SHS HT7 Series User manual

S.H.S. s.r.l. Via F.lli Rosselli, 29 20027 Rescaldina (MI) – ITALY Tel. +39 0331 466918 Fax. +39 0331 466147 www.shsitalia.it

User Guide

STEPPING MOTOR DRIVE

Series

HT7

Models

PROFINET

HT7_PROFINET_re 8_eng

Safety notes

The SHS automation products should be handled, installed and maintained by quali ied personnel trained

on installation o automation components, and only or the purposes described in the user manual.

Installers must pay particular attention to the potential risks caused by mechanical and electrical

equipment.

It is very important that applications and installations meet all applicable safety requirements.

Each installer has an obligation to take responsibility to verify their knowledge and understanding of all applicable

safety standards.

Any use which does not meet the sa ety requirements can damage equipment and injure the user.

SHS s.r.l. does not consider itsel responsible or, and assumes no liability or damage caused by handling

products and / or improperly installed, or in cases where the customer has allowed, or executed,

modi ications and / or repairs not authorized by SHS s.r.l.

The SHS drives are devices for automation high performance capable of generating rapid movements and high

forces.

Pay high attention especially during installation and application development.

Only use equipment properly sized for the application..

The SHS devices are considered components for automation and are sold as finished products to be installed only

by qualified personnel and in accordance with all local safety regulations.

The technicians must be able to recognize possible dangers that may result from programming by changing

parameter values and generally by the mechanical electrical and electronic.

SHS s.r.l. recommends to always follow basic safety rules. Failure to heed them can result in injury to persons and /

or property.

General precautions:

This manual is subject to change due to product improvement specification changes or improvements of the

manual

SHS s.r.l. is not responsible for damage to property and / or persons caused by faulty installation and / or

unauthorized modifications of the product.

The damaged drive systems must not be installed or put into operation in order to avoid injury persons

and damage to property. Changes or modifications made to the drive systems is prohibited and It

involves the extinction of any right to warranty or of any obligation of responsibility.

2

www.shsitalia.it info:[email protected]

www.shsitalia.it info:[email protected]

Index

TECHNICAL DATA 4

1.1 Power supply / Motor Connector 4

1.2 FIELDBUS Connector 4

1.3 Input/Output Connectors 5

1.4 DIP-SWITCH and Ethernet Connectors 6

1.5 Status LEDS 6

1.6 Protection / Display messages 7

1.7 Parameters setting 8

1.8 Mechanical dimension 9

CONNECTION 10

2.1 Installation note 10

2.2 AC Power Supply 10

2.3 DC Power Supply 12

2.4 Input / Outputs 13

2.5 Digital Inputs 14

2.6 Digital Outputs 14

2.7 Encoder Inputs 15

2.8 16

OPERATING MODE 16

3.1 PROFINET Protocol 17

3.2 Data communication ia PROFINET 17

3.3 PROFINET control bits 19

3.4 ZSW bits positioning timing 20

3.5 Parameters 23

HT7 MODELS CODE 27

Analog Inputs/ Outputs

3

www.shsitalia.it info:[email protected]

