Shurco ShurCover User manual

Sheeting System w/SMART3™

P/N 1127925

Shur-Co®, LLC Terms & Conditions

SHIPPING. Orders are shipped F.O.B.

from the Shur-Co®, LLC sites listed below. No full freight is

allowed or prepaid shipment accepted unless quoted and approved in

writing prior to acceptance of the order. All shipments are made by the most

reasonable means in accordance with size and weight of order, unless speci-

fi ed routing instructions are furnished by the customer. Shipments are made

daily via courier. Claims for shortages must be made within 10 days. All claims

for damages or loss in transit must be made with the carrier. No collect calls

will be accepted. To ensure delivery of orders, we need your full street address

and phone number. When you receive your shipment, examine it carefully. Be

sure all cartons listed on the delivery sheet are accounted for. Large items may

be packaged separately. If a carton is damaged, open it and inspect the con-

tents before signing for delivery. If merchandise is damaged, describe damage

on the delivery receipt. Failure on your part to document damaged or missing

merchandise on the delivery receipt releases the carrier of all liability; repair or

replacement will be the customer’s responsibility.

WARRANTY. We warrant all new products are free of defects in materials and

workmanship.* This warranty is effective if products are properly installed and

used for the purpose for which they were intended and applies to the original

buyer only. Except as set forth above or in any product-specifi c warranty docu-

mentation, we make no other warranties, express or implied, including but not

limited to warranties of merchantability of fi tness for a particular use.

Returns of a product for warranty must be accompanied by a Return Mer-

chandise Authorization number (RMA#), obtained by by calling UK Customer

Service at 01795 473499, and sent, with freight paid by us, to Shur-Co®UK

Ltd., Donovan House, Unit 41, Rochester Airport Estate, Rochester, Kent ME1

3QX. All products returned without an RMA# will be refused. When we issue

the RMA#, we will also issue a call tag to have UPS (or other freight company)

pick up the product. C.O.D. returns not accepted. We will pay no storage fees

for a warranty product return prior to pick by us or the freight company. If a

warranty product return is scheduled to be picked up by us, we will pick up the

product at our earliest convenience.

If a product returned is found, in our judgement, to be defective in material

or workmanship, our obligation under this warranty is limited to the repair or

replacement of the product, which will be made by us. Repair or replacement

will be at our discretion, with replacements being made using current products

performing in the equivalent function. Labor charges, other than those incurred

at our factory, including, but not limited to, any labor to install a repaired or re-

placement product, are not covered under this warranty. All expenses associ-

ated with delivering defective products to our factory and delivering repaired or

replacement products from our factory to the owner will be paid by us.

If the product returned is found, in our judgement, to be non-warrantable, the

owner will be contacted to authorize repair work, purchase of a replacement

product or return of the product, all of which will be at the owner’s expense.

Payment authorization must be received by us before any non-warrantable

product is repaired, replaced or returned. All expenses associated with deliver-

ing the repaired non-warrantable product, a replacement product or the non-

warrantable product from our factory to the owner will be paid by the owner.

In no event will we be liable for any damages of any kind to person, product or

property, including but not limited to indirect, incidental, special, consequential

or punitive damages, or damages for loss of profi ts or revenue, even if we

have been advised of the possibility of such damages. There are no warran-

ties for used products or products that have been repaired, altered, modifi ed

or subjected to misuse, negligence or accident. We will not repair or replace

products that fail or malfunction due to ordinary wear and tear, except as ex-

pressly noted in a product-specifi c warranty. Use of non-Shur-Co®, LLC parts

in conjuction with Shur-Co®, LLC products will void this product warranty.

*Certain products have specifi c warranties that differ from this warranty, for example motors and elec-

tronics. Product-specifi c warranty documentation is available for these items. In the event of a confl ict

between this warranty and a product-specifi c warranty, the product-specifi c warranty will govern.

RETURN POLICY. All sales fi nal. See WARRANTY above for return details.

OTHER. All prices, product listings, sizes, weights and manufacturing details

are subject to change without notice. No person is authorized to modify the

foregoing conditions of sale whatsoever.

SHUR-CO® of NORTH DAKOTA

1746 4th Ave. NW

West Fargo, ND 58078

Ph 877.868.4488 | Fax 701.277.1283

SHUR-CO® of OHIO

1100 N. Freedom, St. Rt. 88 & 14

Ravenna, OH 44266

Ph 866.356.0242 | Fax 330.297.5599

SHUR-CO® of TEXAS

34505 I-10 West, S. Frontage Rd.

Brookshire, TX 77423

Ph 866.689.0039 | Fax 281.934.3311

SHUR-CO® UK, Ltd.

Unit 41 Rochester Airport Estates

Laker Rd., Rochester, Kent ME1 3QX

Ph +44 (0)1795.473499

Fax +44 (0)871.272.8278

For more info, log on to our website:

www.shurco.com

Corporate HQ and Outlet Store

SHUR-CO® of SOUTH DAKOTA

2309 Shur-Lok St., PO Box 713

Yankton, SD 57078-0713

Ph 800.474.8756 | Fax 605.665.0501

ShurTite™ Service Centers

SHUR-CO® of CANADA

490 Elgin St., Unit #1

Brantford, Ontario N3S 7P8

Ph 800.265.0823 | Fax 519.751.3997

SHUR-CO® of SIOUX FALLS

47184 258th St., Suite B

Sioux Falls, SD 57107

Ph 844.573.9322 | Fax 605.543.5469

SHUR-CO® of ILLINOIS

Ph 866.356.0246 | Fax 217.877.8270

SHUR-CO® of OHIO

Ph 866.356.0242 | Fax 330.297.5599

SHUR-CO® of COLORADO

10220 Brighton Rd., Unit #1

Henderson, CO 80640

Ph 866.355.9173 | Fax 303.289.2298

SHUR-CO® of FLORIDA

3353 SE Gran Park Way

Stuart, FL 34997

Ph 800.327.8287 | Fax 772.287.0431

SHUR-CO® of ILLINOIS

3993 E. Mueller Ave.

Decatur, IL 62526

Ph 866.356.0246 | Fax 217.877.8270

SHUR-CO® of IOWA

3839 Midway Blvd.

Ft. Dodge, IA 50501

Ph 866.356.0245 | Fax 515.576.5578

SHUR-CO® of MICHIGAN

5100 Lakeshore Dr.

Lexington, MI 48450

Ph 800.327.8287 | Fax 772.287.0431

SHUR-CO®, LLC SERVICE AND DISTRIBUTION CENTERS

P/N 1124308 Rev. D

UK HELP LINE: +44 (0) 1795 473499

Thank you for buying this sheetinging system from Shur-Co®We ap-

preciate your condence in our products. Please read and thoroughly

understand this manual before installing and/or operating this system.

Pay particular attention to important safety and operating instructions,

as well as warnings and cautions. The hazard symbol is used to

alert users to potentially hazardous conditions and is followed by cau-

tion, warning or danger messages.

Failure to READ AND FOLLOW INSTRUCTIONS could result in fail-

ure of your system and/or personal injury. Your trailer requirements

may, however, call for minor variations to these instructions.

Please inspect your sheeting system periodically; repair or replace

worn or damaged parts.

QUESTIONS? CALL OUR HELP LINE:

+44 (0) 1795 473499

MON-FRI 8 AM-5 PM CENTRAL TIME

We at Shur-Co® are concerned with your safety and the safety of all

those operating this system. Therefore, we have provided safety de-

cals at various locations on your sheeting system. Keep decals as

clean as possible at all times. Replace any decal that has become

worn or damaged, painted over or otherwise difcult to read. Replace-

ment decals are available through Shur-Co® dealers.

SAFETY INSTRUCTIONS

To prevent rust, paint all exposed metal, such as weld seams and/or

metal exposed by grinding or cutting, with corrosion-resistant paint.

ShurCover Sheeting System

P/N 1127925

!

MESSAGE TO OWNERS

SAFETY

RUST PREVENTION

Hardware Identication/Box Preparation..................................... 1

Sheet Installation...................................................................... 2-3

Center Pole Drive Motor.............................................................. 4

Web Spool & Drive Motor......................................................... 5-8

SMART3™ Wireless Receiver ............................................... 9-13

System Setup ....................................................................... 14-16

Replacement Parts............................................................... 17-20

1. Aluminum Welder

2. #3 Phillips Insert Bit or #3 Phillips Screwdriver

3. Band Saw or Hack Saw

4. Torque Wrench

5. Socket Wrench

6. 17mm Socket

7. 17mm Combination Wrench

8. 8mm Socket or Nut Driver

9. 1/2" Socket

10. 19mm Socket

11. 19mm Combination Wrench

12. Tape Measure

13. Pencil

14. Electric Drill

15. 8mm Drill Bit (for 3/8" self-tapping screws)

16. 10mm Drill Bit (for 3/8" cap screws)

17. Air or Electric Wrench w/9/16” Socket

18. 9/16" Combination Wrench

19. 9/16" Socket

20. 5mm Drill Bit

21. 1/2" Combination Wrench

22. #2 Phillips Screw Driver

23. 3/8" Hex Driver

24. Wire Crimp Tool

25. 13mm Socket

26. 10mm Socket

Optional: Hot Knife, Spray Paint, Caulk or Rubber Sealant

TABLE OF CONTENTS

TOOLS REQUIRED

1.

