Shurco 4500 HD Series User manual

Aluminum System for Grain Trailers

reverse roll

P/N 1122107 Rev. P

Shur-Co®, LLC Terms & Conditions

SHIPPING. Orders are shipped F.O.B. from the Shur-Co®, LLC sites listed be-

low. No full freight is allowed or prepaid shipment accepted unless quoted and

approved in writing prior to acceptance of the order. All shipments are made

by the most reasonable means in accordance with size and weight of order,

unless specifi ed routing instructions are furnished by the customer. Shipments

are made daily via U.P.S. and common carrier. Claims for shortages must

be made within 10 days. All claims for damages or loss in transit must be

made with the carrier. No collect calls will be accepted. To ensure delivery of

orders, we need your full street address and phone number. When you receive

your shipment, examine it carefully. Be sure all cartons listed on the delivery

sheet are accounted for. Large items may be packaged separately. If a carton

is damaged, open it and inspect the contents before signing for delivery. If

merchandise is damaged, describe damage on the delivery receipt. Failure

on your part to document damaged or missing merchandise on the delivery

receipt releases the carrier of all liability; repair or replacement will be the

customer’s responsibility.

WARRANTY. We warrant all new products are free of defects in materials and

workmanship.* This warranty is effective if products are properly installed and

used for the purpose for which they were intended and applies to the original

buyer only. Except as set forth above or in any product-specifi c warranty docu-

mentation, we make no other warranties, express or implied, including but not

limited to warranties of merchantability of fi tness for a particular use.

Returns of a product for warranty must be accompanied by a Return Merchan-

dise Authorization number (RMA#), obtained by by calling Customer Service

at 866-748-7435, and sent, with freight paid by us, to Shur-Co®, LLC, 2309

Shur-Lok St., PO Box 713, Yankton, SD 57078. All products returned without

an RMA# will be refused. When we issue the RMA#, we will also issue a call

tag to have UPS (or other freight company) pick up the product. C.O.D. returns

not accepted. We will pay no storage fees for a warranty product return prior

to pick by us or the freight company. If a warranty product return is scheduled

to be picked up by us, we will pick up the product at our earliest convenience.

If a product returned is found, in our judgement, to be defective in material

or workmanship, our obligation under this warranty is limited to the repair or

replacement of the product, which will be made by us. Repair or replacement

will be at our discretion, with replacements being made using current products

performing in the equivalent function. Labor charges, other than those incurred

at our factory, including, but not limited to, any labor to install a repaired or re-

placement product, are not covered under this warranty. All expenses associ-

ated with delivering defective products to our factory and delivering repaired or

replacement products from our factory to the owner will be paid by us.

If the product returned is found, in our judgement, to be non-warrantable, the

owner will be contacted to authorize repair work, purchase of a replacement

product or return of the product, all of which will be at the owner’s expense.

Payment authorization must be received by us before any non-warrantable

product is repaired, replaced or returned. All expenses associated with deliver-

ing the repaired non-warrantable product, a replacement product or the non-

warrantable product from our factory to the owner will be paid by the owner.

In no event will we be liable for any damages of any kind to person, product or

property, including but not limited to indirect, incidental, special, consequential

or punitive damages, or damages for loss of profi ts or revenue, even if we

have been advised of the possibility of such damages. There are no warran-

ties for used products or products that have been repaired, altered, modifi ed

or subjected to misuse, negligence or accident. We will not repair or replace

products that fail or malfunction due to ordinary wear and tear, except as ex-

pressly noted in a product-specifi c warranty. Use of non-Shur-Co®, LLC parts

in conjuction with Shur-Co®, LLC products will void this product warranty.

*Certain products have specifi c warranties that differ from this warranty, for example motors and elec-

tronics. Product-specifi c warranty documentation is available for these items. In the event of a confl ict

between this warranty and a product-specifi c warranty, the product-specifi c warranty will govern.

RETURN POLICY. All sales fi nal. See WARRANTY above for return details.

OTHER. All prices, product listings, sizes, weights and manufacturing details

are subject to change without notice. No person is authorized to modify the

foregoing conditions of sale whatsoever.

SHUR-CO®, LLC SERVICE AND DISTRIBUTION CENTERS

Corporate HQ and Outlet Store

SHUR-CO® of SOUTH DAKOTA

2309 Shur-Lok St., PO Box 713, Yankton, SD 57078

Ph 800.474.8756 | Fax 605.665.0501

SHUR-CO® of FLORIDA

3353 SE Gran Park Way, Stuart, FL 34997

Ph 800.327.8287 | Fax 772.287.0431

SHUR-CO®of IDAHO

610 N. 16th Ave., Caldwell, ID 83607

Ph 866.356.0246 | Fax 217.877.8270

SHUR-CO® of ILLINOIS

3993 E. Mueller Ave., Decatur, IL 62526

Ph 866.356.0246 | Fax 217.877.8270

SHUR-CO®of NORTH DAKOTA

1746 4th Ave. NW, West Fargo, ND 58078

Ph 877.868.4488 | Fax 701.277.1283

SHUR-CO®of OHIO

4676 Lynn Rd.

Rootstown, OH 44266

Ph 866.356.0242 | Fax 330.297.5599

SHUR-CO® of VERMILLION

1212 N. Norbeck St., Vermillion, SD

Ph 800.474.8756 | Fax 605.665.0501

SHUR-CO®of CANADA

490 Elgin St., Unit #1

Brantford, Ontario N3S 7P8

Ph 800.265.0823 | Fax 519.751.3997

SHUR-CO®UK, Ltd.

Unit 41 Rochester Airport Estates

Laker Rd., Rochester, Kent ME1 3QX

Ph +44 (0)1795.473499

Fax +44 (0)871.272.8278

For more information, log on to our website:

www.shurco.com

P/N 1122107 Rev. P

Thank you for buying this tarping system from Shur-Co®. We appreci-

ate your condence in our products. Please read and thoroughly un-

derstand this manual before installing and/or operating this system.

Pay particular attention to important safety and operating instructions,

as well as warnings and cautions. The hazard symbol is used

to alert users to potentially hazardous conditions and is followed by

caution, warning or danger messages.

Failure to READ AND FOLLOW INSTRUCTIONS could result in fail-

ure of your tarping system and/or personal injury. Your trailer require-

ments may, however, call for minor variations to these instructions.

Please inspect your tarping system periodically. Repair or replace

worn or damaged parts to your system.

QUESTIONS? CALL OUR HELP LINE:

1-866-748-7435

MON-FRI 8 AM-5 PM CENTRAL TIME

We at Shur-Co® are concerned with your safety and the safety of all

those operating this system. Therefore, we have provided safety de-

cals at various locations on your tarping system. Keep decals as clean

as possible at all times. Replace any decal that has become worn

or damaged, painted over or otherwise difcult to read. Replacement

decals are available through Shur-Co® dealers.

To prevent rust, paint all exposed metal, such as weld seams and/or

metal exposed by grinding or cutting, with corrosion-resistant paint.

4500 Series HD for Semi Grain Trailer - Reverse Roll

P/N 1122107 Rev. P

Hardware Identication.......................................................................1

Pivot Bracket Installation Front & Rear............................................2-5

Pivot Bracket Installation ....................................................................6

Front Flex Arm & Electric Motor Installation ....................................7-8

Rear Flex Arm Installation - 2" Roll Tube.......................................9-10

Rear Flex Arm Installation - 3" Roll Tube.....................................11-12

2" Roll Tube Extension Installation ..............................................13-15

3" Roll Tube Extension Installation ..............................................16-18

Electric Mounting & Wiring ..........................................................19-24

Operation..........................................................................................25

Conversion to Manual Power ...........................................................26

Electric Motor Replacement .............................................................27

Replacement Parts......................................................................28-32

1. Welder

2. Hammer

3. Center Punch or Transfer Punch

4. #3 Phillips Insert Bit

5. Air or Electric Impact Wrench (9/16” deep socket)

6. 7/16" Deep Socket

7. 3/8" Combination Wrench

8. 9/16" Combination Wrench

9. 1/2" Combination Wrench

10. 1/8" Hex Wrench Long T-Handle

11. 3/16" Hex Wrench Long T-Handle (recommended)

12. 7/32" Drill Bit

13. 5/16" Drill Bit (for 3/8” self-tapping screws)

14. 11/32" Drill Bit

15. 13/32" Drill Bit

16. 3/8" Drill

17. 1 1/8" Hole Saw

18. 1 1/2" Hole Saw

19. 2" Hole Saw (if bracket for conductor socket is not used)

20. Standard/Flathead Screwdriver

21. #2 Phillips Screwdriver

22. Utility Knife

23. Ratchet

24. Hack Saw (metal cutter)

25. Pliers

26. Snap-Ring Pliers

27. Wire Cutters

28. Grinder

29. Tape Measure

!

TOOLS REQUIRED

RUST PREVENTION

SAFETY

MESSAGE TO OWNERS TABLE OF CONTENTS

1. Always wear safety glasses during installa-

tion and operation.

2. Stay clear of moving parts.

3. No other use of this system is authorized,

except as designed.

SAFETY INSTRUCTIONS

P/N 1122107 Rev. P

1

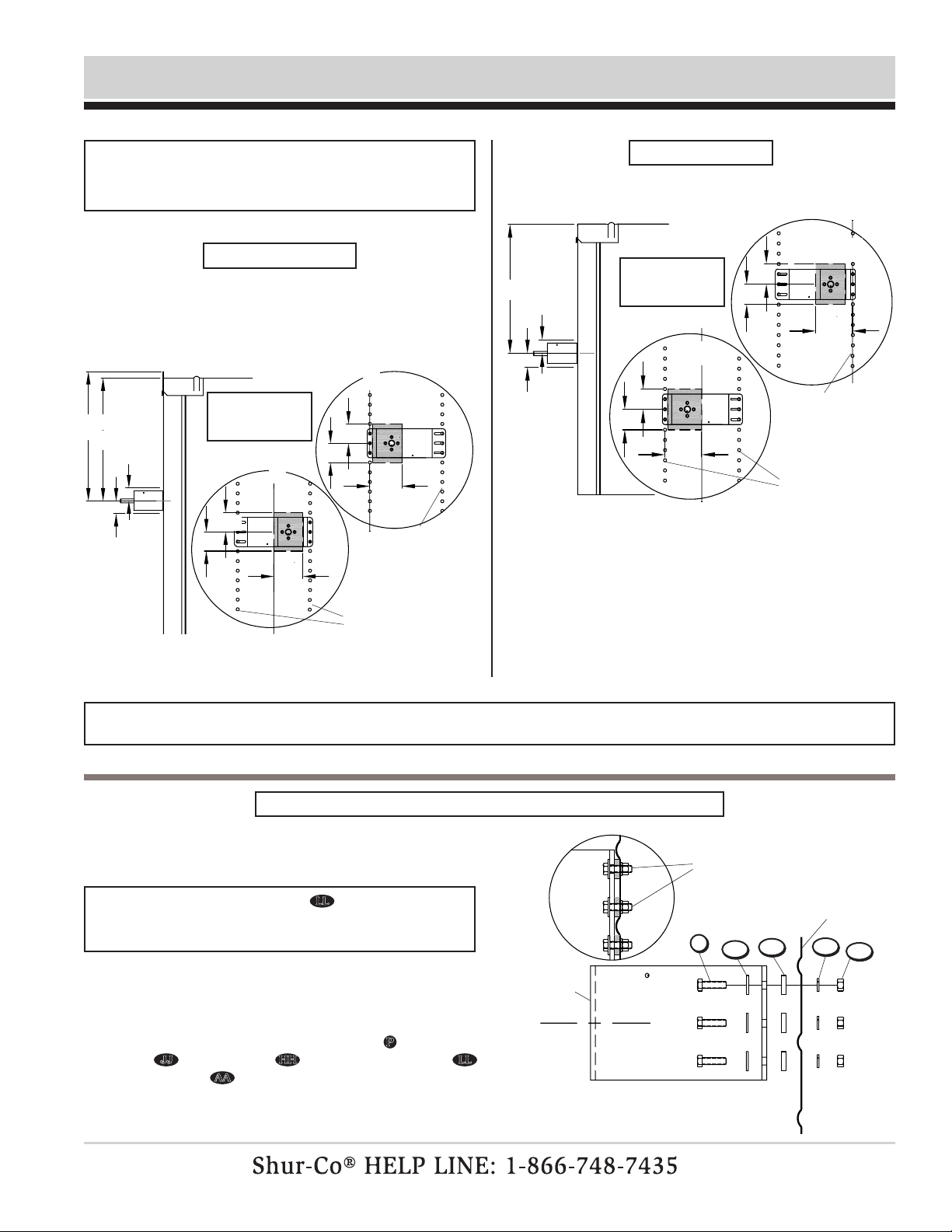

Hardware Identication

1704946 Flanged Top Lock Nut - 5/16"

1700429 Flat Washer - 3/8"

1701455 Carriage Bolt - 5/16" x 2 1/2"

1700419 Nylon Lock Nut - 5/16"

1701045 Cap Screw - 5/16" x 3/4"

1700407 Hex Nut - 3/8"

1700434 Lock Washer - 3/8"

1118318 Spacer Washer - 1/4" x 1.81"

1201022 Cap Screw - 5/16" x 3 1/2"

1702890 Flat Washer - 1 1/4"

1701543 Nylon Lock Nut - 1/4"

1700408 Hex Nut 1/4"

1700427 Flat Washer - 1/4"

1700428 Flat Washer - 5/16"

1701580 Nylon Lock Nut - 3/8"

1704905 Hex Flanged Cap Screw #10 x 1"

1703959 Cap Screw 1/4" x 3/4"

1702926 Cap Screw - 5/16" x 7/8"

1120291 Pivot Bracket Washer

1704367 Cap Screw - #10 x 3/4"

1704905 Flanged Cap Screw - #10 x 1"

1808844 Nylon Lock Nut - #10

1700436 Lock Washer - 1/4"

1704931 Flanged Nylon Lock Nut - 5/16"

1704297 Nylon Lock Nut - 5/16"

1702668 Top Lock Nut - 3/8"

AR

S

T

U

V

W

X

Y

Z

B

C

D

E

F

G

H

J

K

L

M

N

P

Q

FF

GG

HH

JJ

KK

LL

DD

EE

AA

BB

CC

1705198 Self-Drilling Screw - 1/4" x 1"

1700403 Self-Tapping Screw - 1/4" x 3/4"

1704338 Self-Tapping Screw - 1/4" x 1"

1700398 Self-Drilling Screw - 1/4" x 3/4"

1702891 Cap Screw - 3/8" x 1 1/4"

1700400 Self-Tapping Screw - 3/8" x 1"

1704264 Cap Screw - 3/8" x 2" - Grade 8

1704943 S

houlder Bolt - 3/8" x 2

- 5/16" x 1/2" Thd

.

1704237 Carriage Bolt - 3/8" x 2"

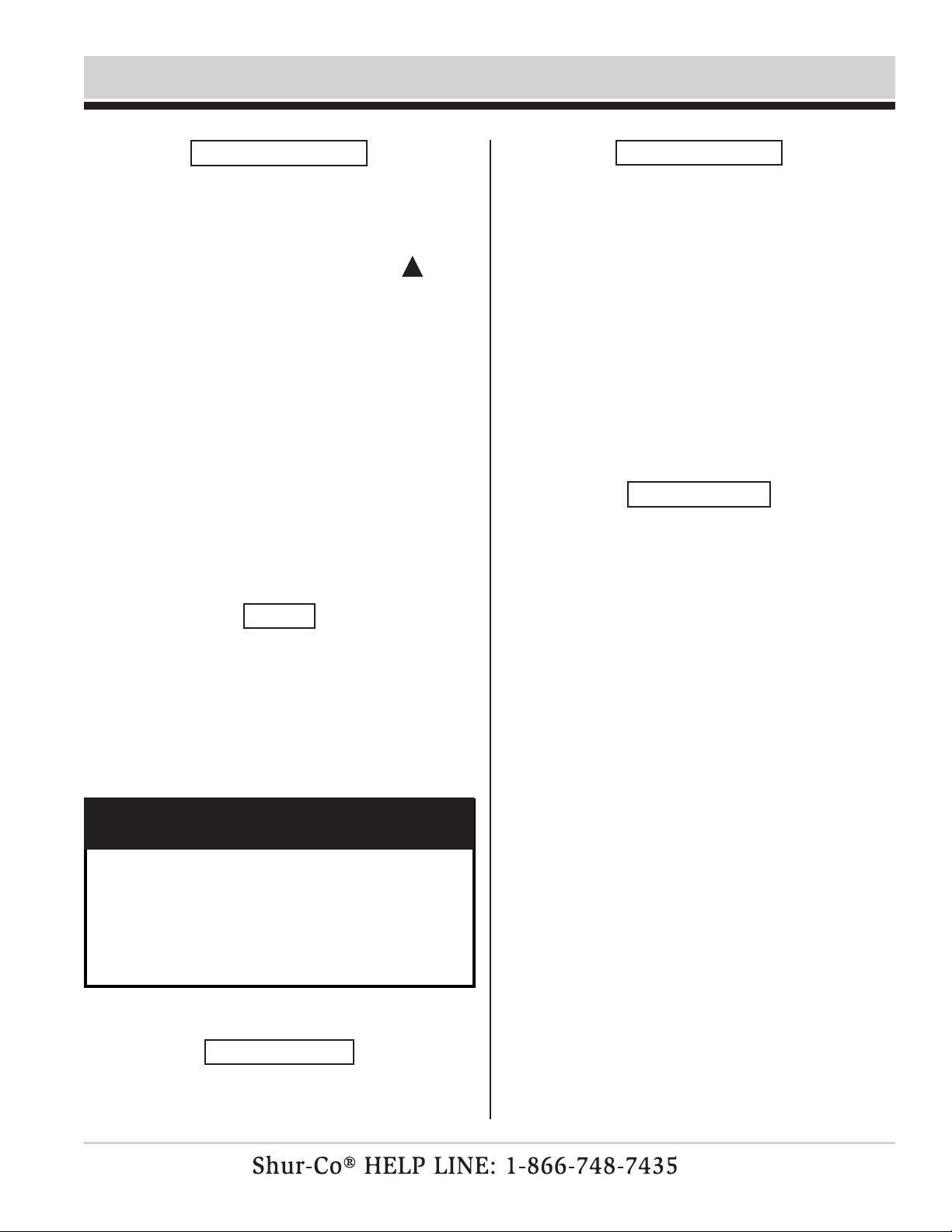

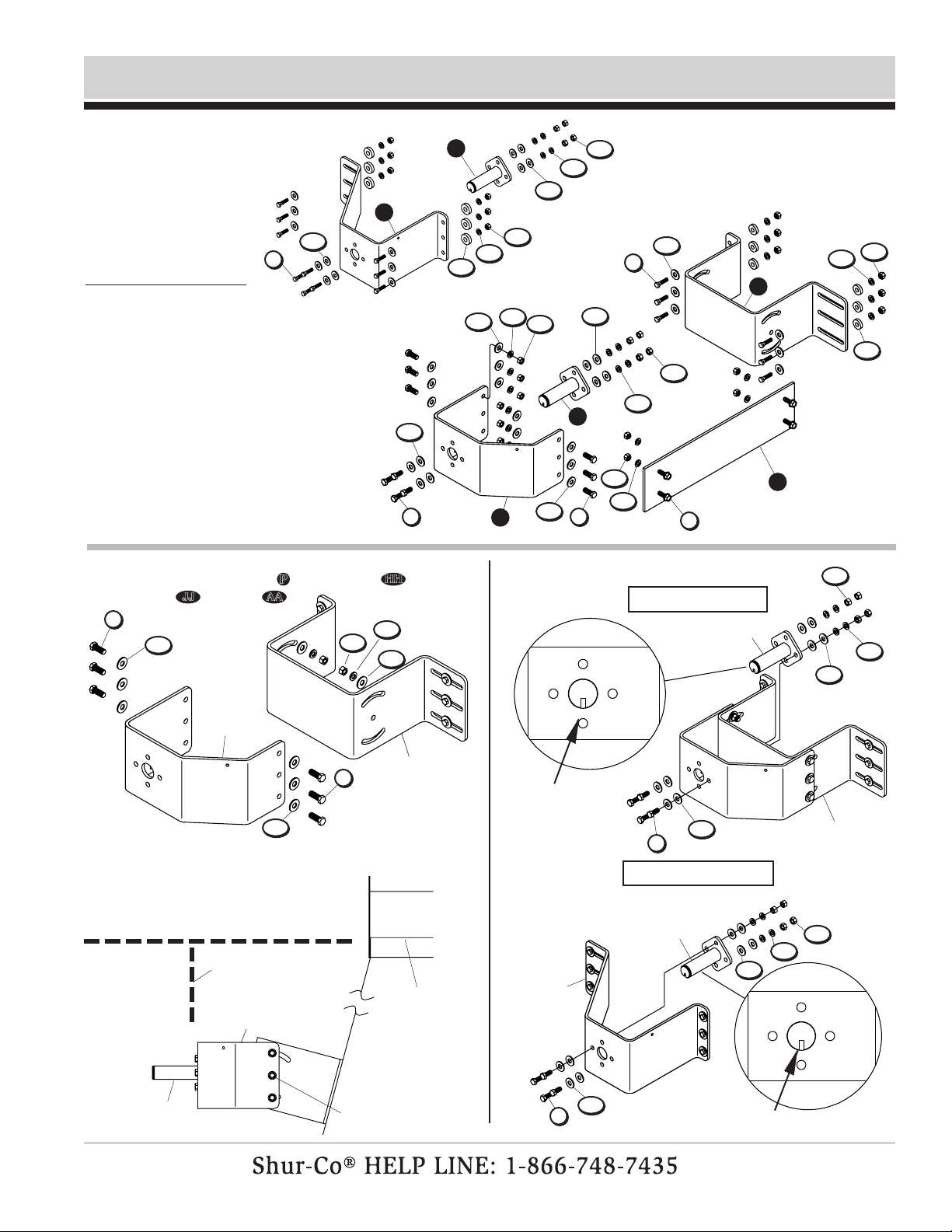

P/N 1122107 Rev. P Pivot Bracket Installation - Vertical Trailer - Reverse Roll

NOTE: Mount brackets into support braces on trailer, if possible. If bracket cannot be mounted into support braces, reinforce

mounting area with backer plate for adequate support. Before drilling any holes, make sure ex arm has clear pathway to operate.

NOTE: Read pages 2 and 3 entirely before drilling holes.

Determine if rivets are centered or off center on front and

rear of trailer.

NOTE: Use pivot bracket washers LL only when horizontal

corrugation on trailer skin prevents bracket from contacting

trailer skin.

STEP 1: If installing pivot bracket or pivot mount bracket on

horizontally corrugated trailer skin, use brackets as

guide to mark hole locations. Mark and drill 13/32”

holes in trailer and fasten with screws P, at washers

JJ , lock washers HH , pivot bracket washers LL

and nuts AA . Locate pivot bracket washers between

pivot bracket and trailer skin as shown.

pivot

bracket

corrugated

trailer skin

locate pivot bracket

washers between

pivot bracket &

trailer skin

INSTALL BRACKETS ON HORIZONTALLY CORRUGATED TRAILERS

4”

4”

6”

rivets off

center

STEP 2: Locate rear pivot mount bracket so center of pivot lies

within shaded area shown below.

STEP 1: Locate front pivot mount bracket on driver side of

trailer so center of pivot lies within shaded area shown

below. Measure 41" down from top of cap or 43" from

top of windshield.

4"

4"

41"

4"

4"

6"

4”

4”

41”

4"

4"

6"

rivets on

center line

rivets off

center

6”

4”

4”

rivets on

center line

43"

c

l

locate center

of pivot inside

shaded area

c

l

c

l

c

l

locate center

of pivot inside

shaded area

FRONT OF TRAILER

REAR OF TRAILER

2

PAA

HH

JJ LL

P/N 1122107 Rev. P

3

Pivot Bracket Installation - Vertical Trailer - Reverse Roll - cont’d

STEP 3:

Place pivot mount

brackets on trailer as shown below.

Using brackets as guide, mark mounting hole loca-

tions.

STEP 4:

Remove rivets and mount brackets into rivet holes.

If not possible, drill 13/32" holes in trailer. Fasten with

screws

P

, at washers

JJ

, lock washers

HH

, pivot

bracket washers

LL

and nuts

AA

.

center of

trailer

c

l

c

l

c

l

c

l

RIVETS/CORRUGATION OFF CENTER

RIVETS/CORRUGATION ON CENTER

RIVETS/CORRUGATION OFF CENTER

RIVETS/CORRUGATION ON CENTER

FRONT OF TRAILER

REAR OF TRAILER

P

P

P

P

AA

AA

AA

AA

HH

HH

HH

HH

JJ

JJ

JJ

JJ

LL

LL

LL

LL

P/N 1122107 Rev. P

4

Front Bracket Installation - Sloped Trailer - Reverse Roll

NOTE: Mount brackets into support braces on trailer, if

possible. If bracket cannot be mounted into support braces,

reinforce mounting area with backer plate for adequate support.

If bracket does not sit ush with skin of trailer, install spacers

between mounting bracket and skin of trailer to assure solid

contact through support braces or backer plate.

Before drilling any holes, make sure ex arm has clear

pathway to operate.

STEP 4: Drill 13/32" holes in trailer. Fasten sloped pivot mount

bracket to trailer with screws P, at washers JJ , lock

washers HH and nuts AA .

3"

3"

41"

STEP 2: Locate sloped pivot mount bracket 41" below top of

cap, measuring vertically as shown. Do not measure

along slope of trailer.

3"

3"

41"

STEP 3: Place pivot mount brackets on trailer as shown below.