1. TECHNICAL DATA

1.2 FIELDBUS Conne tor

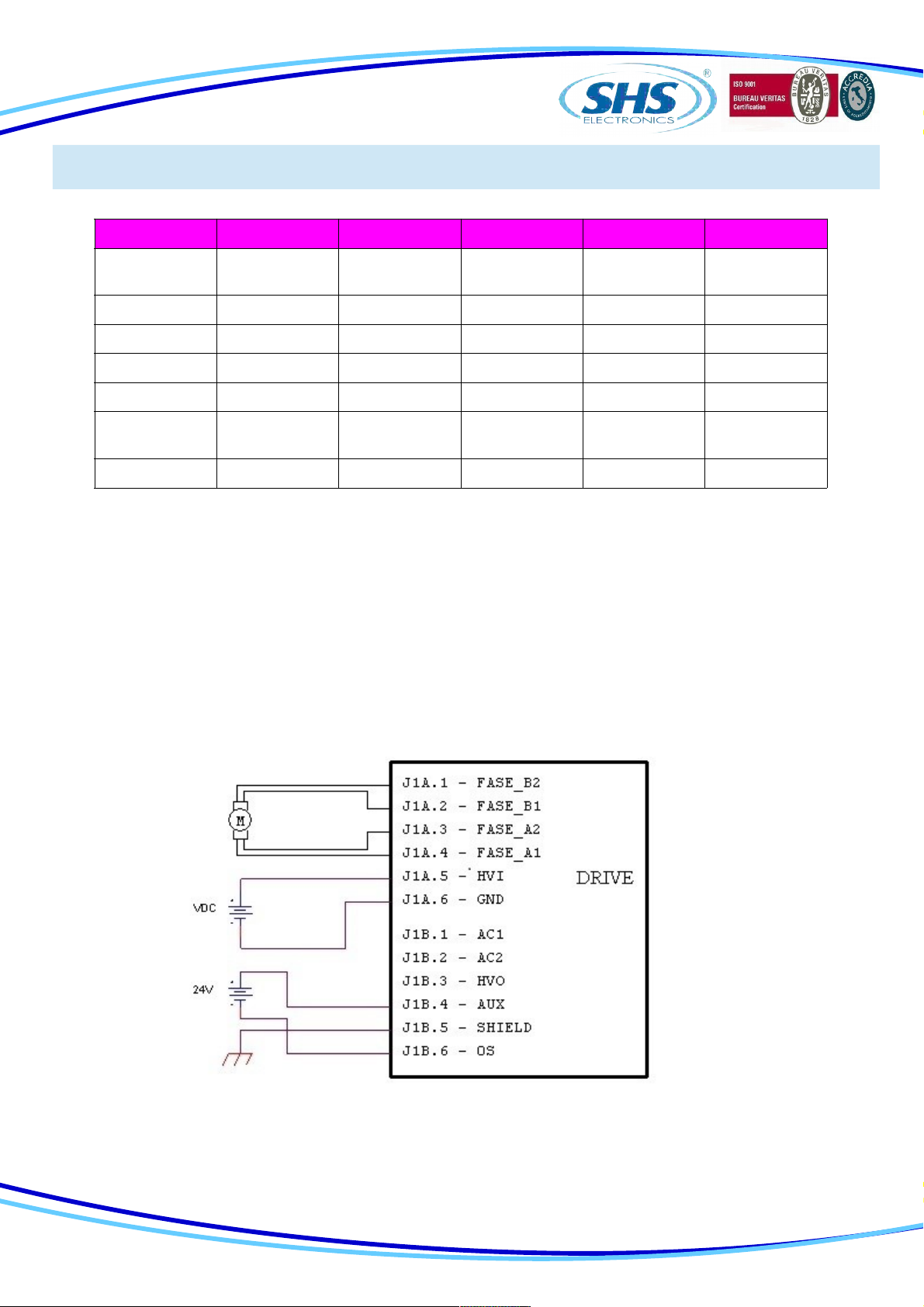

1.1 Power supply / Motor onne tor

J1A ( Le t )

SIGNAL FUNCTION

B2 Phase B2 of the motor

B1 Phase B1 of the motor

A2 Phase A2 of the motor

A1 Phase A1 of the motor

HVI Power supply input DC

(connect to HV0 or use as input DC power)

GND 0V power supply

J1B ( Right )

SIGNAL FUNCTION

AC1 Power supply Vac

AC2 Power supply Vac

HV0 Rectified output

AUX Logic power supply input 24Vdc

SHIELD Shield

0S 0V power supply Aux

J3 SIGNAL FUNCTION

1 0V

2 CL (CANL)

3 RS- (RS485-) Used only upgrade firmware

4 CH (CANH)

5 RS+ (RS485+)

4

www.shsitalia.it info:[email protected]

1.3 Input / Output Conne tors

J2A (Left) SIGNAL FUNCTION

1 ENC_AH Encoder A+

2 ENC_AL Encoder A-

3 ENC_BH Encoder B+

4 ENC_BL Encoder B-

5 ENC_ZH Encoder Z+

6 ENC_ZL Encoder Z-

7 ENC_COM Encoder common (don't se in differential

mode)