Always wear safety glasses during installation.

2. Keep body and clothing clear of moving parts.

3. Use only OSHA-approved ladders or scaf-

folding during installation process.

4. No other use of this system is authorized,

except as designed.

SAFETY INSTRUCTIONS

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

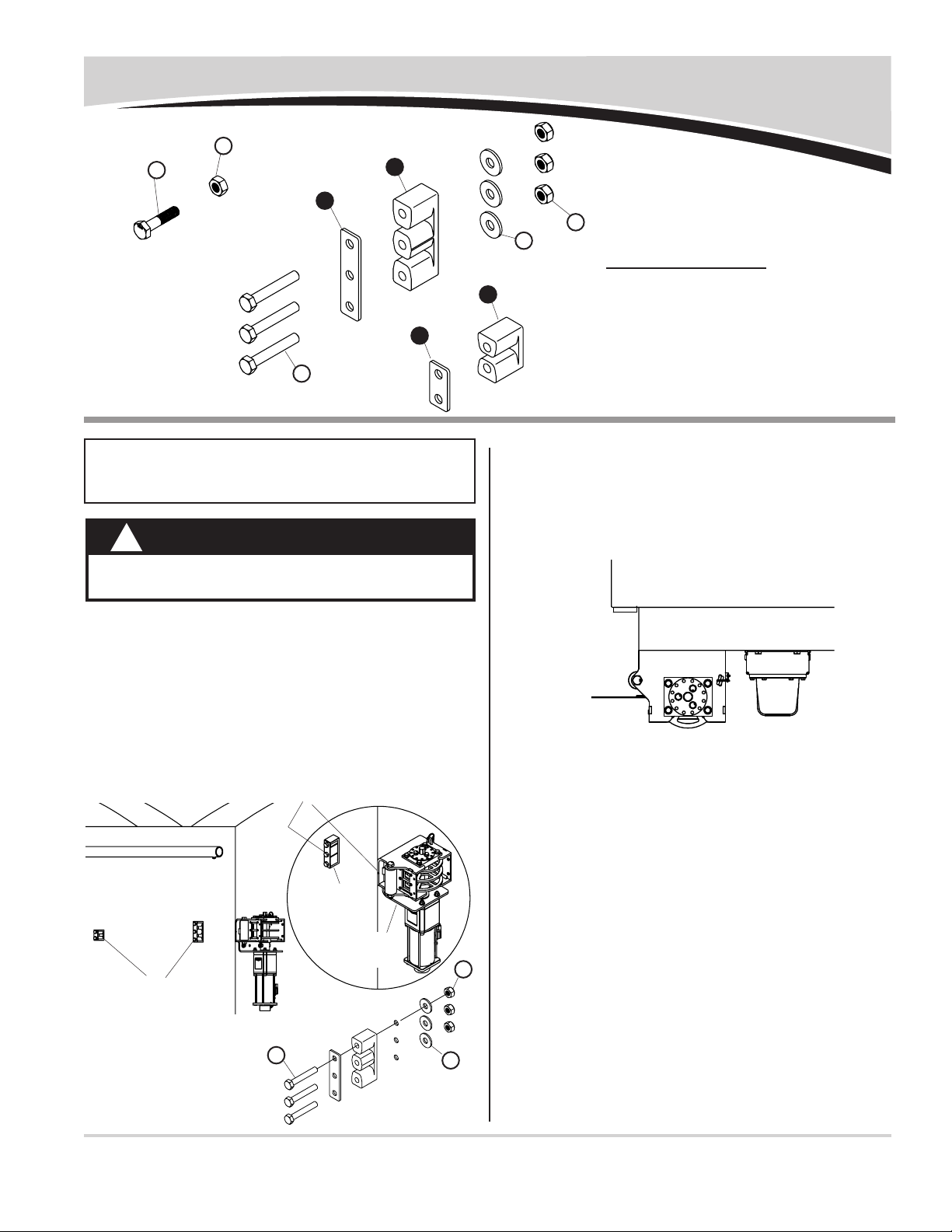

Hardware Identication

1

1700398 - Self-Drilling Screw - 1/4" x 3/4"

1705461 - Cap Screw - M12 x 1.75 x 130

1705355 - Cap Screw - M10 x 1.5 x 150

1700407 - Hex Nut - 3/8"

1705556 - Cap Screw - M10 x 1.5 x 65

remove sharp edges on top

rail - paint all exposed metal

C

D

E

F

G

B

M

N

A

H

1704338 - Self-Tapping Screw - 1/4" x 1"

1704931 - Flanged Nylon Lock Nut - 5/16"

1705378 -

Self-Tapping Screw - 5/16" x 3/4"

1705357 - Cap Screw - M10 x 1.5 x 45

- CL10

1700419 - Nylon Lock Nut - 5/16"

CAUTION

Box extensions (tip tops), if used, must be

secured to truck box. System could blow off if

box extensions are not secured to box.

!

SHEET INSPECTION

BOX PREPARATION

Measure sheet. Determine sheet length and width with slight

tension applied. Compare with length and width stated on paper

attached to sheet. If sheet length and width do not match what

is on paper, do not proceed. Call your local dealer or call Shur-

Co® Customer Service at +44 (0) 1795 473499.

Prepare body before installing ShurCover sheeting system. Re-

move or grind any sharp edges smooth to prevent sheet dam

age.

To prevent rust, paint all exposed metal, such as weld seams

and/or metal exposed by grinding or cutting, with corrosion-

resistant paint.

1700434 - Lock Washer - 3/8"

O

1705371 - Cap Screw - M5 x 12

1700428 - Flat Washer - 5/16"

P

Q

1705350 - Lock Washer - M10

1705347 - Fender Washer - 10.5 x 30

V

W

X

1705361 - Nylon Lock Nut - M10 x 1.5 -

CL10

1705373 - Nylon Lock Nut - M12 x 1.75

T

1701176 - Flat Washer - 3/8"

U

1705555 - Nylon Lock Nut - M10 x 1.5

Y

1700400 - Self-Tapping Screw - 3/8" x 1"

1702926 - Cap Screw - 5/16" x 7/8"

