SiboTech HPM-610 User manual

HART/ PROFIBUS-DP Gateway

HPM-610

User Manual

REV 1.5

SiboTech Automation Co., Ltd.

Technical Support: +86-21-5102 8348

E-mail: [email protected]

www.sibotech.net

1

Catalog

1 Product Overview...................................................................................................................................................... 3

1.1 Product Summary........................................................................................................................................... 3

1.2 Product Features............................................................................................................................................. 3

1.3 Technical Specifications................................................................................................................................. 3

1.4 Safety and explosion-proof features...............................................................................................................4

1.5 Related Products............................................................................................................................................. 4

2 Quick Start Guide...................................................................................................................................................... 5

2.1 Configuration of Gateway.............................................................................................................................. 5

2.1.1 Pre-configured settings........................................................................................................................ 5

2.1.2 Software configuration........................................................................................................................ 5

3 Hardware Descriptions.............................................................................................................................................. 8

3.1 Product Appearance........................................................................................................................................ 9

3.2 Indicator LED............................................................................................................................................... 10

3.3 Configuring Switch/button........................................................................................................................... 10

3.3.1 Status setting switch.......................................................................................................................... 10

3.3.2 PROFIBUS-DP/ MODBUS address setting button.......................................................................... 11

3.3.3 Internal / external sampling resistance switch...................................................................................11

3.4 Interface........................................................................................................................................................ 12

3.4.1 Power Interface..................................................................................................................................12

3.4.2 PROFIBUS-DP interface...................................................................................................................12

3.4.3 RS485/RS422 interface..................................................................................................................... 12

3.4.4 RS-232 interface................................................................................................................................ 14

3.4.5 HART interface..................................................................................................................................14

3.5 Topology of HPM-610 and fieldbus devices................................................................................................15

4 Software Instructions............................................................................................................................................... 17

4.1 Software Interface Description.....................................................................................................................17

4.2 Software Usage............................................................................................................................................. 19

4.2.1 Connect to the hardware.................................................................................................................... 19

4.2.2 Upload the configuration file in the gateway.................................................................................... 19

4.2.3 Configure Fieldbus............................................................................................................................ 20

4.2.4 Configure the HART network........................................................................................................... 22

4.2.5 Conflict detection...............................................................................................................................27

4.2.6 AutoMap............................................................................................................................................ 28

4.2.7 Download configuration file..............................................................................................................28

4.2.8 Memory..............................................................................................................................................29

4.2.9 Diagnose............................................................................................................................................ 30

4.2.10 Serial debug..................................................................................................................................... 33

4.2.11 Switching tools................................................................................................................................ 35

5 Working principle.................................................................................................................................................... 35

www.sibotech.net

2

5.1 Flowchart when performing one HART Command..................................................................................... 39

5.2 General Sending and Receiving Data...........................................................................................................39

5.3 Trigger Command......................................................................................................................................... 40

5.4 Data Exchange with PROFIBUS-DP........................................................................................................... 41

5.5 Data Exchange with MODBUS....................................................................................................................41

6 In STEP7: Access Data of Gateway and Select Data Module................................................................................ 42

6.1 How STEP7 access data of gateway.....................................................................................................................42

6.2 How STEP7 select data module........................................................................................................................... 43

7 Installation................................................................................................................................................................44

7.1 Machine Dimension......................................................................................................................................44

7.2 Installation Method.......................................................................................................................................45

www.sibotech.net

3

1 Product Overview

1.1 Product Summary

HPM-610 is a gateway that can achieve interconnection between HART and PROFIBUS DP and MODBUS.

HART side can be configured as a primary master or the secondary master. PROFIBUS-DP and MODBUS side

can be a slave. The HPM-610’s PROFIBUS DP and MODBUS functionality cannot work simultaneously.

1.2 Product Features

Easy to use: The user simply refers to the product manuals and application examples, configures according to

the requirements then it can achieve communication in a short period of time.

Powerful function: Supports the interconnection between HART and PROFIBUS-DP/MODBUS, transparent

transmission between HART and serial (RS232/RS485/RS422).

Abundant debug function: Direct display of data exchange, command diagnosis of HART slave and common

debugging, these function are very convenient for user's communication test job.

1.3 Technical Specifications

[1] HART can be used as a primary master or the secondary master.

[2] Support only one HART channel; in the multi-point mode, connects 13 devices when using internal register

and 15 HART devices when using an external resistor (250Ω).

[3] Supports single-point and multi-points working mode of HART

[4] In single-point mode, supports data burst operation of slave device

[5] Supports all commands of the HART protocol

[6] Each HART command can be configured for change-of-state output, polling output, initialization output or

disable output

[7] HART per channel supports up to 128 user commands, HART output data buffer up to 1000 bytes, and the

www.sibotech.net

4

input data buffer up to 1600 bytes.

[8] Supports internal or external sampling resistor

[9] PROFIBUS side supports DP V0 and slave functionality according to IEC61158

[10] Adaptive baud rate on PROFIBUS-DP(9600 bit/s ~ 12 Mbit/s)

[11] Achieve largest input/output of PROFIBUS protocol: output data bytes

244 bytes, input data

bytes

244bytes, the sum of them

488bytes

[12] Serial port side can be configured as MODBUS slave, supports function code: 03H, 04H, 06H, 10H.

[13] MODBUS slave supports RTU and ASCII mode

[14] The serial port can be configured as universal mode, and achieve transparent data transmission with HART

slave devices.

[15] Power: 24VDC (9V~30V), 80mA(24VDC);

[16] Operating Temp: -40°F to 158°F (-40 ºC to 70 ºC), Rel. Humidity: 5%-95% ( non-condensing);

[17] External dimension(W*H*D): 40mm* 125mm * 110mm(1.6in*4.9in*4.5in);

[18] Installation: 35mm DIN RAIL;

[19] Protection Level: IP20;

1.4 Safety and explosion-proof features

HPM-610 is NOT the product with the features of safety and explosion-proof, please put it in the control

room when using.

1.5 Related Products

Other related products in SiboTech: HTM-611, HTM-631, HME-615, HME-635, PM-160, EP-321MP and so

on.

If you want to get instruction about these products, please visit SiboTech website:

http://www.sibotech.net/en , or call the technical support phone number: +86-21-5102 8348 ext 8061.

www.sibotech.net

5

2 Quick Start Guide

The following is an example for using HPM-610. PROFIBUS DP master read the present value of the main

variables (PV) of the HART device which short address is 0.

2.1 Configuration of Gateway

2.1.1 Pre-configured settings

1. Turn the configuration bit of DIP switch of gateway to “ON”;

2. Connect the RS232 interface of gateway and the serial port of the computer with the serial cable in the

package box. Wiring methods refer to section 3.4.3 of this manual;

3. Install the configuration software HT-123.

4. Power it on, the digital Led displaying “CF” indicates that the gateway is in the configuring state.

Double-click the installed software icon HT-123 to start the gateway configuration.

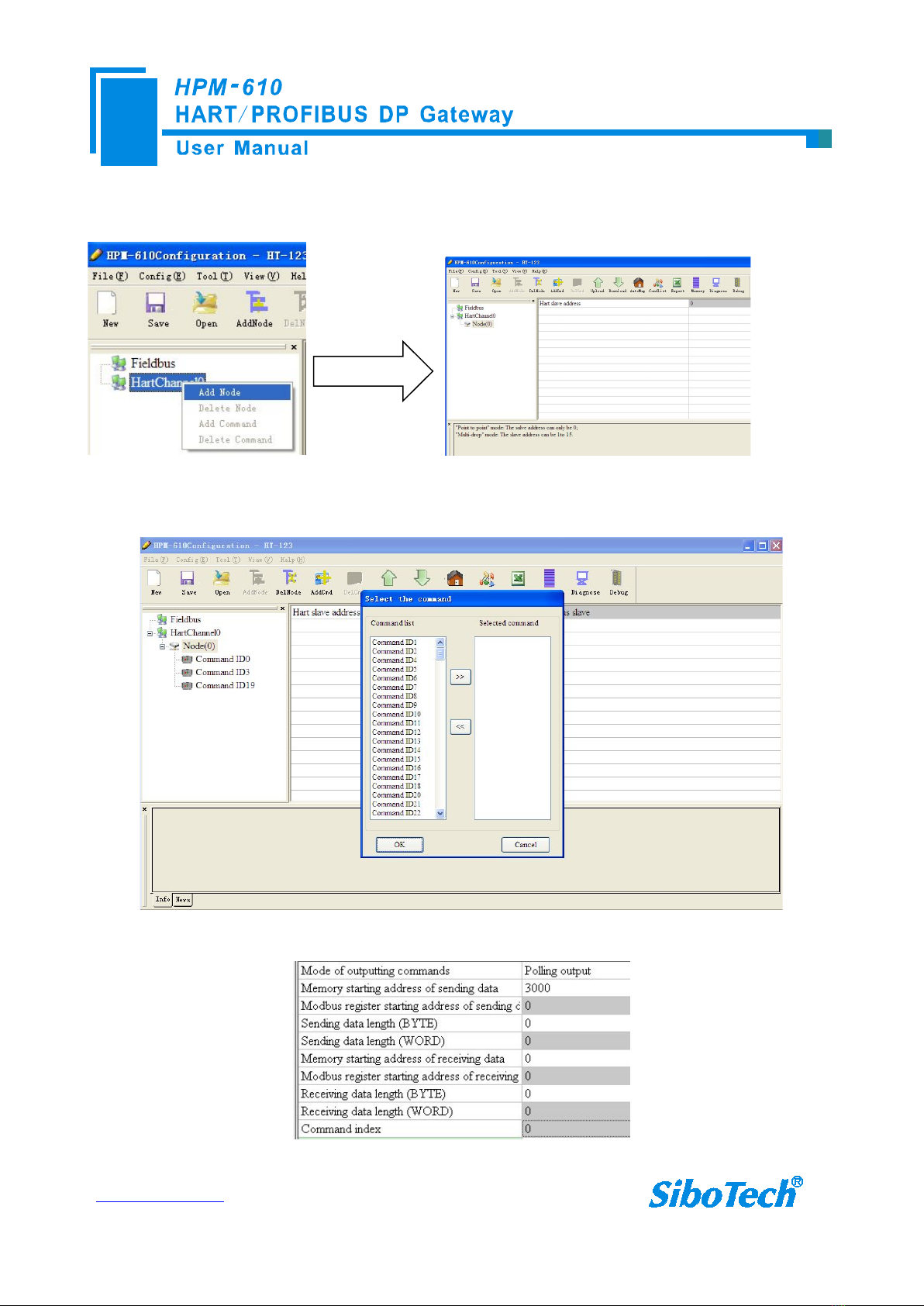

2.1.2 Software configuration

1. Open the HT-123 software installed on your computer.

2. Click “Fieldbus” in the tree view on the left, then the configuration table in the figure appears to the right:

www.sibotech.net

6

In the first row of the table, Select “PROFIBUS SLAVE”.

When you completed to input the parameter, press “Enter” to confirm.

3. Click “HartChannel0” in the tree view on the left, with the configuration table in the figure appears to the

right:

Then you can completed the configuration of HART network.

Notes: HART protocol specifies that the slave device which address is 0 must work in single-point mode, this

allows digital communication and analog communication to exist at the same time. Slave address 1 to 15 of the

device work in multi-point mode, the analog output of the device is at the minimum value (e.g. 4mA), only allows

www.sibotech.net

7

digital communication. The protocol also specifies that the factory address of HART slave device is 0.

4. Right-click HartChannel0, in the pop-up menu, select “Add Node”, as shown below:

5.Right-click “Node (0)”, in the pop-up menu, select Add command to add a command (command 1), then press

OK to return. The command ID you added will be shown in the left tree.

6.Click the “command ID1”, with the configuration table in the figure appears to the right:

Configure the parameters, then press Enter to confirm.

www.sibotech.net

8

7.Click the icon label, select the serial port with which the gateway is connected to the computer, and

then click Download:

2.2 Function Demo

HART interface of the gateway connects with a 2-wire pressure transmitter with slave address 0;

PROFIBUS-DP master uses Siemens S7-300 series PLC, the modeling software uses STEP7. In data exchange

window, you can see the main

variable value of the pressure transmitter:

RS232 Interface

24V

power

supply

Pressure

transmitter

≥250

Ω

HPM-610

Siemens

S7-300

DP port

Computer

STEP 7

RS232 port

PROFIBUS read the

HART data "00, 48, 07,

3A, 3A, BE, C6", the

front two numbers mean

the device state, "07"

indicates that the

pressure unit is bar, "3A,

3A, BE, C6" which

means that the pressure

value, the size is

0.000712376(bar)

+

-

Loop -

Loop +

www.sibotech.net

9

3 Hardware Descriptions

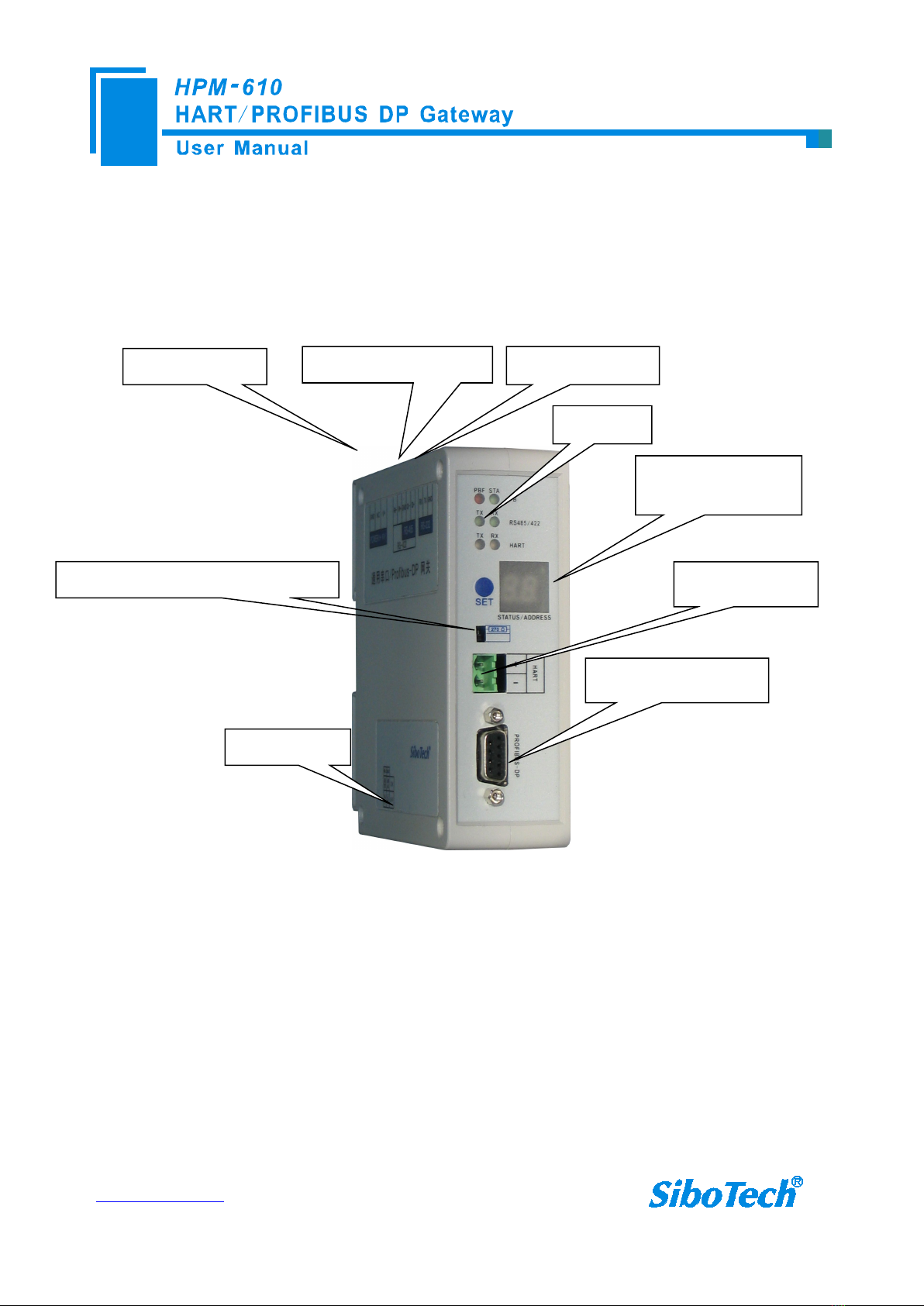

3.1 Product Appearance

Note: This picture is for reference only. Product appearance should accord to the real object.

PROFIBUS Interface

HART Interface

24VDC Interface

RS485/RS422 Interface

Indicators

DIP switch

State/address

displaying/setting

RS232 Interface

Selecting switch of sampling resistance

www.sibotech.net

10

3.2 Indicator LED

Indicator LED State Status Description

PBF Always Red PROFIBUS DP communication fails

Close Communication is ok.

STA Green Blinking PROFIBUS DP bus data is

communicating

Close No data is communicating.

TX Blinking Bus data is sending

Close No data is sending

RX Blinking Bus data is receiving

Close No data is receiving

3.3 Configuring Switch/button

3.3.1 Status setting switch

Configuration switch is located at the bottom of product, bit 1 is the debugging bit and bit 2 is the

configuration bit.

The debugging (bit 1) Configuration (bit 2) Description

Off Off Running mode

Off On Configuration Mode

On Off Debugging mode

On On Configuration Mode

Note: ①After configuring the switch, you have to restart the HPM-610 to make the settings take effect!

②Set to debug mode, “MODBUS slave” or “common mode” will be compulsory to appoint RS485

interface acting as the communication port and RS232 interface acting as debugging interface.

③Configuration interface uses the RS232 interface.

Off

On 1 2

www.sibotech.net

11

3.3.2 PROFIBUS-DP/ MODBUS address setting button

Under normal working condition of the HPM-610, press the button twice quickly, then the high bit of digital

LED starts to flash, click the button can set the high bit of PROFIBUS/MODBUS address. Then keep pressing the

button for about 3 seconds, the low bit of digital tube starts to flash, click the button can set the low bit of

PROFIBUS/MODBUS address. Finally, keep pressing the button for about 3 seconds, the address flashing three

times shows that the address was set successfully. After coming in the status of setting PROFIBUS/MODBUS

address, if no button action within ten seconds, HPM-610 exits the status of setting address automatically and

continues to display the original address. The settable range of PROFIBUS/ MODBUS address is 0 to 99

(decimal).

3.3.3 Internal / external sampling resistance switch

Users can choose to use the internal sampling resistor or external sampling resistor to get the HART signal.

The specification of the internal resistor is 270Ω, 2W. When the power of the sampling resistor is more than 2W,

you must choose to use external resistance.

Switch to the top, using the internal

sampling resistor

270Ω

Switch to the bottom, using an

external sampling resistor

270Ω

www.sibotech.net

12

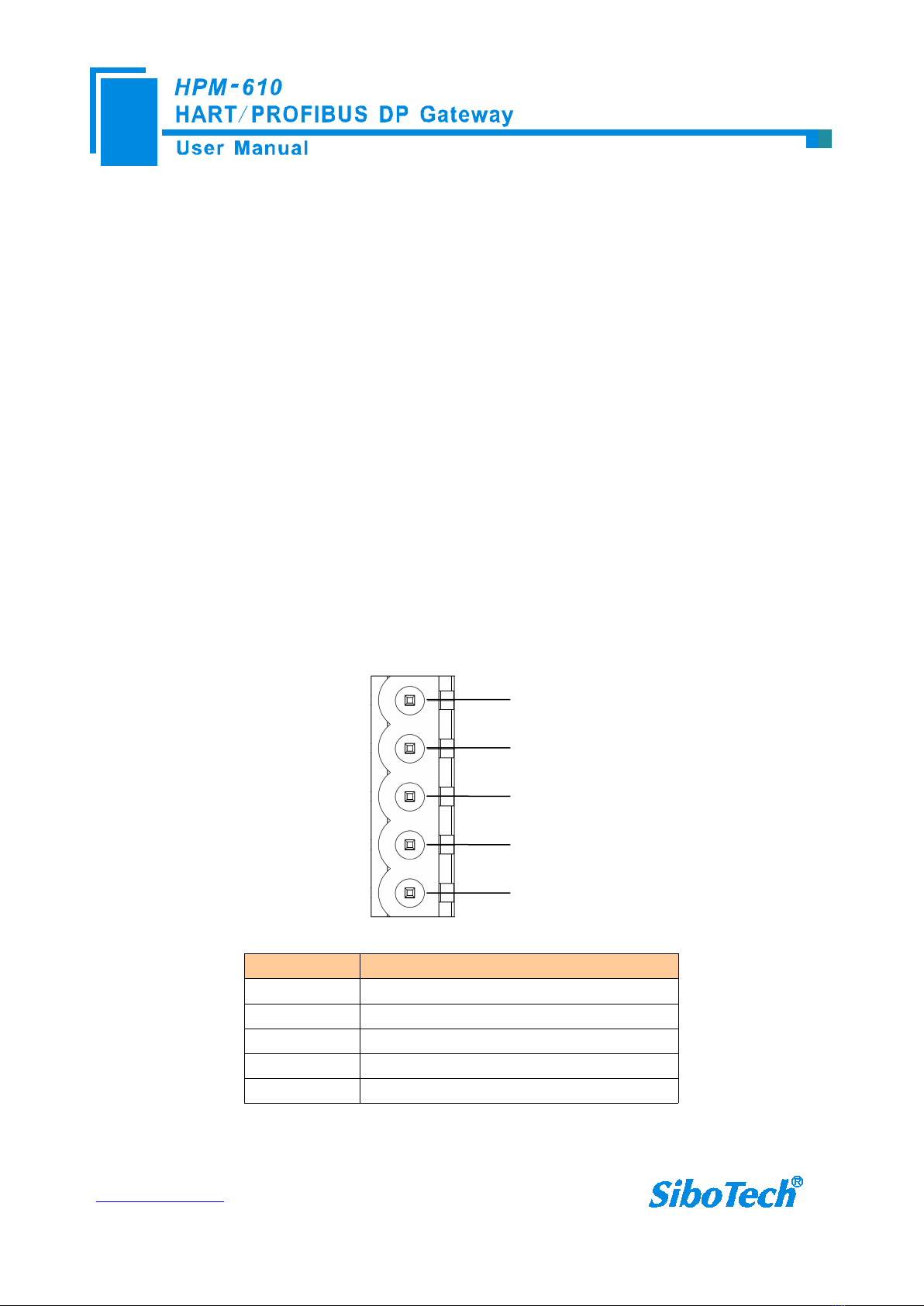

3.4 Interface

3.4.1 Power Interface

GND

NC

24V+

1

2

3

Pin Function

1 GND

2 NC(No Connect)

3 24V+,DC (9-30V)

3.4.2 PROFIBUS-DP interface

PROFIBUS DP interface uses DB9 male-connector, and the pins are defined as follows:

Pin Function

3 PROFI_B, Data positive

5 GND

8 PROFI_A, Data negative

3.4.3 RS485/RS422 interface

The RS-485/422 interface of HPM-610 is a standard RS485/422 compatible port, and this serial port

characteristics of the product will be described as follows:

5

1

PROFI_A (Pin 8)

GND (Pin 5)

PROFI_B (Pin 3)

www.sibotech.net

13

3.4.3.1. The basic characteristics of RS-485 transmission technology

①Network topology: Linear bus, there are active bus termination resistors at both sides.

②Transfer rate: 1200 bps~115.2Kbps.

③Media: Shielded twisted-pair cable and also can cancel the shielding, depending on environmental

conditions (EMC).

④Site number: 32 stations per subsection (without repeater), and can increase to 127 stations (with repeater).

⑤Plug connection: 3-pin pluggable terminal.

3.4.3.2. The main points on RS-485 transmission equipments installation

①All the devices are connected to the RS-485 bus;

②Each subsection can be connected up to 32 sites;

③The two farthest end of each bus provides a termination resistor—120Ω 1/2W to ensure reliable operation

of the network.

Serial interface uses 5-pin pluggable terminal and users can wire it according to the wiring instructions on the

panel.

