Shurco 4500 HD Series User manual

Aluminum Single-Arm System for

Open-Top Vans & Live-Bottom Trailers

P/N 1121522 Rev. F

P/N 1121522 Rev. A

Shur-Co®, LLC Terms & Conditions

SHIPPING. Orders are shipped F.O.B. from the Shur-Co®, LLC sites listed be-

low. No full freight isallowed or prepaid shipment accepted unless quoted and

approved in writing prior to acceptance of the order. All shipments are made

by the most reasonable means in accordance with size and weight of order,

unless specifi ed routing instructions are furnished by the customer. Shipments

are made daily via U.P.S. and common carrier. Claims for shortages must

be made within 10 days. All claims for damages or loss in transit must be

made with the carrier. No collect calls will be accepted. To ensure delivery of

orders, we need your full street address and phone number. When you receive

your shipment, examine it carefully. Be sure all cartons listed on the delivery

sheet are accounted for. Large items may be packaged separately. If a carton

is damaged, open it and inspect the contents before signing for delivery. If

merchandise is damaged, describe damage on the delivery receipt. Failure

on your part to document damaged or missing merchandise on the delivery

receipt releases the carrier of all liability; repair or replacement will be the

customer’s responsibility.

WARRANTY. We warrant all new products are free of defects in materials and

workmanship.* This warranty is effective if products are properly installed and

used for the purpose for which they were intended and applies to the original

buyer only. Except as set forth above or in any product-specifi c warranty docu-

mentation, we make no other warranties, express or implied, including but not

limited to warranties of merchantability of fi tness for a particular use.

Returns of a product for warranty must be accompanied by a Return Merchan-

dise Authorization number (RMA#), obtained by by calling Customer Service

at 866-748-7435, and sent, with freight paid by us, to Shur-Co®, LLC, 2309

Shur-Lok St., PO Box 713, Yankton, SD 57078. All products returned without

an RMA# will be refused. When we issue the RMA#, we will also issue a call

tag to have UPS (or other freight company) pick up the product. C.O.D. returns

not accepted. We will pay no storage fees for a warranty product return prior to

pick by us or the freight company. If a warranty product return is scheduled to

be picked up by us, we will pick up the product at our earliest convenience.

If a product returned is found, in our judgement, to be defective in material

or workmanship, our obligation under this warranty is limited to the repair or

replacement of the product, which will be made by us. Repair or replacement

will be at our discretion, with replacements being made using current products

performing in the equivalent function. Labor charges, other than those incurred

at our factory, including, but not limited to, any labor to install a repaired or re-

placement product, are not covered under this warranty. All expenses associ-

ated with delivering defective products to our factory and delivering repaired or

replacement products from our factory to the owner will be paid by us.

If the product returned is found, in our judgement, to be non-warrantable, the

owner will be contacted to authorize repair work, purchase of a replacement

product or return of the product, all of which will be at the owner’s expense.

Payment authorization must be received by us before any non-warrantable

product is repaired, replaced or returned. All expenses associated with deliver-

ing the repaired non-warrantable product, a replacement product or the non-

warrantable product from our factory to the owner will be paid by the owner.

In no event will we be liable for any damages of any kind to person, product or

property, including but not limited to indirect, incidental, special, consequential

or punitive damages, or damages for loss of profi ts or revenue, even if we

have been advised of the possibility of such damages. There are no warran-

ties for used products or products that have been repaired, altered, modifi ed

or subjected to misuse, negligence or accident. We will not repair or replace

products that fail or malfunction due to ordinary wear and tear, except as ex-

pressly noted in a product-specifi c warranty. Use of non-Shur-Co®, LLC parts

in conjuction with Shur-Co®, LLC products will void this product warranty.

*Certain products have specifi c warranties that differ from this warranty, for example motors and elec-

tronics. Product-specifi c warranty documentation is available for these items. In the event of a confl ict

between this warranty and a product-specifi c warranty, the product-specifi c warranty will govern.

RETURN POLICY. All sales fi nal. See WARRANTY above for return details.

OTHER. All prices, product listings, sizes, weights and manufacturing details

are subject to change without notice. No person is authorized to modify the

foregoing conditions of sale whatsoever.

SHUR-CO® of NORTH DAKOTA

1746 4th Ave. NW

West Fargo, ND 58078

Ph 877.868.4488 | Fax 701.277.1283

SHUR-CO® of OHIO

1100 N. Freedom, St. Rt. 88 & 14

Ravenna, OH 44266

Ph 866.356.0242 | Fax 330.297.5599

SHUR-CO® UK, Ltd.

Unit 41 Rochester Airport Estates

Laker Rd., Rochester, Kent ME1 3QX

Ph +44 (0)1795.473499

Fax +44 (0)871.272.8278

For more info, log on to our website:

www.shurco.com

Corporate HQ and Outlet Store

SHUR-CO® of SOUTH DAKOTA

2309 Shur-Lok St., PO Box 713

Yankton, SD 57078-0713

Ph 800.474.8756 | Fax 605.665.0501

ShurTite™ Service Centers

SHUR-CO® of CANADA

490 Elgin St., Unit #1

Brantford, Ontario N3S 7P8

Ph 800.265.0823 | Fax 519.751.3997

SHUR-CO® of SIOUX FALLS

47184 258th St., Suite B

Sioux Falls, SD 57107

Ph 844.573.9322 | Fax 605.543.5469

SHUR-CO® of ILLINOIS

Ph 866.356.0246 | Fax 217.877.8270

SHUR-CO® of OHIO

Ph 866.356.0242 | Fax 330.297.5599

SHUR-CO® of FLORIDA

3353 SE Gran Park Way

Stuart, FL 34997

Ph 800.327.8287 | Fax 772.287.0431

SHUR-CO® of ILLINOIS

3993 E. Mueller Ave.

Decatur, IL 62526

Ph 866.356.0246 | Fax 217.877.8270

SHUR-CO® of IOWA

3839 Midway Blvd.

Ft. Dodge, IA 50501

Ph 866.356.0245 | Fax 515.576.5578

SHUR-CO® of MICHIGAN

5100 Lakeshore Dr.

Lexington, MI 48450

Ph 800.327.8287 | Fax 772.287.0431

SHUR-CO®, LLC SERVICE AND DISTRIBUTION CENTERS

P/N 1121522 Rev. F

Thank you for buying this tarping system from Shur-Co®. We appreci-

ate your condence in our products. Please read and thoroughly un-

derstand this manual before installing and/or operating this system.

Pay particular attention to important safety and operating instructions,

as well as warnings and cautions. The hazard symbol is used

to alert users to potentially hazardous conditions and is followed by

caution, warning or danger messages.

Failure to READ AND FOLLOW INSTRUCTIONS could result in fail-

ure of your tarping system and/or personal injury. Your trailer require-

ments may, however, call for minor variations to these instructions.

Please inspect your tarping system periodically, and repair or replace

worn or damaged parts.

QUESTIONS? CALL OUR HELP LINE:

1-866-748-7435

MON-FRI 8 AM-5 PM CENTRAL TIME

We at Shur-Co® are concerned with your safety and the safety of all

those operating this system. Therefore, we have provided safety de-

cals at various locations on your tarping system. Keep decals as clean

as possible at all times. Replace any decal that has become worn

or damaged, painted over or otherwise difcult to read. Replacement

decals are available through Shur-Co® dealers.

To prevent rust, paint all exposed metal, such as weld seams and/or

metal exposed by grinding or cutting, with corrosion-resistant paint.

4500 Series Aluminum Single-Arm System

P/N 1121522 Rev. F

Hardware Identication.......................................................................1

Pivot Bracket Installation ...................................................................2

Front Flex Arm & Electric Motor Installation ....................................3-4

Roll Tube Extension Installation ......................................................5-6

Stretch Cord Return............................................................................7

Shur-Return™ ....................................................................................8

Rear Cable Return..............................................................................9

Value Series Stretch Cord Return ....................................................10

Electric Mounting & Wiring ..........................................................11-15

Wireless SMARTransmitter® Operating ............................................16

Program Wireless SMARTransmitter®to Receiver...........................17

Electric Motor Replacement .............................................................18

Change from Electric to Manual Operation ......................................19

Replacement Parts......................................................................20-23

Troubleshooting Guide .....................................................................24

1. Welder

2. Hammer

3. Center Punch or Transfer Punch

4. #3 Phillips Insert Bit

5. Air or Electric Impact Wrench (9/16" deep socket)

6. 7/16" Deep Socket

7. 3/8" Combination Wrench

8. 9/16" Combination Wrench

9. 1/2" Combination Wrench

10. 1/8" Hex Wrench Long T-Handle

11. 3/16" Hex Wrench Long T-Handle (recommended)

12. 5/16" Drill Bit (for 3/8” self-tapping screws)

13. 11/32" Drill Bit

14. 13/32" Drill Bit

15. 3/8" Drill

15. 1 1/8" Hole Saw

16. 2" Hole Saw

17. Standard/Flathead Screwdriver

18. #2 Phillips Screwdriver

19. Utility Knife

20. Ratchet

21. Hack Saw (metal cutter)

22. Pliers

23. Snap Ring Pliers

24. Wire Cutters

25. Grinder

26. Tape Measure

!

TOOLS REQUIRED

RUST PREVENTION

SAFETY

MESSAGE TO OWNERS TABLE OF CONTENTS

1. Always wear safety glasses during installa-

tion and operation.

2. Stay clear of moving parts.

3. No other use of this system is authorized,

except as designed.