S

Z

I

1705370 - Cap Screw - M10 x 1.5 x 60 - CL10

1705353 - Machine Screw - M6 x 10

1705349 - Nylon Lock Nut - M8 x 1.25

1705550 - Carriage Bolt - M8 x .50

1705551 - Flanged Cap Screw - M6 x 16

R

L

K

J

1705376 - Flanged Cap Screw - M5 x 16

a

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

2

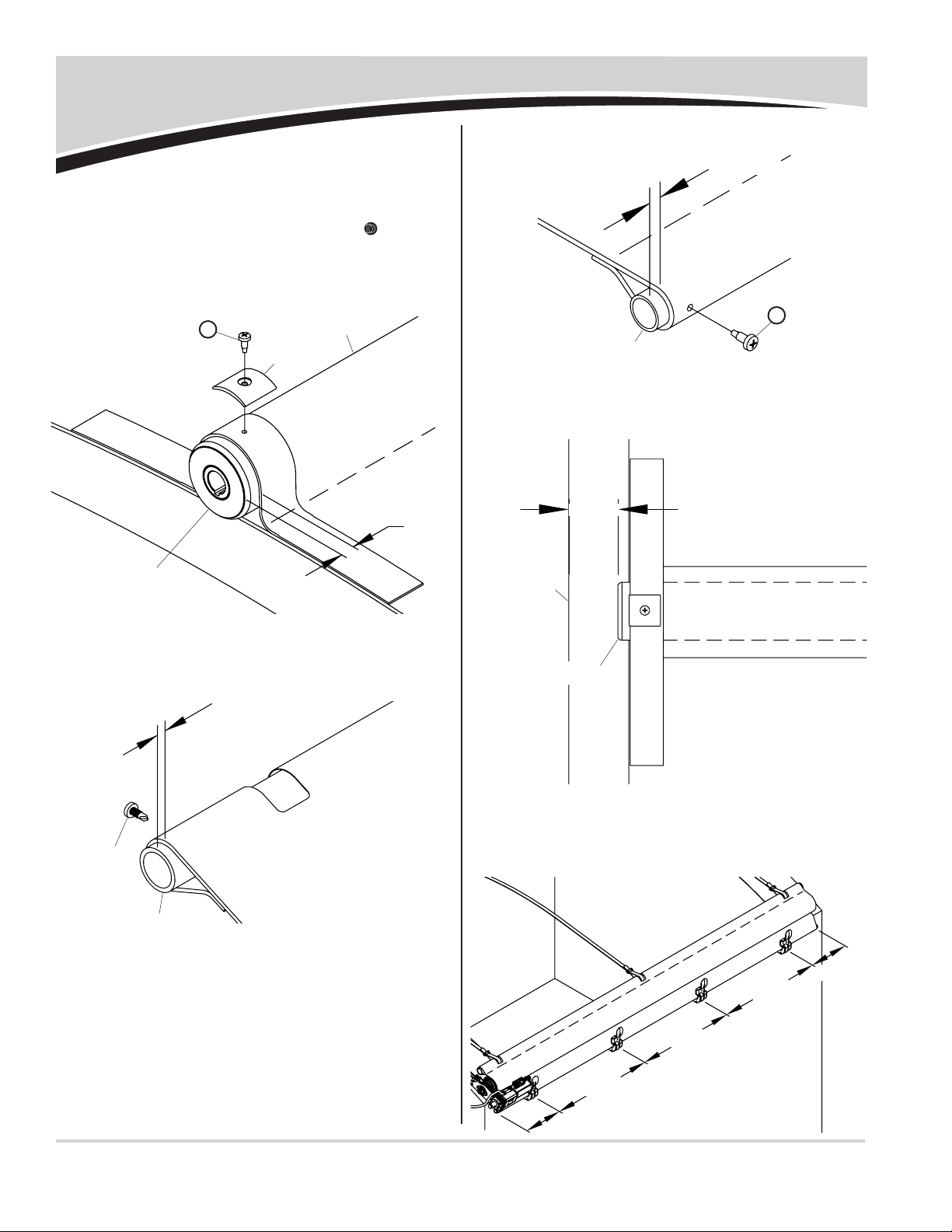

STEP 2: Install double

support arch if

required (not

supplied).

Sheet Installation

STEP 3: Cut center pole, pull bar and xing bar to length. Add

holes per print.

STEP 4: Verify ends of center pole are cut at 90°.

STEP 5: Insert center pole plug assembly into center pole.

Make sure face of assembly is square to center pole.

STEP 6: Weld center pole plug assembly onto end of center

pole.

NOTE: Keyway

must be 180°

from 5mm hole.

cut to length

90°

keyway

hole

center pole

plug

6.5 x3.5

Item Part # Description

1. 1123980 Center Pole Plug - UK

2. 1701354 U-Clamp

3. ______ Center Pole

4. ______ Pulling Bar

5. ______ Fixing Bar

6. ______ Sheet (not shown)

D. 1700398 Self-Drilling Screw - 1/4" x 3/4"

1

2

3

5

4

STEP 1: Install plastic

sheet to both

hoods (not

supplied).

uhmw

D

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

3

Sheet Installation - continued

STEP 11: Secure xing bar to box using preferred method. If

using sheet stops, mount rst and last sheet stops

320mm from edge of sheet. Equally space remaining

sheet stops.

STEP 7: Insert center pole into center pole pocket on sheet.

Align hole in center pole with hole in sheet and secure

sheet to pole with U-clamp and screw D. Pull sheet

tight and repeat on other end of pole. Install third U-

clamp and screw at center of center pole.

STEP 8: Fasten pull bar to sheet with self-drilling screw. Align

hole in sheet with hole in bar and secure. Pull sheet

tight and repeat on other end.

STEP 9: Repeat step 7 for xing bar.

STEP 10: Place sheet on top of box with xing bar hanging over

right side of box. Move sheet forward or backward

until center pole insert plug is 75mm from front face

of hood.

75mm

self-

drilling

screw

sheet

pull bar

fixing bar

sheet

sheet

front of

hood

center pole

16mm

u-clamp

center pole

center pole

pocket

9.5mm

9.5mm

D

D

320mm

320mm

evenly space

evenly space

evenly space

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

4

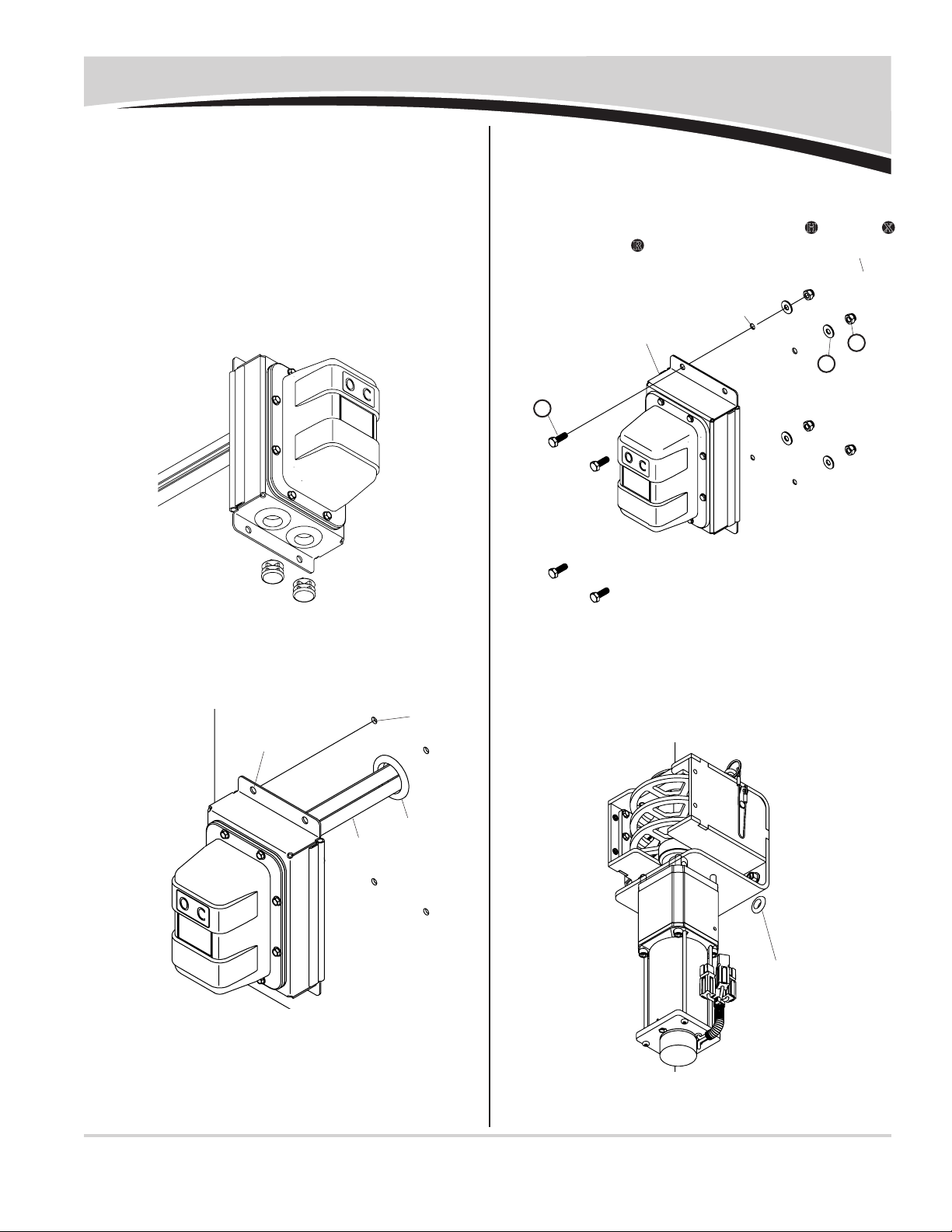

Center Pole Drive Motor

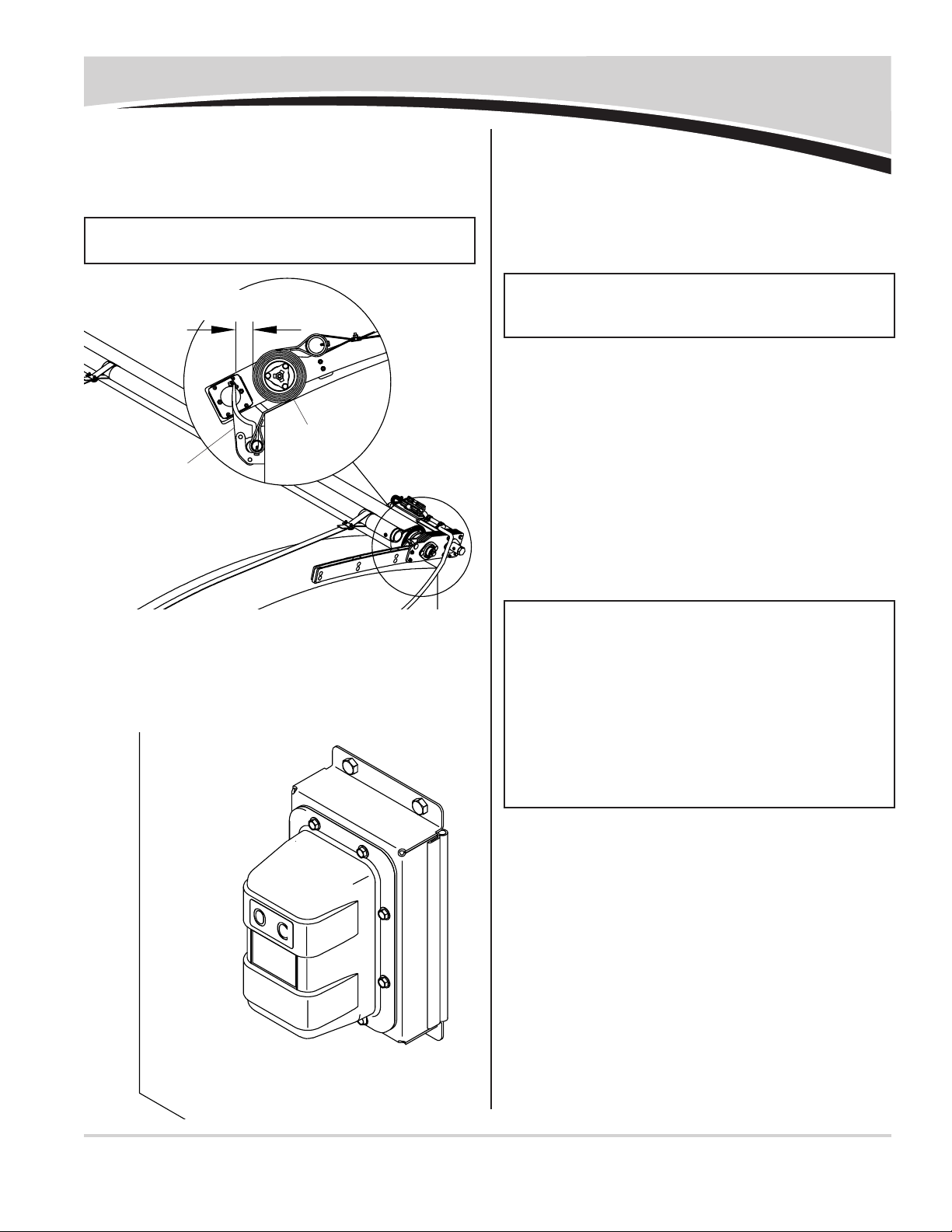

STEP 3: Install center pole drive motor. Insert key stock into

center pole plug keyway. Align keyway on drive shaft

by turning manual override shaft clockwise or coun-

terclockwise and insert shaft into center pole plug.

motor

key

motor

center pole

rotate to align

manual override

shaft to keyway

1

10

Item Part # Description

1. 1124987 Center Pole Pivot Arm Assembly - High Rise

1124981 Center Pole Pivot Arm Assembly - Low Rise

2. 1124968 Center Pole Drive w/Motor

1124978 Center Pole Drive w/Motor - Reverse Roll

3. 1705344 Wire Clip - 1/2"

4. 1124985 Center Pole Cam

5. 1124982 Bushing - 1/2" x .334" x 1/2"

6. 1123996 Key Stock - 1 1/4"

B. 1705353 Machine Screw - M6 x 10

G. 1705551 Flanged Cap Screw - M6 x 16

I. 1705550 Carriage Bolt - M8 x 1.25 x .50

N. 1705355 Cap Screw - M10 x 1.5 x 150

P. 1705349 Nylon Lock Nut - M8 x 1.25

Y. 1705350 Lock Washer - M10

Z. 1705347 Fender Washer - 10.5mm x 30mm

2

5

6

STEP 1: Align holes in pivot arm with holes in center pole drive

and fasten loosely with screws G.

STEP 2: Loosely fasten bushing and cams to center pole drive

with carriage bolt I and lock nut P.

center pole drive

pivot arm

cams &

bushing

3

STEP 5: To adjust pivot arm and drive/motor assembly to be

in contact with hood, rotate cams upward until tight.

Tighten all fasteners securely.

adjust pivot arm

drive/motor

assembly

rotate cams upward

N

Z

Y

I

G

B

P

G

I

P

N

Z

Y

STEP 4: Secure drive motor to center pole with fender washer

Z, lock washer Yand cap screw N. Torque bolt to

54 Nm.

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

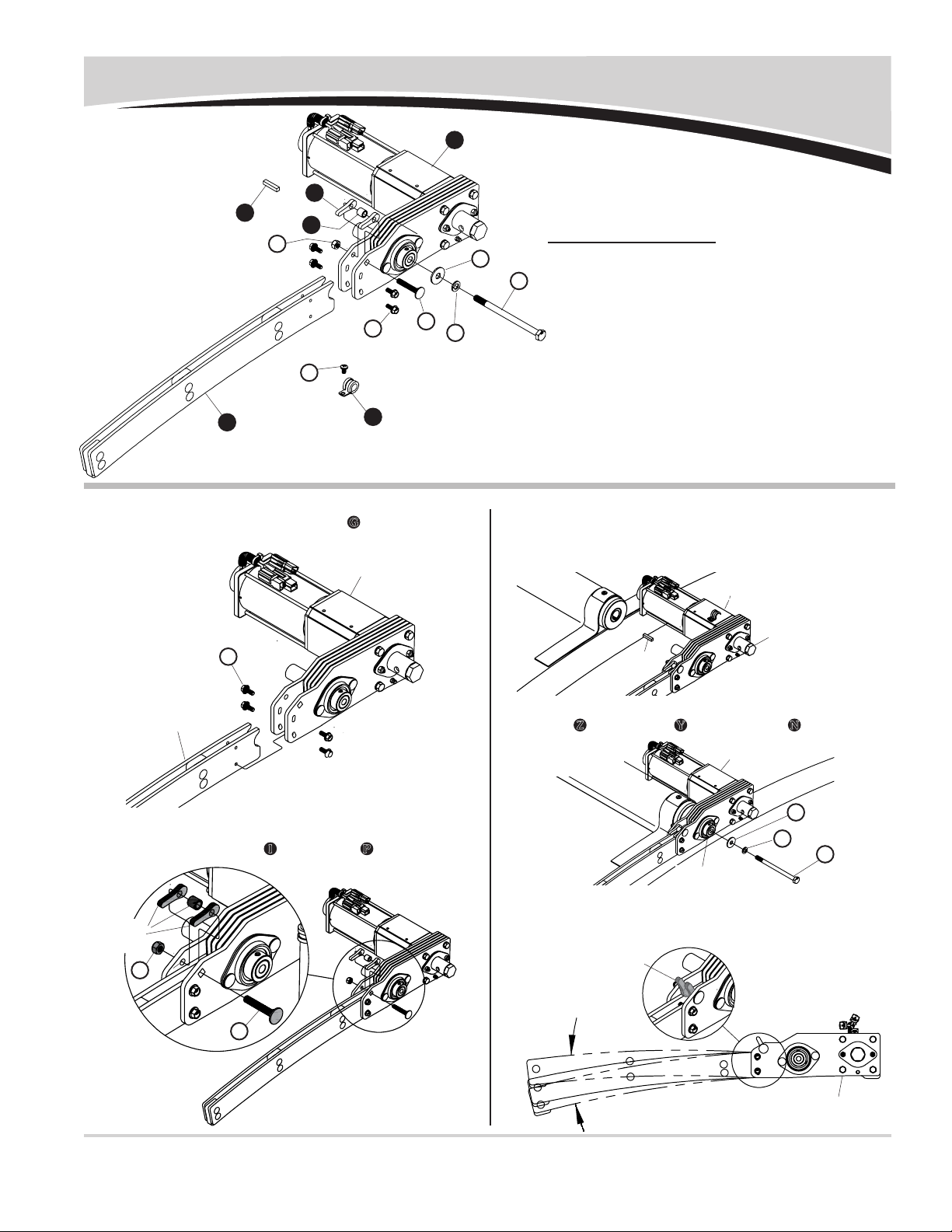

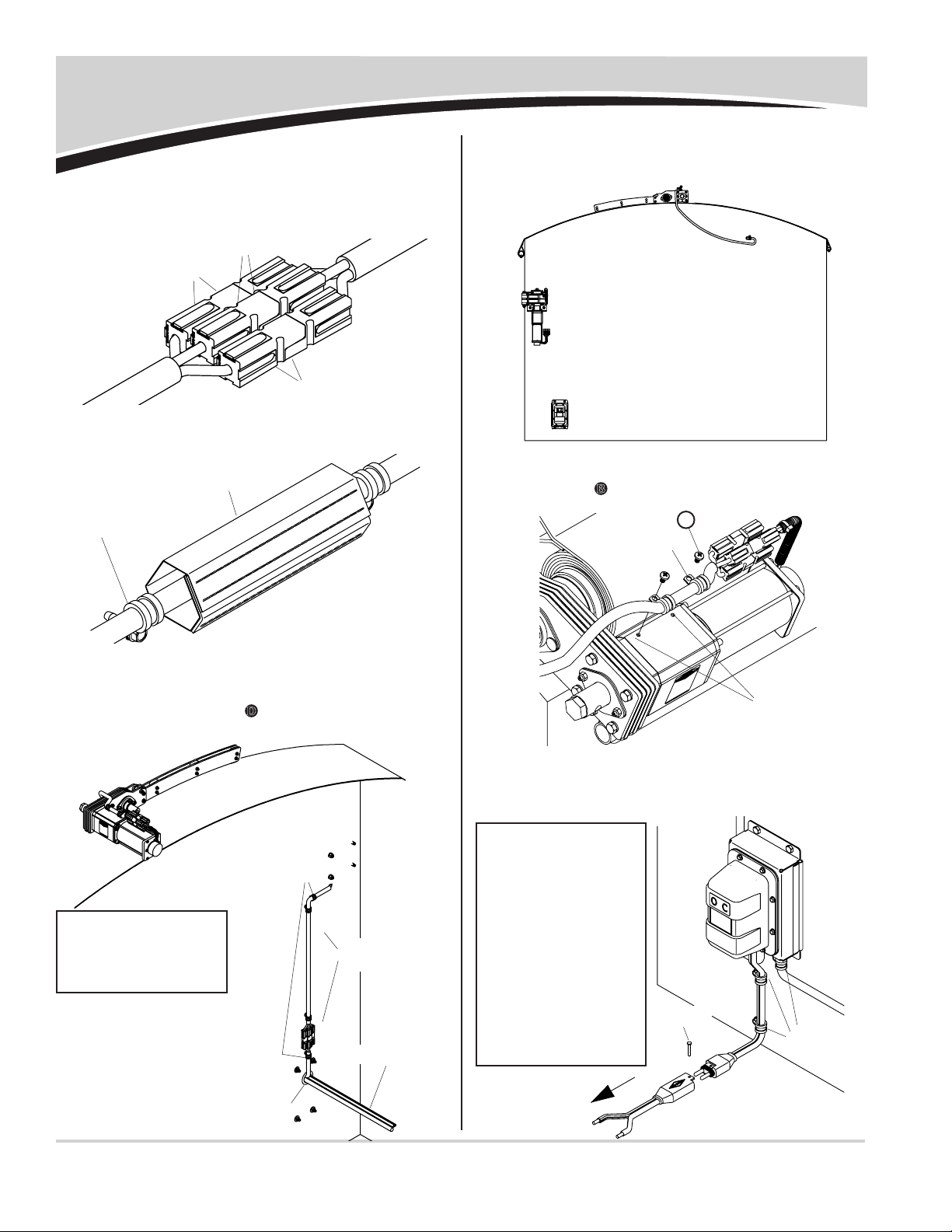

STEP 1:

Remove motor assembly from spool bracket pre-

assembly by removing four 5/16" anged lock nuts.

5

Web Spool & Drive Motor

Item Part # Description

1. 1124434 Spool Bracket - 5.25" UK

1124805 Spool Bracket - 5.25" UK - RR

2. 1705381 Spool Web Guide

3. 1123999 Spool Assembly - 5.25" - UK

4. 1120679 Motor Spacer

5. 1705252 Spool Motor - UK

1705453 Spool Motor - UK - RR

6. 1705460 Spool Roller - UK

7. 1124436 Spool Cover - 5.25" - UK

8. 1124043 Bushing Spacer - 1 3/16"

9. 1805587 Webbing - 6m x 25mm - Front

10. 1805588 Webbing - 12m x 25mm - Rear Ridged

11. 1805589 Webbing - 18m x 25mm - Rear - Trailer

12. 1705581 ShurCover Decal

C. 1705371 Flanged Cap Screw - M5 x 12

F. 1705378 Self-Tapping Screw - 5/16" x 3/4"

J. 1700400 Self-Tapping Screw - 3/8" x 1"

M. 1705370 Cap Screw - M10 x 60

O. 1705461 Cap Screw - M12 x 130

Q. 1704931 Flanged Lock Nut - 5/16"

S. 1700407 Hex Nut - 3/8"

U. 1705361 Lock Nut - M10

V. 1705373 Lock Nut - M12

W. 1700434 Lock Washer - 3/8"

1

4

5

2

6

7

8

NOTE: Steps

1 and 2 are for

pre-assembled

spool brackets

only. All others

start at step 3.

STEP 2: Remove web spool and plastic washer from spool

bracket pre-assembly by removing four screws F.

motor

shaft

spool bracket

spool bracket

plastic washer

web spool

skip to step 5 if using preassembled spool bracket

911

10

web spool

flanged

lock nut

F

S

W

OF

C

J

M

U

V

C

3

Q

12

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

6

Web Spool & Drive Motor - continued

STEP 5C: Mark and drill 8mm holes in (minimum) 4 locations.

8mm holes

STEP 5B: Position top of bracket approximately 300mm below

installed pull bar when in closed position.

STEP 5A: Align edge of bracket ush with side of trailer or edge

of mounting bracket.

300mm

edge of

bracket

edge of

trailer

spool bracket

pull bar

STEP 4: Fasten spool web guide to spool bracket with six

screws C.

spool

bracket

spool web guide

STEP 3: Fasten spool roller to spool bracket with M12 cap

screw O and lock nut V.

spool

bracket

spool

roller

STEP 5: Determine location for spool bracket on front of box.

NOTE: Custom bracket may be required for boxes with

radius and diagonal corners.

O

V

C

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

7

STEP 7: Insert motor shaft through plastic washer and hole

in spool bracket. Secure with four 5/16" anged lock

nuts Q.

Web Spool & Drive Motor - continued

web spool

motor

shaft

spool

bracket

STEP 6: Install web spool and plastic washer into spool bracket.

Secure with impact wrench and screws F.

spool bracket

plastic washer

web spool

top view

spool

bracket

NOTE: Use lock washers and nuts if possible. Minimum wall

thickness of 4.75mm is required when using self-tapping

screws Jwithout lock washers Wand nuts S.

STEP 5D: Secure spool bracket to trailer with impact wrench

and four self-tapping screws J.

spool bracket

F

Q

J

J

W

S

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

8

STEP 11: Rotate web spool until yellow screw M can be installed

into holes on bottom of spool. Install screw and secure

with nut U.

Web Spool & Drive Motor - continued

STEP 10: Push webbing and spacers back into spool and secure

with M8 x 120 cap screw and lock washer. Tighten

screws.

STEP 9: Route webbing through spool bracket web guide and

insert bushing spacers into loops.

spool

bracket

web guide

insert bush-

ing spacers

into loops

webbing

STEP 8: Rotate web spool so M8 x 120 screw is facing forward.

Remove screw and loosen other two screws so two

bushing spacers can be removed.

web spool

remove

bushing

spacers

m8 x120

cap screw

M

U

m8 x120

cap screw

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

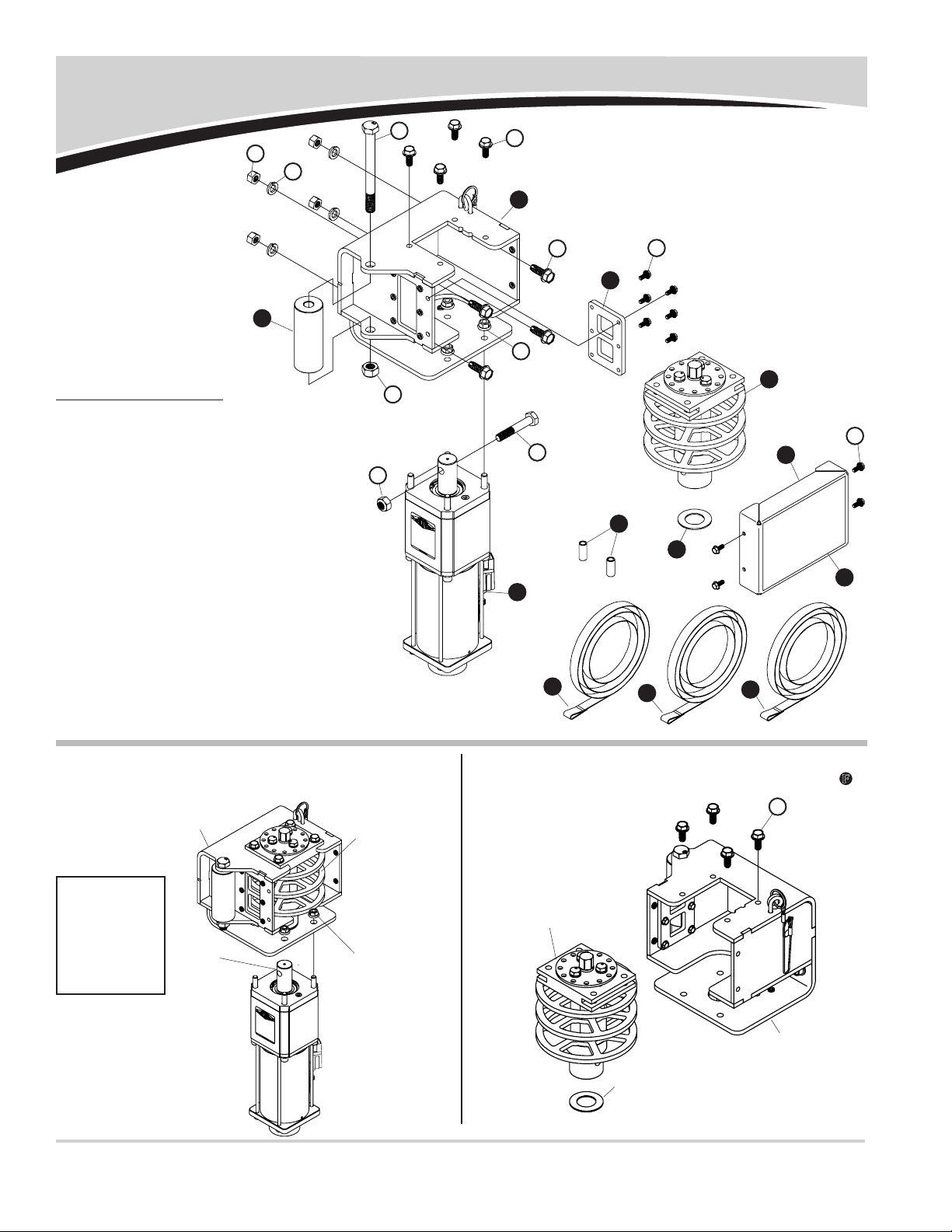

9

SMART1+™ Wireless Receiver

Follow these steps if wiring wireless receiver onto front skin of

trailer. Skip to step 10 if wiring behind skin of trailer.

STEP 1: Determine mounting location for wireless receiver

bracket. Bracket has manual switch and should be

located where easily accessible and safe to operate

sheet, (typically on driver side of front skin, where it

can be reached without climbing on trailer).

Verify wire lengths before drilling holes. Dual-con-

ductor red (+) and black (-) wire must reach 24V DC

power supply. Two marked 3-conductor wires must

reach junction boxes on spool motor or center pole

drive motor. Observe full motion of center pole motor

and supply enough wire for motor to reach fully open

and closed sheet positions.

STEP 2: Using holes on receiver as guide, mark and drill four

5mm holes.

manual

switch

wireless

receiver

driver side

of front skin

holes in

receiver

Item Part # Description

1. 1125035 Velcro® Cable Cover

2. 1126867 SMART3™ Remote

3. 1125047 Jumper Wire - Spool - Standard

1125048 Jumper Wire - Arm - Standard

1125049 Jumper Wire - Spool - Reverse Roll

1125050 Jumper Wire - Arm - Reverse Roll

4. 1127919 SMART3™ Wireless Receiver

5. 1705808 Wire Clip - 5/8"

6. 1705376 Wire Clip - 1/2"

7. 1120817 Female SMARTwire™ - 13.3 mm²- 1.9m

1704994 Female SMARTwire™ - 13.3 mm²- 12m

1704988 Female SMARTwire™ - 13.3 mm²- 19.8m

1704989 Female SMARTwire™ - 21.2mm²- 27.4m

1125396 Female SMARTwire™ - 21.2mm²- 30m

8. 1704757 Harness Lock Pin

9. 1701595 End Plug - 1"

A. 1705376 Flanged Cap Screw - M5 x 16

B. 1705353 Machine Screw - Pan Hd. - M6 x 10

E. 1704338 Self-Tapping Screw - 1/4" x 1"

H. 1702926 Cap Screw - 5/16" x 7/8"

R. 1700419 Nylon Lock Nut - 5/16"

X. 1700428 Flat Washer - 5/16"

5

4

2

3

1

H

E

XR

8

7

9

6

A

B

gear

box

spool

bracket

wire

runs

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

10

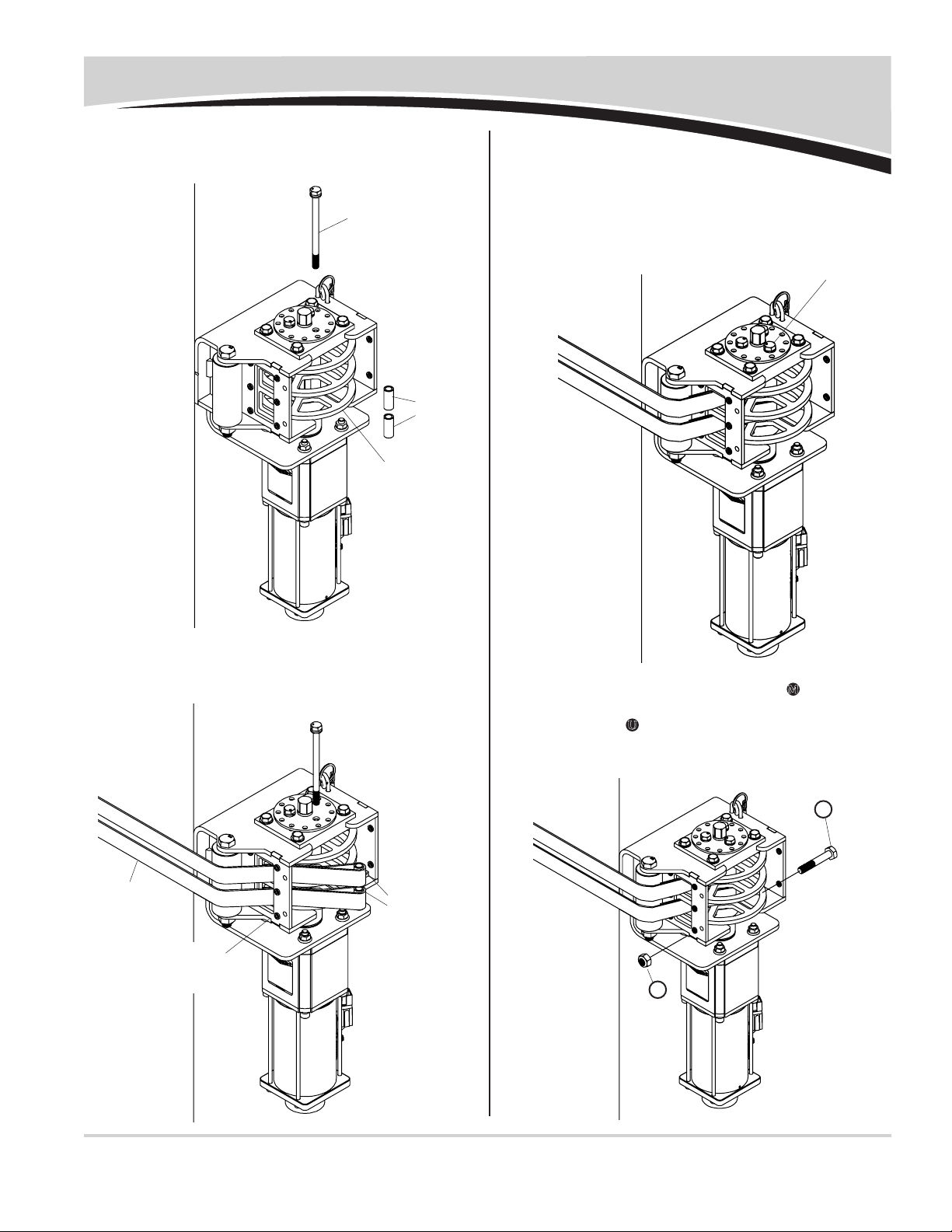

SMART1+™ Wireless Receiver - continued

STEP 4: Connect jumper wire between wireless receiver wire

mandel spool and wire connected to spool motor.

Connect wire ends to matching colored wire ends.

STEP 3: Align holes on wireless receiver with holes on trailer.

Fasten with screws H, washers X and nuts R.

STEP 6: Route connected wires from spool motor to wireless

receiver. Secure wire to bottom of spool bracket with

5/8" wire clip and screw E. Secure to gear box with

1/2" wire clip and screw B. Secure wire to trailer with

5/8" wire clips and self-drilling screws E.

hole in

trailer

spool motor

wireless receiver

wireless receiver

white

black

green

secure 3-conductor

jumper wire w/5/8"

wire clips & screws E

velcro®

cable wrap

not shown

STEP 5: Cut Velcro® cable wrap into six 6" pieces. Wrap around

wire connections. Secure wire with wire clips.

wire clip w/

self-drilling

screw

velcro®

cable wrap

STEP 6A:

Secure wire to motor with 1/2" wire clips and screws

B

,

fastening through existing holes in motor assembly.

wire clip

holes in motor

X

R

H

B

secure wire to

trailer w/5/8"

wire clips &

screws E

secure w/1/2"

wire clips &

screws A

secure w/1/2"

wire clips &

screws B

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

11

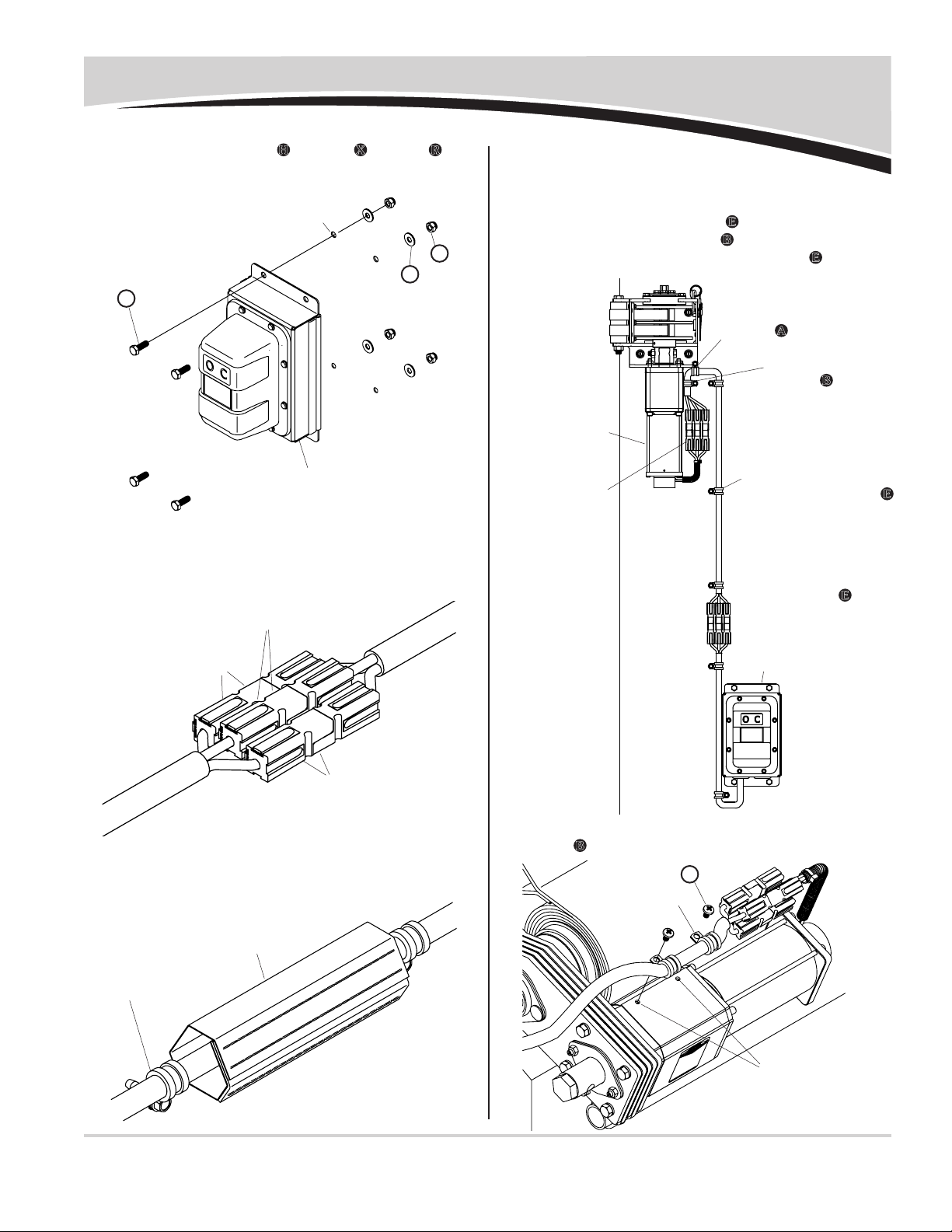

SMART1+™ Wireless Receiver - continued

CAUTION

From this point, spool, sheet and webbing

may move and become tight.

!

STEP 8: Route dual-conductor red (+) and black (-) wires to

24V power supply and connect in best way. Secure

wire with wire clips and self-drilling screws.

NOTE: For tipping trailers, route female SMARTwire™ on

box to trailer pivot, then back to 24V power supply on trailer

frame. Add circuit breaker if 24V power supply is not already

protected with one. Align breaker with red (+) lead, placing

as close as possible to power source.

SKIP TO SYSTEM SETUP.

STEP 9: Determine mounting location for wireless receiver.

NOTE: Receiver has manual switch. Locate where easily

accessible and safe to operate sheet, typically on driver side

of front skin where it can be reached without climbing on

trailer.

to 24v

power

supply

wire clips

& screws

STEP 7: Repeat steps 4 through 5 for center pole drive motor.

center pole drive motor

wireless receiver

spool drive/

motor assembly

jumper wire

STEP 10: Using holes on receiver

as guide, mark and

drill four 5mm holes as

shown.

STEP 11: Measure as

shown from

top left 5mm

hole. Mark

and drill

51mm hole.

28mm

64mm

drill

51mm

hole

5mm hole

lock pin

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

12

STEP 14: Align holes on wireless receiver with holes on trailer.

Fasten receiver to trailer with screws H, washers X

and nuts R.

STEP 13: Install 1 1/2" rubber grommet into 81mm hole. Pass

three wires through rubber grommet and align holes

in bracket with drilled holes. STEP 15: Drill hole in location shown and install rubber grommet

with 14mm ID (grommet not supplied).

SMART1+™ Wireless Receiver - continued

rubber

grommet

three

wires

hole in

bracket

drilled

hole

hole in trailer

wireless receiver

grommet

STEP 12: Pull all three wires out of rubber grommets on bottom

of receiver bracket. Insert two 1" plugs into rubber

grommets.

Verify wire lengths before drilling holes. Dual-con-

ductor red (+) and black (-) wire must reach 24V DC

power supply. Two marked 3-conductor wires must

reach junction boxes on spool motor or center pole

drive motor. Observe full motion of center pole motor

and supply enough wire for motor to reach fully open

and closed sheet positions.

H

X

R

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

13

SMART1+™ Wireless Receiver - continued

STEP 18: Route 3-conductor wire marked for spool motor

through rubber grommet and to junction box on spool

motor. Secure wire to bottom of spool bracket with

wire clip and screw D. Secure wire to trailer with wire

clips and self-drilling screws.

NOTE: Use care to

prevent damage to front

skin while securing wire

clips and drilling holes.

3-strand wire

inside of

trailer shown

grommet

wire clips

& screws

NOTE: For tipping

trailers, route female

SMARTwire™ on box to

trailer pivot, then back

to 24V power supply on

trailer frame. Add circuit

breaker if 24V power

supply is not already

protected with one. Align

breaker with red (+)

lead, placing as close

as possible to power

source.

to 24v power

supply

wire clips

& screws

STEP 16: Connect jumper wire between wireless receiver wire

mandel spool and wire conncected to spool motor.

Connect wire ends to matching colored wire ends.

white

black

green

STEP 17: Cut Velcro® cable wrap into six 6" pieces. Wrap around

wire connections. Secure wire with wire clips.

wire clip w/

self-drilling

screw

velcro®

cable wrap

velcro®cable

wrap not shown

STEP 19A:

Secure wire to motor gear with 1/2" wire clips and

screws B, fastening through existing holes in motor.

wire clip

holes in motor

STEP 20: Route dual-conductor red (+) and black (-) wires to

24V power supply and connect in best way. Secure

wire with wire-clips and self-drilling screws.

STEP 19: Repeat steps 15 to 16 for center pole drive motor,

securing wire to box with wire clips and M6 screws.

lock pin

B

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

14

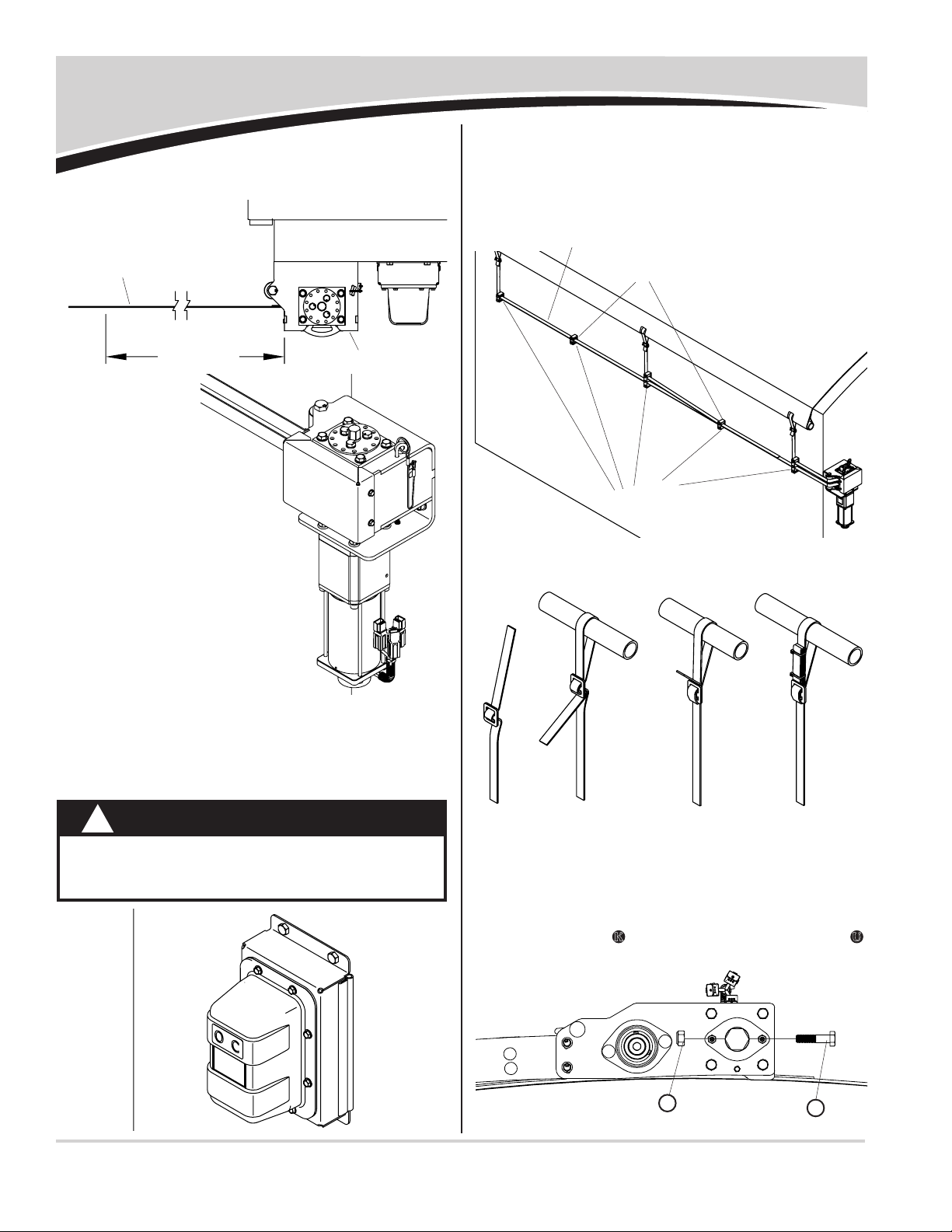

System Setup

STEP 3: Press and hold Open button on wireless receiver

to release motor breaks. Pull webbing out of spool

bracket until webbing has been unwound from spool.

Bolt marked with red end will be in this location. Two

people may be required to safely complete this step.

red mark

NOTE: Add circuit breaker if 24V power supply is not

already protected with circuit breaker. Align breaker with red

(+) lead and place as close to power source as possible.

CAUTION

From this point, spool, sheet and webbing

may move and become tight.

!

STEP 1: Unplug white quick-disconnects for motor wire from

white control box wire, for spool and center pole

motors. This will allow motor breaks to be energized

(released) without running motors.

STEP 2:

Install web guide blocks on side of box. Install at correct

height in reference to spool to extend life of webbing. Dur-

ing operation, webbing should be centered in openings

when entering spool bracket.

web

guide

block

web guide blocks

align center hole in web guide

w/notch in spool bracket

spool

bracket

fasten web

guide to

trailer as

shown

Item Part # Description

1. 1705554 Webbing Strap Guide - Large

2. 1705553 Webbing Strap Guide - Small

3. 1124992 Webbing Strap Guide Plate - Large

4. 1124989 Webbing Strap Guide Plate - Small

K. 1705357 Cap Screw - M10 x 45 - GD10

L. 1705556 Cap Screw - M10 x 65

T. 1705555 Nylon Lock Nut - M10

U. 1705361 Nylon Lock Nut - M10 - GD10.9

a. 1701176 Flat Washer - 3/8"

1

3

4

2

K

U

L

a

T

La

T

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

15

System Setup - continued

STEP 7: Thread webbing through guides and secure webbing

to pull tube. Do not cut webbing to length at this time.

Connection may need to be adjusted but should be

secured to take full torque of motor.

webbing

web guide

blocks

these two web guides maybe be

positioned higher on trailer to

reduce wind whip during travel

STEP 8: Reconnect white quick-disconnect for center pole

motor. Quickly press and release Open button on

wireless receiver until hole in center pole motor is

lined up with hole in drive sprocket. Insert M10 x 45

cap screw K and secure with M10 nylon lock nut U.

STEP 6: Reconnect white quick-disconnect for spool motor

wire. Press and hold close button. Allow webbing to

roll up on spool until 2430mm mark reaches bracket.

Two people may be needed to safely complete this

step.

STEP 4:

Stretch webbing and mark 2540mm from spool bracket.

STEP 5: Fasten spool bracket

cover to spool brack-

et with four M5 x 12

anged screws.

WARNING

Use extreme caution working by spool. Keep

hands and fingers clear of all moving parts

and pinch points.

!

2540.0mm

webbing

spool bracket

SECURE WEBBING TO PULL TUBE

step 1 step 2 step 3 step 4

K

U

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

16

System Setup - continued

STEP 11: With sheet still in fully open position, release webbing

clamps (not supplied) and remove all slack from web-

bing and sheet. Re-secure webbing.

STEP 12: Connect any quick-disconnects that were discon-

nected in previous steps. Open and close sheet using

Open and Close buttons and review operation.

NOTE: During operation, webbing and spool will unwind

until all of webbing is unwound and will act as stop. This will

be fully open location of sheet.

STEP 13: If adjustments are needed, close sheet, disconnect

center pole motor wire from white control wire and

press and hold Open button. Pull some webbing from

spool and release button. Release webbing clamps

and make necessary adjustments. Re-secure clamps.

STEP 14: Connect quick-disconnects and verify operation.

STEP 10: Unplug white quick-disconnect for motor wire on cen-

ter pole motor. Press and hold Open button, this will

release motor breaks. Unwind any remaining webbing

from spool until marked bolt is in far left location. Two

people may be needed to safely complete this step.

STEP 9: Press and hold Open button until center pole reaches

fully open position, just short of reaching sheet stops.

This will protect sheet from damage from rubbing

against stops.

NOTE:

Stop center pole early if you would prefer to prevent

center pole arm assembly from hanging past side of box.

roll-over

bracket

center pole

stop center pole short

of roll-over bracket

NOTE: As a nal check, run sheet open and closed in

Express Mode. System should stall when fully open

and fully closed. One second after stalling, SMART3™

electronics will disconnect power to motors. You can check

this by stalling motor in open and closed positions and listen

carefully for solenoid under black wireless receiver cover to

click after one second of stall.

SMART3™ Operator’s Instruction Guide and ShurCover™

Operating Instructions are available on our web site:

http://www.shurco.co.uk.

UK HELP LINE: +44 (0) 1795 473499

P/N 1127925

Replacement Parts

17

SHEET COMPONENTS

Item Part # Description

1. 1123980 Center Pole Plug - UK

2. 1700398 Self-Drilling Screw - 1/4" x 3/4"

3. 1701354 U-Clamp

4. ______ Center Pole

5. ______ Pulling Bar

6. ______ Fixing Bar

7. ______ Sheet (not shown)

2

1

3

4

6

5

SYSTEM SETUPS

Item Part # Description

1125374 Webbing Guide Kit - Single

(Includes 2, 4, 2 of 5, 6 & 7)

1125375 Webbing Guide Kit - Double

(Includes 1, 3, 3 of 5, 6 & 7)

1. 1705554 Webbing Strap Guide - Large

2. 1705553 Webbing Strap Guide - Small

3. 1124992 Webbing Strap Guide Plate - Large

4. 1124989 Webbing Strap Guide Plate - Small

5. 1705556 Cap Screw - M10 x 65

6. 1705565 Nylon Lock Nut - M10

7. 1701176 Flat Washer - 3/8"

8. 1805587 Front Strap - 6m

9. 1805588 Rear Strap - 12m

10. 1805589 Rear Strap - 18m

1

3

4

2

6

7

5

8910

Table of contents

Other Shurco Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Hoffmann

Hoffmann monty 2300 Operation manual

DEFA

DEFA eConnect user manual

DEFA

DEFA 411102 Fitting instructions

Whispbar

Whispbar K693W Fitting instructions

AEM Performance Electronics

AEM Performance Electronics 2001-2005 Honda K Series instruction manual

Renault

Renault 77 11 423 432 installation instructions