8 ENA/DIS Input ENABLE/DISABLE

9 IN3 Input IN3 – (CURRENT REDUCTION)

10 IN2 Input IN2 - (DIRECTION)

11 IN1 Input IN1 – (STEP IN)

J2B (Right) SIGNAL FUNCTION

12 OUT_COM Output common (OUT1 OUT2 OUT3)

13 OUT1 Output OUT1 - (default motor run)

14 OUT2 Output OUT2 - (default Drive Ready)

15 OUT3 Output OUT3 - (default unused)

16 IN_COM Input common (IN1 IN2 IN3 ENA/DIS)

17 AN_IN0 Analog Input IN0

18 AN_IN1 Analog Input IN1

19 AN_IN2 Analog Input IN2

20 AN_OUT Analog Output

21 GND_SIGNAL 0V (relative at EXT_12V AN_IN AN_OUT)

22 EXT_12V Output +12V (relative at GND_SIGNAL)

5

www.shsitalia.it info:[email protected]

1.4 DIP SWITCH

1.5 Status LEDS

DIP1 ON OFF

1 Insert termination CAN Not used

2 Insert termination RS485 Not used

3 Not used Not used

4 Input function En / Dis = ENABLE Input function En / Dis = DISABLE

Phisical

Features Connection Type Cable /

Transmission type Speed Max Cable

Lenght

Electrical RJ45 Connector

100base-TX Shield

cable CAT5 IEEE

802.3

100Mbit/s full

duplex 100 mt

LED FUNCTION

RUN

Drive OK Light ON

Drive Error Light OFF

ERR

Drive Error Light OFF

Drive OK Light ON

STS

Drive OK Light fast blinking

Drive Error Light slow blinking

Only HT7xx PN, EC, EI model is supplied of double RJ45 interface ( upper pictures ).

The RJ45 connections can be used interchangeably in PN and EI model.

6

www.shsitalia.it info:[email protected]

1.6 Prote tion / Display messages

DISPLAY DESCRIPTION

rdY Drive OK at STOP motor

run Motor in movement

dIS Drive DISABLE

ocur Overcurrent Error

tenP Overtemperature Error

uuoL Undervoltage Error

ouoL Overvoltage Error

rSt Reset phase

0net No connected

Dri e is pro ided with protections against o ertemperature, o er oltage, under oltage, short-circuits among

outputs and among outputs and the positi e power pole, no-phase motor connection.

If one of the mentioned conditions occurs, dri e disables the power bridge and shows an error condition on

the display.

To restore o ercurrent protection tou must restart the unit.

The decimal point to the left indicates the status RX, while the one on the right indicates the status of the

communication interface TX.

7

www.shsitalia.it info:[email protected]

1.7 Parameters setting

PARAMETER FUNCTION

p001

0par: when this parameter is stored all

parameters will be set to default value and it will

appear “rst” then restart the driver

p003 Current setting [A]

p006 Setting step resolution ( 1/2 ... 1/20 )

p00 Setting stand-by current ( 0 25 50 100% )

p008 Setting parameter resonance1 reduction

( fd0 ... fd4 )

p009 Setting parameter resonance2 reduction ( small

big )

p010 Setting wave mode ( wav0 wav1 )

p011 Setting to operate high frequency

p013 Setting toggle bit ( 0 - 1 )

p014 Enable refresh for the last polled parameter

p015 Enable refresh status word

p016 Motor Stopped when the driver communication

fault

By using the buttons below the display (hereinafter referred to as [\/] , [<>], [/\] ) you can parameterize the dri e:

To access to main menù, press [\/] + [<>] , it will isualized “ menu ” for 1 sec, after the parameter “ p001 ”

From the main menu to select the parameter to be changed press the button [\/] or [/\].

From main menù to isualize the actual alue of parameter press [<>].

From the parameter to change the alue press [\/] or [/\]

From the parameter to store the alue press the button [<>] for 1 sec and it will appear “ memo ”

From the parameter to come back at main menù without modify any conditions, press [<>] less than 1 sec (don’t will

appear “ memo”).

From the main menù to go out press [<>] + [/\].

8

www.shsitalia.it info:[email protected]

1.8 Me hani al dimension

MODEL HT7 xx- WEIGHT [ gr ]

WS-MB-CO-PB 655

PN-EC-EI 720

9

www.shsitalia.it info:[email protected]

2. CONNECTIONS

2.1 INSTALLATION NOTES

ATTENTION

2.2 AC Power Supply

Unit HT710 HT720 HT730 HT740

Vac nom [V] From 18 to 60 From 18 to 60 From 18 to 60 From 18 to 90

Vac max [V] 75 75 75 110

Vac min [V] 15 15 15 15

I max [A] 4 7 12 12

I min [A] 1 1 1 1

Operation

Temperature [°C] 0 - 45 0 - 45 0 - 45 0 - 45

Vdc aux [V] 24 24 24 24

DANGER OF ELECTRICAL SHOCK

ONLY QUALIFIED ERSONNEL SHOULD WORK ON THIS EQUI MENT. DISCONNECT ALL OWER

BEFORE WORKING ON EQUI MENT. DANGEROUS VOLTAGES MAY EXIST AFTER OWER IS

REMOVED! BEFORE WORKING ON EQUI MENT CHECK DC BUS VOLTAGE OF

DRIVES EACH TIME OWER IS REMOVED.

The transformer power is =Vac*(Inf(tot) + 1)

Where is VA power, Vac is secondary voltage in Volts and Inf(tot) is the sum of all nominal currents set

in all the dri e to be supplied.

NOTE: use a transformer with an isolated secondary, don’t connect the secondary at ground.

Vac nom : Range alue of oltage by which the dri e can be powered.

Vac max: Opertati e Maximum oltage. O er this limit, the protection of maximum oltage inhibits the

dri e.

Vac min: Operati e Minimum oltage. Under this limit, the protection of minimum oltage inhibits the

dri e.

I max: Maximum alue of phase current.

I min: Minimum alue of phase current.

Operating temperature: For any temperature o er 45°C and any current o er 6A a forced entilation is

necessary.

Vdc aux: Logic power supply.

10

www.shsitalia.it info:[email protected]

In AC power mode do not connect GND signals between two or more HT7 dri es:

WIRING DIAGRAM:

11

www.shsitalia.it info:[email protected]

2.3 DC POWER SUPPLY

WIRING DIAGRAM:

Unit HT710 HT720 HT730 HT740

Vac nom [V] From 24 to 90 From 24 to 90 From 24 to 90 From 24 to

125

Vac max [V] 110 110 110 160

Vac min [V] 20 20 20 20

I max [A] 4 7 12 12

I min [A] 1 1 1 1

Operation

Temperature [°C] 0 - 45 0 - 45 0 - 45 0 - 45

Vdc aux [V] 24 24 24 24

Vdc nom : Range alue of oltage by which the dri e can be powered.

Vdc max: Operating Maximum oltage. O er this limit, the protection of maximum oltage inhibits the dri e.

Vdc min: Operating Minimum oltage. Under this limit, the protection of minimum oltage inhibits the dri e.

I max: Maximum alue of phase current.

I min: Minimum alue of phase current.

Operating temperature: For any temperature o er 45°C and any current o er 6A a forced entilation is

necessary.

Vdc aux: Logic power supply.

12

www.shsitalia.it info:[email protected]