Using brackets as guide, mark mounting hole locations.

c

l

center of

trailer

43"

3"

3"

3"

6"

6"

3"

3"

3"

3"

3" 6"

6"

STEP 1: Locate sloped pivot mount bracket 41” down from top of

cap or 43” from top of windshield, measuring vertically

as shown. Do not measure along slope of trailer.

c

l

c

l

c

l

c

l

c

l

c

l

c

l

RIVETS/CORRUGATION OFF CENTER

RIVETS/CORRUGATION ON CENTER

RIVETS/CORRUGATION OFF CENTER

RIVETS/CORRUGATION ON CENTER

NOTE: Use pivot bracket washers LL only when horizontal

corrugation on trailer skin prevents bracket from contacting

trailer skin (see instructions on page 2).

NOTE: Read entire page before drilling holes. Determine if

rivets are centered or off center on front and rear of trailer.

FRONT OF TRAILER

FRONT OF TRAILER

REAR OF TRAILER

REAR OF TRAILER

P

P

P

P

AA

AA

AA

AA

JJ

JJ

JJ

JJ

HH

HH

HH

HH

LL

LL

LL

LL

P/N 1122107 Rev. P

5

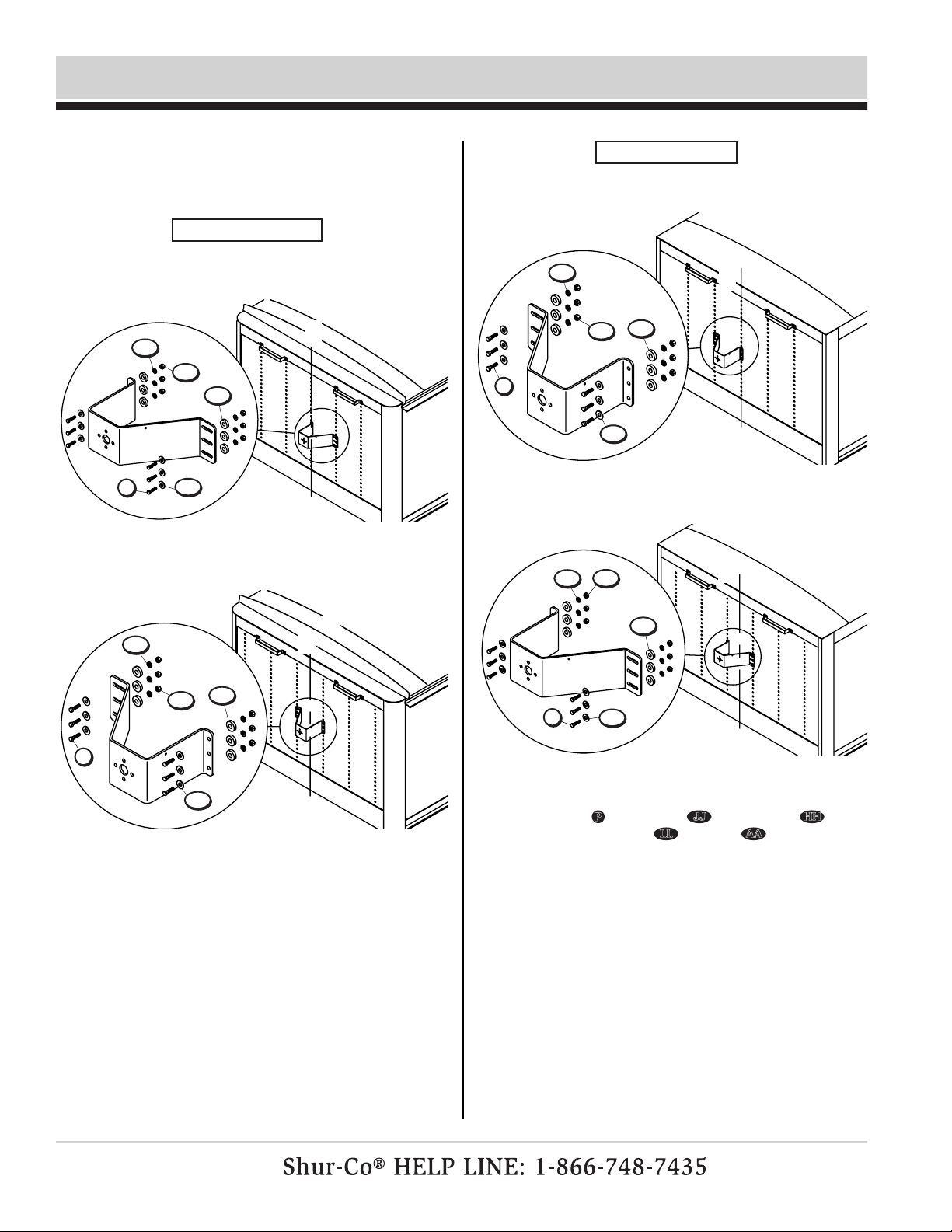

Pivot Bracket Installation - Sloped Trailer - Reverse Roll

STEP 5: Place pivot brackets on pivot mount brackets ias

shown below. Fasten pivot brackets to pivot mount

brackets with screws P, at washers JJ , lock wash-

ers HH and nuts AA .

RIVETS/CORRUGATION OFF CENTER

RIVETS/CORRUGATION ON CENTER

RIVETS/CORRUGATION OFF CENTER

RIVETS/CORRUGATION ON CENTER

c

l

c

l

c

l

c

l

center of

trailer

FRONT OF TRAILER

REAR OF TRAILER

P

P

P

P

AA

AA

AA

AA

HH

HH

HH

HH

JJ

JJ

JJ

JJ

JJ

JJ

JJ

JJ

P/N 1122107 Rev. P

6

Pivot Bracket Installation - Reverse Roll

Item Part # Description

1. 1116920 Pivot Pin - 4 Spring

2. 1120361 Pivot Backer Plate - 5" x 16"

1120418 Pivot Backer Plate - 5" x 20"

3. 1121993 Sloped Pivot Mt. Bracket -

6" Standoff - 6" Wide

1121994 Sloped Pivot Mt. Bracket -

8" Standoff - 6" Wide

4. 1121992 Pivot Bracket - Sloped - 6" Wide

5. 1116919 Vertical Pivot Mount Bracket -

7-1/4" Standoff

1117031 Vertical Pivot Mount Bracket -

9-1/4" Standoff

N. 1700400 Self-Tapping Screw - 3/8" x 1"

P. 1702891 Cap Screw - 3/8" x 1-1/4"

AA. 1700407 Hex Nut - 3/8"

HH. 1700434 Lock Washer - 3/8"

JJ. 1700429 Flat Washer - 3/8"

LL. 1120291 Pivot Bracket Washer

STEP 1: Align and loosely fasten pivot bracket to pivot mount

bracket with screws P, lock washers HH , at wash-

ers JJ and nuts AA .

pivot mount

bracket

pivot

bracket

STEP 2: Align face of pivot bracket vertically and align pivot

pin parallel with top rail of trailer, then tighten screws.

align face of

pivot bracket

vertically

align pivot pin parallel

pivot pin

pivot bracket

top rail

of trailer

tighten screws

pivot

bracket

pivot pin

pivot bracket

assembly

pivot pin

STEP 3: Fasten pivot pins to pivot brackets.

