Siargo FS6122 User manual

FS6122 User Manual

Integrated flow, pressure & temperature sensors

©2021 Siargo Ltd.

VB.0.1

Sold in North America by:

Servoflo Corporation

75 Allen Street

Lexington, MA 02472

www.servoflo.com/info@servoflo.com

781-862-9572

2

www.Siargo.com FS6122 User Manual

MEMS Flow, Pressure and Temperature Sensors

with thermal and piezo sensing technology

FS6122 Series

User Manual

Document No. 06-2021-FS6 EN

Issue date: 2021.06

Revision: VB.0.1

Siargo Ltd.

3100 De La Cruz Boulevard, Suite 210

Santa Clara, California 95054

USA

Tel: +1(408)969.0368

© Copyright 2021 and Liability Disclaimer

Siargo Ltd. and its subsidiaries reserve the right to change the specifications and/or descriptions

without prior notice. Siargo and its subsidiaries shall not assume any inaccuracy or errors in this

manual. For further information and updates, please visit www.Siargo.com.

3

www.Siargo.com FS6122 User Manual

Attention !

Use with caution !

•Please carefully read this manual prior to operating this product.

•Do not open or modify any hardware which may lead to irrecoverable

damage.

•Do not use this product if you suspect any malfunctions or defection.

•Do not use this product for corrosive media or in a strong vibration

environment.

•Use this product according to the specified parameters.

•Only the trained or qualified personnel shall be allowed to perform

product services.

•Be cautious for electrical safety, and even it operates at a low voltage,

any electrical shock might lead to some unexpected damages.

•The gas to be measured should be clean and free of particles, as

even light particles may be accumulated inside the tiny pressure port

that may result in inaccuracy in metrology, clogging, or other

irrecoverable damage.

•Do not apply for any unknown or non-specified gases that may

damage the product.

4

www.Siargo.com FS6122 User Manual

Table of Contents

1. Overview ......................................................................................................................................................5

2. Receipt / unpack of the products ...............................................................................................................6

3. Knowing the products.................................................................................................................................7

3.1 Product description.............................................................................................................................7

3.2 Power and data pinout description....................................................................................................7

3.3 Mechanical dimensions.......................................................................................................................8

4. Installation.......................................................................................................................................................8

5. Basic operation ................................................................................................................................................9

5.1 I2C interface connection diagram.............................................................................................................9

5.2 I2C interface command description..........................................................................................................9

6. Product selection and order information....................................................................................................11

6.1. Product selection ...................................................................................................................................11

6.2. Order contact and customer support ..................................................................................................11

7. Product performance ....................................................................................................................................12

7.1. Technical specifications .........................................................................................................................12

7.2. Pressure loss ...........................................................................................................................................13

7.3. Typical (analog) output..........................................................................................................................13

8. Technical notes for the product performance ............................................................................................14

8.1. Measurement principles ........................................................................................................................14

8.2. Precautions for the best performance of the product .......................................................................14

8.2.1. Contamination and sterilization....................................................................................................14

8.2.2. Altitude changes .............................................................................................................................14

8.2.3. Excessive humidity or condensation.............................................................................................14

8.2.4. Metrology verification....................................................................................................................15

9. Warranty and Liability ..................................................................................................................................16

10. Service contact and information................................................................................................................18

Appendix I: Sensor evaluation kit....................................................................................................................19

Appendix II: Document history ........................................................................................................................20

5

www.Siargo.com FS6122 User Manual

1. Overview

All contact information can be found at the end of this manual.

This manual provides essential information for the FS6122 series of combo sensors for a medical

ventilator or CPAP (Continuous Positive Airway Pressure) equipment applications. The product

performance, maintenance, and troubleshooting, as well as the information for product order,

technical support, and repair, are also included.

The FS6122 sensors are manufactured with the company’s proprietary MEMS (micro-electro-

mechanical systems) sensing and package technology that offers primarily the mass flow and gauge

pressure with optional temperature and humidity sensing in a compact design without the needs for

additional calibrations, which significantly reduces cost for the equipment manufacturers.

