©2009 Shindaiwa, Inc.

2

Introduction

The Shindaiwa C4 series of hand-held

power equipmentis designed and built

to deliver superior performance and

reliability without compromise to quality,

comfort, safety or durability.

Shindaiwa engines represent the leading

edge of high-performance engine

technology, delivering exceptionally high

power with remarkably low displacement

and weight. As an owner/operator, you’ll

soon discover for yourself why Shindaiwa

is simply in a class by itself!

Throughout this manual are special

“attention statements”.

Attention Statements

WARNING!

A statement preceded by the

triangular attention symbol and the

word “WARNING” contains informa-

tion that should be acted upon to pre-

vent serious bodily injury.

CAUTION!

A statement preceded by the word

“CAUTION” contains information

that should be acted upon to prevent

mechanical damage.

IMPORTANT!

A statement preceded by the word

“IMPORTANT” is one that possesses spe-

cial significance.

NOTE:

A statement preceded by the word “NOTE”

contains information that is handy to know

and may make your job easier.

DANGER!

A statement preceded by the

triangular attention symbol and the

word “DANGER” contains information

that should be acted upon to prevent

serious injury or death.

IMPORTANT!

The operational procedures described in this manual are intended to help you get the most from this unit as well as to protect you

and others from harm. These procedures are guidelines for safe operation under most conditions, and are not intended to replace any

safety rules and/or laws that may be in force in your area. If you have questions regarding your Shindaiwa hand held power equip-

ment, or if you do not understand something in this manual, contact Shindaiwa Inc. at the address printed on the back of this Manual.

Shindaiwa Inc. reserves the right to make

changes to products without prior notice,

and without obligation to make alterations

to units previously manufactured.

IMPORTANT!

The information contained in these

instructions describes units available at

the time of publication.

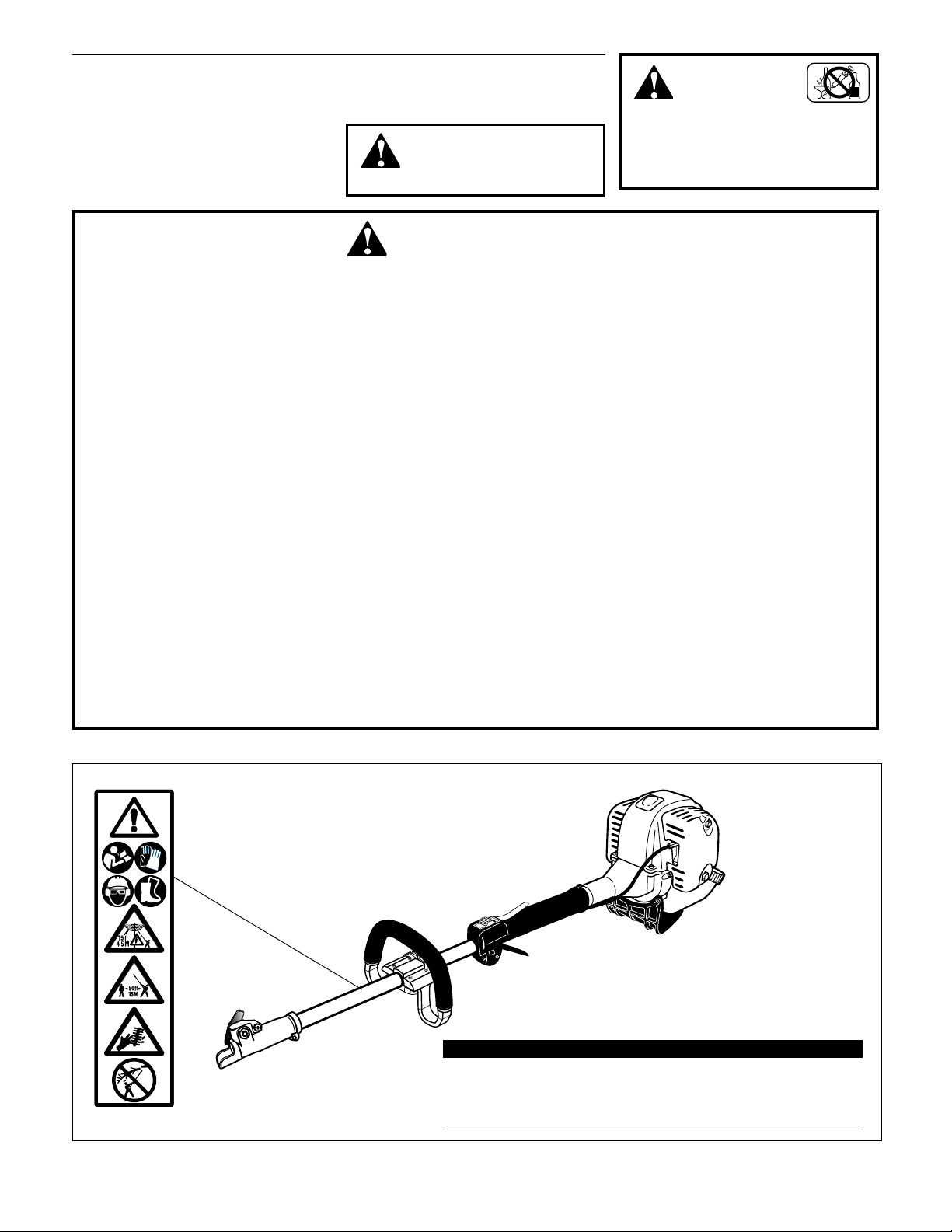

Operational and warning labels

Contents PAGE PAGEPAGE

WARNING!

The engine exhaust from this

product contains chemicals known

to to cause cancer, birth defects or

other reproductive harm.

Be aware of the danger of falling

debris.

Read and follow this manual, make

sure anyone using the unit does

likewise. Failure to do so could

result in serious personal injury or

machine failure. Keep this manual

for future reference.

Attachments for this unit operate

at very high speeds and can do

serious damage or injury if they are

misused or abused. Never allow a

person without training or instruction

to operate this unit!

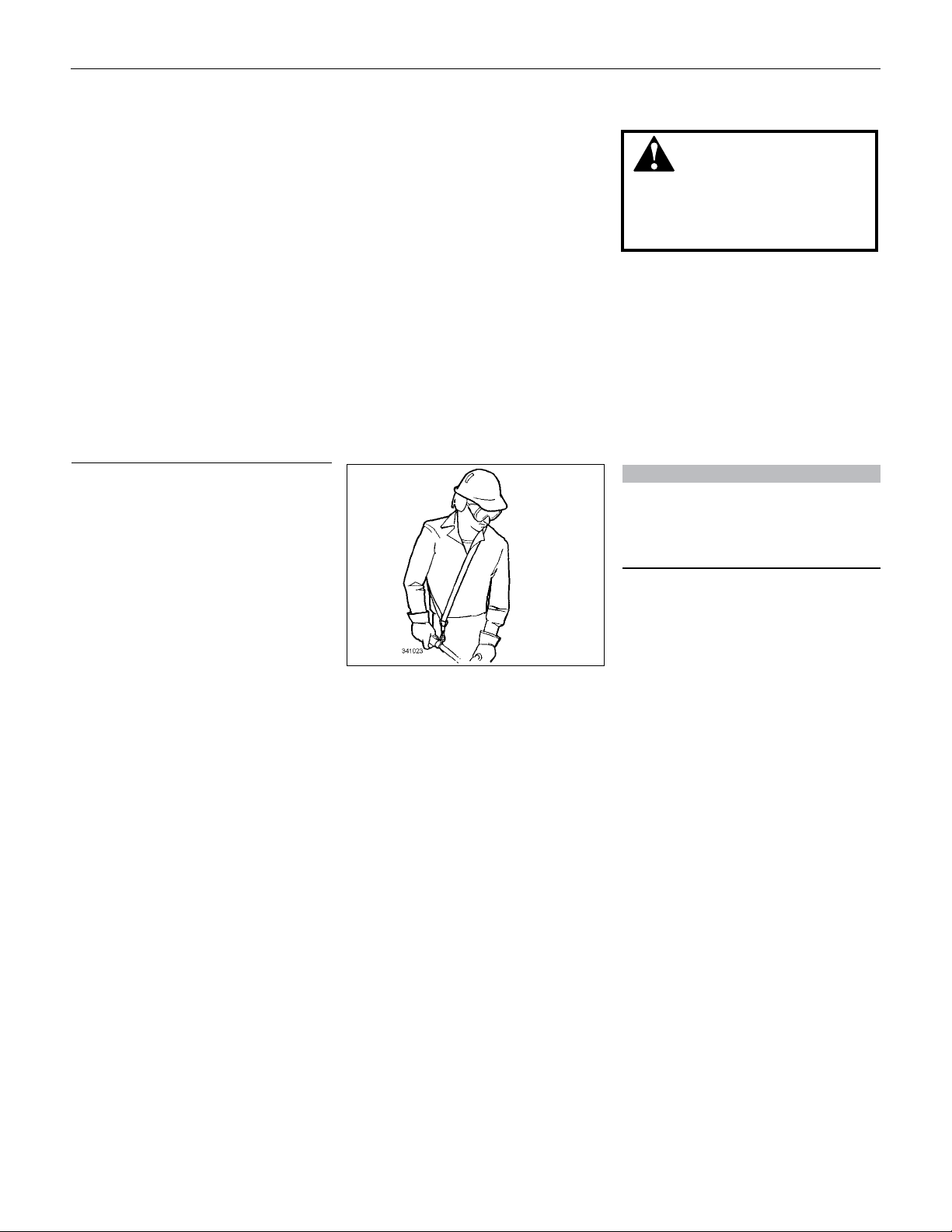

Always wear a hard hat to reduce

the risk of head injuries during

operation of this machine. In addi-

tion, always wear eye and hearing

protection. Shindaiwa recommends

wearing a face shield as additional

face and eye protection.

Wear heavy duty, non-slip gloves.

Safety tip shoes or boots with non-

slip sole should be worn.

This product conducts electricity.

Keep the product and/or operator

a minimum distance of 15 feet

(4.5 meters) away from electrical

sources and power lines.

Keep bystanders at least 50 feet

(15 meters) away from the operat-

ing unit to reduce the risk of being

struck by falling objects or thrown

debris.

The blades / cutting attachments

are SHARP! Handle with care.

Safety..........................................................3

Product Description..................................4

Specifications.............................................5

Assembly and adjustments.......................5

Mixing fuel.................................................7

Filling the fuel tank...................................7

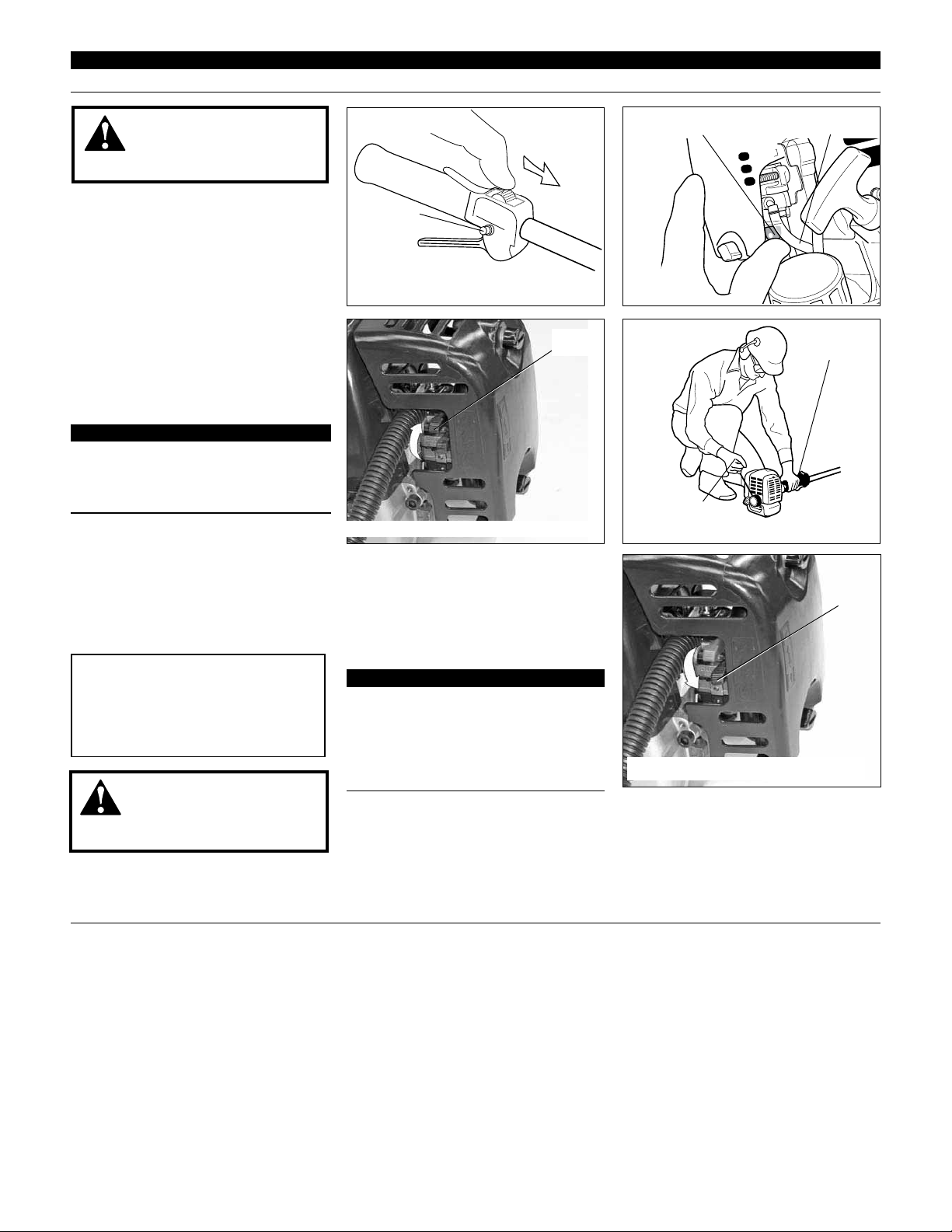

Starting the Engine ..................................8

Stopping the Engine..................................9

Adjusting Engine Idle ...............................9

Operation .................................................10

Maintenance ............................................11

Long Term Storage.................................14

Troubleshooting Guide ..........................15

Warranty Statement................................18