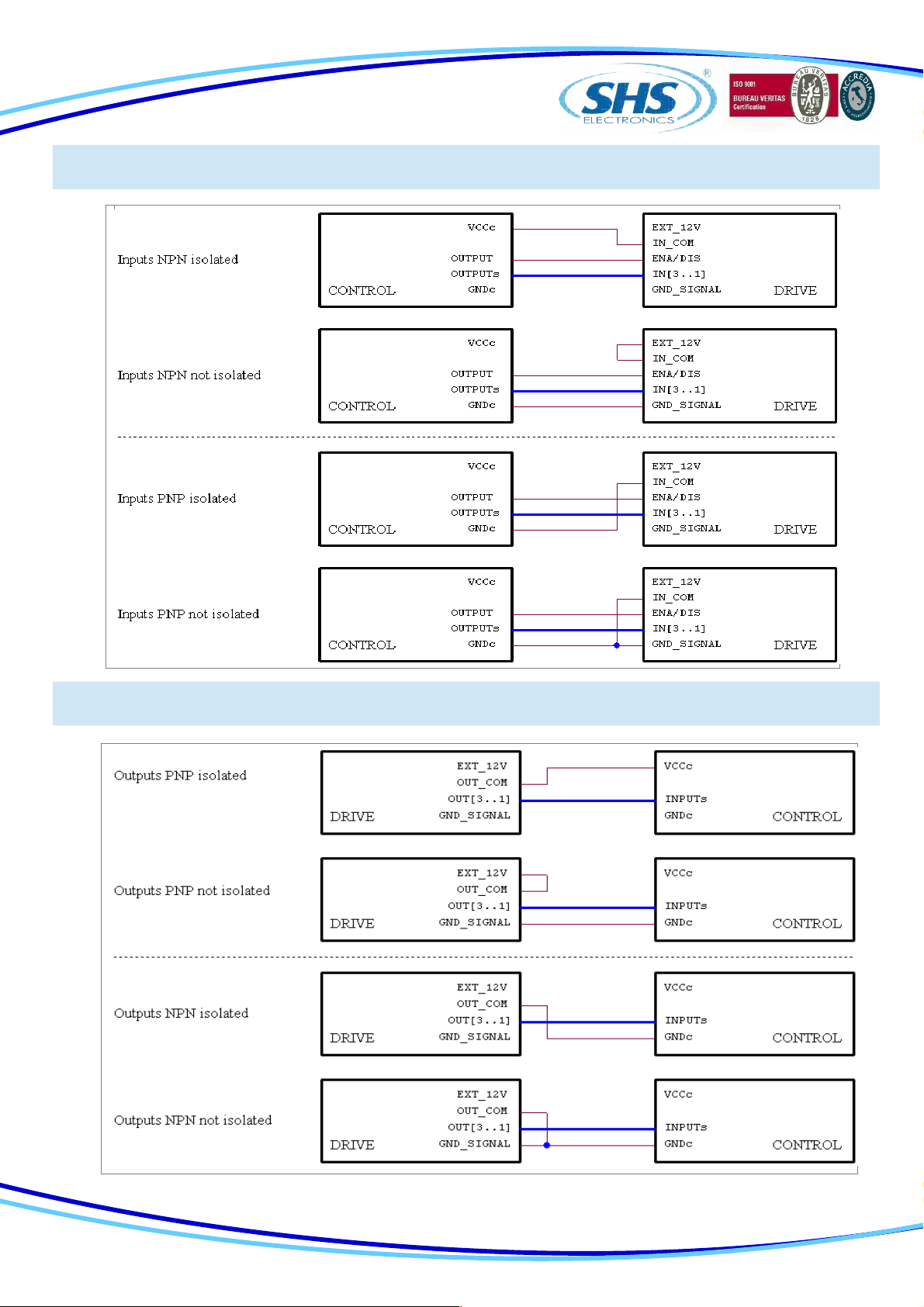

2.4 Inputs / Outputs

INPUTS FEATURES:

ANALOG INPUTS VOLTAGE LEVEL

INPUT FROM 0 TO 10V

OUTPUT FROM 0 TO 10V

(IN1, IN2, IN3, ENABLE) VOLTAGE LEVEL

LOW LEVEL FROM 0 TO 7V

HIGH LEVEL FROM 10 TO 24V

MAX CURRENT 13mA

DIFFERENTIAL INPUTS

(ENCAx, ENCBx, ENCZx) TTL SINGLE ENDED 24V

LOW LEVEL FROM 0 TO 2V FROM 0 TO 6V

HIGH LEVEL FROM 4 TO 5V FROM 9 TO 24V

MAX CURRENT 5mA 13mA

OUTPUTS VOLTAGE LEVEL

PNP OUT

OUT ON COM_OUT VOLTAGE -2V

OUT OFF 0V

NPN OUT

OUT ON 2V

OUT OFF COM_OUT VOLTAGE

Digital inputs and outputs pins are isolated from power.