While the current packages are best for medical applications, the manufacturer also offers

alternative customized packages with customized adapters. Please contact the manufacturer for

additional information.

6

www.Siargo.com FS6122 User Manual

2. Receipt / unpack of the products

Upon receipt of the products, please check the packing box before the dismantlement of the packing

materials. Ensure no damages during shipping. If any abnormality is observed, please contact and

notify the carrier who shipped the product and inform the distributors or sales representatives if the

order is not placed directly with the manufacturer; otherwise, the manufacturer should be informed.

For any further actions, please refer to the return and repair section in this manual.

If the packing box is intact, proceed to open the packing box, and you shall find the product (either

the sensor formality per the actual order), together with the power and data cable if the order is

included as shown below.

Please check immediately for the integrity of the product and the power and data cable; if any

abnormality is identified, please notify the distributor/sales representative or manufacturer as soon

as you can. If any defects are confirmed, an exchange shall be arranged immediately via the original

sales channel. This user manual shall also be included in the packing box or via an online link for an

electronic version which should be sent by your sales agent. In most cases, this manual shall be made

available to the customer before the actual order.

Please note that the sensor has a pinout that is designed to be directly placed onto a printed circuitry

board. Therefore, the power and data cable is an option that will not come with the order

automatically.

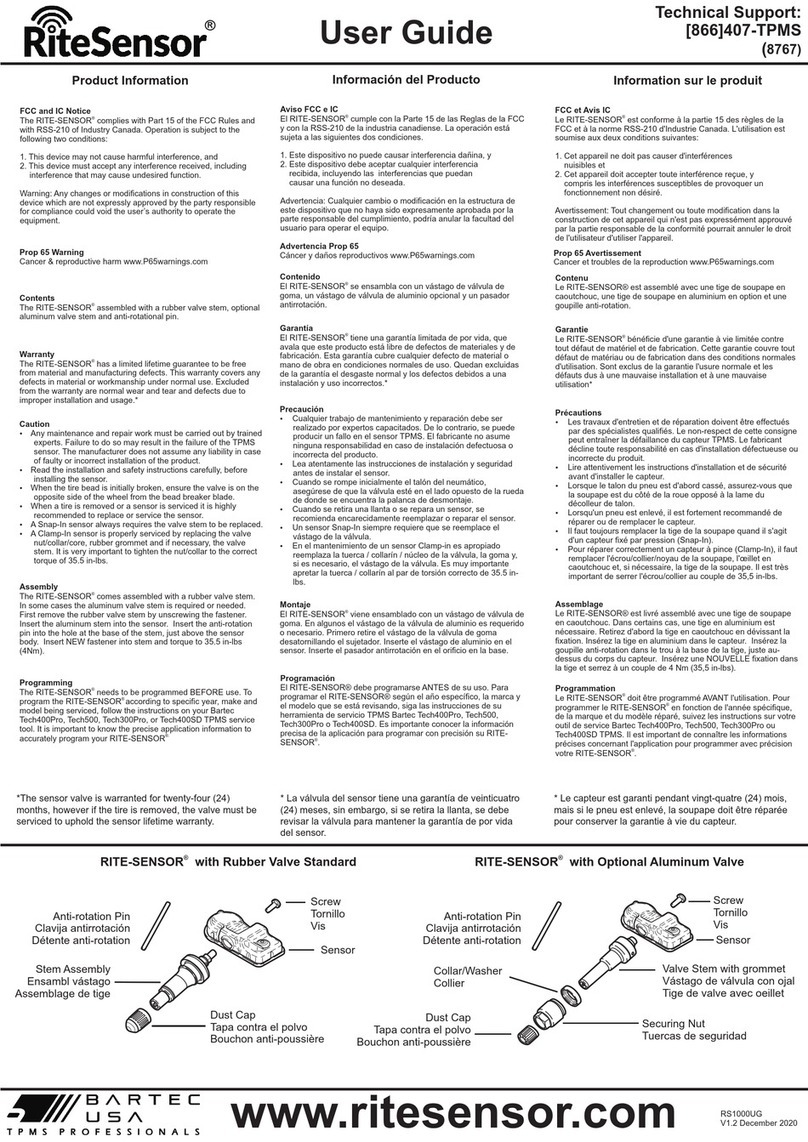

FS6122 Power and data cable

7

www.Siargo.com FS6122 User Manual

3. Knowing the products

3.1Product description

3.2Power and data pinout description

Table 3.2: FS6122 pin assignment.

Note: 1. Power supply: The FS6122 requires a power supply of 5±5% Vdc. The sensor consumes less than

20 mA normally and the minimum supply current must be larger than 15 mA.

2. The pressure analog output can be optional. The pin provides 0.5 ~ 4.5 Vdc corresponding with the

specified pressure full-scale range. If the pressure option is not selected, this pin output is NULL.

3. The flow rate analog outputs 0.5 ~ 4.5 Vdc corresponding with the specified flow full-scale range.

4. SDA and SCL are the I2C serial data line and serial clock line.

PIN

COLOR

DEFINITION

1

White

Analog, pressure data

2

Green

Analog, Flow data

3

Black

GND, ground

4

Red

VCC, power supply

5

Yellow

SCL, I2C clock

6

Blue

SDA, I2C data

Direction for flow

measurement. For dual

directional model, the

arrow does not apply.

ISO22mm

ISO22mm

Power and data

connector.

Note: Analog outputs only apply for flow

and gauge pressure.

8

www.Siargo.com FS6122 User Manual

3.3 Mechanical dimensions

Figure 3.3.1. FS6122 mechanical dimensions.

4. Installation

Do not open or alter any part of the product, which would lead to malfunction and irrecoverable

damage.

For the installation, make sure to the leakage proof of the connections and all electrical precautions

are applied. Please make sure the electrical pins are properly engaged. It should be noted that the

sensor is designed for extremely low pressure per the applications, therefore, the system design

would be important for the flow stability and related flow noises.

9

www.Siargo.com FS6122 User Manual

5. Basic operation

5.1 I2C interface connection diagram

5.2 I2C interface command description

Command

Byte

(Hex)

Length

(int 16)

Command Name

Read/Write

Notes

05H

1

I2C address

Write

Bit 0 is R/W flag bit; Bit 1~ Bit 7 are

available.

oBH

1

Filter depth

Write

Int 8, 0~254

1CH

1

Flowrate offset

reset

Write

1 byte, ensure no-flow conditions

24H

1

Pressure offset

reset

Write

1 byte, ensure no-flow conditions

9DH

4

Write protection

Write

4 bytes, 0x53, 0x49, 0x41, 0x52. One-

time effective.

82H

12

Serial number

Read

ASCII

83H

5

Flow rate

Read

Int32(/1000 SLPM)+CRC

CRC=(Byte1)xOR(Byte2)x(OR(Byte3)XOR(byte4)

84H

9

Flow rate &

Pressure

Read

Int32(/1000 SLPM), INT32(/1000

cmH2O)+CRC

CRC=(Byte1)xOR(Byte2)x…xOR(Byte8)

85H

1

I2C address

Read

Bit 7 ~ Bit 1

8BH

1

Filter depth

Read

Int 8, 0~254

A3H

5

Pressure

Read

Int32(/1000 cmH2O)+CRC

CRC=(Byte1)xOR(Byte2)x(OR(Byte3)XOR(byte4)

B2H

3

Temperature

Read

Int16(/100 °C) + CRC

CRC=(Byte1)xOR(Byte2)

B3H

3

Humidity

Read

Int16(/100 %RH) + CRC

CRC=(Byte1)xOR(Byte2)

10

www.Siargo.com FS6122 User Manual

Note: 1. Before writing to the register, please ensure the write protection is disabled.

2. The I2C address is set to Bit 7~Bit 1. E.g. if the I2C address is 1 (0000 001x), the write address will be

0x02 (0000 0010) and the read address will be 0x03 (0000 0011).

