D900-01-00 2 I56-650-16

suitable for outdoor use.

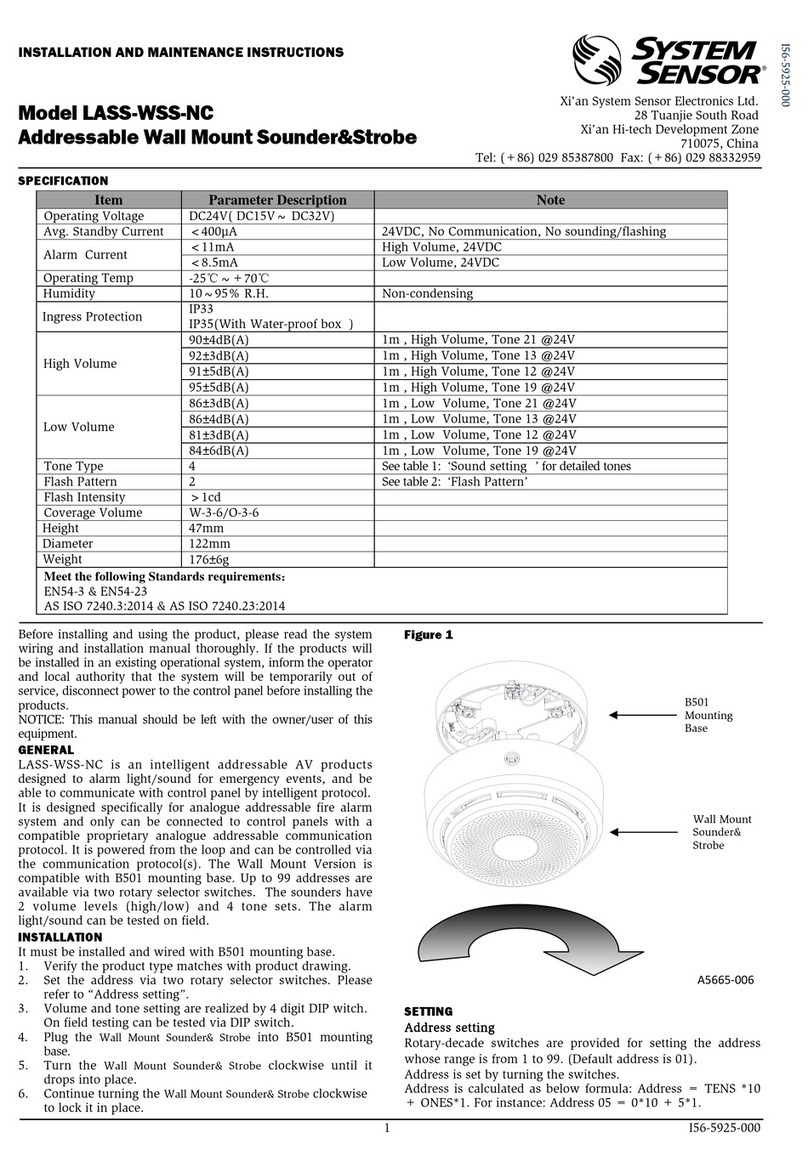

The rated light output of the SS2415ADA, SS1215ADA,

SS241575ADA, SS121575ADA, MASS2415ADA,

MASS241575ADA, MASS1215ADA, and MASS121575ADA

is 15 cd (See Figure 1).

The rated light output of the SS2475ADA and

MASS2475ADA is 75 cd (See Figure 1).

The rated light output of the SS24110ADA and

MASS24110ADA is 110 cd (See Figure 1).

NOTE: The light output at 0°viewing angle for SS12/

241575ADA and MASS12/241575ADA models is 75

cd (See Figure 1).

Any one of eight sounds can be selected on the electronic

sounder, as indicated in Table 2. The sound selected deter-

mines the maximum current and sound power output per

device. See Table 1 for these values.

Independent Sounder/Strobe Operation

There may be applications where it is desirable to drive the

sounder and strobe as independent devices. The System

Sensor MASS12/24ADA series sounder/strobes are easily

configured for this capability. The terminal connection for

this application is shown in Figure 6. Independent strobe

operation in a coded system requires a separate uncoded

power supply for the strobe.

Installation

A. General:

Slotted head screws are used to attach each device or

combination of devices to the electrical outlet box.

Phillips head screws are used to attach accessories to the

horn. Refer to Figures 3,4,5, and 6 for wiring methods.

Notes: Do not loop wires under the terminal screw. Wires

connecting the device to the panel must be broken

The Sounder and/or Strobe will not work without power. The sounder/

strobe gets its power from the fire/security panel monitoring the alarm

system. If power is cut off for any reason, the sounder/strobe will not pro-

vide the desired audio or visual warning.

The Sounder may not be heard. The loudness of the sounder meets (or

exceeds) current Underwriters Laboratories’ standards. However, the

sounder may not alert a sound sleeper or one who has recently used drugs

or has been drinking alcoholic beverages. The Sounder may not be heard

if it is placed on a different floor from the person in hazard or if placed too

far away to be heard over the ambient noise such as traffic, air condition-

ers, machinery or music appliances that may prevent alert persons from

hearing the alarm. The Sounder may not be heard by persons who are

hearing impaired.

The Signal Strobe may not be seen. The electronic visual warning signal

that flashes at least once every three seconds meets or exceeds current Un-

derwriters Laboratories’ standard 1971 and uses an extremely reliable xe-

non flash tube. The visual warning signal is suitable for direct viewing and

must be installed within an area where it can be seen by building occu-

pants. The strobe must not be installed in direct sunlight or areas of high

light intensity (over 60 foot candles) where the visual flash might be disre-

garded or not seen. The strobe may not be seen by the visually im-

paired.

The signal strobe may cause seizures. Individuals who have a positive

photic response to visual stimuli with seizures, such as epileptics, should

avoid prolonged exposure to environments in which strobe signals, in-

cluding this strobe, are activated.

System Sensor recommends that the Multi-Alert Sounder and Signal

Strobe always be used in combination so that the risks from any of the

above limitations are minimized.

The signal strobe cannot operate from coded power supplies. Coded

power supplies produce interrupted power. The strobe must have an unin-

terrupted source of dc power in order to operate correctly.

WARNING

The Limitations of Sounder/Strobes

at the device terminal connection in order to main-

tain electrical supervision. Strobe and strobe/

horn combination are designed for wall mount-

ing ONLY.

The sounder is 1-1/4"deep. Back boxes must be 4"

square by at least 1-1/2"deep – 2-1/8"deep is

recommended.

All strobes must be mounted so that the top of the lens is

24 inches (61 cm) below ceilings or as required by the

authority having jurisdiction.

B. Sounder mounting:

1. Surface Mount: (See Fig. 7)

2. Semi Flush Mount: (See Fig. 10 and 13)

3. Flush Mount: (See Fig. 12)

C. Sounder/Strobe combination mounting:

1. Surface Mount : (See Fig. 9)

2. Semi Flush Mount: (See Fig. 10 and 13)

Flush mounting requires the use of the deep box (Part #

BB-D) or equivalent. Determine which of the two device

holes will be used to attach the device to the box. Mount

the flush plate to the sounder using the other two holes

with two 1-inch phillips head screws and two square

nuts.

D. Strobe mounting:

1. Surface Mount: (See Fig. 8)

2. Semi Flush Mount: (See Fig. 11)

Installation procedures must conform to all applicable

codes and the requirements of the authority having

jurisdiction.

NOTE: The rated output of the sounder is specified at 10

feet. It cannot be assumed that the output will

meet the NFPA standard of 15 dB over ambient

noise at all locations within a room. Additional

sounders may be needed to ensure sound output

level complies with NFPA requirements.

Technical Manuals Online! - http://www.tech-man.com