7

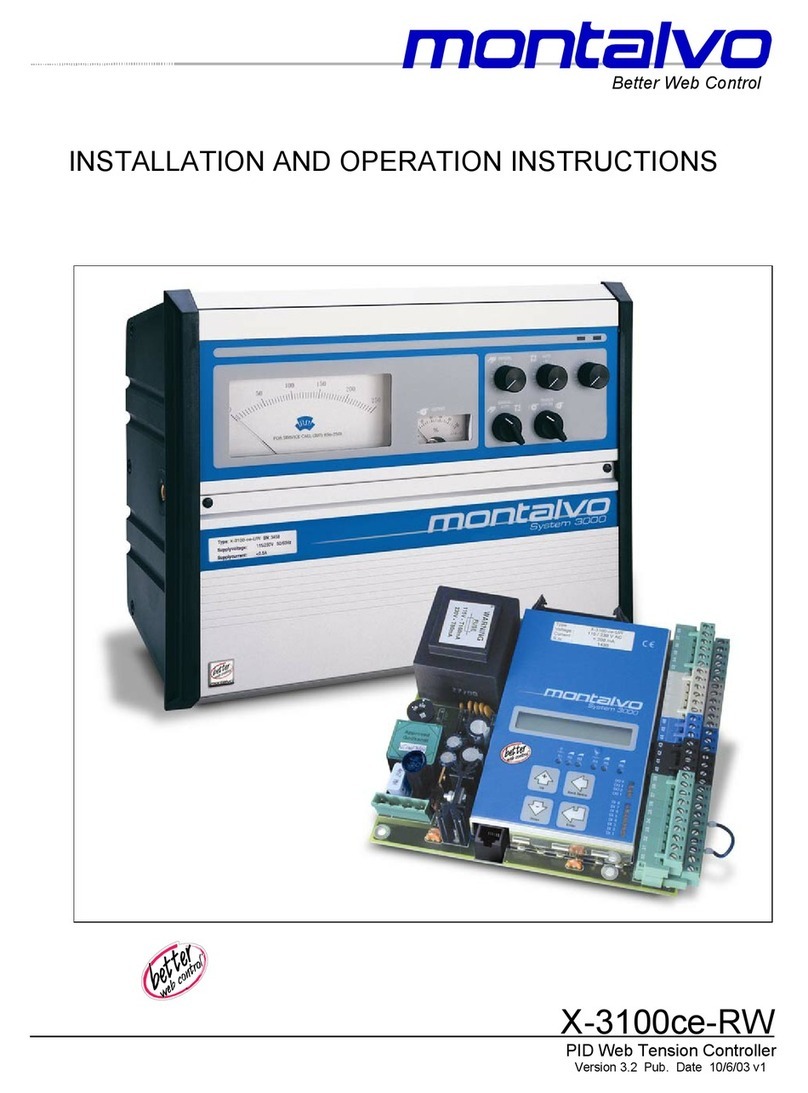

Optional Connections - Used for Rewind Applications

X1.50 0V DC

Connects to the CCW terminals (1) of the splice level poten-

tiometer.

X1.51 Splice Level

Input for external signal is used to set output during splice

mode. A 0 to 10 volt input corresponds to 0 to maximum

output.

X1.52 10 V Reference

Reference voltage applied to the CW terminals (3) of the

splice level potentiometer. Total max. load 5mA.

X1.24 0V DC

Connects to the CCW terminals (1) of the diameter potentio-

meter.

X1.25 Diameter Input

Diameter reference input. Maximum 0 to 10 V with

reference to 0V DC. Signal may be supplied from a

potentiometer, ultrasonic sensor or diameter calculator.

X1.27 10 V Reference

Reference voltage applied to the CW terminals (3) of the

diameter potentiometer. Total max. load 5 mA.

X1.6 Inertia

When activated by a 24 V input or a contact to X1.36, the

output increases by a level set in the INERTIA menu. This

function is used to compensate for the mechanical inertia of

the rewind at start up. It is activated when the main drive is

started.