3. The write protection is a one-time effective function.

5.3 I2C interface read/write sequences

11

www.Siargo.com FS6122 User Manual

6. Product selection and order information

6.1. Product selection

The product part number is composed of the product model number and suffixes, indicating each

of the selectable parameters. Refer to the following for details.

FS6122 - F - P - TH

Note:

1. Except for the temperature/humidity option, the numbers are designated for full-scale value.

2. Except for flowrate, o stands for null or without the corresponding sensing option.

3. Example: FS6122-50-F200-5P40-TH1 is a sensor that measures mass flow rate from reverse 50 to

forward 200SLPM; gauge pressure from -5 to 40 cmH2O, temperature, and relative humidity.

4. The current configuration would not guarantee the response time for humidity, the humidity value

could take additional and unspecific time to reach the real value.

6.2. Order contact and customer support

The sales offices and the sales distributors/representatives are listed at the end of this document. For

small quantities, the order can be placed either through the Siargo website: www.siargo.com or the

sales office. For large quantities, please contact the sales office, distributors, or sales representatives.

Siargo is making every effort to ensure the quality of the products. In case of questions and/or

product supports, please contact the customer service listed at the end of the document.

Temperature & Humidity (1 or 0 for null)

Forward pressure (40 or 100 (110) cmH2O; 0 for null)

Reverse pressure (0, 5, 40, 100 (110) cmH2O)

Forward flowrate (100, 150, 200, 250 SLPM)

Reverse flowrate (0, 50, 100, 150, 200, 250 SLPM)

12

www.Siargo.com FS6122 User Manual

7. Product performance

7.1. Technical specifications

All specifications listed in the following table, unless otherwise noted, apply for calibration

conditions at 20°C and 101.325 kPa absolute pressure with air.

Value

Unit

Flow range

-250 … +250

SLPM

Accuracy (total error band)

±(2.5+0.5FS)

%

Output

Linear, analog 0.5~4.5Vdc / I2C (14bit)

Response time

1.8

msec

Gauge pressure

-5, -40, -100, 0 … 40, 100 (110)

cmH2O

Accuracy (total error band)

±1.o

%FS

Output

Linear, analog 0.5~4.5Vdc / I2C (14bit)

Response time

1.8

msec

Temperature

-10~60

°C

Accuracy

±o.5

°C

Humidity

0~100(no condensation)

%RH

Accuracy

±2.0 (20~80%RH); ±5.0 (other ranges)

%

Resolution

0.7

%RH

Response time (63%)

5.0 (25~75%)

sec

Gas compatibility

Air, O2, N2

Supply voltage

5.0±5%

Vdc

Power consumption

<60

mA

Warm-up time

<50

msec

Temperature compensation

-5~+65

°C

Altitude compensation

-400~+3000 (700~1060)

m (hPa)

Storage temperature

-20 ~ +70

°C

Compliance

RoHS; REACH

CE

IEC 61000-4-2;4;8

Note: 1. The analog output is correlating to the full-scale whatever it is specified.

2. Burst pressure for pressure range: ±40kPa (-5~40 cmH2O) and ±100kPa (-5~100 cmH2O).

3. The data and power cable connector is supplied with the product. It is compatible with AMPMODU

MAT 6 positions. (e.g. TE 5-103956-5 https://www.te.com/usa-en/product-5-103956-5.html)

13

www.Siargo.com FS6122 User Manual

7.2. Pressure loss

7.3. Typical (analog) output

The pressure loss shown in the

graph is one-directional. The

reverse direction will have an

identical loss value.

The temperature and humidity data

can only be accessed via the I2C

interface due to the limited analog

ports.

14

www.Siargo.com FS6122 User Manual

8. Technical notes for the product performance

8.1. Measurement principles

The products utilize the Company’s proprietary micro-machined (MEMS) sensing technology. The

mass flow sensing is via calorimetry with temperature compensation. The gauge pressure is realized

via the piezoresistive sensing, while the temperature sensor is a micromachined platinum thermistor,

and the humidity sensor is again micromachined with the capacitive sensing principle. The MEMS

sensors allow the integration in a small footprint while offering multiparameter sensing.

8.2. Precautions for the best performance of the product

8.2.1. Contamination and sterilization

It is critical to have the measurements performed in a contamination-free environment for data

accuracy. Excessive contaminants such as vapors will lead to data deviation or even product

malfunctions in severe cases.

For the medical applications, it may be desired to have the product to be sterilized from time to time.

Standard EtO sterilization process is recommended. For the detailed procedure please consult your

local experts or contact the manufacturer.

8.2.2. Altitude changes

Unlike some other products on market, the design of the sensor has a built-in pressure balancer that

preventing membrane deformation due to altitude changes. Therefore, the sensor is intrinsically

insensitive to the altitude change-induced errors. The specified altitude in Sec 7.1 has been fully

tested.

8.2.3. Excessive humidity or condensation

The humidity change will not alter the performance of the sensor. However, if excessive humidity is

present resulting in condensation, the measurement port or channel could be blocked or altered.

15

www.Siargo.com FS6122 User Manual

This would result in a very unreliable data output. Please filter or other tools to prevent this situation

to occur when using this product.

8.2.4. Metrology verification

Testing the products with local metrology tools will be performed in almost all cases. It should be

noted that for this particular sensor, special care should be applied while performing such a task.

The gauge pressure tests are relatively simple, as long as the pressure is tested under a stable media

condition, the metrology data should be well reproduced.

For the mass flowrate comparison, however, in addition to the flow system setup conditions

recommended by OIML R137, a stable flow system must be ensured. This is because the current

product is designed for a small pressure loss, therefore the sensor does not have a strong flow

restrictor or conditioners to handle the flow instability that may exist in the system. Therefore to

compare the metrology data, the user should ensure the system is stable, otherwise, the output

could be noisy and metrology deviations would be inevitable. If such cases present, please contact

the manufacturer for further solutions.

For temperature and humidity measurement, because of the small package space, the response of

the humidity could be slower than the specified. For additional information, please contact the

manufacturer.

16

www.Siargo.com FS6122 User Manual

9. Warranty and Liability

(Effective January 2018)

Siargo warrants the products sold hereunder, properly used, and properly installed under normal

circumstances and service. As described in this user manual, it shall be free from faulty materials or

workmanship for 180 days for OEM products and 365 days for non-OEM products from the date of

shipment. This warranty period is inclusive of any statutory warranty. Any repair or replacement

serviced product shall bear the same terms in this warranty.

Siargo makes no warranty, representation, or guarantee and shall not assume any liability regarding

the suitability of the products described in this manual for any purposes that are not specified in this

manual. The users shall be held for full responsibility for validating the performance and suitability

of the products for their particular design and applications. For any of the misusage of the products

out of the scope described herein, the user shall indemnify and hold Siargo and its officers,

employees, subsidiaries, affiliates, and sales channels harmless against all claims, costs, damages,

and expense or reasonable attorney fee from direct or indirect sources.

Siargo makes no other warranty, express or implied, and assumes no liability for any special or

incidental damage or charges, including but not limited to any damages or charges due to installation,

dismantling, reinstallation, etc. other consequential or indirect damages of any kind. To the extent

permitted by law, the exclusive remedy of the user or purchaser, and the limit of Siargo's liability for

any and all losses, injuries, or damages concerning the products, including claims based on contract,

negligence, tort, strict liability, or otherwise shall be the return of products to Siargo, and upon

verification of Siargo to prove to be defective, at its sole option, to refund, repair or replacement of

the products. Regardless of form, no action may be brought against Siargo more than 365 days after

a cause of action has accrued. The products returned under warranty to Siargo shall be at the user or

purchaser's risk of loss and will be returned, if at all, at Siargo's risk of loss. Purchasers or users are

deemed to have accepted this limitation of warranty and liability, which contains the complete and

exclusive limited warranty of Siargo. It shall not be amended, modified, or its terms waived except

by Siargo's sole action.

