DRRD-...-P..E..

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com

Appendix to the operating instructions 8103851

2018-12a

[8103853]

Translation of the original instructions

Energy throughfeed DRRD-...-P..E.. English...............................

For all available product documentation èwww.festo.com/pk

Note

Observe the warnings and instructions in the operating instructions for the

DRRD semi-rotary drive.

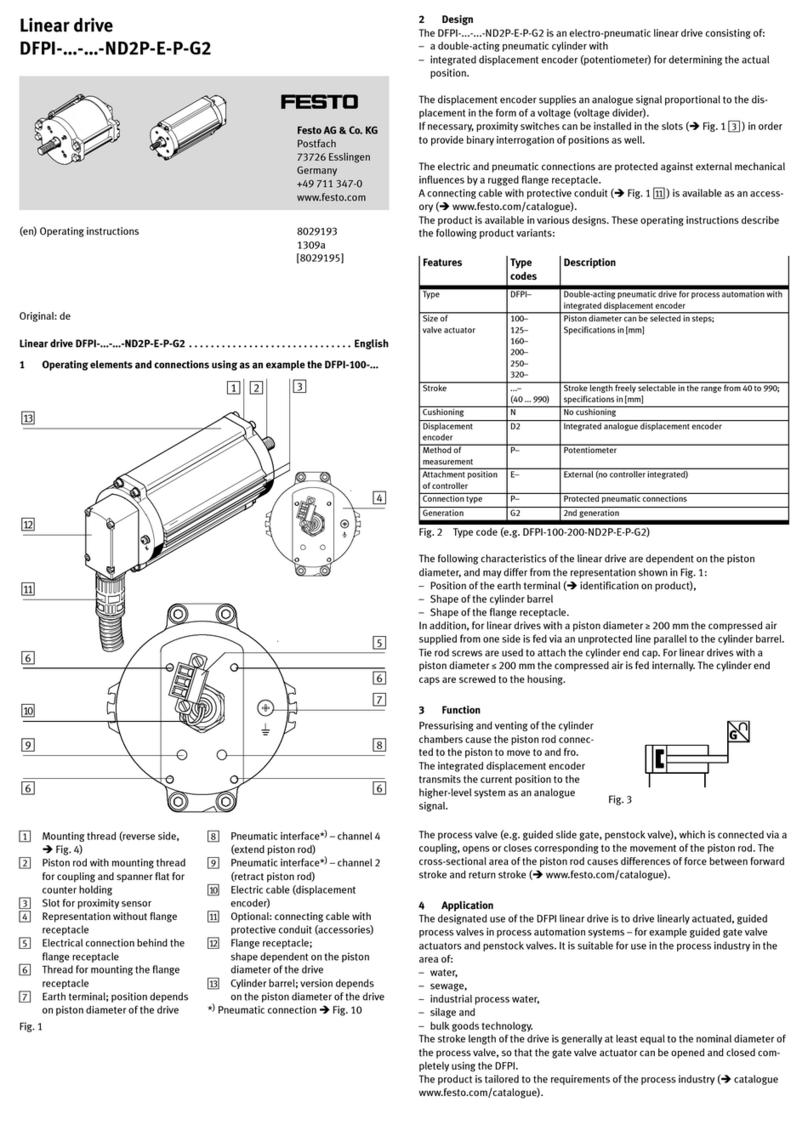

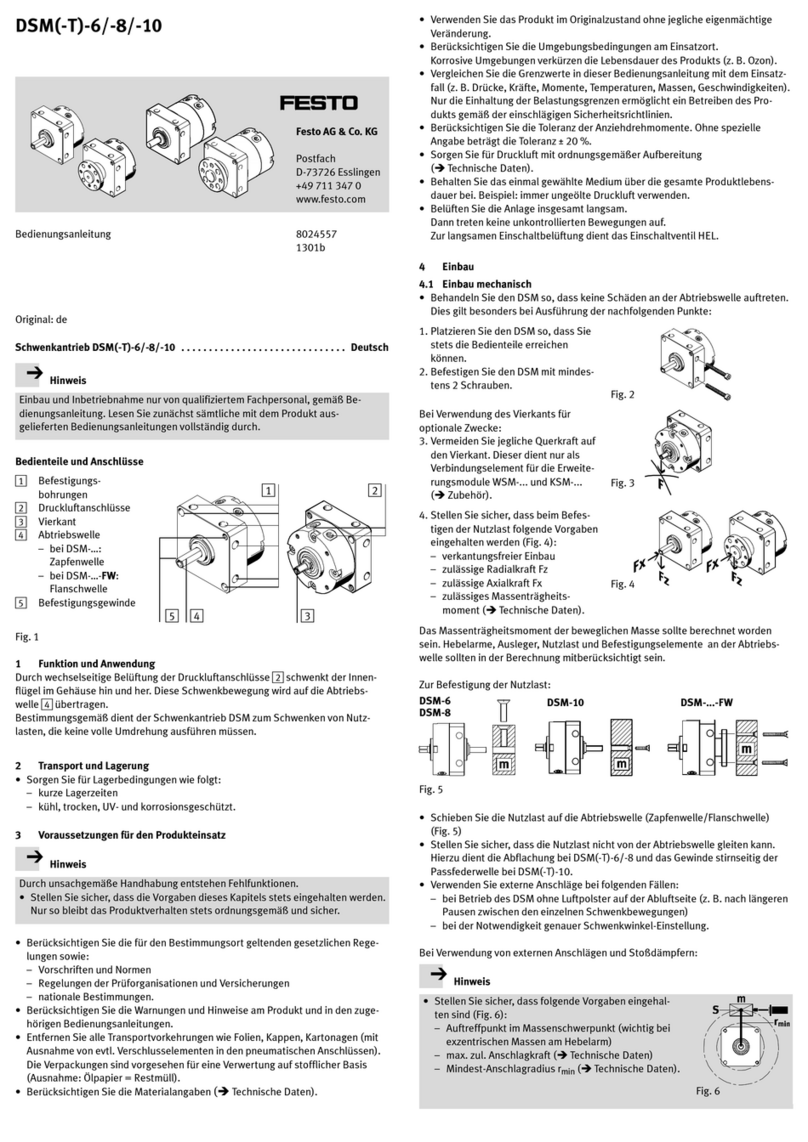

1 Control sections and connections

DRRD-...-P.. (pneumatic)

1 2 4 57

DRRD-...-P..E.. (pneumatic and electric)

1 234 65 7

1Through-hole for mounting the

DRRD (2x)

2Supply port P1 ... P8 (output)

3Electrical output S1 ... S8 (socket)

4Mounting interface for working

load (4x)

5Supply port P1 ... P8 (input)

6Electrical input S1 ... S8 (plug)

7Housing

Fig. 1

2 Function and application

The energy throughfeed DRRD-...-P..E.. serves to permit the passage of com

pressed air and electrical signals through the drive shaft of the DRRD semi-rotary

drive.

3 Installation

3.1 Installation, mechanical

Affix the DRRD with two screws to holes 1and with 2 centring sleeves to the

housing 7.

Affix the working load with at least two screws positioned opposite one another

to the drive flange, and with centring sleeves to threads 4.