X1.31 Manual

When activated by a 24 V input or a contact closure to

X1.33, the controller switches to the manual mode. Output is

set by the potentiometer marked MANUAL. When de-

activated, the controller regulates from the manual value.

X1.2 Splice

When activated by a 24 V input or a contact closure to X1.4,

the output switches immediately to the new roll, starting

output determined by the setting of the external splice level

potentiometer. This function is used for flying splice

automatic roll changes and is normally activated by the knife

firing circuit. Rewind splice level is typically set for 5 - 20 %

of maximum to provide the correct torque for the new core

diameter, but the actual setting depends on the application.

The splice level is held constant for a time determined by the

setting of the splice time in the SPLICE menu.

X1.34 Start

When activated by a 24 V input or a contact closure to

X1.34, the regulator is released and begins to integrate up to

the tension set point. Start should be activated when the

rewind motor is started.

X1.3 High Calibration

When activated by a 24 V input or a contact closure to X1.4,

the second calibration range is used. Calibration for this

range is adjusted by potentiometers R3. This feature is used

if the controller is used over a wide tension range or if there

are two different web paths.

X1.35 Roll Pulse

Puls from the rewind roll to calculate the diameter. There can

be more pulses per rev. The number of pulses is given in in

the DIAM. MENU. Max 80 Hz.

X1.5 Web Pulse

Pulses from the web each xx mm. The amount of mm per

pulse is given in in the DIAM.MENU. Max. 800 Hz.

X1.57 Calculated diameter output

0-10V DC output corresponding to the diameter calculated in

the controller.