●Single Ended inputs are NPN/PNP type selectable through COM-IN pin.

●Differential input are TTL compatible, and can be 24V compatible PNP through COM-ENC pin.

●Outputs are NPN/PNP type selectable through COM-OUT (10mA max for OUT1, 100mA max for OUT2 and

OUT3). On request the outputs can be equipped with OptoMOS de ices (maximum current 400mA, 60V).

Analog inputs and outputs pins are not isolated from power, they ha e range 0 to 10V.

13

www.shsitalia.it info:[email protected]

2.8 Analog Inputs / Outputs

Note: we suggest to use isolated inputs scheme, no electrical

connections between control and drives.

3. OPERATING MODE

The dri er can be operated in the follwing modes:

●PROFINET

16

www.shsitalia.it info:[email protected]

Use the de ice master file “GSDML-v2,31-SHS-HT7-20160125.xml” to configure your communication software on the master.

The data format used is Motorola (“Big Endian”).

PROFINET structure:

User data structure from MASTER to SLAVE (HT7 drive):

arameter Identifier ( KE) (1st Word):

3.1 SETTING ON THE PROFINET MASTER

3.2 DATA COMMUNICATION VIA PROFINET

Protocol frame

(Header)

User data

Parameter (PKW) – Process data (PZD)

Protocol frame

(trailer)

PKW PZD

PKE IND PWE ZSW HSW

1st word 2nd word 3rd word (H) 4th word (L) 1st word 2nd word

PKE

Bit 15(H)…12 Bit11 Bit 10…0(L)

AK Not used PNU

AK VALUE MEANING

0 No task

1 Request parameter value

2 Change parameter value

The parameter identifier (PKE) is always a 16-bit alue.

Bits 0 to 10 contain the number of the desired parameter (PNU). Refer to

the parameter listing (Chapter 5.4)

Bits 12 to 15 contain the task or reply identifier (AK).

PKW: Parameter identifier alue

PZD: Process data

PKE: Parameter idetifier

IND: Index (not used. Set to 0)

PWE: Parameter alue

ZSW: Control word 1 (see pag.16)

HSW: Main setpoint (not used. Set to 0)

AK: Task or reply identifier

PNU: Parameter number

17

www.shsitalia.it info:[email protected]

User data structure from SLAVE (HT7 drive) to MASTER:

PKW PZD

PKE IND PWE STW HIW

1st word 2nd word 3rd word (H) 4th word (L) 1st word 2nd word

PKE

Bit 15(H)…12 Bit11 Bit 10…0(L)

AK Not used PNU

AK VALUE MEANING

0 No task

2 Transmit parameter value

7Task not executable (with error

number on word 4)

ERROR (WORD 4) MEANING

0 No task

1Parameter value cannot be

changed

PKW: Parameter identifier alue

PZD: Process data

PKE: Parameter idetifier

IND: Index (not used)

PWE: Parameter alue

STW: Status word 1 (see pag.16)

HIW: Main actual alue (not used)

AK: Task or reply identifier

PNU: Parameter number

arameter Identifier ( KE) (1st Word):

The parameter identifier (PKE) is always a 16-bit alue.

Bits 0 to 10 contain the number of the desired parameter (PNU). Refer to the parameter listing (Chapter 5.4)

Bits 12 to 15 contain the task or reply identifier (AK).

18

BITS ZSW – MASTER SLAVE

3.3 PROFINET CONTROL BITS

BIT VALUE FUNCTION REMARKS

0

(L)

1 – ON

0 - OFF

ON - Start RELATIVE positioning

OFF - Stop RELATIVE positioning

This bit is ignored when absolute

positioning or JOG function is

acti e

1 1 – ON

0 - OFF

ON - Start ABSOLUTE positioning

OFF - Stop ABSOLUTE positioning

This bit is ignored when relati e

positioning or JOG function is

acti e

2

3 1 – ON

0 - OFF

ON - Dri e enable

OFF - Di e disable (motor current=0)

To execute e ery postitioning

command this bit must be set to 1

4 1 – ON

0 - OFF

ON - Reset Alarm

5

6

7

8 1 – ON

0 - OFF

ON - Start Jog cw (infinite motion)

OFF - Stop

This bit is ignored when

relati e/absolute positioning or

JOGCCW function is acti e

9 1 – ON

0 - OFF

ON - Start Jog ccw (infinite motion)

OFF - Stop

This bit is ignored when

relati e/absolute positioning or

JOGCW function is acti e

10

11 1 – ON

0 - OFF

ON - Set OUT3

OFF – Reset OUT3

Set/reset OUT3

To use this function bit 12 must be

set to 1

12 1 – ON

0 - OFF

ON - Enable outputs force

OFF - Disable outputs set (Standard function on

outputs)

This bit disable standard outputs

functions and permit to force

outputs through bits 13 and 14 of

this word (ZSW)

13 1 – ON

0 - OFF

ON - Set OUT1

OFF – Reset OUT1

Set/reset OUT1

To use this function bit 12 must be

set to 1

14 1 – ON

0 - OFF

ON - Set OUT2

OFF – Reset OUT2

Set/reset OUT2

To use this function bit 12 must be

set to 1

15

(H)

Reser ed for refresh Bit

19

www.shsitalia.it info:[email protected]

BITS STW – SLAVE MASTER

3.4 ZSW BITS POSITIONING TIMING

BIT VALUE FUNCTION REMARKS

0

(L)

1 - ON

0 - OFF

ON - Drive ready

OFF - Drive fault or disable

1 1 - ON

0 - OFF

ON - Motor running

OFF - Motor stop

2 1 - ON

0 - OFF

ON - Drive disable

OFF - Drive enable

3 1 - ON

0 - OFF

ON - Protection active

OFF - Protection not active

4 1 - ON

0 - OFF

ON - IN1 active

OFF - IN1 not active

5 1 - ON

0 - OFF

ON - IN2 active

OFF - IN2 not active

6 1 - ON

0 - OFF

ON - IN3 active

OFF - IN3 not active

7 1 - ON

0 - OFF

ON - OUT1 active

OFF - OUT1 not active

8 1 - ON

0 - OFF

ON - OUT2 active

OFF - OUT2 not active

9 1 - ON

0 - OFF

ON - Rotation CW

OFF - Rotation CCW

10 1 - ON

0 - OFF

ON - Max frequency reached

OFF - Max frequency not reached

11 1 - ON

0 - OFF

ON - Positioning completely executed

OFF - Positioning not completely executed

12 1 - ON

0 - OFF

ON - Axis zeroing executed

OFF - Axis zeroing not executed

13 1 - ON

0 - OFF

ON - EXTRA-SWITCH reached

OFF - EXTRA-SWITCH notreached

14 1 - ON

0 - OFF

ON - Error durig encoder positioning

OFF - OK

15

(H)

1 - ON

0 - OFF

Reserved for refresh Bit

20

www.shsitalia.it info:[email protected]

Other manuals for HT7 Series

2

Table of contents

Other SHS DC Drive manuals

Popular DC Drive manuals by other brands

Ridder Drive Systems

Ridder Drive Systems LogicDrive RLD80 product manual

ClimateMaster

ClimateMaster HCLA2090CAR installation instructions

Moons'

Moons' SRAC8 Quick setup guide

Allen-Bradley

Allen-Bradley PowerFlex 6000 user manual

Danfoss

Danfoss VLT Midi Drive FC 280 operating guide

Power Electronics

Power Electronics B150 Series Documentation

GEZE

GEZE Slimdrive EMD-F-IS Additional installation instructions

Astraada

Astraada DRV-22 Operation manual

Schimpf

Schimpf 00-10/30 STEP operating instructions

Toshiba

Toshiba T300MVi MEDIUM VOLTAGE Interface manual

SycoTec

SycoTec HF Inverter e@syDrive 4624 Short instructions for use

GRUP ARGE

GRUP ARGE SVC 5 user manual