GND

D-

D+

1

2

3

4

5

R-

R+

Pin Function

1 R-, RS-422 Receive Negative

2 R+, RS-422 Receive Positive

3 GND

4 D-, RS-485/RS-422 Transmit Negative

5 D+, RS-485/RS-422Transmit Positive

When you use 2-wire RS485, just connects Pin D+ and D-. If you use 4-wire RS485 or RS422, connects

D+/D- to TX+/TX-.

www.sibotech.net

14

3.4.4 RS-232 interface

RS-232 interface of HPM-610 uses a open 3-pin pluggable terminal, and its pin description is shown as

follows:

RX

TX

GND

1

2

3

Pin Function

1 RX,Connect user device RS232's RX

2 TX,Connect user device RS232's TX

3 GND,Connect user device RS232's GND

3.4.5 HART interface

1

2

HART LOOP+

HART LOOP-

Pin Function

1 Connect HART signal positive

2 Connect HART signal negative

Notes: Actually, HART is an AC signal without +/-. Usually connects Loop+ closer to current loop high voltage

side. But most time random connection works.

www.sibotech.net

15

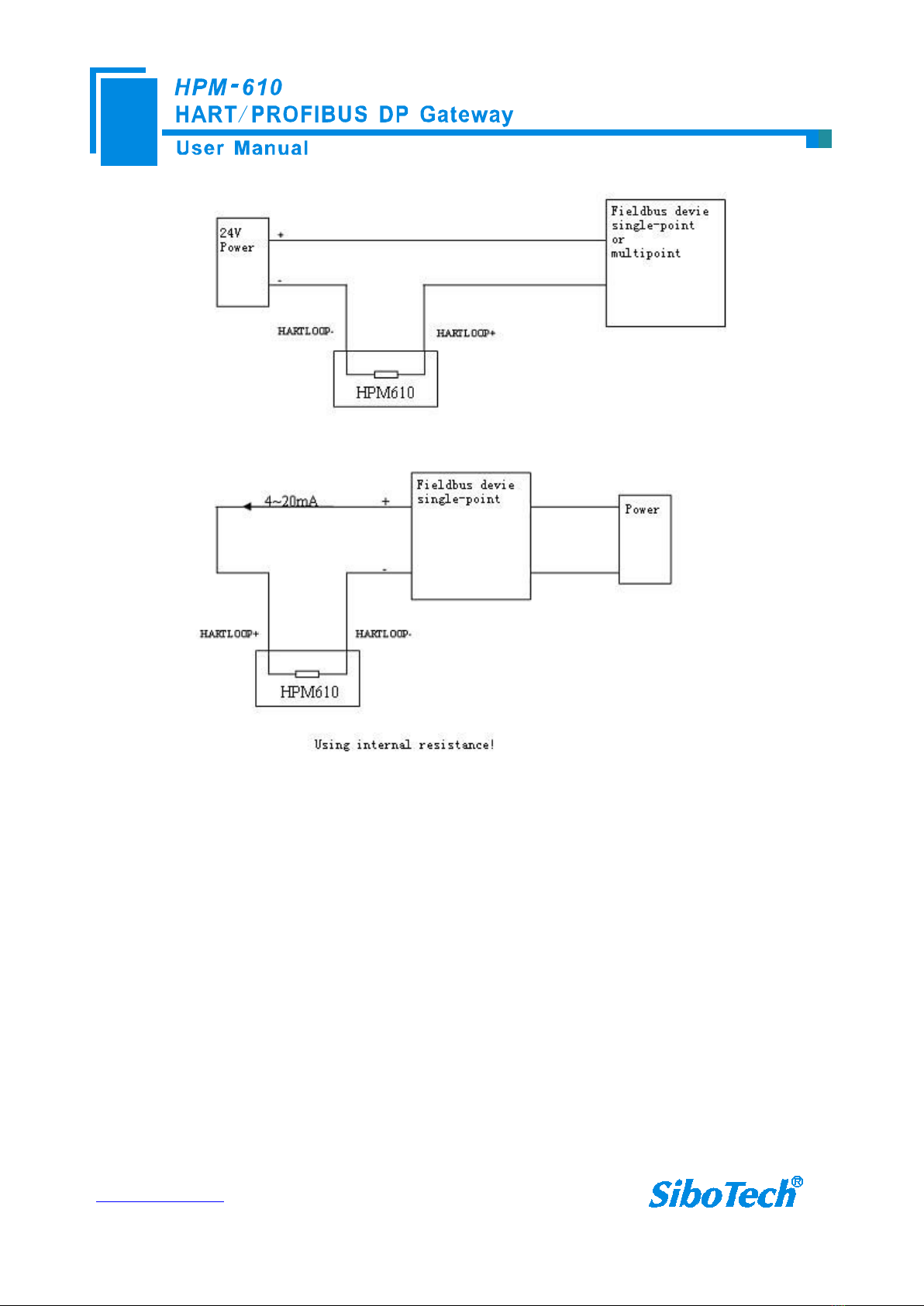

3.5 Topology of HPM-610 and fieldbus devices

These digrams show outside sampling resister used and the the system wiring. Use internal sampling resister just

to replace the 250ohm to internal resister. You must select one from using internal sampling resistor or external

resistor otherwise the HART will not work.

www.sibotech.net

16

Note: 1. Some HART slave instrument need to perform self-test and other internal work when power is on, it may

not proceed with HART communication, so gateway cannot receive the response or data of the instrument right

now. It is recommended the HART slave instrument and gateway uses separate power supply so that the gateway

can immediately establish communication with instrument.

2. When configuring HART read/write commands with HT-123, the commands need to be configured

according to the actual situation. To increase the speed of bus communication, it is recommended not to configure

the empty node (node is not really connected) and empty/dummy/wrong commands.

www.sibotech.net

17

4 Software Instructions

4.1 Software Interface Description

HT-123 a configuring software based on Windows 32bits platform, and used to configure HART series

products.

The following describes how to use the software HT-123 and configure the HPM-610. You may also read the

software user manual to get more detailed information.

Double-click on the icon to enter the main Window of software:

Tool Bar:

Toolbar interface shown as follow:

The function from left to right is: New, Save, Open, AddNode, DelNode, DelCmd, Upload, Download,

AutoMap, Conflict, Excel configuring file output, Data Memory display, Diagnose and Debug.

Network Settings interface:

Contains Fieldbus and the

connection object

Menu Bar

Tool Bar

Title Bar

Parameter Settings interface:

Contains modifiable part and

shall not modify the part

Comment field: Explain the

function of the configuration

options

www.sibotech.net

18

New: Create a new configuration file

Save:Save the configuration file

Open: Open the configuration file

AddNode: Add a HART slave node

DelNode: Delete a HART slave node

AddCmd: Add a HART command

DelCmd: Delete a HART command

Upload: Read the configuration information from the module and shown in the software

Download: Download the configuration file to the module

AutoMap: Used to automatically calculate the mapped memory address with no confliction by each

command

www.sibotech.net

19

Conflict: To check whether there are conflicts with configured commands in the gateway memory data

buffer

Export: Output current configuration to the local hard disk and saved as .xls file format

Memory: Show the internal data exchange of the gateway

Diagnose: Analyze operating condition of fieldbus device; also it can finish some certain analysis

Debug: Send any request frame to Hart fieldbus and show the response information received in HART,

convenient to debug.

4.2 Software Usage

4.2.1 Connect to the hardware

Put the DIP switch of the gateway to “ON”,we use a serial port line to connect the gateway’s RS232 port and one

of computer and power on the gateway . Its Digital tube which displays “CF” indicates it is in the state of configuration.

4.2.2 Upload the configuration file in the gateway

Open the software “HT-123”, click on the icon , firstly, select the computer port connected to the gateway

and then click “upload date”,. If it shows “upload successfully”, it indicates that configuration file had been uploaded to

the HT-123..

Table of contents

Other SiboTech Gateway manuals

Popular Gateway manuals by other brands

CONTROL SOLUTIONS

CONTROL SOLUTIONS Babel Buster IP/XL quick start guide

Netgate

Netgate XG-7100-1U manual

Arris

Arris Touchstone DG2460 user guide

ZyXEL Communications

ZyXEL Communications ZyXEL Prestige 304 quick start guide

Eaton

Eaton Power Xpert Meter 2000 quick start guide

Psion Teklogix

Psion Teklogix 9160 G2 user manual

bihl+Wiedemann

bihl+Wiedemann AS-i/Modbus Gateway user manual

ViewSonic

ViewSonic WPG-350 Software installation guide

Versa Networks

Versa Networks CSG300 Series instructions

ATX

ATX UCrypt IP to Analog 2 Installation & operation manual

Opengear

Opengear ACM5000 user manual

RTA

RTA 460ESPBS-N70PB Product user guide