This manual's product information is believed to be accurate and reliable at the time of release or

made available to the users. However, Siargo shall assume no responsibility for any inaccuracies

and/or errors and reserves the right to make changes without further notice for the relevant

information herein.

This warranty is subject to the following exclusions:

(1) Products that have been altered, modified, or have been subject to unusual physical or

electrical circumstances indicated but not limited to those stated in this document or any

other actions which cannot be deemed as proper use of the products;

17

www.Siargo.com FS6122 User Manual

(2) Products that have been subject to chemical attacks, including exposure to corrosive

substances or contaminants. In the case of battery usage, long term discharge or leakage

induced damages;

(3) Products that have been opened or dismantled for whatever reasons;

(4) Products that have been subject to working conditions beyond the technical specification as

described by this manual or related datasheet published by the manufacturer;

(5) Any damages incurred by the incorrect usage of the products;

(6) Siargo does not provide any warranty on finished goods manufactured by others. Only the

original manufacturer's warranty applies;

(7) Products that are re-sold by unauthorized dealers or any third parties.

18

www.Siargo.com FS6122 User Manual

10. Service contact and information

Siargo Ltd. is making every effort to ensure the quality of the products. In case of questions and or

product supports, please contact customer service at the address listed below. We will respond to

your request in a timely fashion and work with you toward your complete satisfaction.

Customer service and all orders should be addressed to

Siargo Ltd.

3100 De La Cruz Boulevard, Suite 210,

Santa Clara, California 95054, USA

Phone: +01(408)969-0368

For orders, please provide an accurate and full postal address. Siargo will not ship to P.O. Boxes or

via a third party.

the product back to the factory for returns or factory services such as calibration. Please specify as

clear and detailed as possible in your email message the product's status that you intend to ship back

to the factory. Be sure to write the RMA on the returned package or include a letter with the RMA

information.

For further information and updates, please visit www.Siargo.com.

19

www.Siargo.com FS6122 User Manual

Appendix I: Sensor evaluation kit

Siargo offers a sensor evaluation kit, including a digital data converter, USB data cable, and User

Application software, that allows the user to evaluate the product performance on a Microsoft

Windows-based computer. The user can read and visualize the flow rate of the product, obtain the

totalized values, and save the data for further analysis. It can read from up to 128 sensors with the

I2C interface in serial.

For further information and purchase of the evaluation kit, please contact the manufacturer or the

sales representative.

Each converter has a fixed cable that can be

directly connected to the product. The USB

cable connected to the PC is also included.

For most of the products, the power from the

PC via the USB cable will be sufficient to power

the sensor product, no external power will be

required. However, for multiple sensors in serial,

the power via the USB cable may not be enough,

an external power adapter with 8~24Vdc will be

required.

Cable to connect

to the product

USB cable to

connect to PC

External power

adapter (optional)

20

www.Siargo.com FS6122 User Manual

Appendix II: Document history

06.2021 VB.0.1 –Reformated and updated.

10.2020 VA.14 –Revised ISO45001

07.2020 VA.13 –I2C communication protocol update

06.2020 VA.12 –I2C communication protocol update

10.2019 VA.11 –Output pin assignment update

10.2018 VA.10 –Add additional gauge pressure range

04.2018 VA.9 –I2C communication protocol update

07.2017 VA.8 –Response time update; build materials update; Application notes

update; Added document history tracking.

Table of contents

Other Siargo Accessories manuals

Popular Accessories manuals by other brands

Bartec

Bartec RiteSensor user guide

Honeywell Home

Honeywell Home PROSiXPIR Quick installation guide

LEGRAND

LEGRAND Wattstopper CU-250 installation instructions

Allergy Amulet

Allergy Amulet AMULET quick start guide

HAEGER

HAEGER UB-070.001A User instructions

NISBETS ESSENTIALS

NISBETS ESSENTIALS DB303 instruction manual