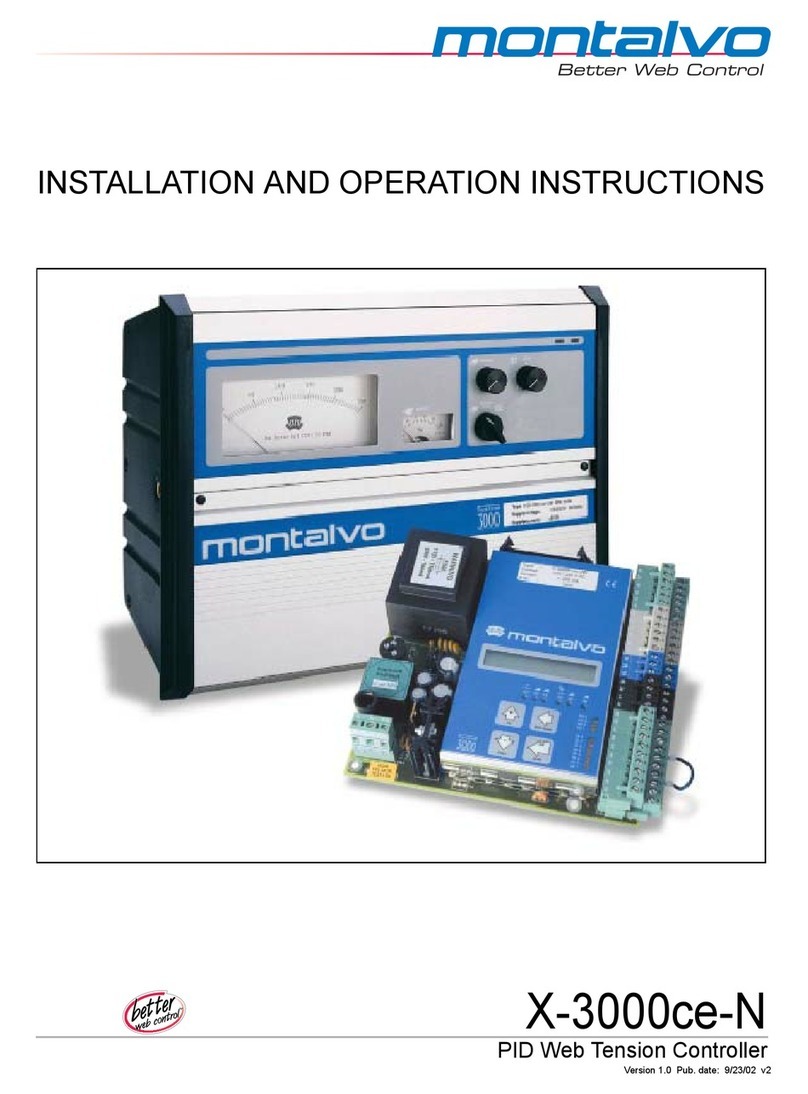

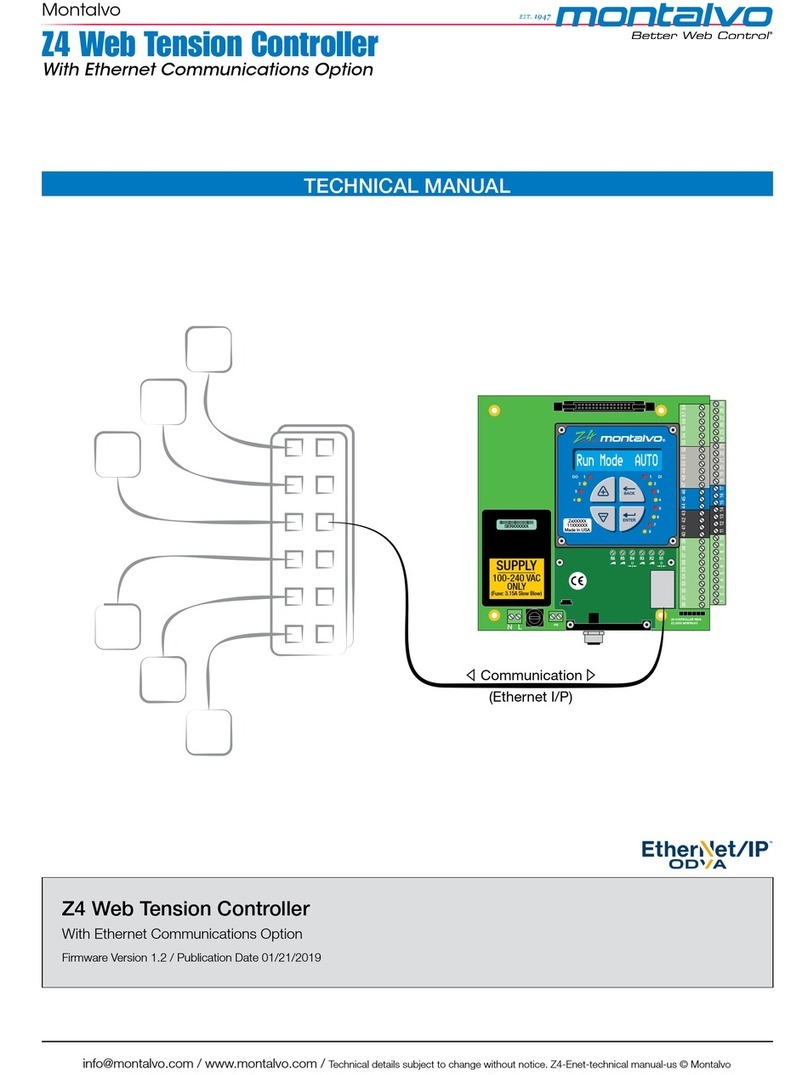

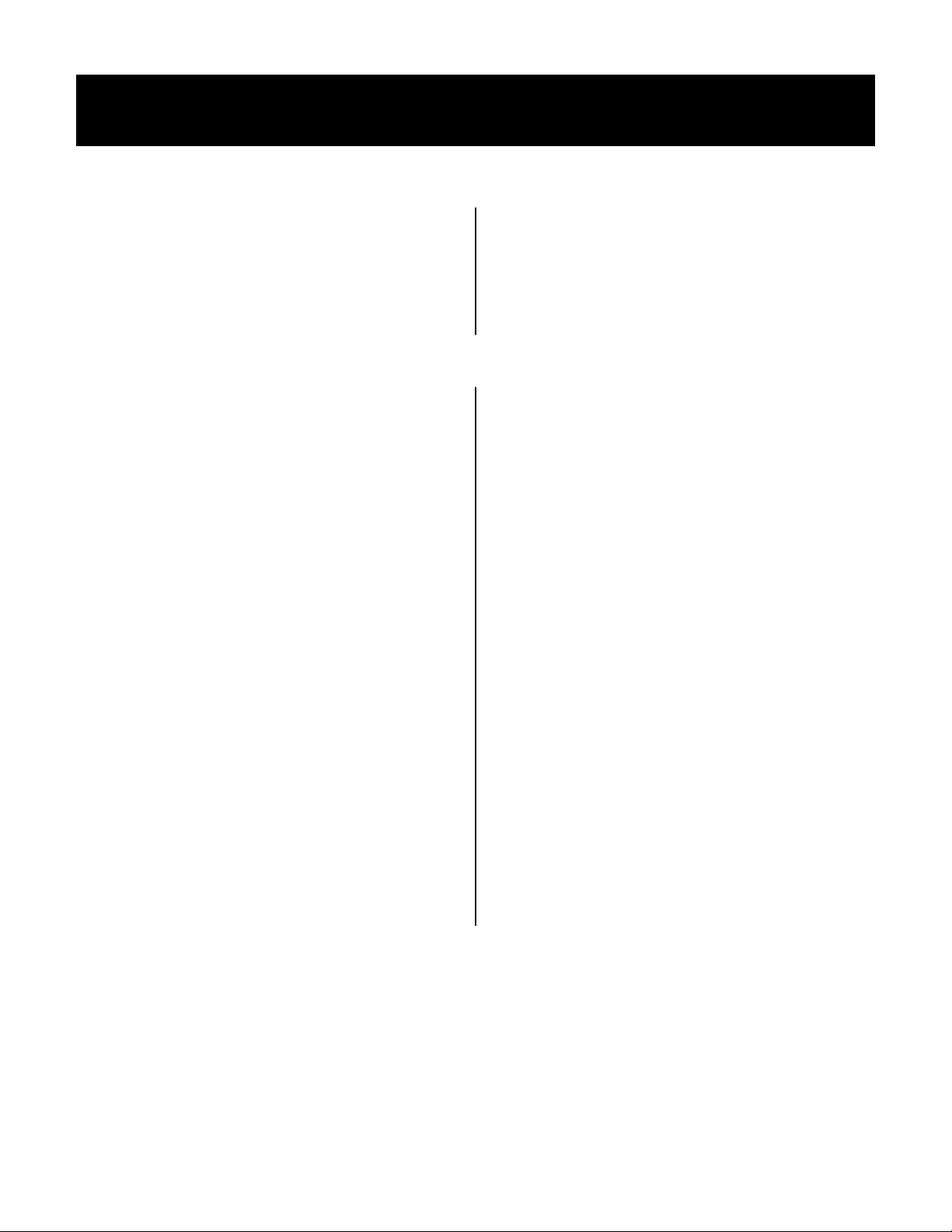

R1 R2 R3 R4 R5 R6

DO 1-4

DI 1-8

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29

L N PE

TENSION 45 %

Type : X/D-3000

Serial no : 960 034

Voltage : 115V/230V AC

Current : 160mA/80mA

L N PE

30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58

1 2 3 4 5 6 7 8 9 10

30 31 32 33 34 35 36 37 38 39

0VDC

MANUAL

TENSION OFF

+24V

INERTIA(MAIN START)

+24V

0VDC

DO3 DO4

0VDC

SPLICE

HIGH CALIBRATION

+24V

WEB PULSE

ROLL PULSE

+24V DC FOR DO

0VDC

DO1 WB DO2

START

Optional Connections - Rewind, Printed Circuit Board Version