1

2

3

4

1

5

keyway in pivot

pin must face

downward

keyway in pivot pin

must face downward

SLOPED TRAILER

VERTICAL TRAILER

N

N

P

P

P

P

P

P

P

AA

AA

AA

AA

AA

AA

AA

AA

AA

HH

HH

HH

HH

HH

HH

HH

HH

HH

JJ

JJ

JJ

JJ

JJ

JJ

JJ

JJ

JJ

JJ

JJ

JJ

JJ

LL

LL

P/N 1122107 Rev. P

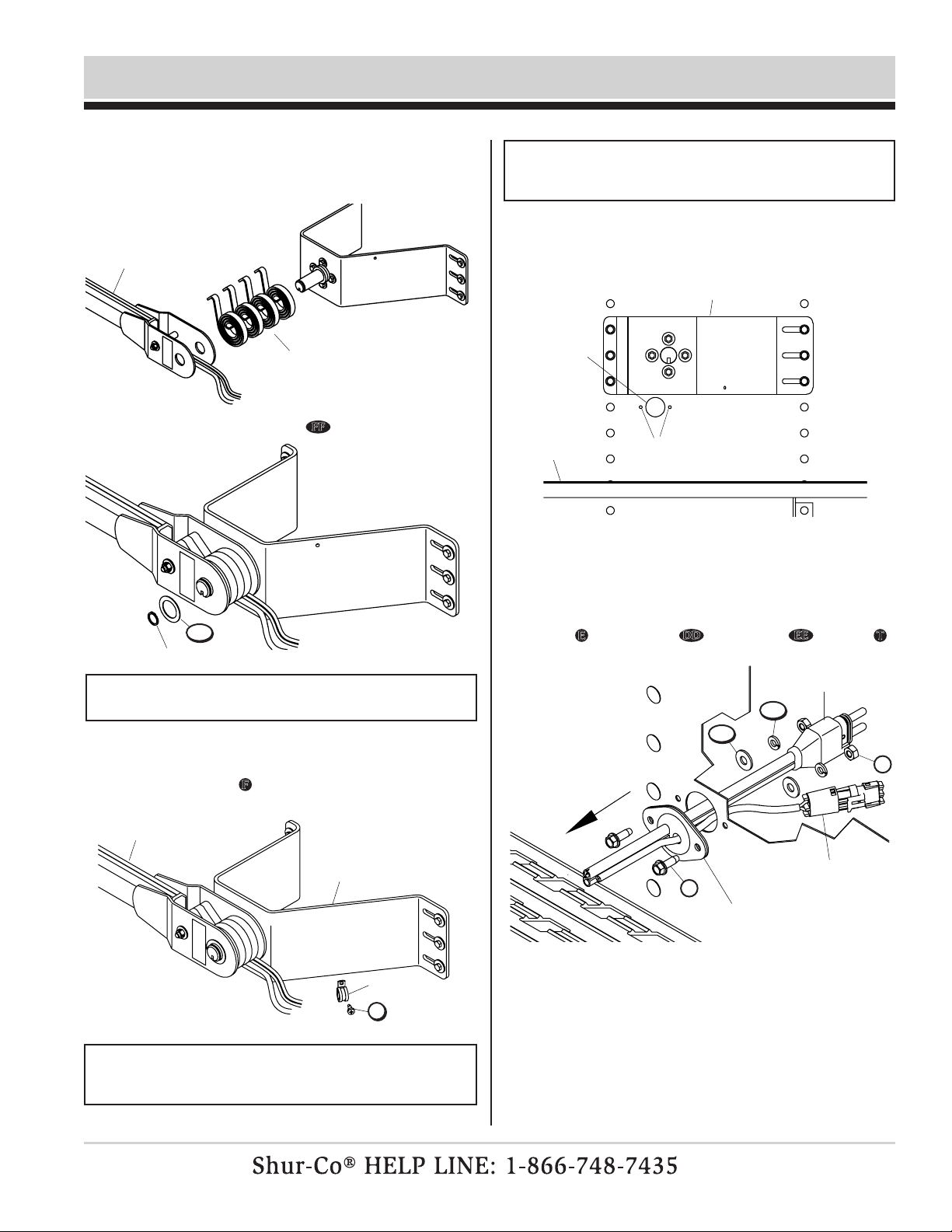

Item Part # Description

1. 1111027 Spiral Torsion Spring

2. 1702888 External Retaining Ring - 1-1/4"

3. 1704987 SMARTwire™ - 6 Ga. Plug x

1/4" Terminal x 10'9"

4. 1704751 Harness Lock Pin - 1/4" x 7/8"

5. 1702108 Wire Clip - 3/4" ID

6. 1121414 Bellow Plate - Square Holes

7. 1121413 Bellow Plate - Round Holes

8. 1704893 Cap Plug w/Holes

E. 1700403 Self-Tapping Screw - 1/4" x 3/4"

F. 1700398 Self-Drilling Screw - 1/4" x 3/4"

L. 1701455 Carriage Bolt - 5/16" x 2-1/2"

V. 1700408 Hex Nut - 1/4"

AA. 1704931 Flanged Nylon Lock Nut - 5/16"

DD. 1700436 Lock Washer - 1/4"

EE. 1700427 Flat Washer - 1/4"

FF. 1702890 Flat Washer - 1 1/4"

KK. 1118318 Spacer Washer - 1/4" x 1.28"

7

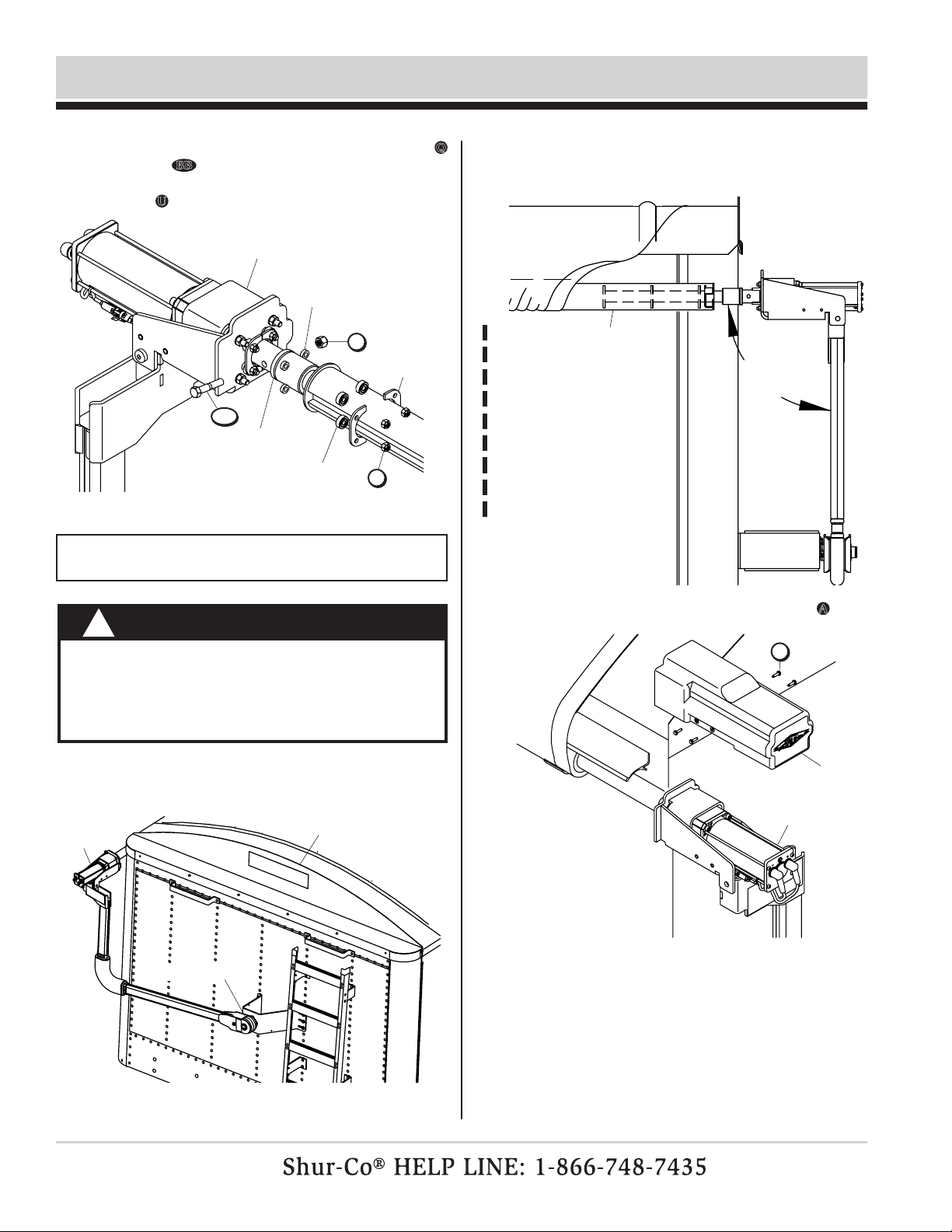

Front Flex Arm & Electric Motor Installation - Reverse Roll

pivot mount

bracket assembly

2

1

STEP 1: Assemble spacer washers KK onto pivot pin.

pivot pin

4

3

5

7

6

8

bellow plate

w/round holes

lower flex arm

flex arm

assembly

w/motor

STEP 2: Align holes in bellow, end

plates and bellow plates

with holes in lower ex arm

assembly as shown. Fasten

with carriage bolts L and lock

nuts X.

bellow plate

w/square holes

NOTE: Do not remove cable tie

from front ex arm and motor

assembly until installation is

complete. See step 9.

WARNING

Do not stand or climb on flex arm. Standing or climb-

ing on flex arm could result in fall/impact causing

serious injury or death.

!

X

E

F

L

L

V

AA

DD

EE

FF

KK

KK

P/N 1122107 Rev. P

8

Front Flex Arm & Motor Installation - Reverse Roll - cont’d

NOTE: Motor assembly on upper ex arm must face toward

trailer as shown.

STEP 7: Align wire plate assembly with 1 1/2" hole. Using

wiring hole as guide, mark and drill two 7/32" holes

as shown.

STEP 6: Measure 11" horizontally from center line of trailer and

1" down from lower edge of pivot bracket. Mark and

drill 1 1/2" hole through trailer skin.

drill

1 1/2"

hole

catwalk drill two

7/32" holes

pivot bracket

STEP 8:

Fasten wire plate assembly to front of trailer with screws

E

, lock washers

DD

, at washers

EE

and nuts

T

.

NOTE: Wire lengths are predetermined. Before installing

SMARTwire™ components, review and conrm wire routing

so wires reach components with ample room for

connection.

STEP 5: Route 6-ga. wire from ex arm through trailer skin.

Fasten wire to pivot bracket with wire clip and self-

drilling screw F in location shown.

NOTE: Fasten wire clip with self-drilling screw on opposite

side of pivot bracket from ex arm to prevent wire from being

pinched during operation.

flex arm

pivot bracket

wire clip

STEP 4: Secure with at washer FF and retaining ring.

retaining ring

STEP 3: Assemble spiral torsion springs and lower ex arm

onto pivot pin. Hook springs over spacer tube.

spiral torsion springs

lower flex arm

smartwire™ plug

E

T

to motor/arm

encoder wire

wiring plate assembly

STEP 9: Remove cable tie from front arm/motor assembly

before operating system.

F

DD

EE

FF

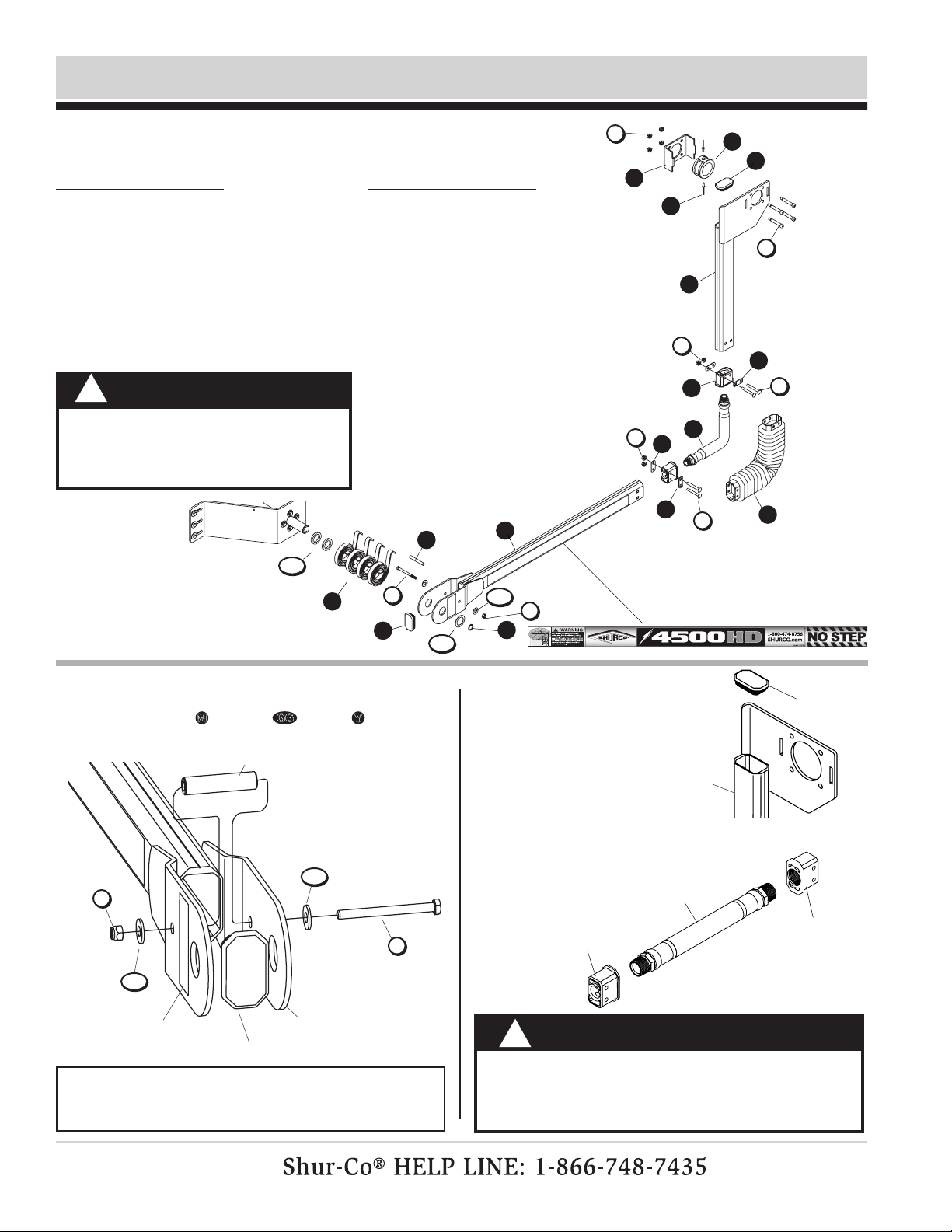

P/N 1122107 Rev. P

9

Rear Flex Arm Installation - 2" Roll Tube - Reverse Roll

STEP 1: Install cap plug on lower ex arm. Fasten spacer tube

into spring support bracket on lower ex arm with

screw M, two at washers GG and nylon lock nut Z.

spring support bracket

on lower flex arm

NOTE: Insert cap screw through ex arm so head of screw

is on inside of assembly (towards trailer). Warning label must

be in plain view on outside of assembly.

cap plug

spacer tube

STEP 2: Install cap plug on

rear upper ex arm.

cap plug

upper flex arm

STEP 3: Thread end ttings onto both ends

of ex arm joint. Tighten so end

ttings are parallel.

flex arm joint

end

fitting

end fitting

1

2

3

4

5

6

7

8

9

10

11

12

13

3

WARNING

Flex arms are under tension while torsion springs are

engaged. Use caution while assembling and disas-

sembling arms. Failure to read and follow instructions

could result in serious injury or death.

!

Item Part # Description

1. 1704942 Rear Arm Bearing Ring

2. 1121430 Bearing Mount Box

3. 1704892 Cap Plug

4. 1121281 Upper Flex Arm - Bearing - RR

5. 1121413 Bellow Plate - Round Holes

6. 1121414 Bellow Plate - Square Holes

7. 1703873 Flex Arm Joint

8. 1704775 Bellow - HD Series Arm

9. 1704891 End Fitting

10. 1122000 Lower Flex Arm w/Warning Decals

11. 1702888 Retaining Ring - 1-1/4"

12. 1117033 Spacer Tube - .35" x 2-5/8"

14

Item Part # Description

13. 1111027 Spiral Torsion Spring

14. 1706103 Blind Rivet - 3/16"

L. 1701455 Carriage Bolt - 5/16" x 2-1/2"

S. 1704943 Shoulder Bolt - 3/8" x 2" -

5/16" x 1/2" Thd.

M. 1201022 Cap Screw - 5/16" x 3-1/2"

X. 1704931 Flanged Nylon Lock Nut - 5/16"

Y. 1700419 Nylon Lock Nut - 5/16"

FF. 1702890 Flat Washer - 1-1/4"

GG. 1700428 Flat Washer - 5/16"

KK. 1118318 Spacer Washer - 1/4" x 1.28"

WARNING

Do not stand or climb on flex arm. Standing or climb-

ing on flex arm could result in fall/impact causing

serious injury or death.

!

S

X

X

M

M

Y

Y

L

FF

KK

GG

GG

GG

P/N 1122107 Rev. P

10

Rear Flex Arm Installation - 2" Roll Tube - Reverse Roll - cont’d

STEP 8: Secure with at washer FF and retaining ring.

retaining

ring

STEP 10: Insert roll tube through bearing mount box, bearing

ring and upper ex arm bearing plate, aligning end of

splined shaft 5" past bearing plate as shown.

Fasten

with

shoulder bolts

S

and nuts

X

as shown, anchoring

bearing ring between bolts.

upper flex arm

flex arm joint

bellow

NOTE: Bracket on upper ex

arm must face toward outside

of trailer as shown above.

bearing

mount box

upper flex arm

bearing plate

bearing

ring

STEP 4: Insert ex arm joint into upper ex arm and slide

bellow over ex arm joint. Align holes in upper ex

arm, bellow plates, ex arm joint and bellow. Fasten

with carriage bolts

L

and lock nuts

X

.

STEP 5:

Insert lower end tting into lower ex arm assembly

with end of bellow over outside of arm. Align holes in

lower ex arm assembly, bellow plates, end tting and

bellow. Fasten with carriage bolts

L

and lock nuts

X

.

bellow plate

w/square hole

bellow plate

w/round hole

upper flex

arm assembly

bellow plate

w/round holes

lower flex

arm assembly

STEP 6: Assemble spacer washers KK onto pivot pin.

pivot pin

STEP 7: Assemble spiral torsion springs and lower ex arm onto

pivot pin. Hook springs over spacer tube.

pivot pin

lower

flex arm

spiral torsion

springs

roll

tube

5"

STEP 9: Roll tarp closed over box

with roll tube hanging be-

low latchplate. Remove

crank assembly and U-

clamps from roll tube.

deburr roll tube

if needed before

sliding through

bearing mount

box & ring

NOTE: Remove any existing returns.

Do not leave unattended until ex

arm is securely fastened to roll tube.

bellow plate

w/square holes

rivets to be

added later

S

X

X

X

L

L

FF

KK

P/N 1122107 Rev. P

11

Rear Flex Arm Installation - 3" Roll Tube - Standard Roll

STEP 1: Install cap plug on lower ex arm. Fasten spacer

tube into spring support bracket on lower ex arm

with screw M, washers GG and nut Y.

Item Part # Description

1. 1705160 Rear Arm Bearing Ring - 3"

2. 1123248 Bearing Mount Box - 3"

3. 1704892 Cap Plug

4. 1124958 Upper Flex Arm - Bearing - 3" - RR

5. 1121413 Bellow Plate - Round Holes

6. 1121414 Bellow Plate - Square Holes

7. 1703873 Flex Arm Joint

8. 1704775 Bellow - HD Series Arm

9. 1704891 End Fitting

10. 1121999 Lower Flex Arm w/Warning Decals

11. 1702888 Retaining Ring - 1-1/4" 6

2

3

1

5

12

7

8

10

spacer tube

11

spring support

bracket on lower

flex arm

NOTE: Insert cap screw through ex arm so head of screw

is on inside of assembly (towards trailer). Warning label must

be in plain view on outside of assembly.

4

3

warning decal

cap plug

6

13

9

STEP 2: Install cap plug on

rear upper ex arm. cap plug

upper flex arm

STEP 3: Fully thread end ttings onto both ends of ex arm

joint. Tighten so end ttings are parallel.

flex arm

joint

end fitting

end fitting

WARNING

Flex arms are under tension while torsion springs are

engaged. Use caution while assembling and disas-

sembling arms. Failure to read and follow instructions

could result in serious injury or death.

!

14

Item Part # Description

12. 1117033 Spacer Tube - .35" x 2-5/8"

13. 1111027 Spiral Torsion Spring

14. 1706103 Blind Rivet - 3/16"

L. 1701455 Carriage Bolt - 5/16" x 2-1/2"

S. 1704943 Shoulder Bolt - 3/8" x 2" -

5/16" x 1/2" Thd.

M. 1201022 Cap Screw - 5/16" x 3-1/2"

X. 1704931 Flanged Nylon Lock Nut - 5/16"

Y. 1700419 Nylon Lock Nut - 5/16"

FF. 1702890 Flat Washer - 1-1/4"

GG. 1700428 Flat Washer - 5/16"

KK. 1118318 Spacer Washer - 1/4" x 1.28"

WARNING

Do not stand or climb on flex arm.

Standing or climbing on flex arm

could result in fall/impact causing

serious injury or death.

!

S

X

X

X

M

M

Y

Y

L

L

FF

KK

GG

G

GG

P/N 1122107 Rev. P Rear Flex Arm Installation - 3" Roll Tube - Standard Roll - cont'd

upper flex arm

STEP 9: Roll tarp closed over box

with roll tube hanging be-

low latchplate. Remove

crank assembly and U-

clamps from roll tube.

flex arm joint

bellow

STEP 8: Secure with washer FF and retaining ring.

retaining

ring

NOTE: Bracket on upper ex

arm must face toward outside

of trailer as shown above.

deburr roll tube

if needed before

sliding through

bearing mount

box & ring

NOTE: Remove any existing returns,

such as cable return, bungee return, etc.

Do not leave unattended until ex arm is

securely fastened to roll tube extension.

STEP 4: Insert ex arm joint into upper ex arm and slide

bellow over ex arm joint. Align holes in upper ex

arm, bellow plates, ex arm joint and bellow. Fasten

with bolts

L

and anged nuts

X

.

bellow plate

w/square hole

bellow plate

w/round hole

upper flex

arm assembly

bellow

plates

lower flex

arm assembly

STEP 6: Assemble spacer

washers KK

onto pivot pin.

STEP 7: Assemble spiral torsion springs and lower ex arm

onto pivot pin. Hook springs over spacer tube.

pivot pin

pivot pin

lower

flex

arm

spiral torsion

springs

STEP 5: Insert lower end tting into lower ex arm assembly

with end of bellow over outside of arm. Align holes

in lower ex arm assembly, bellow plates, end tting

and bellow. Fasten with bolts L and anged nuts X.

STEP 10: Insert roll tube through bearing mount box, bearing

ring and upper ex arm bearing plate, aligning end of

splined shaft 5" past bearing plate as shown.

Fasten

with

bolts

S

and nuts

X

as shown, anchoring bearing

ring between bolts.

bearing

mount box

upper flex arm

bearing plate

bearing ring

3" roll

tube

rivets to be

added later

12

spacer

tube

X

X

L

L

FF

KK

S

X

P/N 1122107 Rev. P

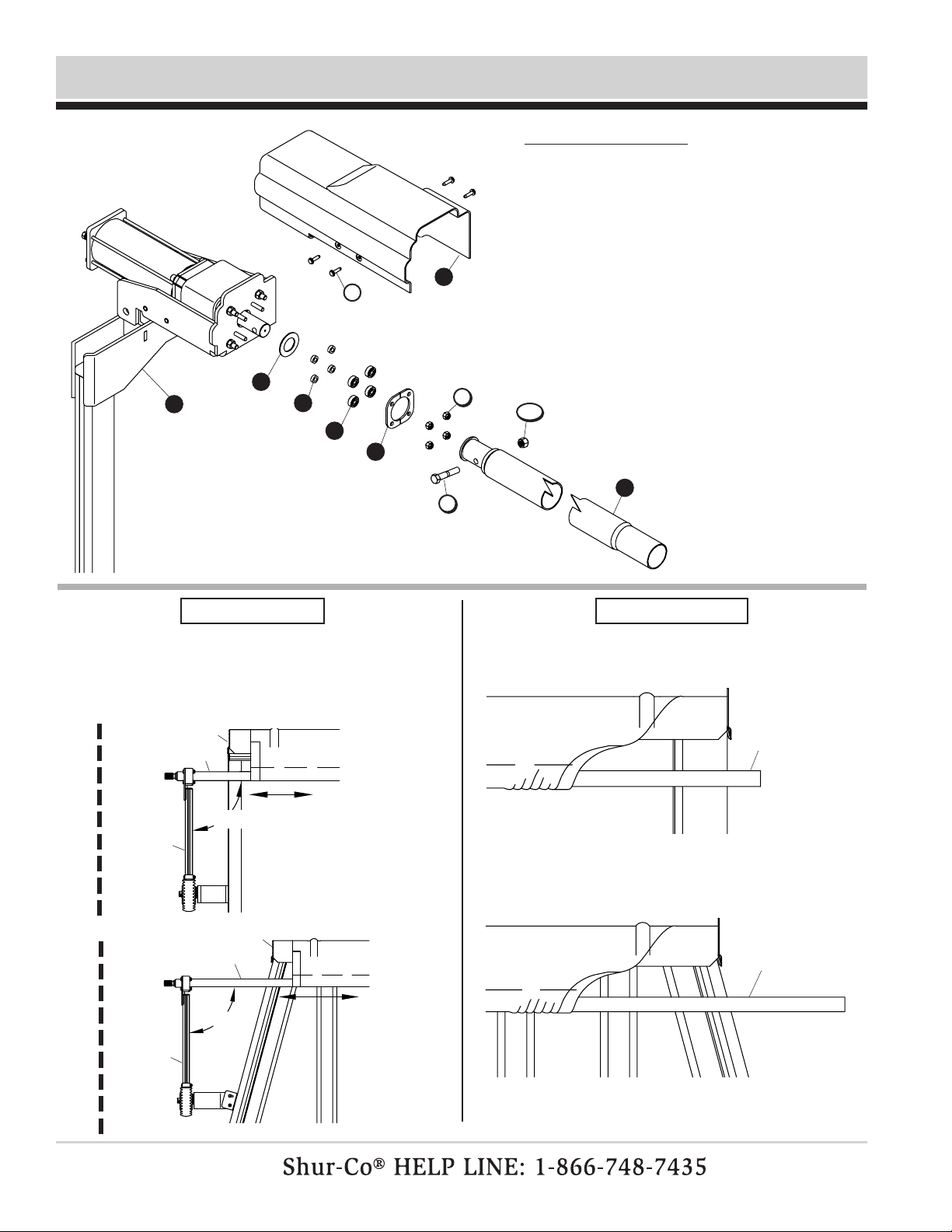

13

Item Part # Description

1. Flex Arm Assembly w/Motor - Std. - RR

Flex Arm Assembly w/Motor - 7-1/4" - RR

2. 1120680 Motor Mount Bearing Spacer

3. 1704736 Radial Ball Bearing - 1/4" x 3/4"