SAFETY INSTRUCTIONS

P/N 1121522 Rev. F

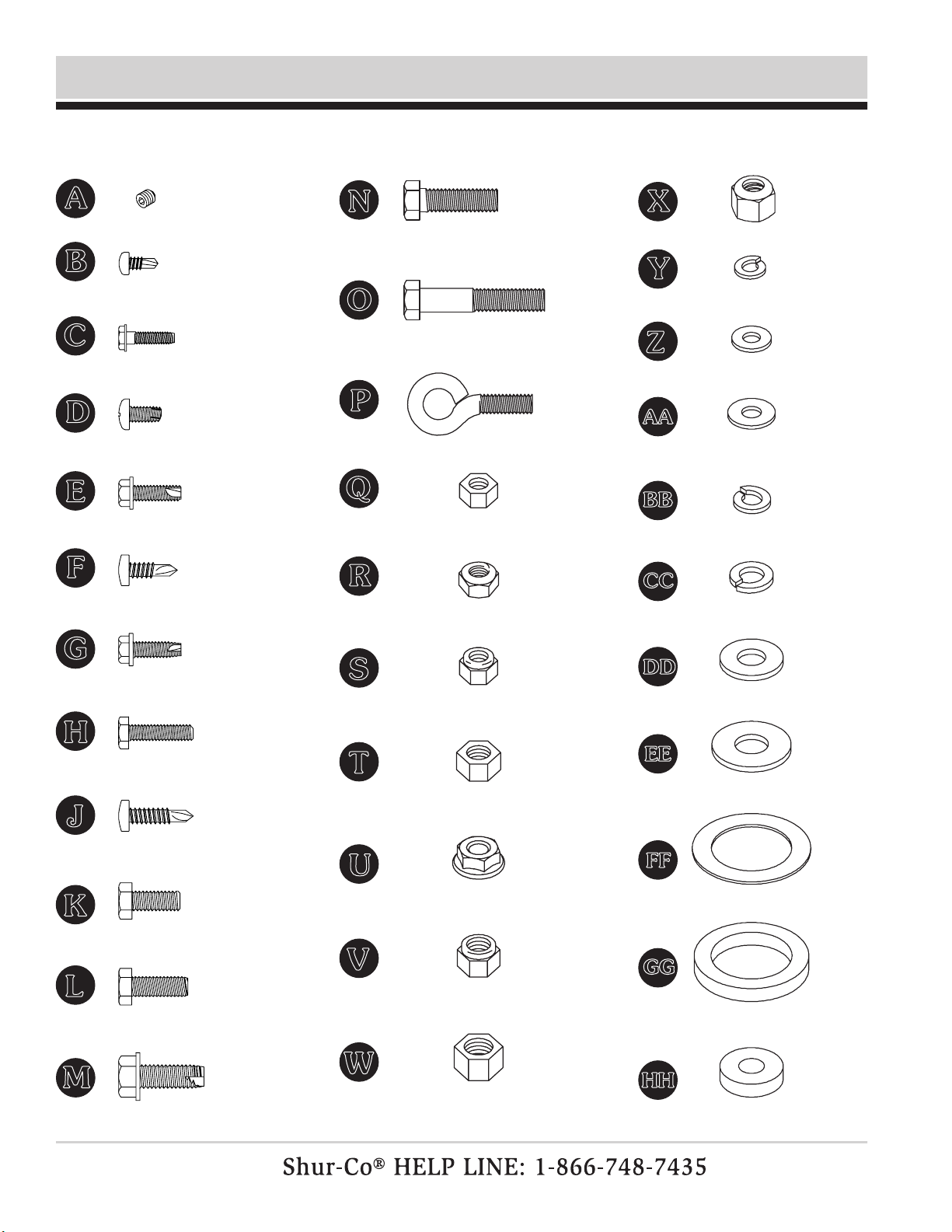

Hardware Identication

1

Inspect all parts in your 4500 Series Electric kit upon arrival.

1700411 Hex Nut - 5/16"

1700429 Flat Washer - 3/8"

1700400 Cap Screw - 3/8" x 1"

1700419 Nylon Lock Nut - 5/16"

1701045 Cap Screw - 5/16" x 3/4"

1700407 Hex Nut - 3/8"

1700434 Lock Washer - 3/8"

1118318 Spacer Washer - 1/4" x 1.81"

1702891 Cap Screw - 3/8" x 1 1/4"

1702890 Flat Washer - 1 1/4"

1701543 Nylon Lock Nut - 1/4"

1808844 Nylon Lock Nut - #10

1700427 Flat Washer - 1/4"

1703373 Flat Washer - 1/2"

1704057 Cap Screw - 3/8" x 2"

1704905 Flanged Cap Screw - #10 x 1"

1700398 Self-Drilling Screw - 1/4" x 3/4"

1702926 Cap Screw - 5/16" x 7/8"

1700428 Flat Washer - 5/16"

A

B

C

D

E

F

G

H

J

K

L

N

O

P

Q

R

S

T

V

W

Y

X

Z

AA

1120291 Pivot Bracket Washer

1700403 Self-Tapping Screw - 1/4" x 3/4"

1704338 Self-Tapping Screw - 1/4" x 1"

1704367 Cap Screw - #10 x 3/4"

1700408 Hex Nut - 1/4"

1700436 Lock Washer - 1/4"

1701580 Nylon Lock Nut - 3/8"

M

1704743 Self-Drilling Screw - #10 x 1/2"

1701423 Set Screw - #10 x 3/16"

1700717 Eyebolt - 5/16" x 7/8"

1704946 Flanged Top Lock Nut - 5/16"

U

1704353 Self-Drilling Screw - 1/4" x 1"

1700736 Self-Tapping Screw - 1/4" x 1/2"

1700433 Lock Washer - 5/16"

BB

CC

DD

EE

FF

GG

HH

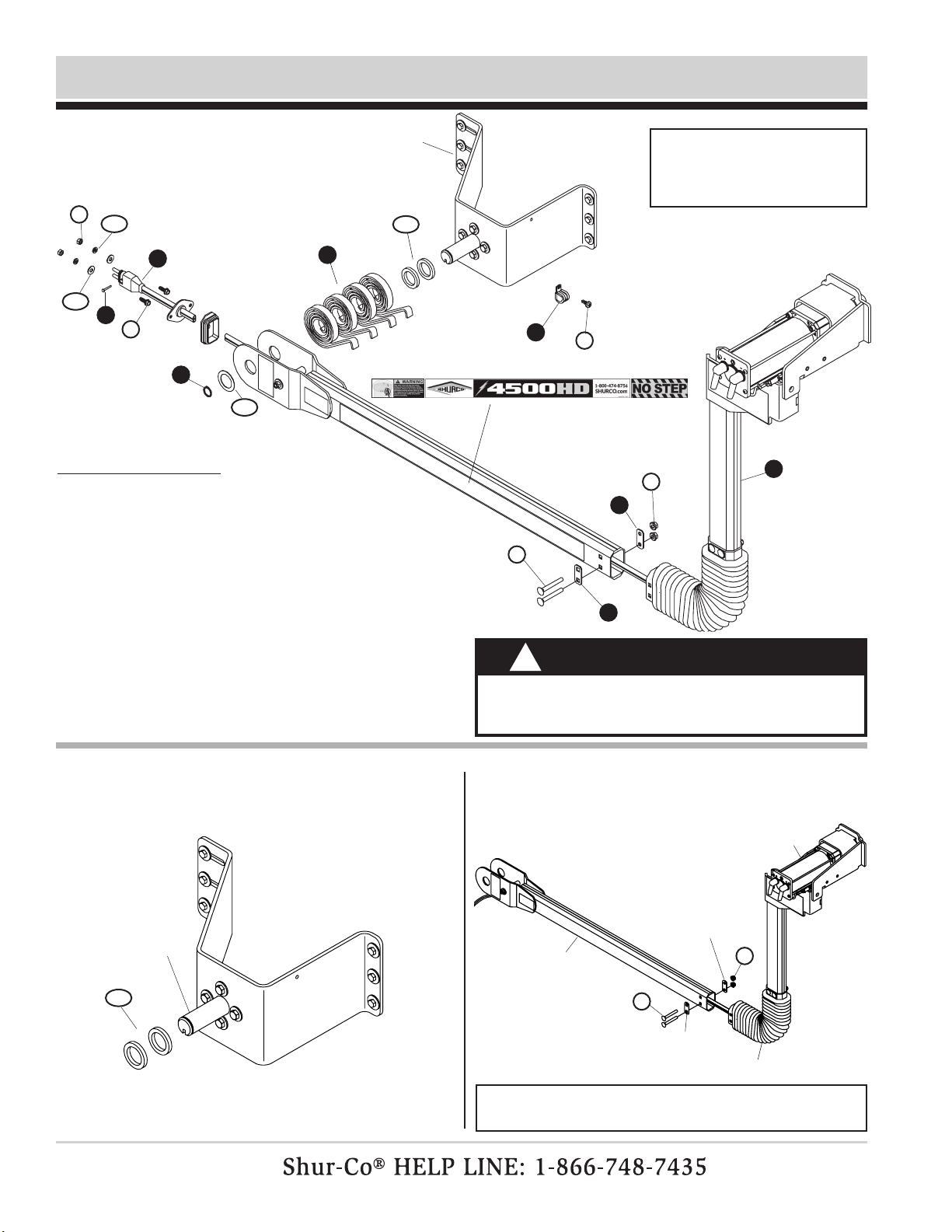

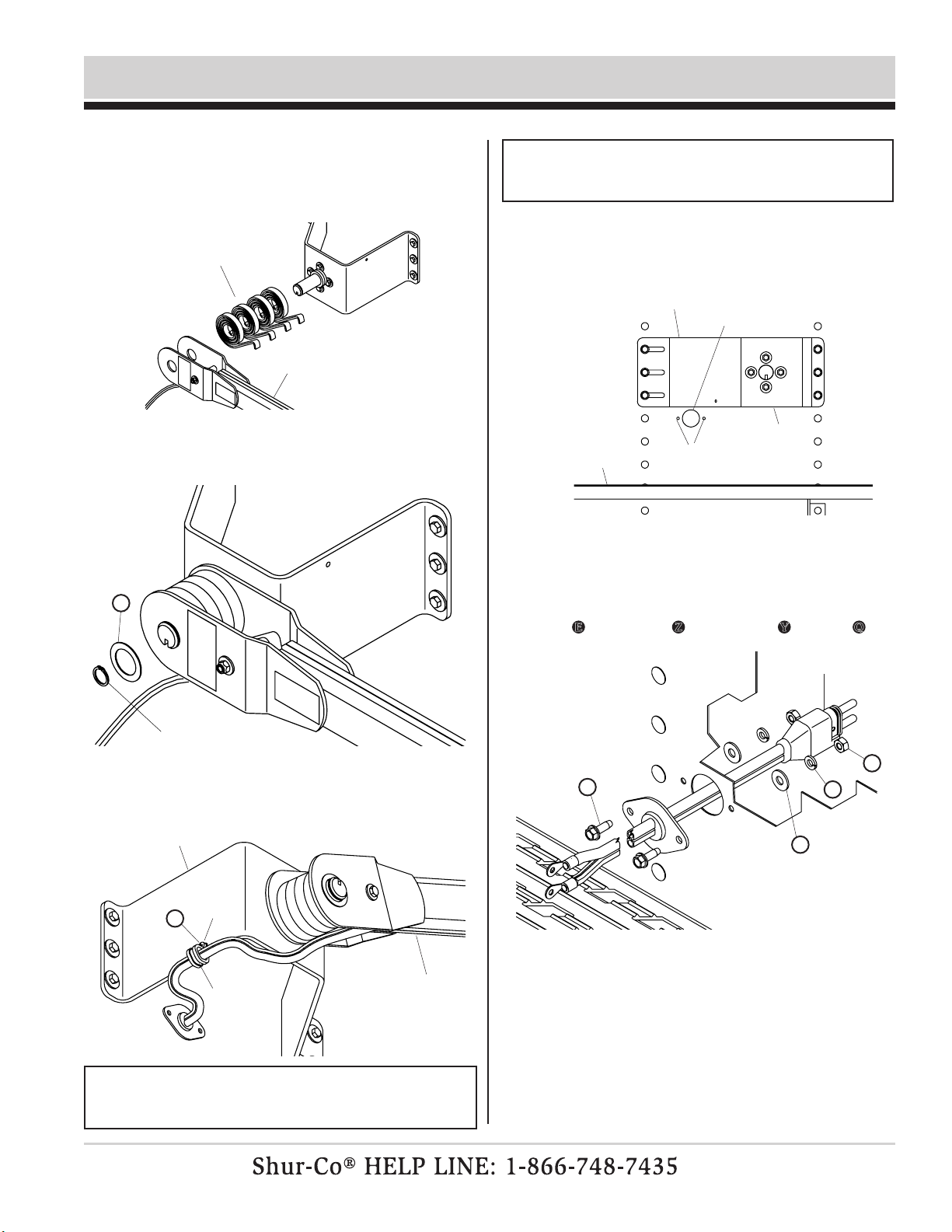

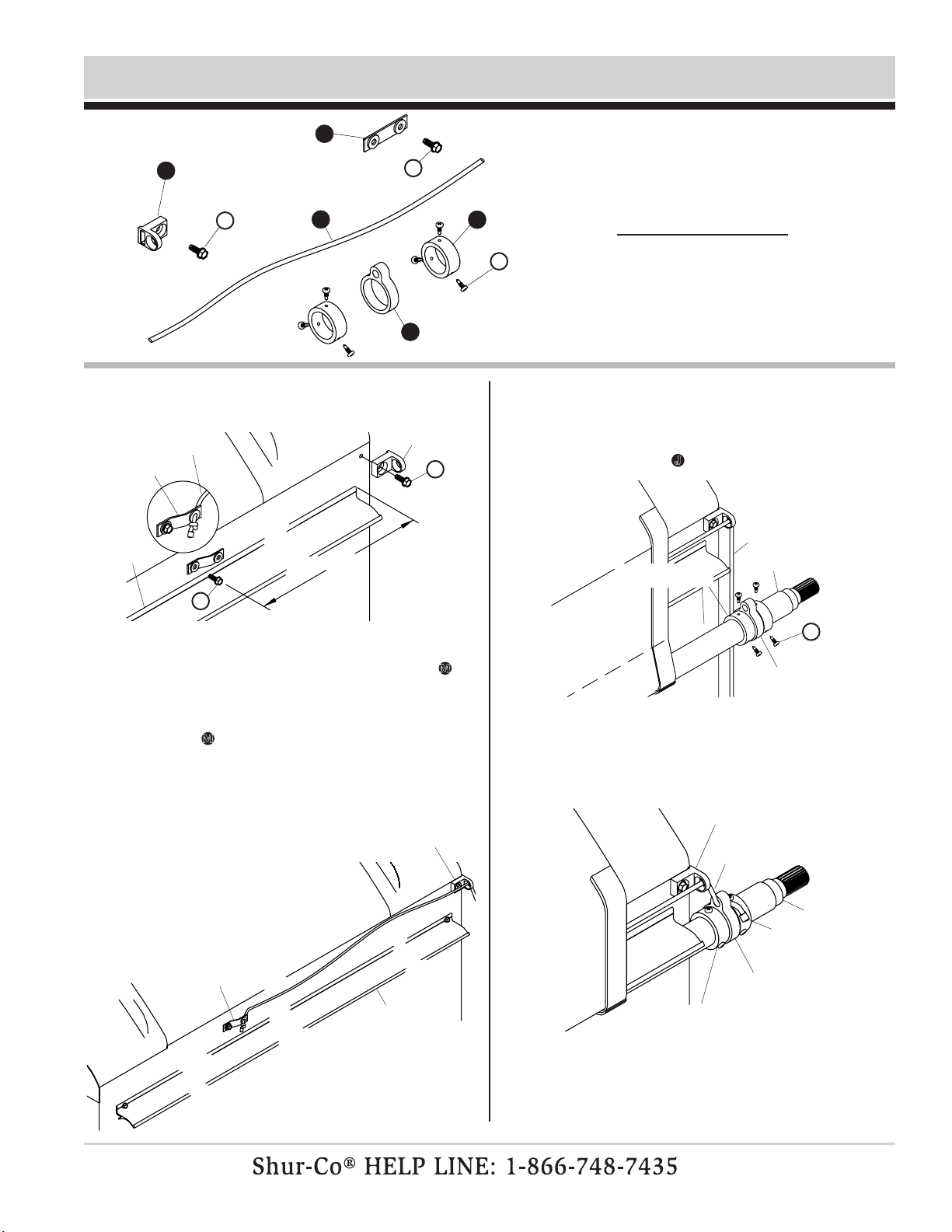

P/N 1121522 Rev. F Pivot Bracket Installation

2

rivets off

center

front of trailer

STEP 1: Locate front pivot mount bracket on passenger side

of trailer so center of pivot lies within shaded area

shown below. Measure 41" down from top of cap or

43" from top of windshield.

4"

4" 4"

4"

6"

4"

4"

6"

rivets on

center line

43"

c

l

locate center

of pivot inside

shaded area

STEP 2: Place pivot mount brackets on trailer in orientation

shown below. Using brackets as guide, mark mounting

hole locations.

N

rivets/corrugation off center

rivets/corrugations on center

center of

trailer

NOTE: Read entire section before drilling holes. Determine if

rivets on front of trailer are centered or off center.

NOTE: Mount front pivot bracket into support braces on trailer

if possible. If bracket cannot be mounted into support braces,

reinforce mounting area with backer plate for adequate support.

Before drilling any holes, make sure ex arm will have clear

pathway to operate.

Item Part # Description

1. 1116920 Pivot Pin - 4 Spring

2. 1116919 Vertical Pivot Mount Bracket - 7 1/4" Standoff

1117927 Vertical Pivot Mount Bracket - 12 1/4" Standoff

1117767 Pivot Mount Bracket - 1 1/4"

3. 1120361 Pivot Backer Plate - 5" x 16"

1120418 Pivot Backer Plate - 5" x 20"

N. 1702891 Cap Screw - 3/8" x 1 1/4"

V. 1700407 Hex Nut - 3/8"

CC. 1700434 Lock Washer - 3/8"

DD. 1700429 Flat Washer - 3/8"

pivot bracket pivot pin

STEP 1: Fasten pivot pin to pivot bracket with keyway facing

downward as shown.

Keyway in pivot pin must

face downward.

PIVOT PIN INSTALLATION

31

STEP 3:

Remove rivets and mount brackets into rivet holes. If this

is not possible, drill 13/32" holes in trailer. Fasten with

screws

N

, at washers

DD

, pivot bracket washers

CC

, lock washers

HH

and nuts

W

.

2

c

l

c

l

c

l

2

41"

N

N

W

W

NOTE: Use pivot bracket washers only when horizontal

corrugation on trailer skin prevents bracket from contacting skin.

STEP 3:

If installing pivot bracket or pivot mount bracket on

horizontally corrugated trailer skin, center bracket

between corrugations and use brackets as guide to

mark hole locations. Mark and drill 13/32" holes in

trailer and fasten with screws

N

, at washers

DD

, lock washers

CC

, pivot bracket washers

HH

and

nuts

W

. Locate pivot bracket washers between pivot

bracket and trailer skin as shown.

N

pivot bracket

corrugated trailer skin locate pivot bracket

washers between pivot

bracket & trailer skin

horizontally corrugated trailers

W

N

W

W

CC

CC

CC

CC

CC

DD

DD

DD DD

DD

DD

DD

HH

HH

HH

P/N 1121522 Rev. F

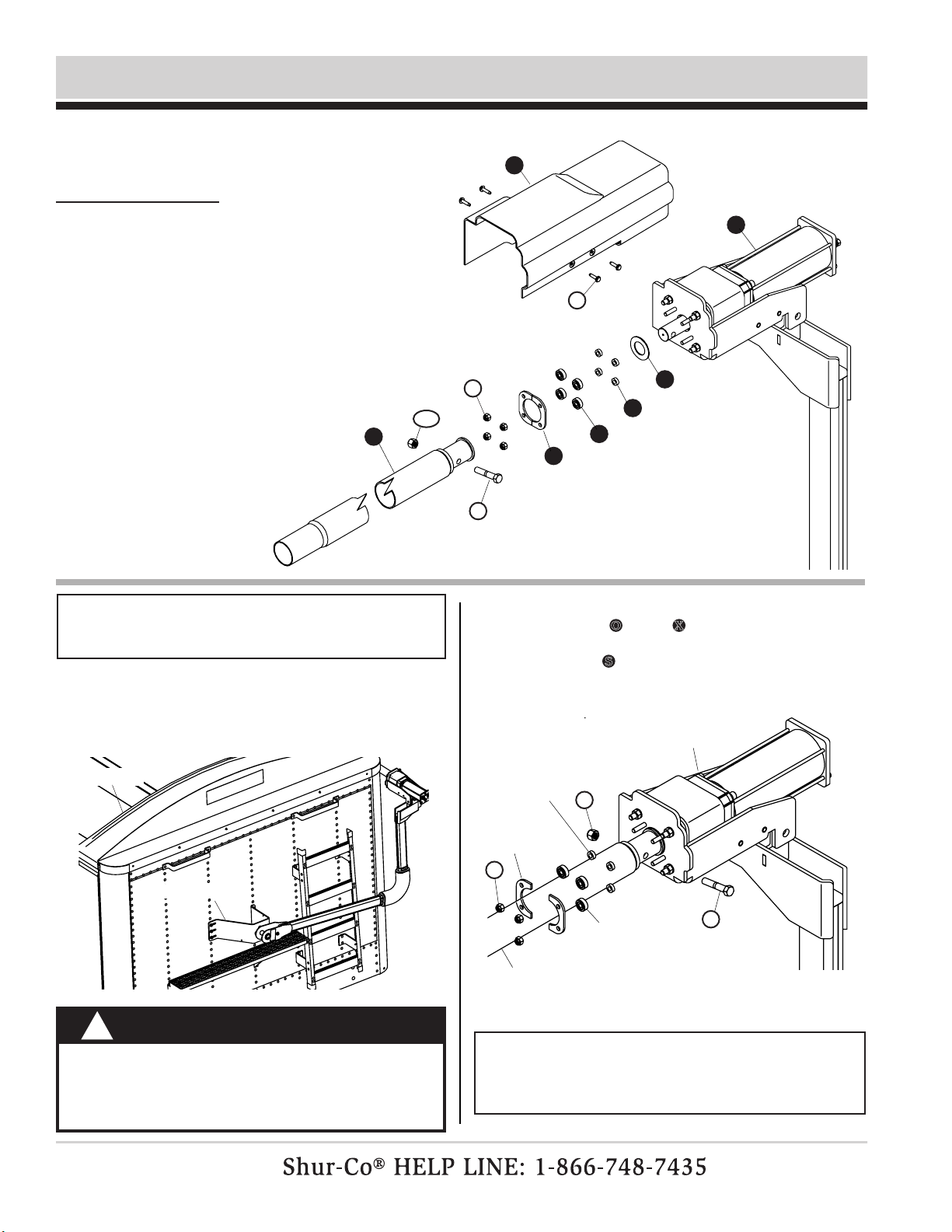

3

Front Flex Arm & Electric Motor Installation

1

pivot mount

bracket assembly

3

2

STEP 1: Assemble spacer washers onto pivot pin.

pivot pin

T

5

4

6P

Item Part # Description

1. 1121296 Flex Arm Assembly - Std.

1121298 Flex Arm Assembly - 7 1/4"

2. 1111027 Spiral Torsion Spring

3. 1702888 External Retaining Ring - 1 1/4"

4. 112141511SMARTwire™ - 6 Ga. Plug - 10' 9"

5. 1704751 Harness Lock Pin - 1/4" x 7/8"

6. 1702108 Wire Clip - 3/4" ID

7. 1121414 Bellow Plate - Square Holes

8. 1121413 Bellow Plate - Round Holes

P. 1700398 Self-Drilling Screw - 1/4" x 3/4"

F. 1701455 Carriage Bolt - 5/16" x 2 1/2"

O. 1700403 Self-Tapping Screw - 1/4" x 3/4"

T. 1700408 Hex Nut - 1/4"

W. 1704931 Flanged Nylon Lock Nut - 5/16"

BB. 1700436 Lock Washer - 1/4"

CC. 1700427 Flat Washer - 1/4"

GG. 1702890 Flat Washer - 1 1/4"

HH. 1118318 Spacer Washer - 1/4" x 1.28"

O

7

W

F

8

flex arm joint w/bellow

lower flex arm

assembly

NOTE: Motor assembly on upper ex arm must face toward

trailer as shown.

upper flex

arm w/motor

W

F

bellow plate

w/square holes

STEP 2: Align holes in bellow and bellow plates with holes in

lower ex arm assembly as shown. Fasten with 5/16"

x 2 1/2" carriage bolts and lock nuts.

bellow plate

w/round holes

NOTE: Do not remove cable tie

from front ex arm and motor

assembly until installation is

complete. See step 4.

WARNING

Do not stand or climb on flex arm. Standing or climb-

ing on flex arm could result in fall/impact causing

serious injury or death.

!

BB

CC

GG

HH

HH

P/N 1121522 Rev. F

4

Front Flex Arm & Motor Installation - continued

STEP 7: Align adapter plug with 1 1/2" hole. Using plug as

guide, mark and drill two 7/32" holes as shown.

STEP 6: Measure 11" horizontally from center line of trailer and

1" down from lower edge of pivot bracket. Mark and

drill 1 1/2" hole through trailer skin.

drill 1 1/2" hole

pivot bracket

catwalk drill two

7/32" holes

pivot bracket

STEP 8:

Fasten adapter plug to front of trailer with screws

E

,

at washers Z, lock washers Y and nuts Q.

smartwire™ plug

NOTE: Wire lengths are predetermined. Before installing

SMARTwire™ components, review and conrm wire routing so

wires will reach components with ample room for

connection.

Z

Y

Q

E

STEP 5: Choose appropriate pilot hole on pivot bracket to route

6-ga. wire from ex arm through trailer skin. Fasten

wire clip to pilot hole with 1/4" x 3/4" self-drilling screw.

NOTE: Fasten wire clip to pilot hole on opposite side of pivot

bracket from ex arm to prevent wire from being pinched

during operation.

P

wire clip

pilot

hole

flex arm

pivot bracket

STEP 4: Secure with 1 1/4" at washer and retaining ring.

retaining ring

f

STEP 3: Assemble spiral torsion springs and lower ex arm

onto pivot pin. Hook springs over 3/8" x 3 1/2" cap

screw and spacer tube.

spiral torsion springs

lower flex arm

STEP 9: Remove cable tie from front arm/motor assembly

before operating system.

P/N 1121522 Rev. F

5

Roll Tube Extension Installation

NOTE: To prevent rust, paint all exposed metal, such as weld

seams and/or metal exposed by grinding or cutting, with

corrosion-resistant paint.

STEP 1: Slide roll tube/roll tube extension weldment back into

position and align upper ex arm on front of trailer.

Install motor, positioning motor as shown below. Make

sure torsion springs load when tarp opens.

face panel

pivot bracket

WARNING

!

Flex arms are under tension while torsion springs

are engaged. Use caution while assembling and

disassembling arms. Failure to read and follow

instructions could result in serious injury or death.

NOTE: Verify again that ex arm is on a vertical plane

and parallel to face panel before proceeding. Make sure

all fasteners holding motor to upper ex arm bracket are

tightened securely.

STEP 2: Refasten and

secure roll tube to electric motor shaft

with screw

O

and nut

X

. Install bearing spacers, radial

ball bearings and bearing mount retainer and secure

with nuts

S

.

roll tube

electric motor

bearing

mount

retainer

radial

ball

bearing

bearing

spacer

O

S

X

Item Part # Description

1. 1121296 Flex Arm Assembly w/Motor - Std.

1121298 Flex Arm Assembly w/Motor - 7 1/4"

2. 1120680 Motor Mount Bearing Spacer

3. 1704736 Radial Ball Bearing - 1/4" x 3/4"

4. 1128243 Motor Mount Bearing Retainer

5. 1120679 Motor Spacer

7. 1120697 Roll Tube Extension w/Drive Shaft - 34.43"

1120698 Roll Tube Extension w/Drive Shaft - 45.37"

1120699 Roll Tube Extension w/Drive Shaft - 74.87"

8. 1704982 4500 Series Motor Cover - Black

K. 1704057 Cap Screw - 3/8" x 2"

N. 1704367 Hex Flange Cap Screw - #10 x 3/4"

U. 1701543 Nylon Lock Nut - 1/4"

AA. 1701580 Nylon Lock Nut - 3/8"

4

5

3

U

K

2

1

7

N

8

AA

P/N 1121522 Rev. F

6

Roll Tube Extension Installation - continued

STEP 4: Reverse step 2 to unfasten and remove motor from

roll tube extension. Remove roll tube extension from

roll tube. Cut roll tube at marked location.

vertical plane

flex

arm

roll tube

roll tube

extension

cut here

face panel

90°

roll tube extension

w/drive shaft

roll tube

STEP 5: Insert swaged end of roll tube extension w/drive shaft

into roll tube. Align extension straight with roll tube

and weld all around. Grind smooth.

weld &

grind

smooth

roll tube

extension

w/drive shaft

NOTE: Pull roll tube away from tarp and trailer before welding

to protect from weld spatter. Align roll tube extension straight

with roll tube before welding so tarp system will roll smoothly.

STEP 3: Hold ex arm with motor and roll tube extension in

vertical plane to trailer and 90° to roll tube. Mark roll

tube at location to be cut.

NOTE: Requires two people for safe installation.

CAUTION

On certain trailers, clearance lights might be in

way of roll tube and can be damaged if caution is

not taken. In some instances, a ‘de

flector’ might

have to be installed to prevent

roll tube from causing

damage to lights.

!

STEP 7: Adjust rear roll tube extension to align ex arm on

vertical plane parallel to face panel. Do not drill holes

and/or fasten until tarp and roll tube are in desired

position.

STEP 8: Re-fasten tarp to roll tube with existing U-clamps and

screws. Tighten all fasteners securely. Tighten front

and rear ex arm connections.

STEP 6: Fasten motor cover onto motor with screws C.

motor

cover

motor

C

P/N 1121522 Rev. F

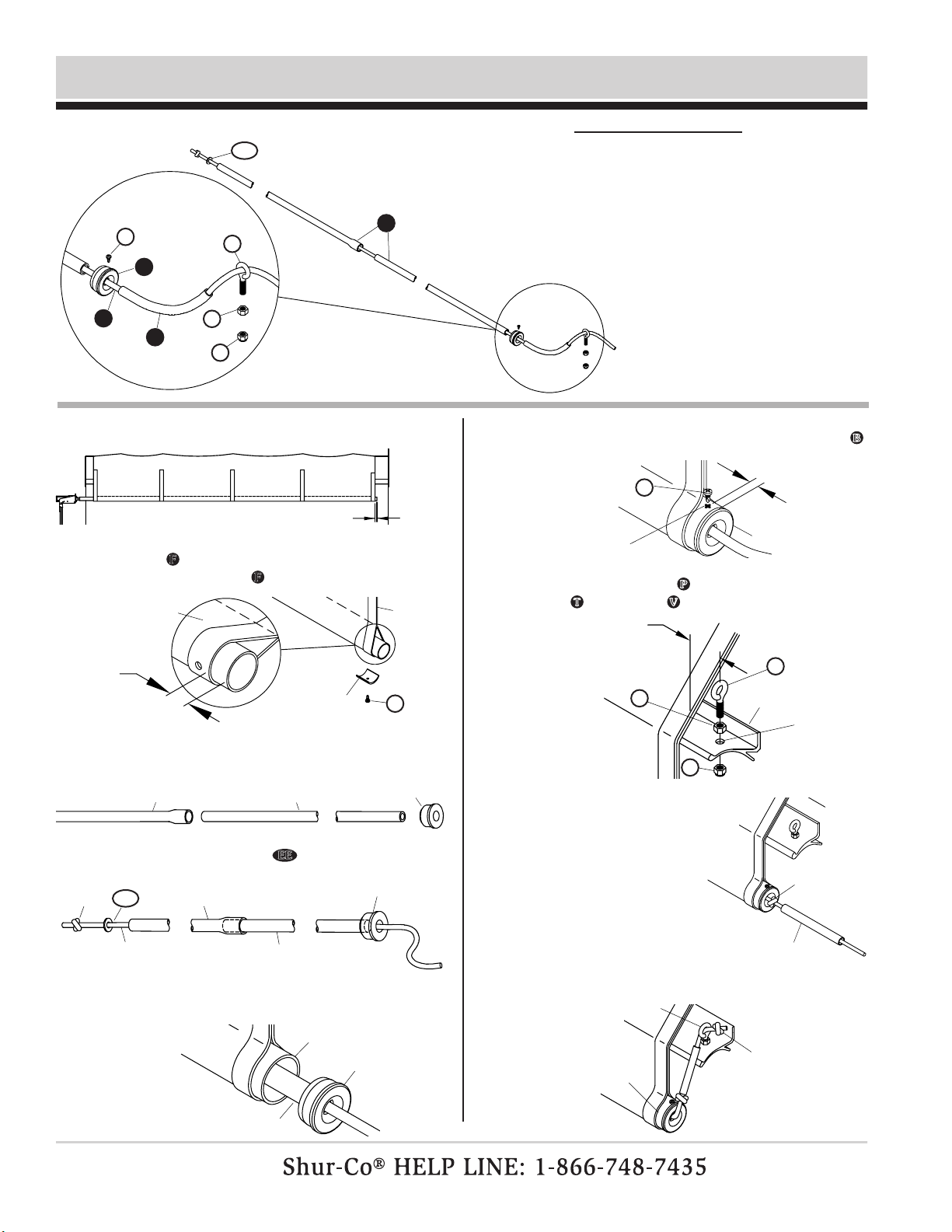

7

Stretch Cord Return

tarp

protective cover

belled pipe straight pipe

end plug

straight pipe

belled pipe

stretch cord

tie knot

7/16"

end plug

mark location

roll tube

knot in

stretch cord

tie knot

3

1

4

2

STEP 3: Insert straight stretch cord return pipe into belled

stretch cord return pipe. Insert end plug into straight

stretch cord return pipe.

STEP 6:

Mark location about 7/16" from edge of end plug.

Secure end plug to roll tube with self-drilling scre

w B.

STEP 4: Insert stretch cord through end plug and roll return

pipes. Slide at washer EE over stretch cord and tie

knot in cord.

STEP 5: At rear of box, insert stretch cord return assembly

into roll tube. Lightly tap end plug into roll tube.

STEP 7: Drill 11/32" hole through latchplate, 1 1/2" from edge

of tarp. Insert eyebolt P through hole and secure with

nut T and lock nut V.

STEP 9:

Tie knot in cord at

end plug. Slide pro-

tective cover over

stretch cord.

STEP 10: Thread stretch cord through eyebolt, applying enough

tension to almost lift roll tube. Tie knot.

tarp

1 1/2"

latchplate

drill

11/32"

hole

roll return assembly

end plug

roll tube

tarp

Item Part # Description

1. 1111067 Stretch Cord Return Tube Set

2. 1114360 Stretch Cord Return Cord - 11 1/2’

3. 1100138 Nylon End Plug

4. 1107680 Protective Stretch Cord Cover

B. 1704743 Self-Drilling Screw - #10 x 1/2"

F. 1700398 Self-Drilling Screw - 1/4" x 3/4"

P. 1700717 Eyebolt - 5/16" x 7/8" Thread

T. 1700411 Hex Nut - 5/16"

V. 1700419 Nylon Lock Nut - 5/16"

EE. 1703373 Flat Washer - 1/2"

T

V

P

STEP 8: With tarp closed and hanging

over edge of box, pull stretch

cord to remove all slack in

stretch cord return assembly.

STEP 1: Align roll tube to extend 1" past rear of tarp.

STEP 2: Center rst U-clamp on rear tarp strap, positioning

screw Fon crease at bottom of tarp pocket. Fasten

U-clamp with screw F.

1"

rear

of

box

u-clamp

5" pocket on tarp

1"

rear

tarp

strap

B

T

P

V

F

B

eyebolt

EE

EE

P/N 1121522 Rev. F

8

Shur-Return™

male end

female end

rear of tarp

u-clamp

expanded spring

untie knot

compressed spring

connector

seam

groove

1

2

3

4

5

STEP 1:

Align grooves in male and female UPS-able Shur-

Return™ ends, insert female end into connector sleeve

and align set screws

A

opposite seam and

tighten.

STEP 2: Cautiously untie knot and slowly allow spring to

expand to full length of UPS-able Shur-Return™.

STEP 3: Remove all 1/4" x 3/4" screws on U-clamps from rear

11' of tarp, then replace with screws D.

STEP 5: Tap end plug into roll tube and mark location 7/16"

from edge of end plug. Secure end plug to roll tube

with screw B.

STEP 6: Drill 11/32" hole into

latchplate 1 1/2" past end

of tarp. Insert eyebolt P

through hole and secure

with nut T and nut V.

STEP 7:

Insert Shur-Return™ rope

through eyebolt, remove

all slack from rope and tie

knot.

NOTE: Follow steps 1 and 2 on page 7 before proceeding.

Steps 1 and 2 on this page are for UPS-able Shur-Return™

only.

NOTE: Spring is compressed. Use caution when untying knot.

NOTE: Do not

overtighten

set screws.

end plug

shur-return™

rope

roll tube

end plug

roll tube

7/16"

1 1/2"

tie

knot

eyebolt

rope

NOTE: Failure to replace screws

could result in Shur-Return™ failure.

TIP: Do not cut off

excess rope until sure

tarp will open completely.

drill

11/32"

hole

Item Part # Description

1. 1100138 Nylon End Plug

2. 1107879 Connector Sleeve

3. 1100826 Shur-Return™ Rope

4. 1100827 Spring Retainer Plug

5. 1100832 Shur-Return™ Assembly

(Spring - Rope - Slide)

A. 1701423 Set Screw - #10 x 3/16"

B. 1704743

Self-Tapping Screw - #10 x 1/2"

D. 1700736

Self-Tapping Screw - 1/4" x 1/2"

F. 1700398 Self-Drilling Screw - 1/4" x 3/4"

P. 1700717 Eyebolt Anchor - 5/16" x 7/8"

T. 1700411 Hex Nut - 5/16"

V. 1700419 Nylon Lock Nut - 5/16"

A

B

STEP 4: Insert Shur-Return™ into roll tube at rear of box, with

rope at open end of roll tube. Thread rope through

nylon end plug.

D

B

P

T

V

A

P

T

V

D

P/N 1121522 Rev. F

9

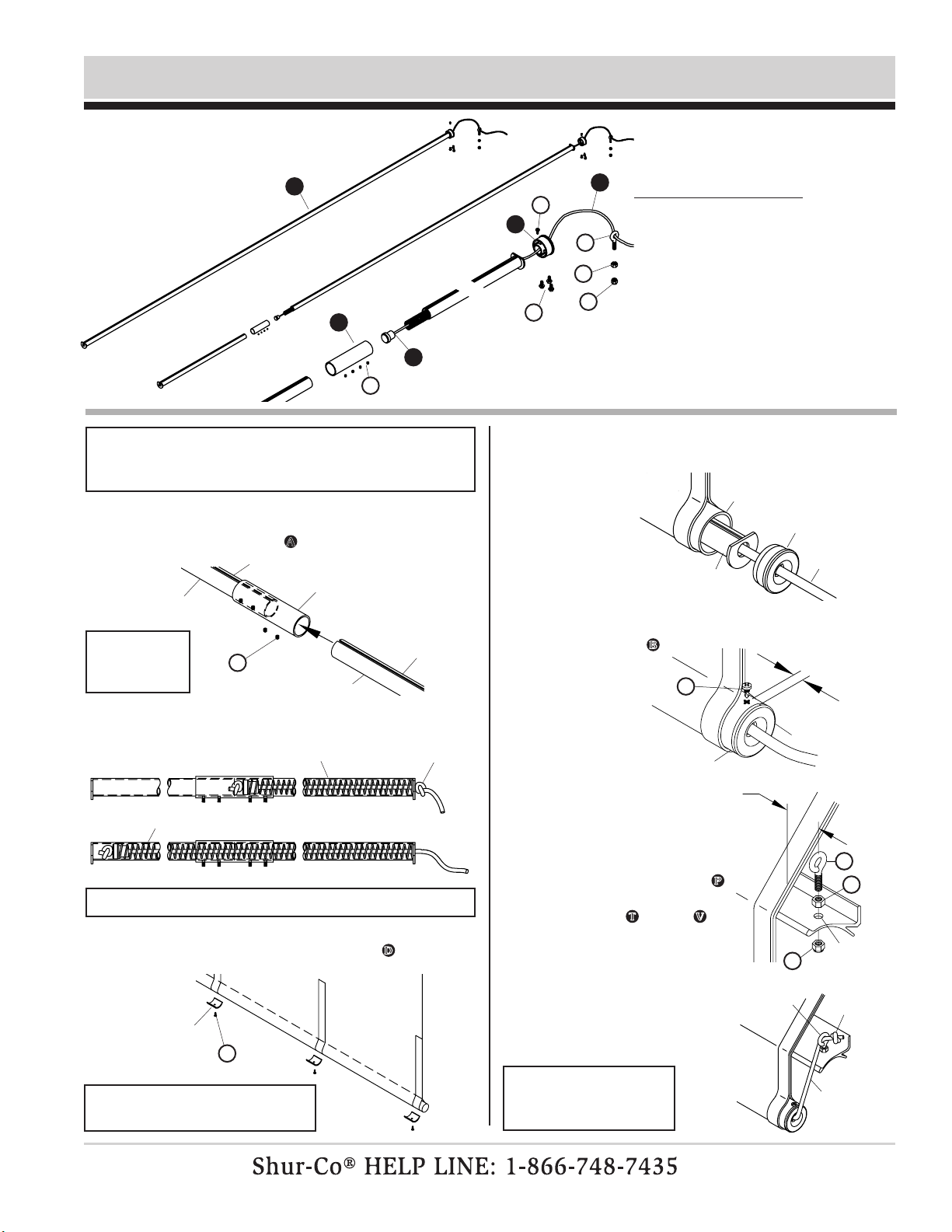

Rear Cable Return

STEP 1: Mark point on center line of face panel 3 1/8" above

upper edge of top rail.

1

2

3

17

5

67

8

9

10

11

12

13

14

7

8

STEP 8: Slide cable return loop and retaining collars over roll

tube. Fasten collars to roll tube with screws J.

STEP 4: Align cable return parallel with top rail on box.

STEP 5: Mark mounting holes and repeat steps 2 and 3.

STEP 6: Release tarp from latchplate and let hang over side

of trailer.

3 1/8"

crank assembly

roll tube

cable

return

loop

roll tube

TIPS - Install spacer, such as S/40 PVC pipe, to align cable

with pulleys and/or separate cable loop from weld. Adjust

cable to prevent rubbing on objects and fraying. Remove

weld spatter or debris from roll tube. Replace cable assembly

every two years. Roll tube must extend at least 4" past front

of trailer - purchase 4' roll tube P/N 1111719, if required.

7

10

4

18

8

15

16

13

STEP 7: Remove crank assembly from roll tube.

STEP 2: Center punch and drill 13/32" hole at mark.

STEP 3:

Align center mounting hole on return to drilled hole in cap

and fasten with screw

M

, lock washer

CC

and nut

W

.

Item Part # Description

1113025 Rear Cable Return Kit - Heavy Duty

1120650 Front Cable Return Kit - Heavy Duty -

Reverse Roll

1116117 Cable Guide Kit

1. 1114728 Universal Cable Return Housing

2. 1115014 Spacer Washer - 1 5/8"

3. 1115206 Velcro® Brand Hook

4. 1702655 Machine Screw - #10 x 1 1/4"

5. 1114582 Cable Return Strap

6. 1114691 Front Retainer Plate

7. 1703006 Pulley - 1"

8. 1111056 Plastic Spacer - 3/8"

9. 1110913 Rear Retainer Plate

10. 1702654 Machine Screw - #10 x 1"

11. 1702656 Machine Screw - #10 x 1 1/2"

12. 1702672 Cap Screw - 1/4" x 2 1/4"

13. 1702653 Machine Screw Nut - #10

14. 1701543 Nylon Lock Nut - 1/4"

15. 1112997 Rope Block Retainer Plate

16. 1701134 Oval Sleeve - 3/32" Cable

17. 1702896 Extension Spring

18. 1111054 Flat Washer - #10

M. 1700400 Self-Tapping Screw - 3/8" x 1"

W. 1700407 Hex Nut - 3/8"

CC. 1700434 Lock Washer - 3/8"

M

W

retaining

collars

J

CC

P/N 1121522 Rev. F

10

Value Series Stretch Cord Return

STEP 3: Mount shock cord tie-down strap 10’ back from rear

edge of latchplate. Drill 5/16" hole and fasten with

screws M.

STEP 2:

Using eye bracket as guide, mark and drill 5/16" hole

in trailer. Fasten bracket to trailer with screws M.

STEP 1: Open tarp against tarp stops. At rear of box, locate

eye bracket in conguration shown.

10’

latchplate

tie-down

strap

eye bracket

shock

cord

STEP 4: Lead shock cord through eye bracket, then through

grommet on tie-down strap. Tie knot in shock cord at

tie-down strap to secure. Trim end of shock cord and

wrap with tape to prevent fraying.eye bracket

latchplate

tie-down strap

Item Part # Description

1. 1703445 Shock Cord Eye Bracket

2. 1114948 Shock Cord Tie-Down Strap

3. 1100169 Shock Cord - 138"

4. 1114947 Roll Tube Eye

5. 1704352 Retaining Collar

J. 1704353 Self-Drilling Screw - 1/4" x 1"

M. 1700400 Self-Tapping Screw - 3/8" x 1"

2

1

3

STEP 5: Allow shock cords to hang down. Slide roll tube eye

onto rear end of roll tube and align eye about 1" from

shock cord, toward outside of trailer. Space retain-

ing rings about 1/8" from each side of roll tube eye.

Tighten screws Jto secure retaining rings.

roll tube eye

roll tube

shock cord

retaining ring

STEP 6: Roll tarp closed tight under latchplate and pull shock

cord through roll tube eye to create tension. Tie per-

manent knot in shock cord at rear of roll tube.

STEP 7: Roll tarp open and closed to make sure roll tube

returns correctly. Adjust tension in shock cord as

needed. Trim end of shock cord and wrap with tape

to prevent fraying.

roll tube

tape

shock cord

roll tube eye

retaining

collar

eye bracket

M

M

M

M

J

J

5

4

P/N 1121522 Rev. F

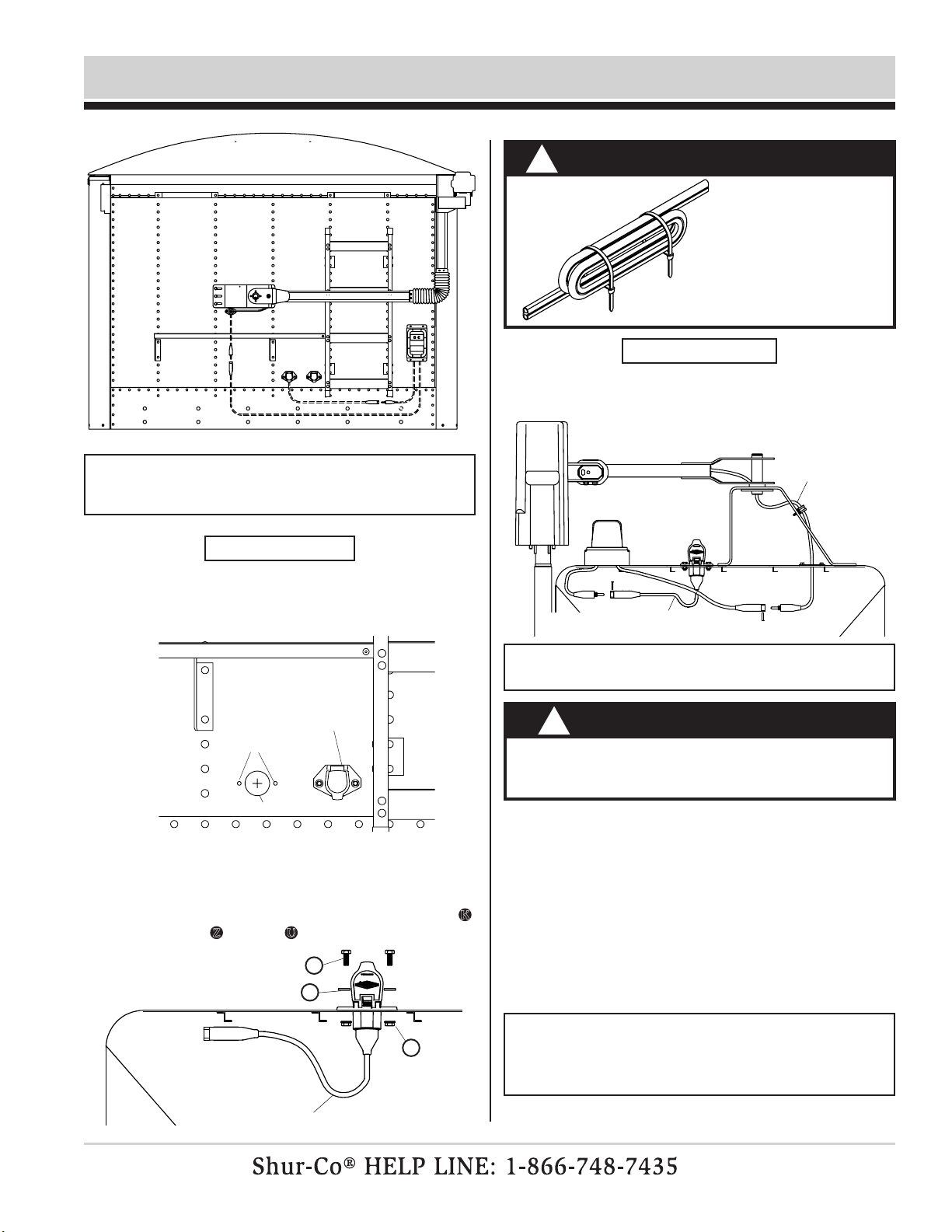

11

Rocker Switch - Cab Wiring

STEP 2: Mount solenoid in suitable location - a ventilated area

near battery is ideal. Determine best route for wire,

usually along frame with existing wire harness. Run

6-ga. wire from conductor plug to solenoid and from

power supply to solenoid as shown in diagram. Run

14-ga. wire from solenoid to switch.

STEP 3:

Locate rocker switch in convenient operating location.

Switch can be mounted in cab, on dash panel, on driver

side door jamb or in convenient location outside cab.

connect wires to

switch as shown

set screw

insert

conductor plug

positive wire -

colored stripe

on top

brass contact

wire

STEP 4: Unfasten and remove insert from conductor plug. Feed

6-ga. wire through plug and into brass contacts on

insert. Tighten set screws to secure wires. Replace

insert into conductor plug and secure screw.

negative

(ground)

wire

STEP 1: Mount circuit breaker as close as possible to battery

or power supply.

battery

rocker

switch

relay solenoid

circuit

breaker

conductor

plug

jumper wire

provided

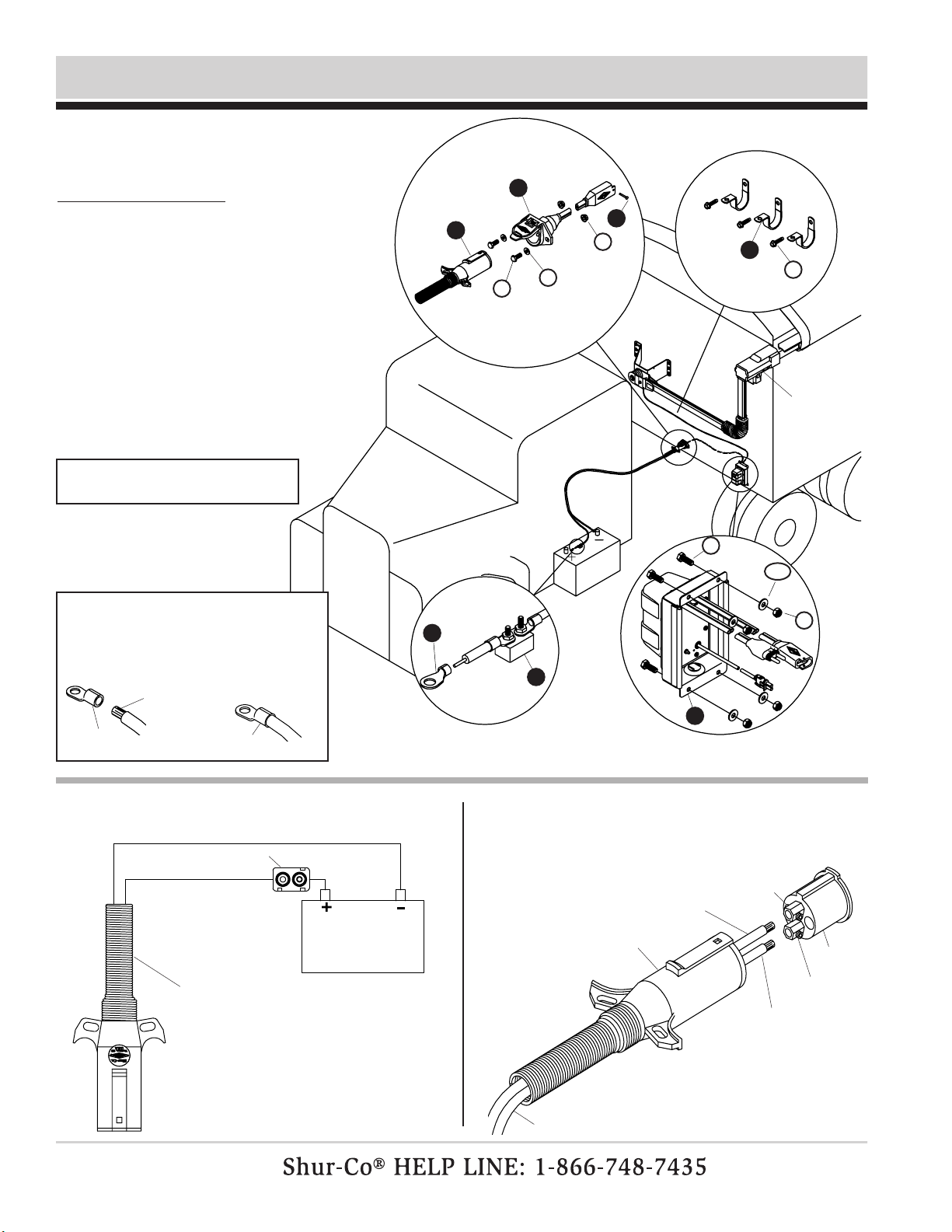

Item Part # Description

1. 1703661 Rocker Switch Mounting Bracket

2. 1116020 Rocker Switch

3. 1703845 Motor-Reversing Solenoid

4. 1704751 Harness Lock Pin - 1/4" x 7/8"

5. 1115385 Heavy-Duty Dual-Conductor Plug

6. 1120670 SMARTwire™ Dual-Conductor Socket

7. 1704354 40-Amp Modied-Reset Circuit Breaker

8. 1703896 Solenoid Cover

9. 1703659 Push-On Terminal - 14 Ga. 1/4”

10. 1704153 Ring Terminal - 14 Ga. x 1/4” Stud

11. 1703244 Ring Terminal - 6 Ga. x 3/8” Stud

12. 1703245 Ring Terminal - 6 Ga. x #10 Stud

13. 1702707 Ring Terminal - 6 Ga. 1/4 Stud

H. 1704905 Flanged Cap Screw - #10 x 1"

K. 1701045 Cap Screw - 5/16" x 3/4"

R. 1808844 Nylon Lock Nut - #10

U. 1704946 Flanged Top Lock Nut - 5/16"

Z. 1700427 Flat Washer - 1/4"

electric

motor

3

2

7

1

5

6

U

K

mount circuit breaker as close

to power supply as possible

H

8

4

Z

R

WARNING

!

When transporting trailer, wiring from in-

cab rocker switch must be connected to

4500 HD system on trailer. If motor is not

connected to power while in transit, tarp

may unwind and blow off.

NOTE: Cut wires to length and strip only enough wire

insulation to install ring terminals. Insert bare wire into

ring terminals and crimp securely.

strip wire

insulation

ring terminal crimp securely

9

11

10

13

12

P/N 1121522 Rev. F

12

Rocker Switch - Trailer Mounting & Wiring

NOTE: Release switch at end of cycle or modied-reset

circuit breaker will trip. After breaker resets, switch will

activate motor again. To reduce unnecessary strain on tarp

components, release switch at end of each cycle.

CAUTION

Check all hardware for complete assembly before

operating. Inspect system at this time and adjust

as required.

!

OPERATION:

A) Check motor direction by activating switch to Open. If switch

is running system backwards, change wire leads on dual con-

ductor plug to opposite connections.

B) Close tarp: Push switch to Close and hold. Observe tarp and

release switch when tarp is fully closed.

C) Open tarp: Push switch to Open and hold. Observe tarp and

release switch when tarp is fully opened.

CAUTION

Do not cut SMART-

wire™. Bind excess

wire with cable ties.

!

STEP 1:

Connect SMARTwire™ from electric motor to SMART-

wire™ from dual conductor and secure connection with

lock pin.

Secure all wires to trailer with cable clips and

screws. If needed, use cable ties.

smartwire™

from motor

NOTE: Coat each connection with dielectric grease (P/N

1704378) to prevent corrosion.

STEP 2: Align socket over 2" hole. Using holes in anges on

socket as guide, mark and drill two 5/16" holes.

drill two

5/16" holes

7-pole

conductor

drill 2" hole

STEP 1: Locate dual-pole conductor socket near 7-pole con-

ductor socket as shown. Determine location and drill

2" hole through trailer skin.

STEP 3: Fasten conductor socket to trailer with screws K,

washers Z and nuts U.

smartwire™

smartwire™ from

dual conductor

NOTE: Wire lengths are predetermined. Before installing

SMARTwire™ components, review and conrm wire routing so

wires will reach components with ample room for

connection.

WIRING SCHEMATIC

DUAL CONDUCTOR

K

U

front of trailer

Z

P/N 1121522 Rev. F

13

STEP 2: Unfasten and remove insert from conductor plug.

Feed 6-ga. wire through plug and into brass contacts

on insert. Tighten set screws to secure wires. Replace

insert into conductor plug and secure screw.

Wireless Receiver - Cab Wiring

set screw

insert

conductor plug

positive wire - colored

stripe on top

brass contact

wire

negative

(ground) wire

STEP 1: Mount circuit breaker as close as possible to battery

or power supply.

circuit breaker

battery

conductor plug

electric

motor

mount circuit breaker as close

to power supply as possible

Item Part # Description

1. 1115385 Heavy-Duty Dual-Conductor Plug

2. 1120670 SMARTwire™ Dual-Conductor Socket

3. 1109015 Harness Lock Pin - 1/4" x 7/8"

4. 1702108 Wire Clip - 3/4"

5. 1704354

40-Amp Modied-Reset Circuit Breaker

6. Shur-Co® Wireless Receiver

7. 1703244 Ring Terminal - 6 Ga. x 3/8" Stud

G. 1704338 Self-Tapping Screw - 1/4" x 1"

K. 1701045 Cap Screw - 5/16" x 3/4"

L. 1702926 Cap Screw - 5/16" x 7/8"

U. 1704946 Flanged Top Lock Nut - 5/16"

V. 1700419 Lock Nut - 5/16"

Z. 1700427 Flat Washer - 1/4"

AA. 1700428 Flat Washer - 5/16"

6

3

1

U

2

5

V

L

4

G

KZ

NOTE: Cut wires to length and strip

only enough wire insulation to install

ring terminals.

Insert bare wire into ring

terminals and crimp securely.

strip wire

insulation

ring

terminal crimp securely

NOTE: Only one electric tarp

system can be hooked up at a time.

7

AA

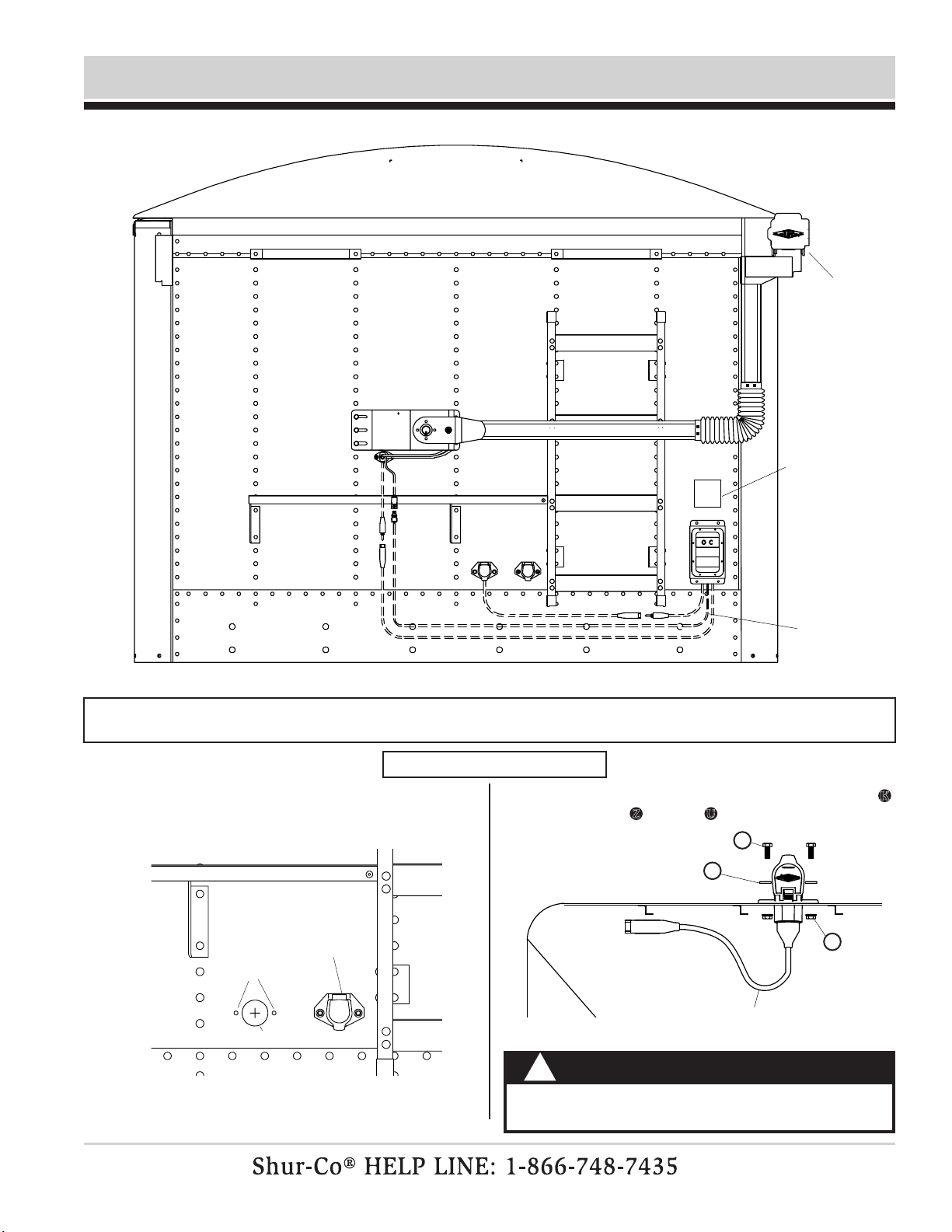

P/N 1121522 Rev. F

14

Wireless Receiver - Trailer Mounting & Wiring

front of trailer

electric

motor

STEP 3: Fasten conductor socket to trailer with screws K,

washers Z and nuts U.

smart wire

STEP 2: Align socket over 2" hole. Using holes in anges on

socket as guide, mark and drill two 5/16" holes.

drill two

5/16" holes

7-pole

conductor

drill 2" hole

DUAL-CONDUCTOR SOCKET

NOTE: Wire lengths are predetermined. Before installing SMARTwire™ components, review and conrm wire routing so wires will

reach components with ample room for connection.

STEP 1: Locate dual-pole conductor socket near 7-pole con-

ductor socket as shown. Determine location and drill

2" hole through trailer skin.

CAUTION

Do not fasten SMARTwire™ components

to trailer

through hopper walls.

!

K

U

Z

smartwire™

decal

p/n1705546

encoder wire

for smart2™

& smart3™

systems

P/N 1121522 Rev. F

15

CAUTION

Check all hardware for complete assembly before

operating. Inspect system at this time and adjust

as required.

!

NOTE: Receiver may be pressure washed, but keep nozzle

at least 3' from system while spraying.

STEP 1: Connect SMARTwire™ from wireless receiver to

SMARTwire™ from electric motor. Connect SMART-

wire™ from wireless receiver to SMARTwire™ from

conductor socket. Secure connections with lock pins.

Secure wires to trailer with cable clips and screws. If

needed, use cable ties.

NOTE: Coat each connection with dielectric grease (P/N

1704378) to prevent corrosion.

smartwire™

from motor

lock pin

lock pin

smartwire™

from wireless

receiver

smartwire™

from conductor

socket

Wireless Receiver - Trailer Mounting & Wiring

STEP 2: Align holes in wireless receiver over 2" hole in trailer

as shown below. Using holes on anges on receiver

as guide, mark and drill four 5/16" holes as shown.

STEP 1: In order to clear travel area of front arm, locate Shur-

Co® wireless receiver as low as possible on front of

trailer. Determine location and drill 2" hole through

trailer skin.

drill 2" hole

mark & drill

four 5/16" holes

align holes

in wireless

receiver with

hole in trailer

2" hole in trailer

STEP 3: Install grommet into 2" hole. Insert wire from wireless

receiver through grommet.

STEP 4: Align holes on wireless receiver with holes on trailer.

Fasten receiver to trailer with screws L, washers

AA and nuts V. Adhere warning decal P/N 1705546

above receiver in location shown.

wireless

receiver

wire from

wireless

receiver

grommet

2" hole

SHUR-CO®WIRELESS RECEIVER WIRING SCHEMATIC

L

V

STEP 2: Check motor direction by pressing either button. If

button is released and operation continues, system

is in Express Mode. To stop operation, press button

again. If switch is running system backwards, program

remote to wireless receiver and rewire as directed in

troubleshooting guide in remote instructions.

press c to

close tarp

press o to

open tarp

apply

warning decal

p/n1705546

encoder

wire

AA

P/N 1121522 Rev. F

16

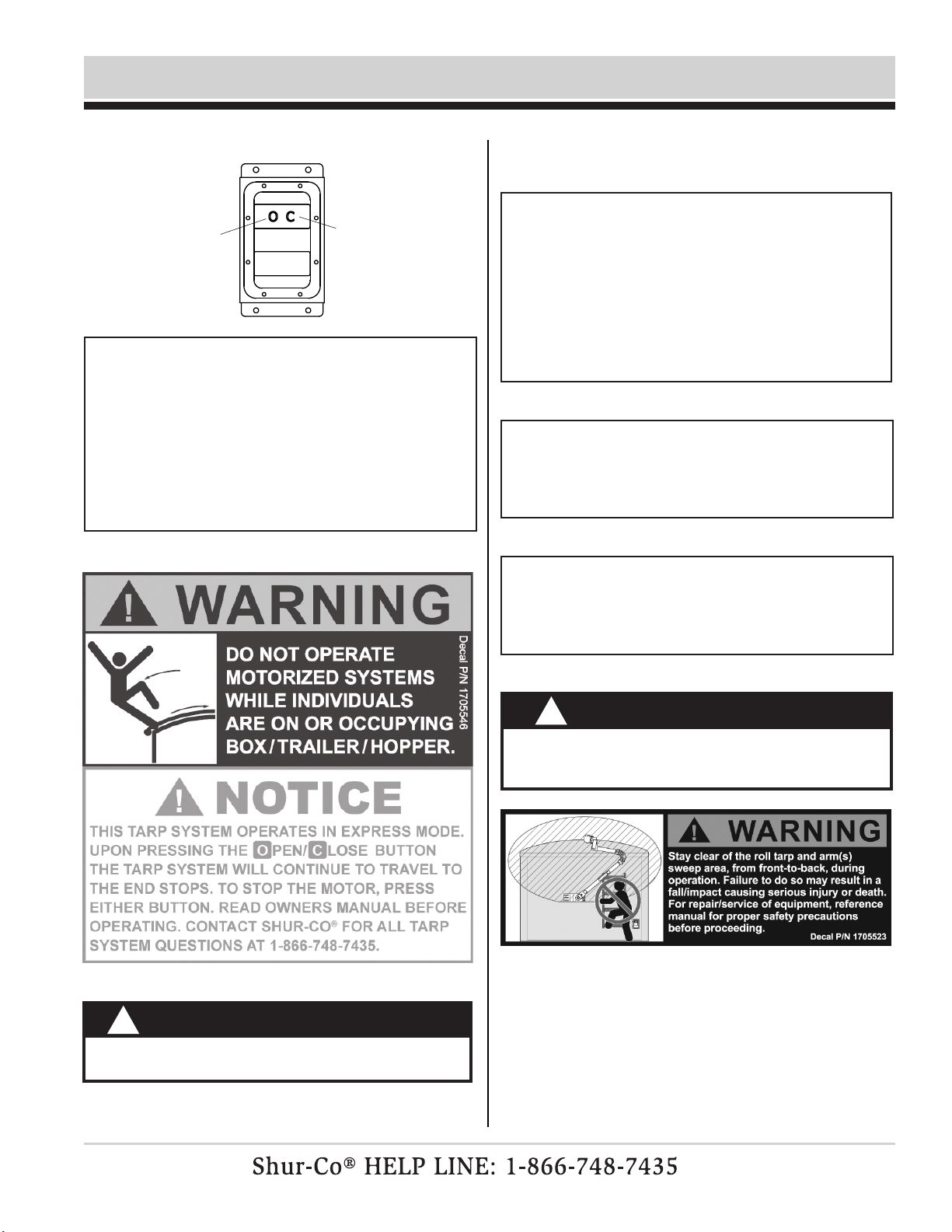

Operation

press c to

close tarp

press o to

open tarp

NOTE: Tarp systems will operate in EXPRESS MODE when

using buttons on trailer-mounted control box, if encoder

wires are connected. For SMART2™ systems, travel stops

must also be set, otherwise you must press and hold

buttons. When in EXPRESS MODE, press and release

buttons to open and close tarp (operation will continue

until complete after releasing button). When in MANUAL

MODE, press and hold buttons (operation will stop if button

is released). See remote instruction manual for detailed

instructions on remote operation.

WARNING

Stay clear of roll tarp and arm(s) area of travel during

operation. Failure to do so could result in serious

injury or death.

!

NOTE: Tarp systems operate in EXPRESS MODE when

commanded to operate from buttons on trailer-mounted

control box. Closing remote lid or pressing select button will

not stop system in this case. Pressing OPEN or CLOSE

button on remote will stop system if in range.

NOTE: Tarp systems operate in EXPRESS MODE when

using buttons on trailer-mounted control box, if encoder

wires are connected. For SMART2™ systems, travel stops

must also be set. Otherwise you must press and hold

buttons (see remote instructions for SMART2™ systems).

NOTICE

Decal shown above must be placed above wire-

less receiver on front of box.

!

NOTE: 4500 Series HD trailer-mounted control boxes now

operate in EXPRESS MODE. Pressing Oor Cbutton

on control box initiates express open or close operation.

After that, pressing either button will stop tarp operation. If

neither button is pressed, operation will automatically stop

at end of travel. On SMART2™ systems, if travel stops are

not set, trailer-mounted control box operates in MANUAL

(momentary) MODE. Remotes for both systems are shipped

with tarp channel set to EXPRESS MODE and can be

congured as desired.

P/N 1121522 Rev. F

17

Electric Motor Replacement

lock washer

ring terminal

electric motor terminal

hex nut

rubber boot

motor

cover

CAUTION

Check all hardware for complete assembly be-

fore operating. Inspect system at this time and

adjust as required.

!

NOTE: Leave roll tube fastened to motor bracket.

STEP 1: Disconnect electric power to trailer. Unfasten and

remove motor cover. Unfasten screw O and nut X

holding motor shaft to roll tube/front arm assembly.

STEP 2: Disconnect electric wires from motor terminals.

STEP 3: Unfasten and remove only washers BB and nuts T

holding motor to motor bracket/front arm assembly,

leaving motor mount bearing retainers in place. Re-

move existing motor.

STEP 3: Fasten motor shaft to roll tube with screw O and nut

X. Replace motor cover and fasten to motor with

screws C. Reconnect electric power.

motor

shaft

O

STEP 2: Connect electric wires to motor terminals.

lock washer

ring terminal

electric motor terminal

hex nut

rubber boot

motor

cover

C

motor

shaft

existing

motor

new

motor

motor bracket/

front arm

assembly

motor bracket/

front arm

assembly

motor

bracket

roll tube O

C

X

X

T

T

STEP 1: Install new motor. Fasten motor to motor bracket with

washers BB and nuts T.

REMOVE EXISTING MOTOR INSTALL NEW MOTOR

BB

BB

Other manuals for 4500 HD Series

2

Table of contents

Other Shurco Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction