*For additional assistance, please contact Toshiba Adjustable Speed Drive Marketing Dept. at (800) 872-2192

10

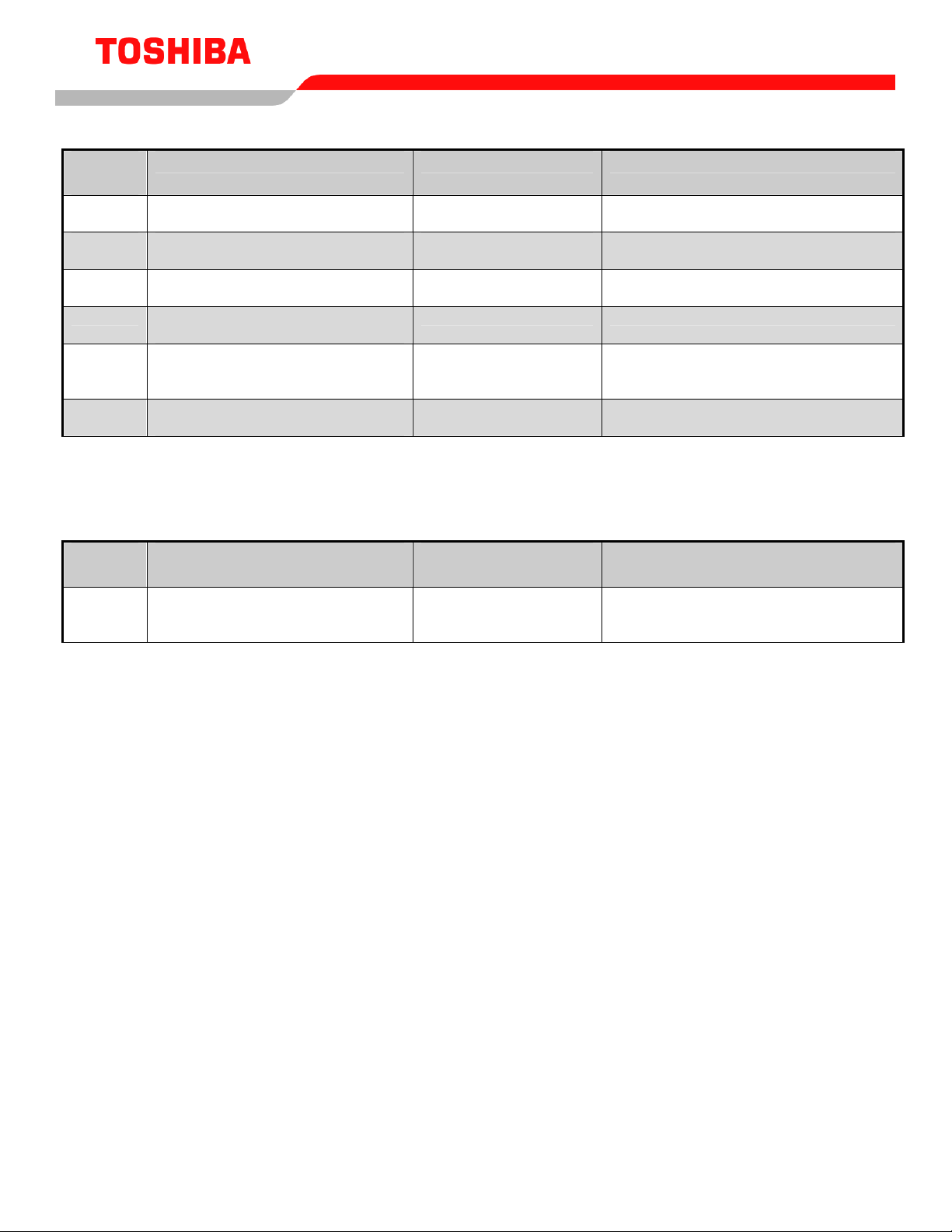

Programming

Direct

Access Parameter Path Parameter Name Comments

F012 ProgramÎFundamental

ParametersÎFrequency Setting Upper Limit Set to 60

F011 ProgramÎFundamental

ParametersÎFrequency Setting Maximum Frequency Set to 60

F009 ProgramÎFundamental

ParametersÎStandard Mode Selection Accel #1 Set to 5

F010 ProgramÎFundamental

ParametersÎStandard Mode Selection Decel #1 Set to 5

F201 ProgramÎFrequency Setting

ParametersÎSpeed Reference

Setpoints

VI/II Set 0 hz at 20%

Set 60 hz at 100%

F360 ProgramÎFeedback

ParametersÎFeedback Settings Input Selection Set to VI/II for the PID feedback signal

The above programming assumes a system in which an increase in 4-20 mA feedback signal causes

the drive to reduce output frequency. If the system is such that increasing feedback should cause an

increase in output frequency, the ‘II’ terminal should be reversed by programming the following:

Direct

Access Parameter Path Parameter Name Comments

F201 ProgramÎFrequency Setting

ParametersÎSpeed Reference

Setpoints

VI/II Set 60 hz at 20%

Set 0 hz at 100%

Setting the Setpoint

In general, the setpoint is set by adjusting the setpoint to whatever level (frequency) is necessary to

yield the desired process variable setting. The commanded frequency and actual output frequency

will most likely not be the same; it is only the process variable’s (pressure, temperature, etc.) value

that is of concern. It is the ratio of Frequency Command to Maximum Output Frequency that the drive

uses to determine the feedback value it is trying to maintain (the setpoint).

Setpoint via keypad (Local Mode)

Press LOCAL/REMOTE button to illuminate the panel’s green LED. Hit RUN and adjust the keypad

pot to whatever value it takes to develop the desired process variable value. If you still need to setup

the setpoing via the keypad but need to Start/Stop from terminal, then set the F004 Frequency Mode

#1 to Use Common (TTL).

Setpoint via pot on RR terminal (Remote Mode)

Press LOCAL/REMOTE button to turn green LED off. Make F-CC OR R-CC. Adjust RR pot to

whatever setting it takes to generate the desired process variable value.

efesotomasyon.com -Toshiba inverter,drive,servo,plc