4. 1128243 Motor Mount Bearing Retainer

5. 1120679 Motor Spacer

6. 1120697 Roll Tube Extension w/Drive Shaft - 34.43"

1120698 Roll Tube Extension w/Drive Shaft - 45.37"

1120699 Roll Tube Extension w/Drive Shaft - 74.87"

7. 1704982 4500 Series Motor Cover - Black

A. 1704367 Hex Flange Cap Screw - #10 x 3/4"

Q. 1704264 Cap Screw - 3/8" x 2" - Grade 8

U. 1701543 Nylon Lock Nut - 1/4"

BB. 1701580 Nylon Lock Nut - 3/8"

2" Roll Tube Extension Installation - Reverse Roll

STEP 1: Adjust roll tube toward front or rear of trailer so rear

ex arm lies on vertical plane parallel to face panel

and perpendicular to roll tube extension. Mark roll

tube where roll tube extension ends.

VERTICAL TRAILER

SLOPED TRAILER

align flex arm

with vertical

plane parallel

to face panel

face panel

flex

arm

vertical plane

roll tube

face panel

roll tube

vertical plane

flex

arm

align flex arm

with vertical

plane parallel

to face panel

90°

90°

STEP 2: Slide tarp back on roll tube.

roll tube

tarp roll tube

tarp

VERTICAL TRAILER

SLOPED TRAILER

4

5

3

2

1

6

7

A

REAR OF TRAILER FRONT OF TRAILER

U

Q

BB

P/N 1122107 Rev. P

14

2" Roll Tube Extension Installation- Reverse Roll - cont’d

STEP 5: Reverse step 3B to unfasten and remove motor from

roll tube extension. Remove roll tube extension from

roll tube. Cut roll tube at marked location.

STEP 4: Hold ex arm with motor and roll tube extension in

vertical plane to trailer and 90° to roll tube. Mark roll

tube at location to be cut.

vertical plane

vertical plane

flex

arm

roll tube

roll tube

flex

arm

roll tube

extension

roll tube

extension

cut here

cut here

VERTICAL TRAILER

face panel

face panel

90°

NOTE: Requires two people for safe installation.

SLOPED TRAILER

CAUTION

On certain trailers, clearance lights might be in

way of roll tube and can be damaged if caution is

not taken. In some instances, a ‘de

flector’ might

have to be installed to prevent

roll tube from causing

damage to lights.

!

90°

STEP 3A: Slide motor spacer over motor shaft.

STEP 3B: Slide roll tube extension over motor shaft. Fasten with

screws Q and lock nuts BB . Finger tighten only.

Fasten roll tube extension to motor mount bracket:

motor

spacer

motor shaft

roll tube

extension

motor

shaft

roll tube extension

w/drive shaft

roll tube

STEP 6: Insert swaged end of roll tube extension w/drive shaft

into roll tube. Align extension straight with roll tube

and weld all around. Grind smooth.

weld &

grind

smooth

roll tube

extension

w/drive shaft

NOTE: Pull roll tube away from tarp and trailer before welding

to protect from weld spatter. Align roll tube extension straight

with roll tube before welding so tarp system will roll smoothly.

Q

BB

P/N 1122107 Rev. P

15

2" Roll Tube Extension Installation - Reverse Roll - cont’d

STEP 11: When both front and rear ex arms are vertical, drill

3/16" holes and fasten bearing ring to roll tube with

two rivets.

STEP 10: Adjust rear roll tube extension to align ex arm on

vertical plane parallel to face panel. Do not drill holes

and/or fasten until tarp and roll tube are in desired

position.

STEP 12: Fasten tarp to roll tube with existing U-clamps and

screws. Tighten all fasteners securely. Tighten front

and rear ex arm connections.

roll tube

bearing ring

NOTE: Verify ex arm is on vertical plane and parallel to face

panel before proceeding. Make sure all fasteners holding

motor to upper ex arm bracket are tightened securely.

STEP 8: Fasten and

secure roll tube to electric motor shaft with

screw

Q

and lock nut

BB

. Install bearing spacers,

radial ball bearings and bearing mount retainer and

secure with nuts

U

.

drill 3/16"holes

WARNING

!

Flex arms are under tension while torsion springs

are engaged. Use caution while assembling and

disassembling arms. Failure to read and follow

instructions could result in serious injury or death.

NOTE: To prevent rust, paint all exposed metal, such as weld

seams and/or metal exposed by grinding or cutting, with

corrosion-resistant paint.

STEP 7:

Slide roll tube/roll tube extension weldment back into

position and align upper ex arm on front of trailer. Fol-

low step 8 to install motor, positioning motor as shown

below. Make sure torsion springs load when tarp opens.

face panel

pivot bracket

roll tube

electric motor

bearing

mount

retainer

radial ball bearing

bearing

spacer

STEP 9: Fasten motor cover onto motor with screws A.

motor

cover

motor

rivet

A

U

Q

BB

P/N 1122107 Rev. P 3" Front Roll Tube Extension Installation - Reverse Roll

Item Part # Description

1. 1122264 Drive Shaft

2. 1118194 Cartridge Clamp

3. 1128243 Motor Mount Bearing Retainer

4. 1704736 Radial Ball Bearing - 1/4" x 3/4"

5. 1120680 Motor Mount Bearing Spacer

6. 1120679 Motor Spacer

H. 1705198 Pan Hd. Self-Drilling Screw - 1/4" x 1"

N. 1700400 Self-Tapping Screw - 3/8" x 1"

Q. 1704264 Cap Screw - 3/8" x 2" - GR8

R. 1704237 Carriage Bolt - 5/16" x 1"

U. 1701543 Nylon Lock Nut - 1/4"

Z. 1704297 Nylon Lock Nut - 5/16"

BB. 1701580 Nylon Lock Nut - 3/8"

STEP 3:

Slide motor spacer over motor shaft. Slide drive shaft

over motor shaft. Fasten with screws

Q

and nuts

BB

.

Finger tighten only.

motor spacer

motor shaft

drive shaft

roll tube

STEP 1: Loosely fasten cartridge clamp to drive shaft with

screw R and lock nut Z. Insert drive shaft into roll

tube as shown. To secure drive shaft to roll tube,

tighten nut Z to 20 ft.-lbs.

motor mount

assembly

STEP 2: Install three screws H through roll tube and ats on

drive shaft collar. Drill 5/16" hole between ats and

collar, then fasten screw N through roll tube and drive

shaft collar.

drill 5/16" hole

drive

shaft

collar

1/2"

align all

screws 1/2"

from edge of

roll tube

4

3

2

1

5

6

drive shaft

cartridge

clamp

16

CAUTION

If clearance lights are in path of roll tube, install

de

flector to prevent

roll tube from damaging lights.

!

WARNING

!

Flex arms are under tension while torsion springs

are engaged. Use caution while assembling and

disassembling arms. Failure to read and follow

instructions could result in serious injury or death.

U

Z

H

H

N

N

R

Z

R

Q

Q

BB

BB

P/N 1122107 Rev. P

17

3" Front Roll Tube Extension Installation - Reverse Roll - cont'd

CAUTION

On certain trailers, clearance lights might be in

way of roll tube and can be damaged if caution is

not taken. In some instances, a ‘de

flector’ might

have to be installed to prevent

roll tube from causing

damage to lights.

!

face panel

torsion springs

motor

STEP 6: Align ex arm vertically with front of trailer and at 90°

angle to roll tube.

align flex arm

w/vertical

plane parallel

to face panel

roll tube

vertical plane

90°

STEP 5: Position motor as shown below. Make sure torsion

springs load when tarp opens.

STEP 4:

Fasten drive shaft to electric motor shaft with screw

Q

and nut

BB

. Install bearing spacers, radial ball bearings

and bearing mount retainer and secure with 1/4" lock

nuts

U

.

drive shaft

electric motor

bearing

mount

retainer

radial ball bearing

bearing spacer

NOTE: Make sure all fasteners holding motor to upper ex

arm bracket are tightened securely.

STEP 7: Fasten motor cover onto motor with screws A.

motor

cover

motor

A

U

Q

BB

Other manuals for 4500 HD Series

2

Table of contents

Other Shurco Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction