Siargo FS35001 User manual

FS35001 User Manual

MEMS Mass flow sensors for manifold installation

©2022 Siargo Ltd.

VA.0.01

2

www.Siargo.com FS35001 User Manual

MEMS Mass Flow Sensors

With proprietary thermal-D® sensing for manifold configuration

FS35001 Series

User Manual

Document No. 08-2022-FSTD4 EN

Issue date: 2022.08

Revision: VA.0.01

Siargo Ltd.

3100 De La Cruz Boulevard, Suite 210

Santa Clara, California 95054

USA

Tel: +1(408)969.0368

© Copyright 2022 and Liability Disclaimer

Siargo Ltd. and its subsidiaries reserve the right to change the specifications and/or descriptions

without prior notice. Siargo and its subsidiaries shall not assume any inaccuracy or errors in this

manual. For further information and updates, please visit www.Siargo.com.

3

www.Siargo.com FS35001 User Manual

Attention !

Use with caution !

•Please carefully read this manual prior to operating this product.

•Do not open or modify any hardware which may lead to irrecoverable

damage.

•Do not use this product if you suspect any malfunctions or defection.

•Do not use this product for corrosive media or in a strong vibration

environment.

•Use this product according to the specified parameters.

•Only the trained or qualified personnel shall be allowed to perform

product services.

•Be cautious for electrical safety, and even it operates at a low voltage,

any electrical shock might lead to some unexpected damages.

•The gas to be measured should be clean and free of particles, as

even light particles may be accumulated inside the tiny pressure port

that may result in inaccuracy in metrology, clogging, or other

irrecoverable damage.

•Do not apply for any unknown or non-specified gases that may

damage the product.

4

www.Siargo.com FS35001 User Manual

Table of Contents

1. Overview.................................................................................................. 5

2. Receipt / unpack of the products ................................................................ 6

3. Knowing the products ............................................................................... 7

3.1 Product description ...................................................................................................7

3.2 Power and data pinout description .............................................................................7

3.3 Mechanical dimensions..............................................................................................8

4. Installation............................................................................................... 9

5. Basic operation........................................................................................10

5.1 I2C interface connection diagram........................................Error! Bookmark not defined.

5.2 I2C interface command description .....................................Error! Bookmark not defined.

5.3 I2C interface read/write sequences......................................Error! Bookmark not defined.

6. Product selection.....................................................................................10

7. Product performance ...............................................................................16

7.1 Technical specifications ........................................................................................... 17

7.2 Typical (analog) output............................................................................................18

7.3 Pressure loss...........................................................................................................18

8. Technical notes for the product performance.............................................19

8.1 Measurement principles...........................................................................................19

8.2 Precautions for the best performance of the product .................................................19

8.2.1 Contamination and sterilization ...................................................................................19

8.2.2 Altitude changes.........................................................................................................19

8.2.3 Excessive humidity or condensation .............................................................................20

8.2.4 Metrology verification .................................................................................................20

9. Warranty and Liability..............................................................................21

10. Service contact and information ...............................................................23

Appendix I: Sensor evaluation kit ...................................................................24

Appendix II: Document history.......................................................................25

5

www.Siargo.com FS35001 User Manual

1. Overview

This manual provides essential information for the operation of the FS35001 series of gas mass flow

sensors for general-purpose gas flow monitor and control applications with the full-scale mass flow

rate from 0.2 to 20 SLPM, and both analog and digital outputs. The product performance,

maintenance, and troubleshooting as well as the information for product order, technical support,

and repair are also included.

FS35001 product provides the manifold configuration for the mechanical connections. Optionally it

can also be offered with a manifold body with the 4mm one-touch flexible piping. It can be applied

to medical equipment and instrumentation applications. The series covers a wide dynamic flow

range with a working pressure rating of up to 1.0 MPa (10 bar or 150 PSI), and a compensated

temperature ranging from -5 to 50°C.

The sensing elements are manufactured with Siargo’s proprietary MEMS (micro-electro-mechanical

systems) thermal mass flow sensing technologies (Thermal-D®) that measures the calorimetry and

diffusivity of the flow medium. The sensor surface is passivated with silicon nitride ceramic materials

together with a water/oil proof nano-coating for performance and reliability. Compared to the

conventional calorimetric flow sensing technology, this unique sensing approach offers better

linearity, removes gas sensitivity for gases with similar thermal diffusivities, and improves

temperature performance. It can also auto recognize pre-programmed gases with significant

differences in thermal diffusivity. It is the first of the kind in the industry that senses the mass flow

with multiple gases without a manual gas conversion factor. As such, it ensures high precision for gas

measurements with air calibration.

Thermal-D

®is a trademark of Siargo’s thermal sensing technology.

6

www.Siargo.com FS35001 User Manual

2. Receipt / unpack of the products

Upon receipt of the products, please check the packing box before the dismantlement of the packing

materials. Ensure no damages during shipping. If any abnormality is observed, please contact and

notify the carrier who shipped the product and inform the distributors or sales representatives if the

order is not placed directly with the manufacturer; otherwise, the manufacturer should be informed.

For any further actions, please refer to the return and repair section in this manual.

If the packing box is intact, proceed to open the packing box, and you shall find the product (either

the sensor formality per the actual order), together with the power and data cable if the order is

included as shown below.

Please check immediately for the integrity of the product and the power and data cable; if any

abnormality is identified, please notify the distributor/sales representative or manufacturer as soon

as you can. If any defects are confirmed, an exchange shall be arranged immediately via the original

sales channel. This user manual shall also be included in the packing box or via an online link for an

electronic version which should be sent by your sales agent. In most cases, this manual shall be made

available to the customer before the actual order.

FS35001 Power and data cable (optional)

Figure 2.1: FS35001 flow sensor and accessories

7

www.Siargo.com FS35001 User Manual

3. Knowing the products

3.1 Product description

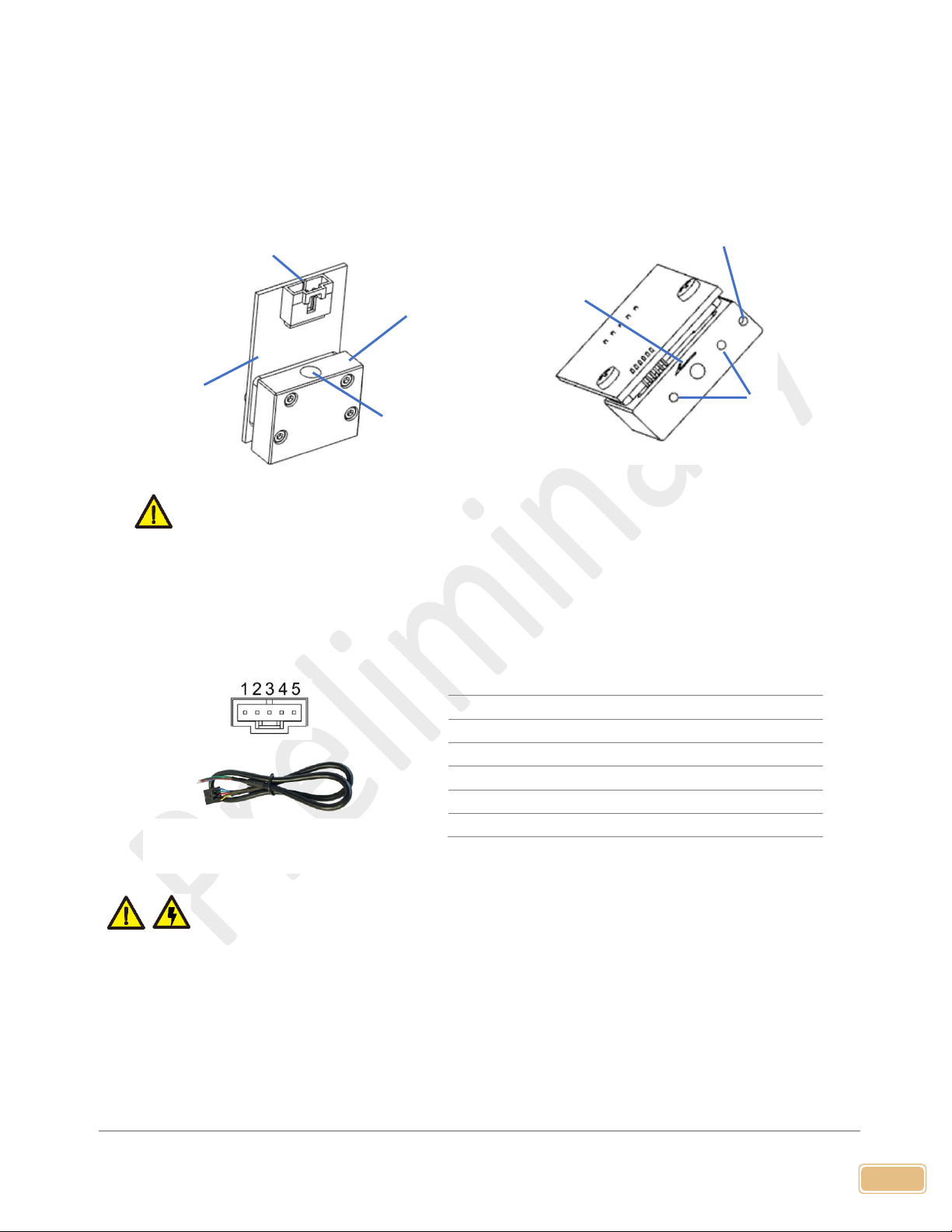

Figure 3.1: FS35001 parts description

3.2 Power and data pinout description

Table 3.1: FS35001 pin/wire assignments.

DO NOT connect or disconnect the sensor cable when power is on!! It will damage the

electronic chipsets inside the sensor module! The standard cable has an AMPMODU

MTE (5 positions) compatible connector with a length of 0.5 meters.

Note: 1. Power supply: The FS35001 requires a power supply of 8 ~ 24 Vdc. No particular requirements for

the external power supply, but standard industrial power cautions should be applied.

2. The analog outputs 0.5 ~ 4.5 Vdc are corresponding to the specified full-scale flow range at the

time of order. If the analog option is not selected, this pin output could be NULL.

Wire

Color

Definition

1

Blue

RS485 B(+) / SDA(I2C)

2

Green

Analog output, 0.5 ~ 4.5 Vdc

3

Red

Power supply, 8 ~ 24 Vdc

4

Black

Ground

5

Yellow

RS485 A(-) / SCL(I2C)

Control

electronics

Data/power socket

Flow block

Installation

mounting port.

Note: The manifold base port size should not be smaller than those of the flow ports on the

product.

Manifold flow

ports

Figure 3.2: FS35001 pinout

2.54mm centers; 0.635mm square

Flow direction

Dowel pin port

8

www.Siargo.com FS35001 User Manual

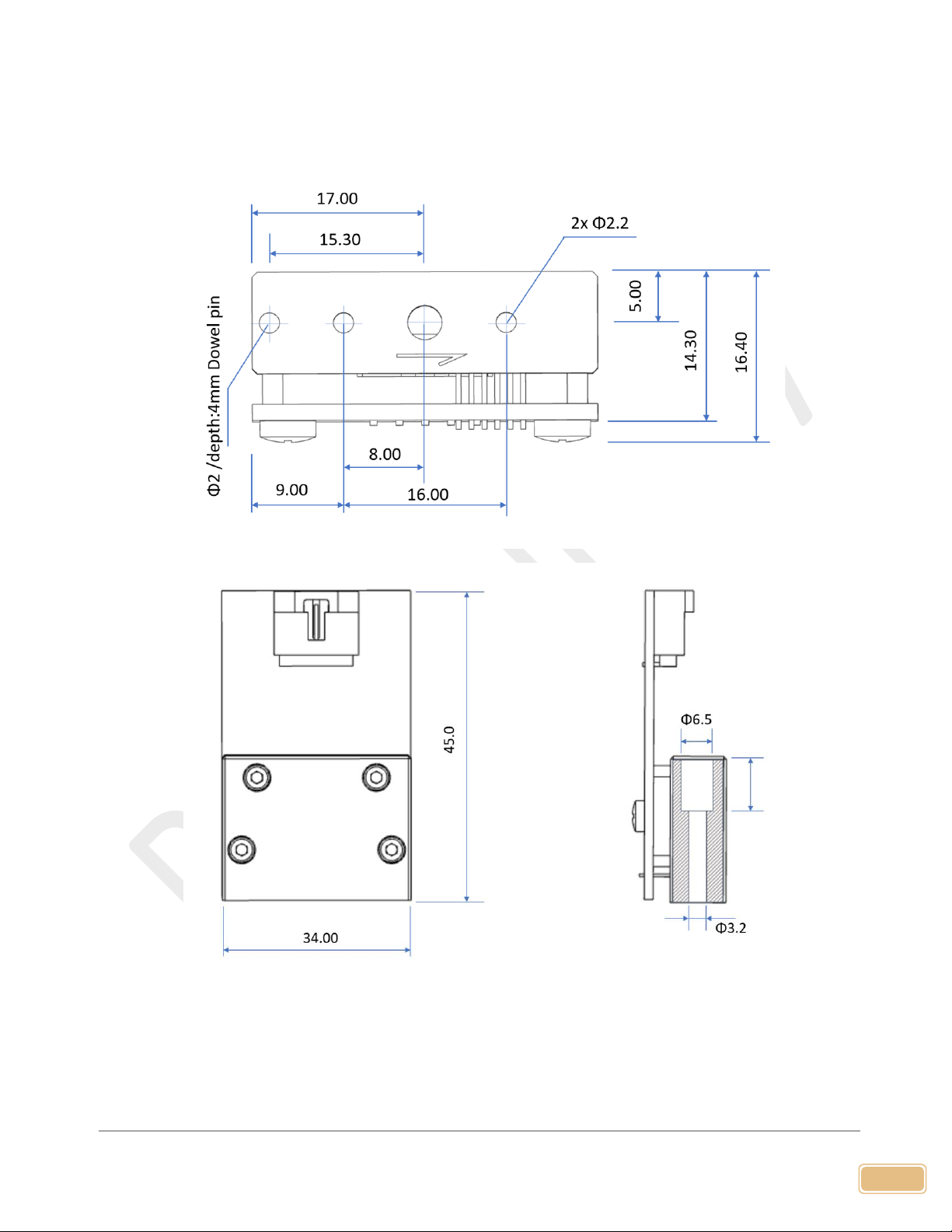

3.3 Mechanical dimensions

Figure 3.3.1. FS35001 manifold mechanical dimensions.

9

www.Siargo.com FS35001 User Manual

4. Installation

Do not open or alter any part of the product, which would lead to malfunction and irrecoverable

damage.

For the installation, make sure the leakage proof of the connections and all electrical precautions are

applied. Please make sure the electrical cable is properly engaged. It should be noted that the sensor

is designed for medium to low pressure per the applications, therefore, the system design would be

important for the flow stability and related flow noises.

In order to prevent over-forced installation, The mounding torque applied should be within 0.35±0.03

N·m. Sealing O-ring is recommended to be the ones that comply with ISO 3601/1; the mounting

screw is specified for M3x20mm by ISO 14583; the dowel pin should be Φ2m6x6 mm.

Please align the products with your gas manifold block properly, and no excessive force should be

applied during installation, and subsequent leakage tests would be required for safety and

performance.

10

www.Siargo.com FS35001 User Manual

5. Basic operation

5.1 RS485 Modbus communication protocol

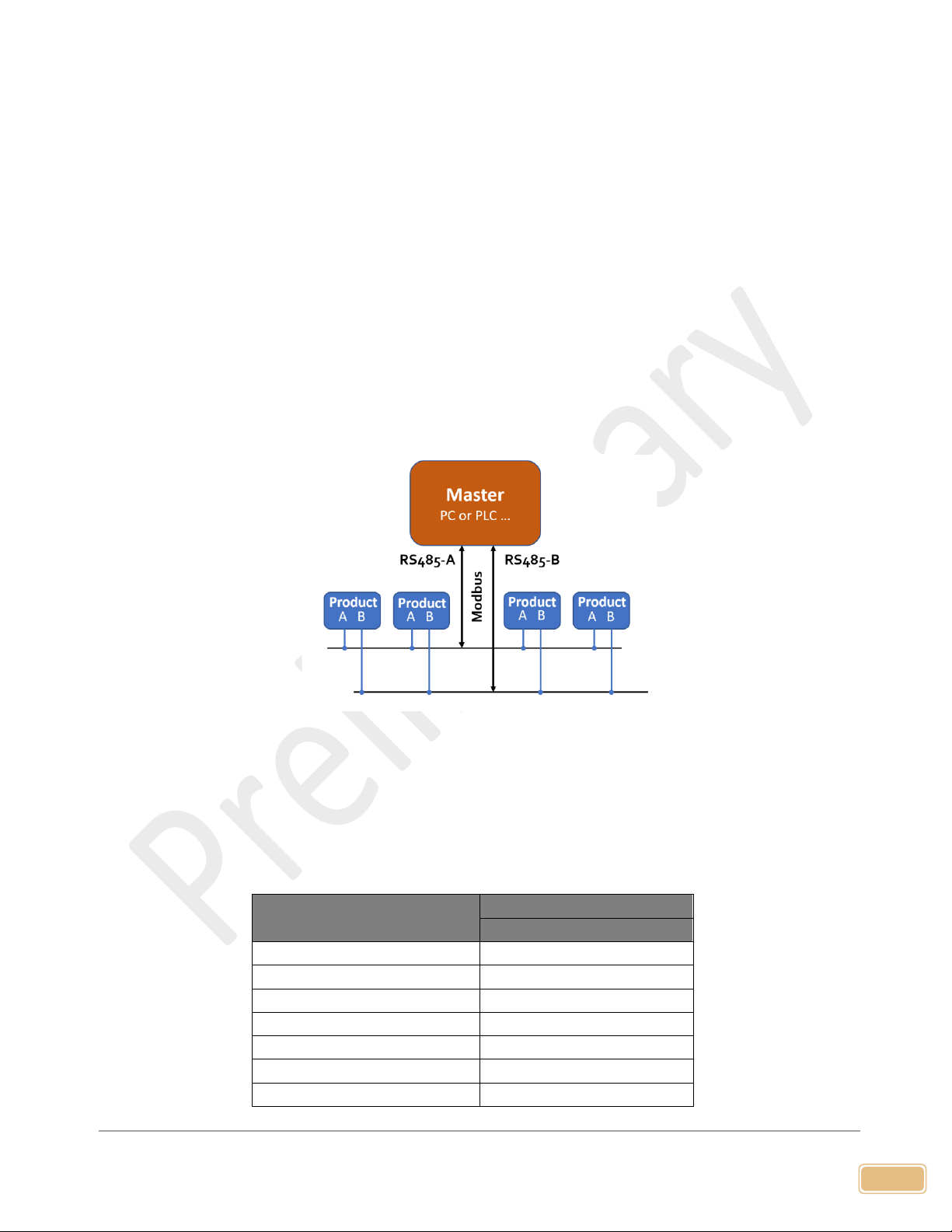

The digital communication protocol is based on standard Modbus RTU Half-plex mode. A master (PC

or PLC) can communicate with multiple slaves (the current product) for data exchange and

communication parameter configuration. Refer to Table 3.2 for cable connection.

5.1.1 Hardware connection

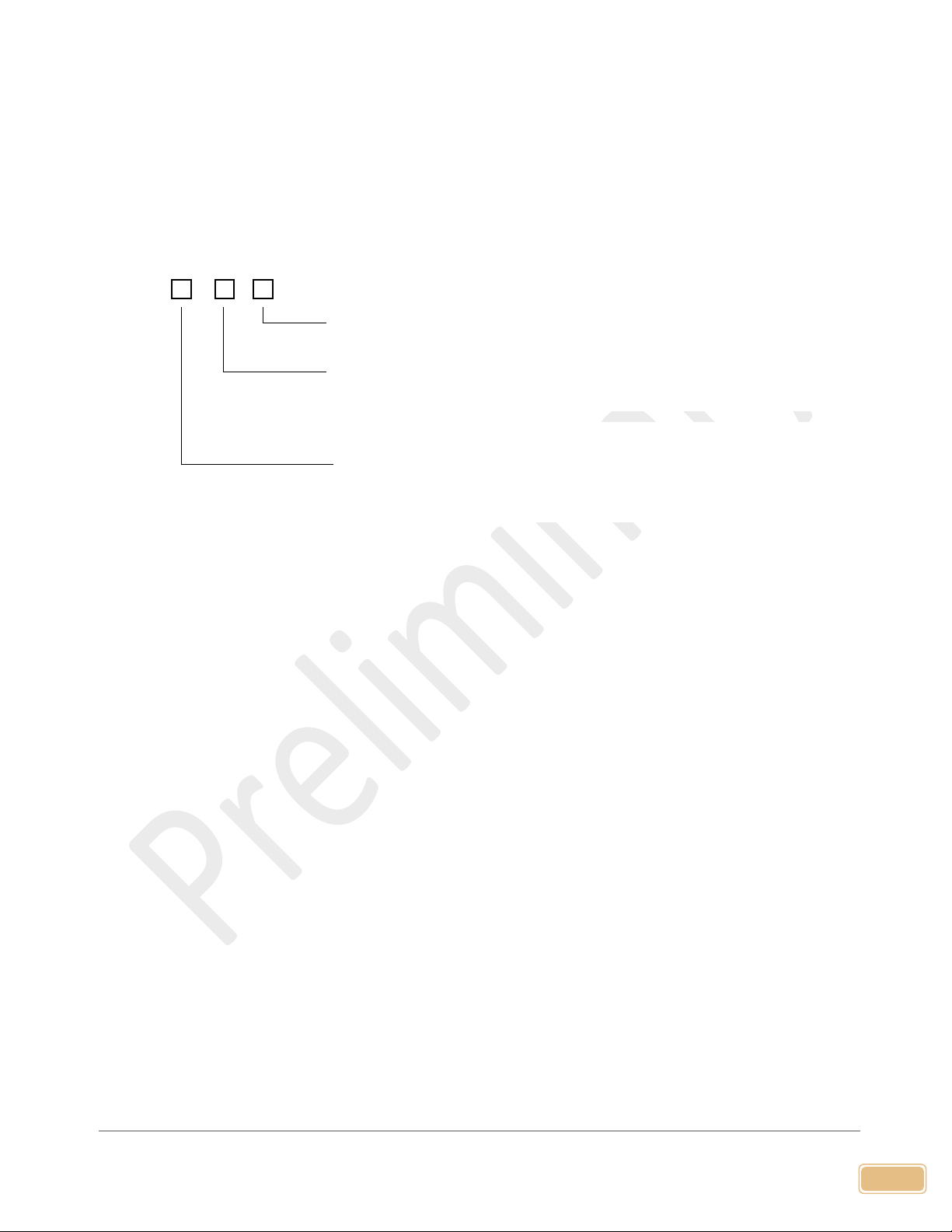

The RS485 hardware layer is TIA/EIA-485-A, as illustrated below. In this configuration, the product

(FS4100) is a slave.

Figure 5.1: RS485 hardware

5.1.2 Communication parameters

The PC UART communication parameters are listed in table 5.1.

Table 5.1: PC UART communication parameters

Parameters

Protocol

RTU

Baud rate (Bits per second)

38400 bps

Start bits

1

Data bits

8

Stop bits

1

Even/Odd parity

None

Bits period

104.2 µsec

Bytes period

1.1458 msec

11

www.Siargo.com FS35001 User Manual

Maximum data length

20

Maximum nodes

247

5.1.3 Frame

The frame function is based on the standard Modbus RTU framing:

Table 5.2: frame function

Start_bits

Address

Function codes

Data

CRC

Stop_bits

T1-T2-T3-T4

8 bit

8 bit

N 8 bit (20≥n≥0)

16 bit

T1-T2-T3-T4

Start_bits: 4 periods bit time, for a new frame.

Address: The address can be set from 1 to 247 except for 157 (0x9d). 0 is the broadcast address.

Function codes: Define the product's functions/actions (slaves), either execution or response.

Data: The address of the register, length of data, and the data themselves.

CRC: CRC verification code. The low byte is followed by the high byte. For example, a 16-bit

CRC is divided into BYTE_H and BYTE_L. In the framing, the BYTE_L will come first, then

followed by the BYTE_H. The last one is the STOP signal.

Stop_bits: 4 periods bit time, for ending the current frame.

5.1.4 Function codes

The Modbus function codes applied for the product are the sub-class of the standard Modbus

function codes. These codes are used to set or read the registers of the product:

Table 5.3: function codes

Code

Name

Functions

0x03

Read register

Read register(s)

0x06

Set single register

Write one single 16-bit register

0x10

Set multiple registers

Write multiple registers

5.1.5 Registers

The product (FS4100) has multiple registers available for the assignment of the various functions. With these

functions, the user can obtain the data from the products, such as product address and flow rates from the

registers, or set the product functions by writing the corresponding parameters.

The currently available registers are listed in the following table, and the registers may be customized upon

contacting the manufacturer. Where R: read; W: write-only; W/R: read and write.

12

www.Siargo.com FS35001 User Manual

Note: At the time of shipping, the write protection function is enabled except for address and baud rate.

Once the user completes the register value change, the write protection will be automatically enabled

once again to prevent incidental data loss.

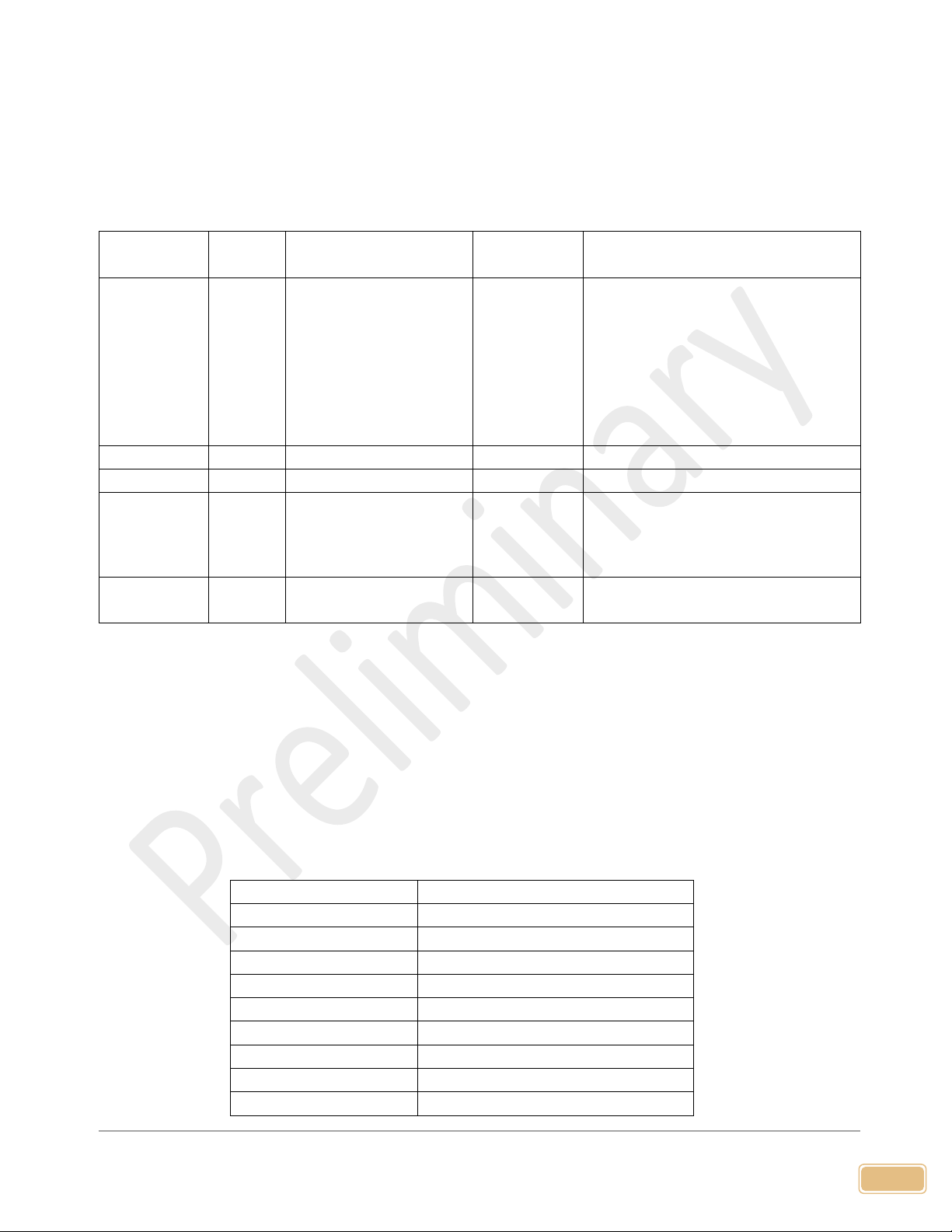

Table 5.4: Registers

Functions

Description

Register

Modbus

Address

Product address (R/W)

0x0081

40130 (0x0081)

Serial number

Serial number of the product (R)

0x0030

40049 (0x0030)

Flow rate

Current flow rate (R)

0x003A ~ 0x003B

40059 (0x003A)

Baud rate

Communication baud rate (R/W)

0x0082

40131 (0x0082)

GCF

Gas conversion factor (R/W)

0x008B

40140 (0x008B)

Digital filter depth

Response time or sampling time (R/W)

0x008C

40141 (0x008C)

Offset calibration

Offset reset or calibration (W)

0x00F0

40241 (0x00F0)

Write protection

Write protection of selected parameters (W)

0x00FF

40256 (0x00FF)

The detailed information of each register is described below: Y: enabled; N: disabled

Address

0x0081

Write

Y

Read

Y

Description

Address of the product

Value type

UINT 16

Notes

Values from 1 to 247 except for 157 (0x9d).

The broadcast address is not enabled, and the default address is 1.

SN, Serial number

0x0030

Write

N

Read

Y

Description

Series Number of the product, SN

Value type

UINT 8 (12 bits)

Notes

SN= value(0x0030), value(0x0031),….,value (0x0035);

Receiving 12 bits as: 2A 41 31 42 32 33 34 35 36 2A , the corresponding Serial

Number is **A1B23456**.

Flow rate

0x003A ~ 0x003B

Write

N

Read

Y

Description

Current flow rate

Value type

UINT 16

Notes

Flow rate = [Value (0x003A) * 65536 + value (ox003B)] / 1000

e.g.: When the user reads “0” from register 0x003A and “20340” from register

0x003B, current flow rate = (0 * 65536 + 20340) / 1000 = 20.340 SLPM

Baud rate

0x0082

Write

Y

Read

Y

Description

Communication baud rate

Value type

UINT 16

13

www.Siargo.com FS35001 User Manual

Notes

0: baud rate=4800; 1: baud rate=9600; 2: baud rate=19200; 3 baud rate=38400.

The default value is 3.

e.g.: When the user reads “3” from register 0x0082, the baud rate is 38400.

GCF

0x008B

Write

Y

Read

Y

Description

The gas conversion factor for applicable gas is different from calibration gas

Value type

UINT 16

Notes

The GCF of air is 1000 (default), normally read from register 0x008B.

Note: The product will disable this function with write protection once the

metering gas is confirmed with the proper GCF. For a specific GCF

value, please contact the manufacturer.

Response time

0x008C

Write

Y

Read

Y

Description

Digital filter depth setting

Value type

UINT 16

Notes

0 ~ 9 programmable, corresponding to 20~ 29data sampling in the software

filter.

The default value is 3, corresponding to 23= 8 data sampling.

Offset calibration

0x00F0

Write

Y

Read

N

Description

Reset or calibrate the offset

Value type

UINT 16, Fixed value 0xAA55

Notes

To reset or calibrate the offset, write 0xAA55 to register 0x00F0.

Note: When you execute this function, make sure there is NO flow in the

flow channel.

Write protection

0x00FF

Write

Y

Read

N

Description

Write protection disabler for a set value to a specific register.

Value type

UINT 16, Fixed value 0xAA55

Notes

This function is enabled at the time of product shipment. To enable the write

function of a specific parameter, such as GCF, or offset, the user needs to send

0xAA55 to the register 0x00FF, and then the write function will be enabled

(write protection is disabled). After the write execution is completed, the

firmware will automatically re-enable the write protection.

14

www.Siargo.com FS35001 User Manual

5.2 I2C communication protocol

5.2.1 I2C interface connection diagram

5.2.2 I2C interface read/write sequences

15

www.Siargo.com FS35001 User Manual

5.2.3 I2C interface command description

Please note the addition of the CRC in the protocol. If you are using an older version, you may need to update

your firmware for the current products.

Command

Byte

Length

(int 16)

Command Name

Read/Write

Notes

0x00A4

1

I2C address

Read/Write

Int 16.

bit 0 is the R/W flag bit;

bit 1 ~ bit 7 are available;

bit 8 ~ bit 15 = 0.

The default I2C address is 1.

Hex: 0x0002 (write) /0x0003 (read),

Bin: 0000 0000 0000 0010 (write)

0000 0000 0000 0011 (read).

0x0030

6

Sensor serial number

Read

ASCII

0x003A

2

Flow rate

Read

Int 32/1000 SLPM

0x008C

1

Filter depth

Read/Write

Int 16, 0 ~ 9, corresponding to 20~ 29

data in the software filter.

The default value is 3, corresponding

to 23= 8 data in the software filter

0x00F0

1

Reset the offset of

differential pressure

Write

Fixed value, 0xAA55

Note: The I2C address is set to bit7 ~ bit 1, e.g., if the I2C address is 1 (0000 001x), the write address will be

0x02 (0000 0010) and the read address will be 0x03 (0000 0011).

5.2.4 CRC checksum calculation

The 8-bit CRC checksum transmitted after each two data bytes (int 16) is generated by a CRC

algorithm. Its properties are listed in the table below. To calculate the checksum, only these two

previously transmitted data bytes are used.

Property

Value

Name

CRC-8

Protected data

I2C read and write

Width

8 bits

Polynomial

0x07 (x8 + x2 + x + 1)

Initialization

0x00

Reflect input

False

Reflect output

False

Final XOR

0x00

Example

CRC(0x4E20) = 0x6D

16

www.Siargo.com FS35001 User Manual

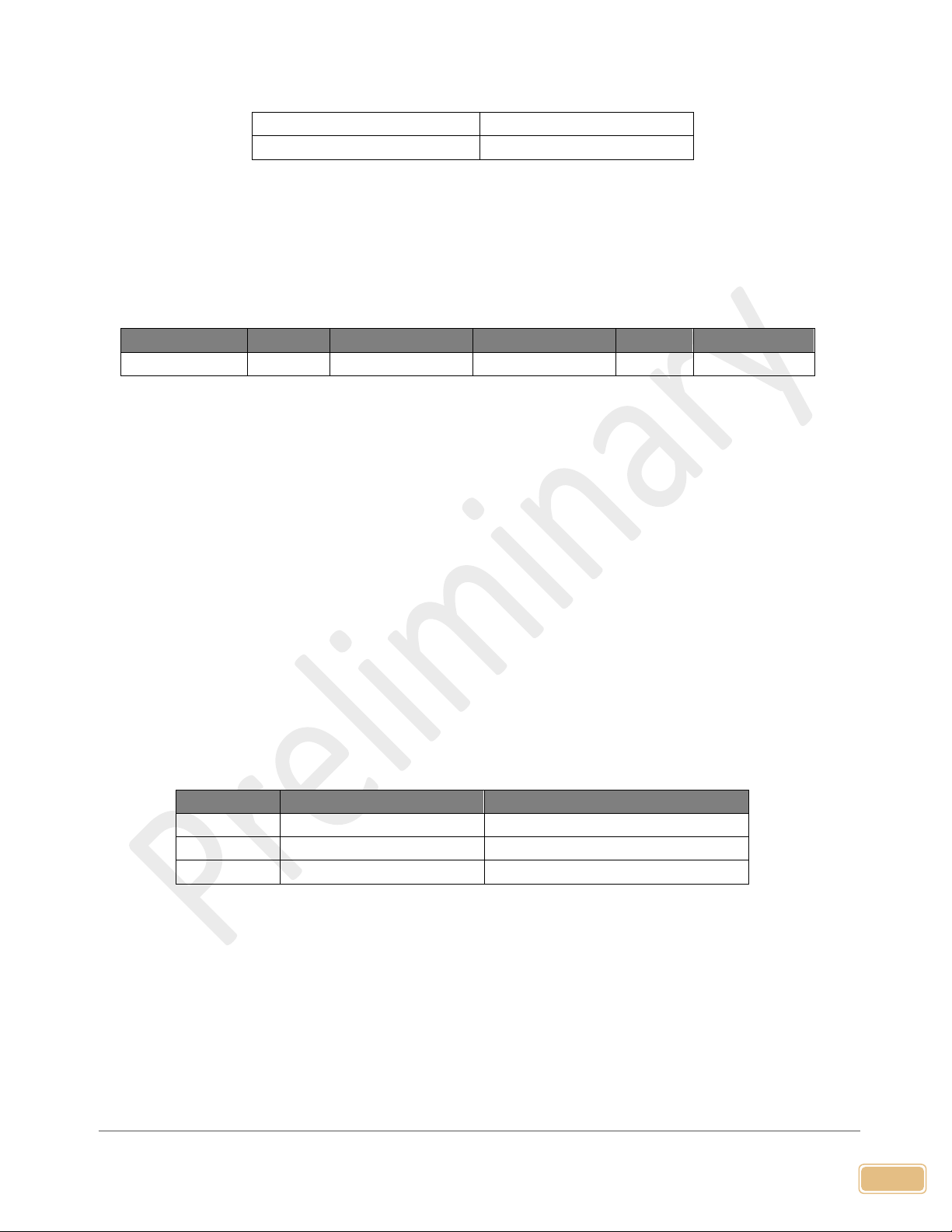

6. Product selection

The product part number is composed of the product model number and suffixes, indicating each

of the selectable parameters. Refer to the following for details.

FS35001 - -

Note: For CO2, the full-scale flow is 60% of the specified ones.

Gas: A –air; N2; O2; Ar; C –CO2; E –He; H –H2. For other

gases, please contact the manufacturer.

Output: V –analog; B –RS485 Modbus half plex; E –I2C;

Also available with BV, and EV.

Full scale flow rate: 200, 500, 1000, 2000, 4000, 6000, 10000,

15000, and 20000 sccm. For higher flow rate options, please

contact the manufacturer.

17

www.Siargo.com FS35001 User Manual

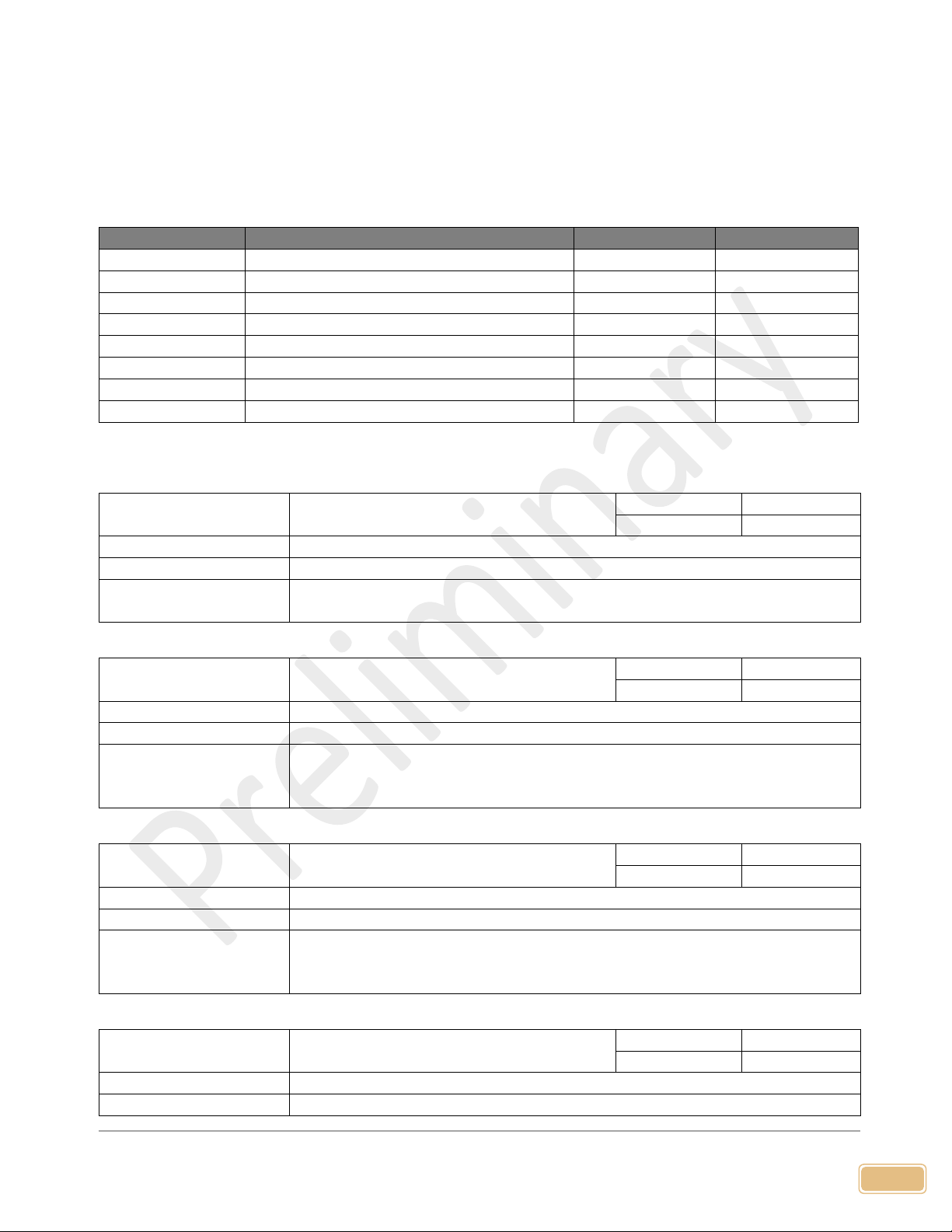

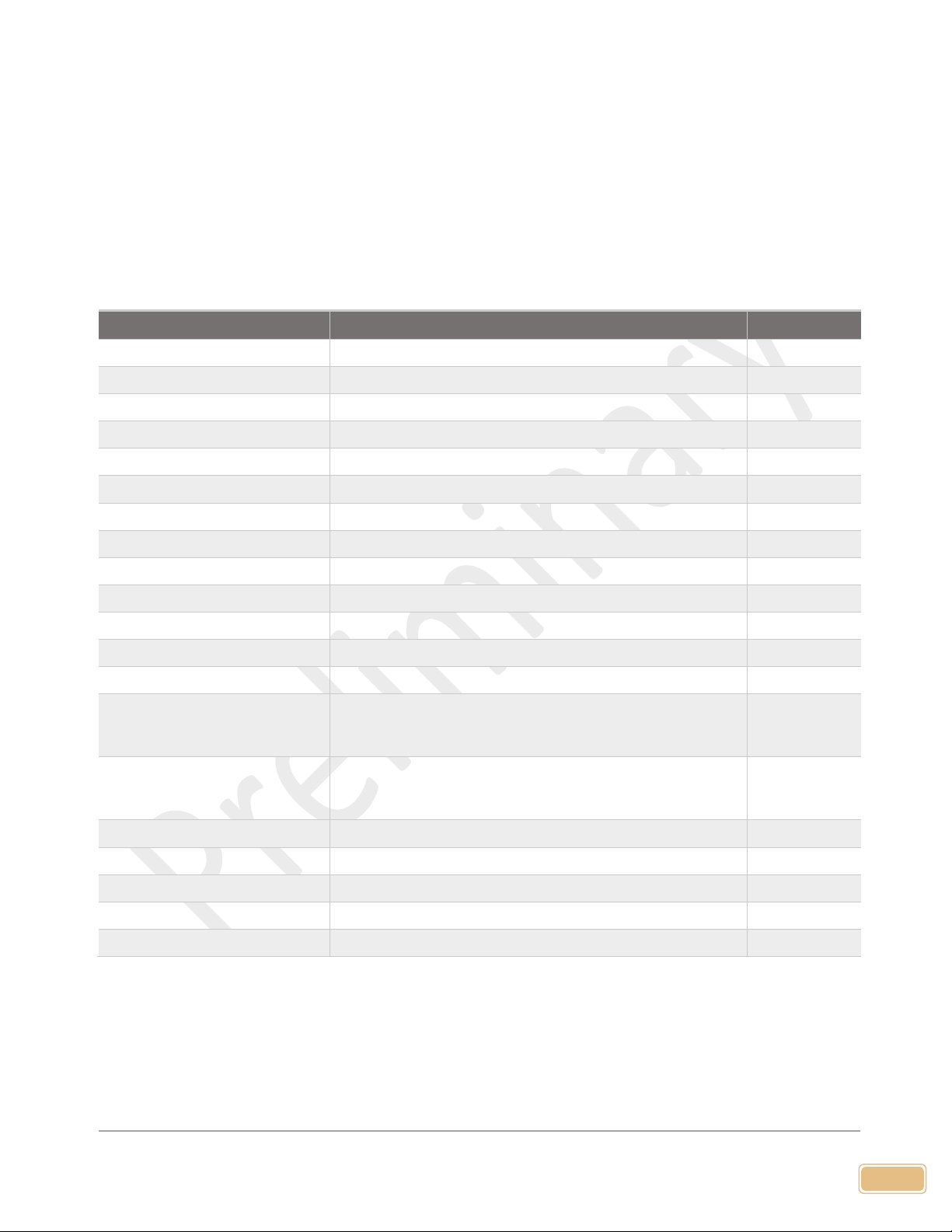

7. Product performance

7.1 Technical specifications

All specifications listed in the following table, unless otherwise noted, apply for calibration

conditions at 20°C and 101.325 kPa absolute pressure with air.

Value

Unit

Flow range

0 ~ 100…20000; or 0~±100 …±20000

sccm

Accuracy

±(1.5+0.5FS)

%

Repeatability

0.5

%

Turn-down ratio

100:1

Response time*

10

msec

Temperature range

-5 ~ 50

°C

Maximum pressure

1.0 (150)

MPa (psi)

Humidity

<95, no condensation

%RH

Analog null shift

±30

mV

Power supply

8 ~ 24

Vdc

Working current

50

mA

Output

Linear, analog 0.5 ~ 4.5 Vdc / Rs485 Modbus / I2C

Analog load

Sourcing: 25 / Sinking: 15

mA

Maximum overflow

3000 (3SLPM) (200, 500, 1000 models);

18000 (18 SLPM) (2000, 4000, 6000 models)

45000(45SLPM) (10000, 15000 models)

sccm (SLPM)

Maximum flow change

500 (200, 500, 1000 models);

3000 (2000, 4000, 6000 models)

7500(10000, 15000 models)

sccm/sec

Calibration

Air @ 20°C, 101.325 kPa

Storage temperature

-20 ~ +70

°C

Compliance

RoHS; REACH

CE

IEC 61000-4-2; 4-8

Wetted materials

Aluminum alloy; silicon nitride; Ablestik 84-3J; FR4

Note: 1. Allow the product to warm up for 60 seconds for the best performance.

2. Response time shown is the default. It can be programmed to the fastest <2 msec.

18

www.Siargo.com FS35001 User Manual

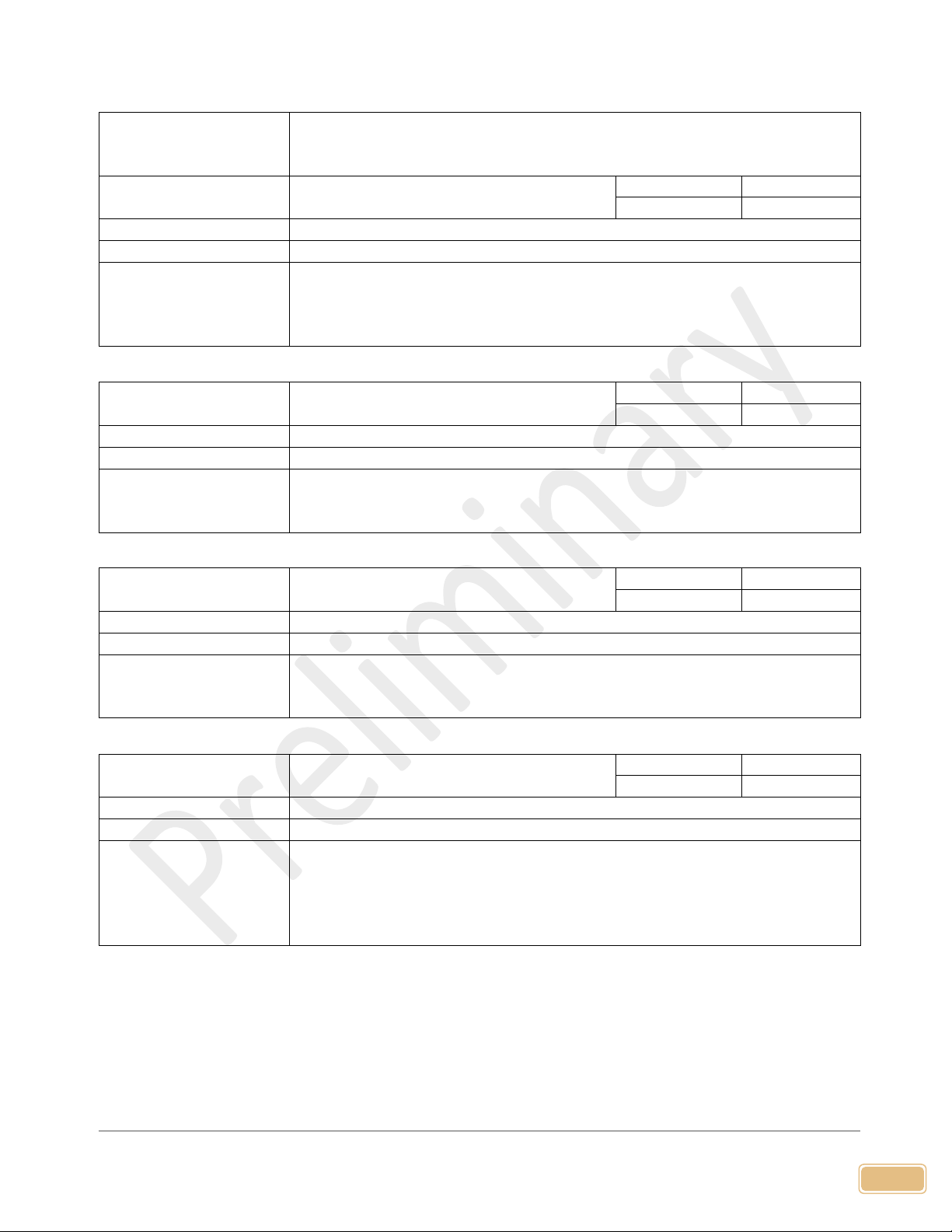

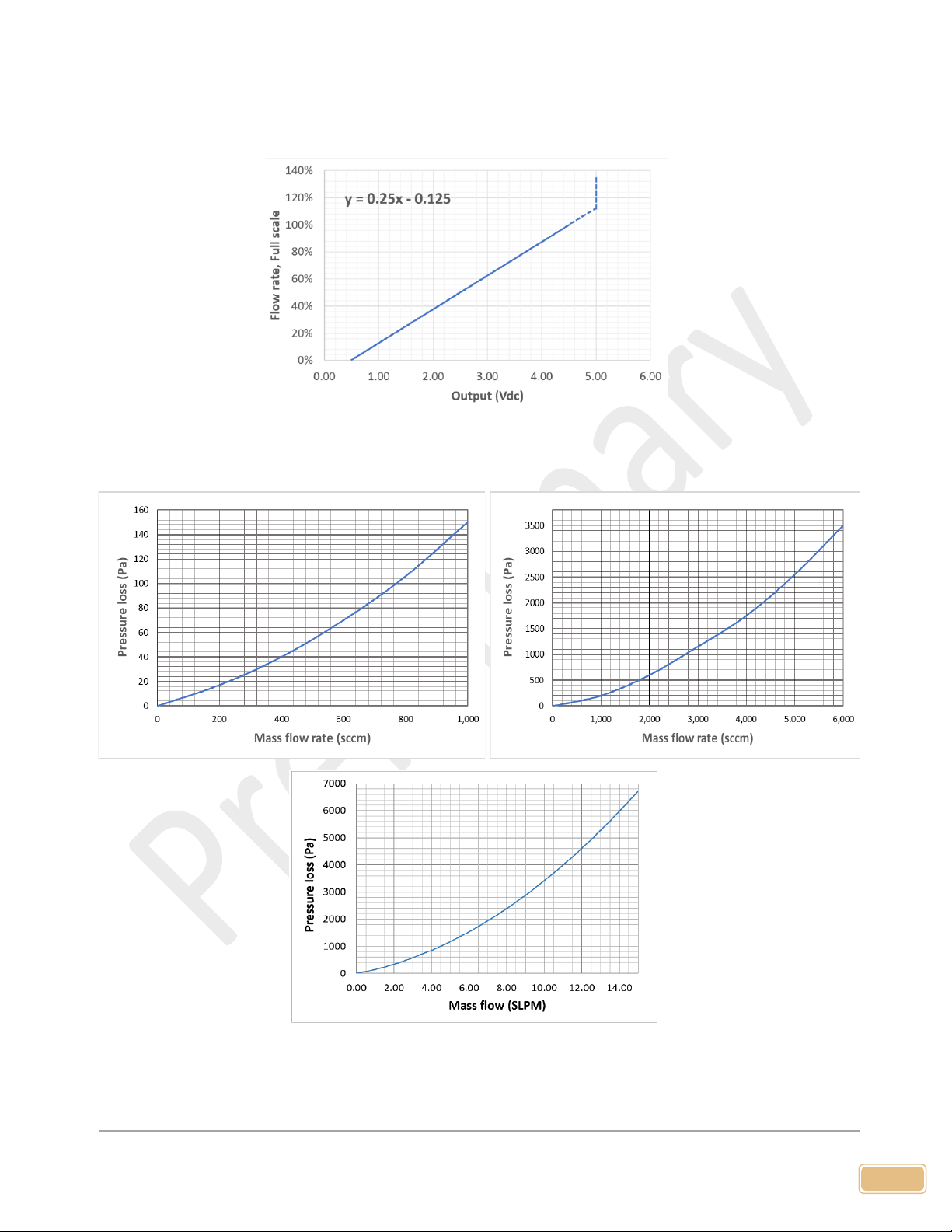

7.2 Typical (analog) output

Figure 7.1: Typical analog output

7.3 Pressure loss

Figure 7.2: Upper row: from left to right, for models of full scale up to 1000 sccm; and of full scale from 2000

to 6000 sccm. Lower row: models of full scale from 10000 to 15000 sccm (10 to 15SLPM).

19

www.Siargo.com FS35001 User Manual

8. Technical notes for the product performance

8.1 Measurement principles

The products utilize the Company’s proprietary micro-machined

(MEMS) calorimetric sensing with thermal diffusivity detection and

data process technology. A thermal signal generator with a pair of

sensing elements up and downstream of the micro heater is precisely

manufactured and separated at predefined micrometer distances on

a chip surface with excellent thermal isolation. When a fluid is

flowing through the sensing chip, the fluid carries the thermal signal

downstream. The sensing elements register the temperature

differences and measure the fluidic thermal diffusivity, further

correlated to the fluid mass flow rate via the calibration process.

Compared to the calorimetric sensing products offered by other

manufacturers on the market, the proprietary sensing approach

offers a large dynamic range with a better performance against the environmental parameter

alternations. It removes some gas sensitivities for gases with the same diffusivity and much-

improved the linearity when a gas conversion factor is used for the metering of the non-calibration

gases. Please refer to the company's US patents and other publications made available to the public

for additional information.

8.2 Precautions for the best performance of the product

8.2.1 Contamination and sterilization

It is critical to have the measurements performed in a contamination-free environment for data

accuracy. Excessive contaminants such as vapors will lead to data deviation or even product

malfunctions in severe cases.

For medical applications, it may be desired to have the product to be sterilized from time to time. A

standard EtO sterilization process is recommended. For the detailed procedure please consult your

local experts or contact the manufacturer.

8.2.2 Altitude changes

Figure 8.1: Illustration of

the measurement principle.

illustration.

20

www.Siargo.com FS35001 User Manual

Unlike some other products on market, the design of the sensor has a built-in pressure balancer that

prevents membrane deformation due to altitude changes. Therefore, the sensor is intrinsically

insensitive to altitude change-induced errors. The specified altitude in Sec 7.1 has been fully tested.

8.2.3 Excessive humidity or condensation

The humidity change will not alter the performance of the sensor. However, if excessive humidity is

present resulting in condensation, the measurement port or channel could be blocked or altered.

This would result in a very unreliable data output. Please filter or other tools to prevent this situation

to occur when using this product.

8.2.4 Metrology verification

Testing the products with local metrology tools will be performed in almost all cases. It should be

noted that for this particular sensor, special care should be applied while performing such a task.

The gauge pressure tests are relatively simple, as long as the pressure is tested under a stable media

condition, the metrology data should be well reproduced.

For the mass flowrate comparison, however, in addition to the flow system setup conditions

recommended by OIML R137, a stable flow system must be ensured. This is because the current

product is designed for a small pressure loss, therefore the sensor does not have a strong flow

restrictor or conditioners to handle the flow instability that may exist in the system. Therefore to

compare the metrology data, the user should ensure the system is stable, otherwise, the output

could be noisy and metrology deviations would be inevitable. If such cases are present, please

contact the manufacturer for further solutions.

For temperature and humidity measurement, because of the small package space, the response of

the humidity could be slower than specified. For additional information, please contact the

manufacturer.

Table of contents

Other Siargo Accessories manuals