Tightening torques are shown in the table below.

4

1

7

Fig. 2

Size 16 20 25 32 35 40 50 63

Mounting of DRRD

Screw in 1

(direct mounting)

M5 M5 M6 M8 M8 M10 M10 M12

Tightening torque [Nm] 6 6 10 18 18 30 30 55

Screw through 1

(through-fastening)

M4 M4 M5 M6 M6 M8 M8 M10

Tightening torque [Nm] 3 3 6 10 10 18 18 30

Centring sleeve ZBH [mm] 9 9 12 15 15 15 15 25

Mounting of working load

Screw in 4M4 M4 M5 M6 M6 M6 M8 M10

Tightening torque [Nm] 3 3 6 10 10 10 20 40

Centring sleeve ZBH [mm] 7 7 9 9 9 9 12 15

Fig. 3

3.2 Installation, pneumatic

If using the energy throughfeed with pneumatic connections DRRD−...−P. . :

Connect tubes to pneumatic connections 2and 5.

Corresponding port identifications are used to indicate which tube to fit to

which push-in fitting (tubing dimensions èFig. 8).

2

5

Fig. 4

3.3 Installation, electric

Warning

Danger of short circuit! If one of the electrical inputs 6is supplied with voltage,

there will be voltage at all electrical inputs, because the positive and negative

lines are connected together inside the component.

Ensure that the electrical inputs 6share a common voltage source.

Otherwise the DRRD may be irreparably damaged by large compensating

currents.

Leave the cover caps on the unused plugs 6.

The plugs 6on the side of the housing are not protected in any other way

against accidental contact.