings

for wires

For corner

mounting

For fastening the base to the

swivel bracket

PCB

fixing

arm

Opening for the

cover latch

Base

Plug

Nut

Sphere Swivel

bracket

Screw

Swivel Bracket

Components