7 Series Motorized External Instructions 6

www.screeninnovations.com Installation Questions: 512-832-6939 BDMEX V2.0 D

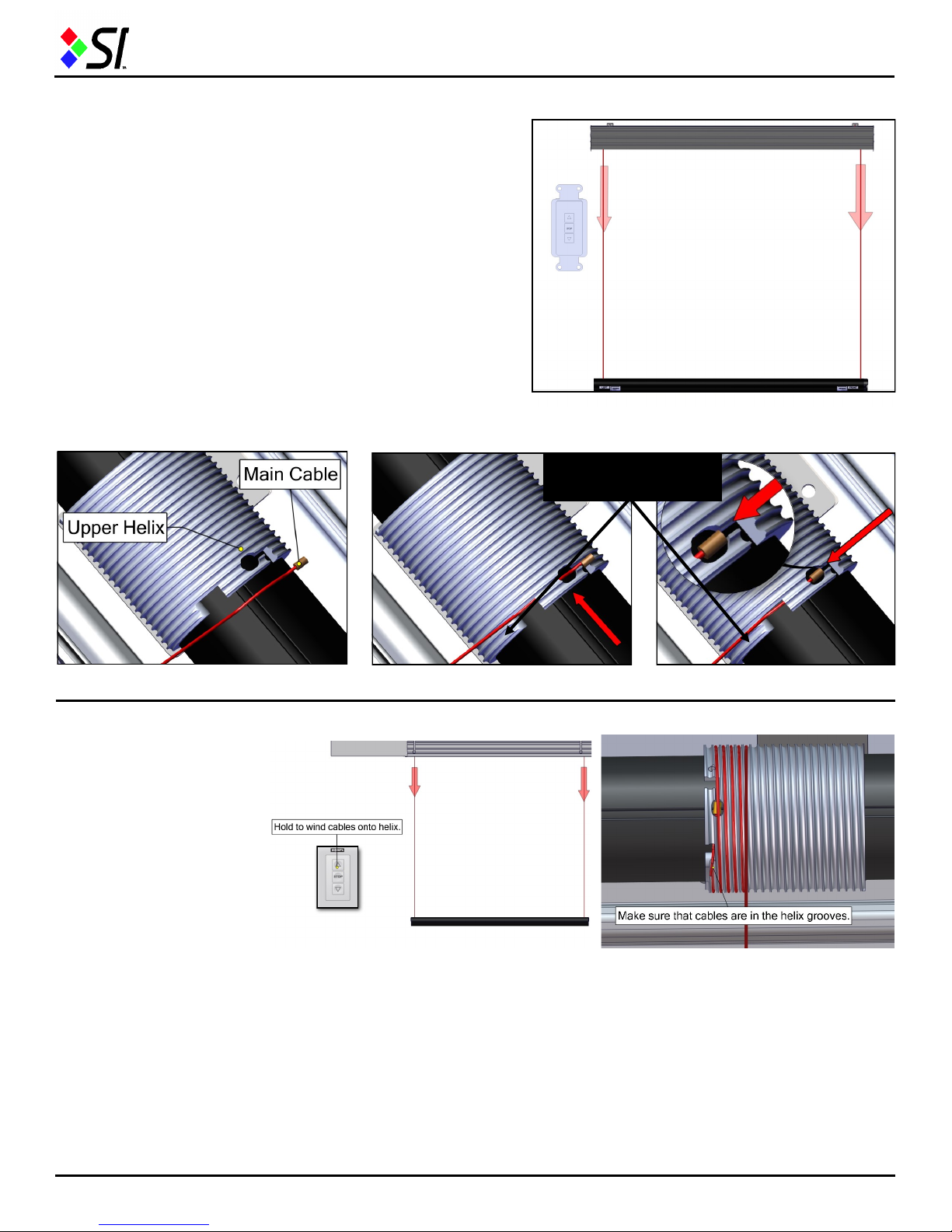

10. a) IMPORTANT: The wing

and tube are going to be lifted

up off the floor-make sure the

wing and tube are centered

and nothing is interfering with

the cables before raising the

screen.

10. b) With one on person on

each side, guide the cables

into the first groove of the

helixes, and apply downward tension to straighten each cable to plumb.

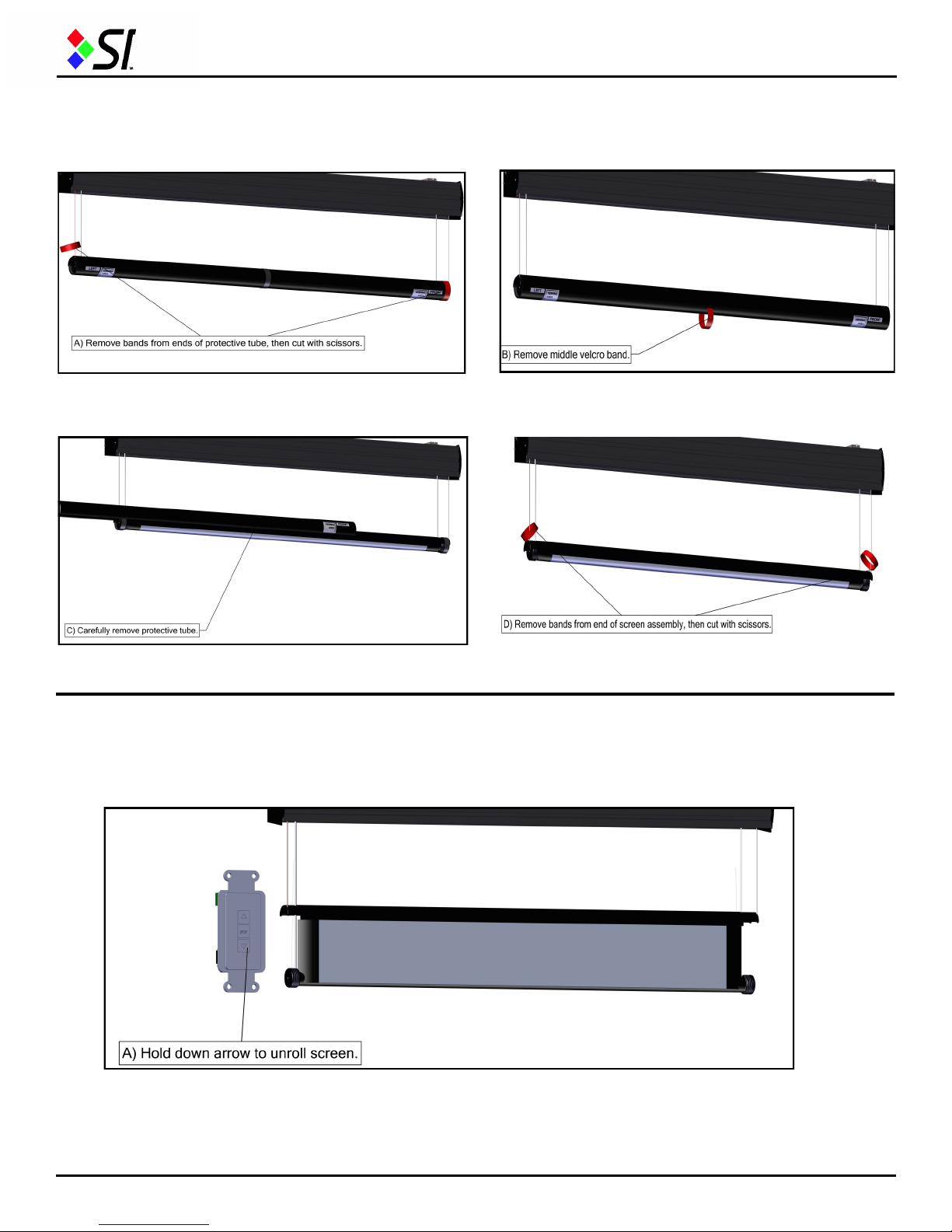

10. c) Using the wall switch, press and hold the Up arrow button until the screen is lifted off the floor, then release the

button to stop the screen.

10. d) Once the screen has been lifted off the floor by the cables, verify that the cables start in the first groove, and are

following the grooves of the helix as shown in the above right image. If you experience a problem with the cables, lower

the screen with the Down button, realign the cables with the grooves, and repeat step 11.c).

Guide cable into

first groove of helix.

Pull straight down on

cables until screen is

raised off the floor.

Raising the screen using the wall switch

Connecting the screen assembly to upper cassette

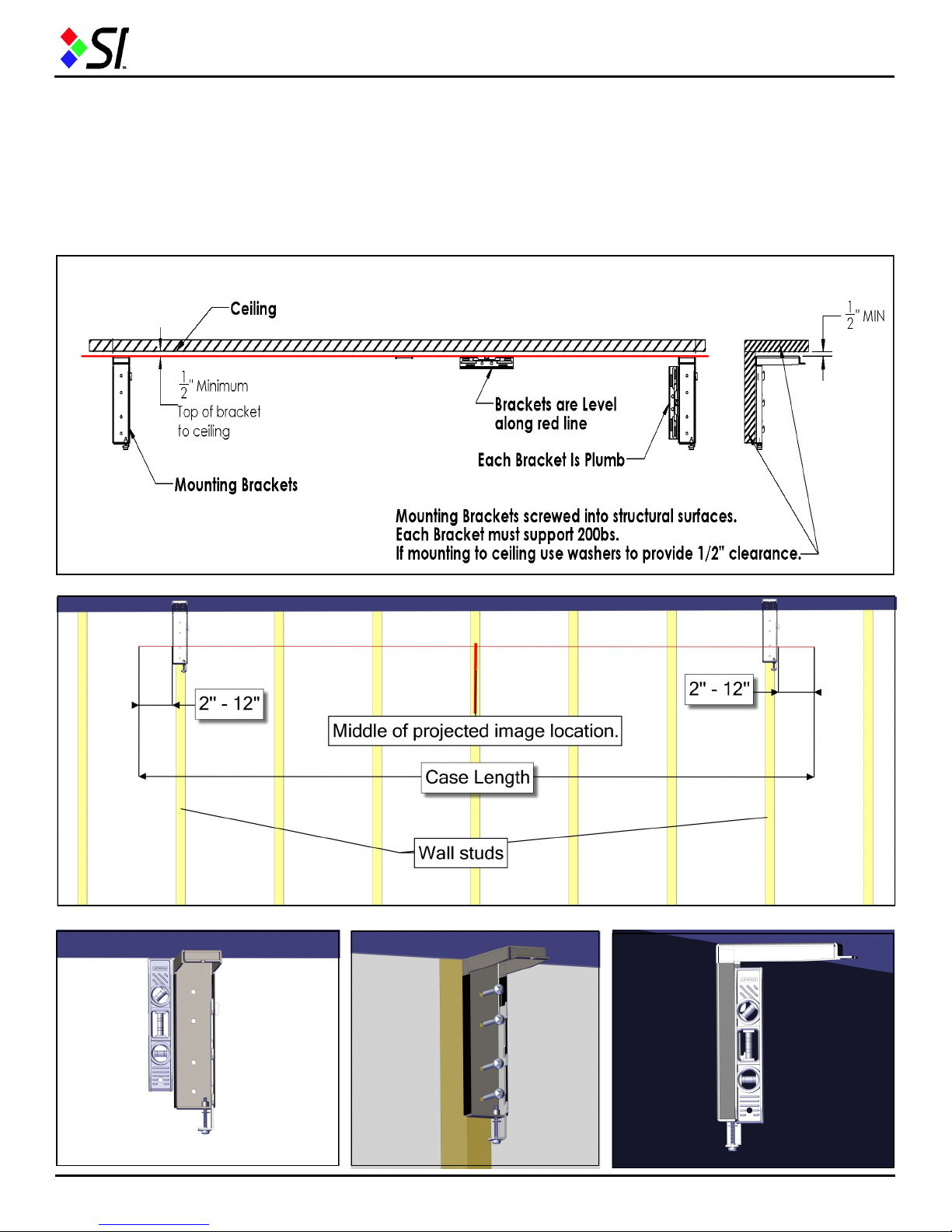

9. a) Position the black screen packing tube on the floor centered

directly below the case. The “Left” label will be on the viewers left

hand side, while the Front label should be visible on viewer’s right

side.

9. b) Connect the wall switch by first plugging the RJ45 end of the

wall switch cable into any of the RJ45 ports on the left side of the

case. Next, plug other end of the cable (RJ9) into the port on back of

Somfy wall switch-make sure to press in until it clicks.

9. c) Plug in the supplied power cord to power the screen.

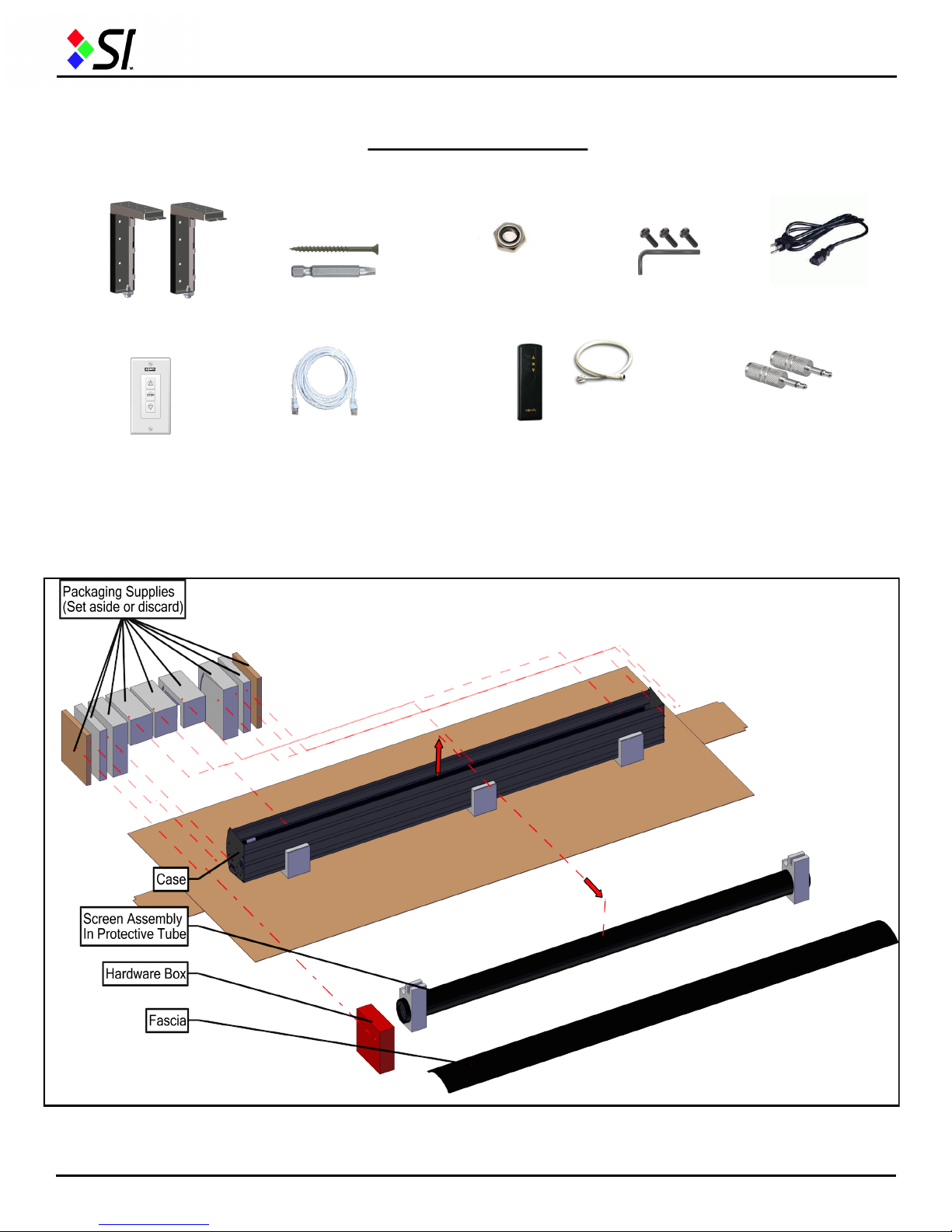

9. d) At each end of the black screen tube, locate and unwrap the

left and right steel cables—they are wrapped in grey foam packaging

material. Connect the steel cables to the threaded helixes (inside the

case) by first sliding the cable underneath the edge of the helix as

shown below. Pull down on the cable to lock it in place. Refer to the

three drawings below for guidance.

Make sure cable follows

first groove in helix