Sices DST2600 User manual

Filename: EAAM016305EN

Rev. 05 Date: 05/11/2014

ID Document: EAAM0163

Product: DST2600

ii DST2600 User’s Manual

1. FORWARD................................................................................................................4

2. MANUAL VALIDITY..................................................................................................4

2.1 Firmware version..................................................................................................4

3. ABOUT SAFETY.......................................................................................................5

3.1 Safety ground connection.....................................................................................5

4. CONNECTIONS........................................................................................................6

4.1 Power line connection...........................................................................................6

4.2 Load wiring...........................................................................................................6

5. BATTERY CHARGE MAINTAINER..........................................................................6

6. PROTECTIONS AND INTERNAL FUSES................................................................7

6.1 Battery protections................................................................................................7

6.2 Phase line protections ..........................................................................................7

7. FRONT PANEL BREAKERS....................................................................................8

8. FRONTAL PANEL DESCRIPTION...........................................................................8

8.1 Frontal panel view ................................................................................................8

8.2 LED lights.............................................................................................................9

8.2.1 Genset working modes indication...................................................................9

8.2.2 Visualization modes and warning/alarm lights................................................9

8.2.3 MAINS LIVE light............................................................................................9

8.2.4 Generator live/ engine running light (GENERATOR/ENGINE).....................10

8.2.5 Change over status lights (KM/KG)..............................................................10

8.3 Key switches.......................................................................................................10

8.3.1 Cursor keys (arrows UP and DOWN)..........................................................10

8.3.2 MODE/ACK key............................................................................................12

8.3.3 AUX/PROGRAM key....................................................................................12

8.3.4 Changeover selection KM/KG......................................................................13

8.3.5 Engine START key.......................................................................................13

8.3.6 Engine STOP key.........................................................................................13

8.4 Multifunctional display.........................................................................................14

8.4.1 Internal display backlight..............................................................................14

8.4.2 Visualization modes .....................................................................................14

8.4.2.1 MODE 1................................................................................................15

8.4.2.2 MODE 2................................................................................................16

8.4.2.3 MODE 3................................................................................................18

8.4.2.4 MODE 4................................................................................................19

9. CLOCK....................................................................................................................20

10. TEST (engine starting test)...................................................................................20

10.1 Manual command.........................................................................................21

10.2 Digital input command..................................................................................21

10.3 Periodical test...............................................................................................21

10.4 Command from serial port............................................................................22

DST2600 User’s Manual iii

10.5 SMS command.............................................................................................22

11. WORKING SEQUENCES .......................................................................................22

11.1 Genset protections .......................................................................................22

11.2 Protections disabling ....................................................................................22

11.3 Working modes ............................................................................................22

11.4 Mains............................................................................................................23

11.5 Generator.....................................................................................................23

11.6 Inhibition of automatic genset operations.....................................................23

11.7Engine..........................................................................................................24

11.8 Engine commands........................................................................................24

11.9 Manual start..................................................................................................25

11.10 Automatic start and stop...............................................................................25

12. CHANGE-OVER LOGIC .........................................................................................25

13. LOAD MANAGEMENT ...........................................................................................26

14. DST2600 Start up...................................................................................................27

15. PARAMETERS PROGRAMMING...........................................................................27

15.1 Entering and modifying parameters..............................................................27

15.2 Password setting..........................................................................................29

16. ANOMALIES...........................................................................................................29

16.1 Forward........................................................................................................29

16.2 Anomalies signalling organization ................................................................30

17. TECHNICAL CHARACTERISTICS.........................................................................30

17.1 Fundamentals...............................................................................................30

17.2 Current absorption........................................................................................31

17.2.1 Battery current absorption with no mains voltage ...................................31

17.2.2 Mains absorption.....................................................................................31

18. DIMENSIONS AND INSTALLING...........................................................................32

4 DST2600 User’s Manual

DST2600 is an integrated automatic mains failure control panel equipped with all the devices

and functions needed for such applications, included battery charge maintainer and siren.

Generator currents and voltages measurements are done with true Root Mean Square

method, mains voltages with means value.

Images, drawings and some descriptions in this document can be related to versions of the

device provided with one or more options.

The present document is applicable starting from FW rev. 00.01.

Information about DST2600 firmware revision can be obtained in two different ways::

A label on device identifies the serial number, the installed options and other

information. This label also reports the software revision identified by the writing “FW”

or “SW” followed by a numeric code “0085XXYY” or “0141XXYY”.

When the device is powered, on the multifunction display will appear for about 3

seconds the following message:

SICES s.r.l.

DST2600 revXX.YY

In both cases, XX is a two digit number the identifies the major software version, YY is a two

digit number that identifies the minor software version.

The complete device SW code is EB0220085XXYY or EB0220141XXYY. If the software

revision is 00.06 (or 0.06) the actual code SW is EB02201410006.

Inside this document, a vertical bar on the page right edge highlights some change in the

paragraphs since the previous document version. Change in table fields are highlighted by a

grey background. The list of the changes is in page ii.

To improve the product, SICES, during the time, will introduce some changes in the products.

In spite of every effort made to maintain updated the documentation, some new features or

function couldn’t be covered by this document.

In any case, check first for an updated version of the document on our website www.sices.eu;

if you need technical support, please write to techelp@sices.eu

DST2600 User’s Manual 5

Icon highlights prescriptions related to the safe use of the device.

Please carefully read the present handbook before install or use the device.

The device must be positioned and installed in such a way to drain off the heat it

generates; avoid occluding the vent-holes.

Don’t expose directly the device to inclemency of the weather or to ambients saturated

with atmospheric humidity or saline.

When working in “AUTO” mode, the genset can automatically start at any moment.

CAUTION: TO AVOID ELECTRICAL SHOCK, THE FRONTAL PANEL

REMOVING AND ALL THE OPERATION INSIDE THE PANEL MUST BE CARRIED

OUT EXCLUSIVELY BY AUTHORIZED PERSONNEL AND ONLY IF MAINS

SOURCE IS DISCONNECTED, THE GENSET ENGINE IS NOT RUNNING AND

ENGINE STARTING BATTERY DISCONNECTED.

Safety ground connection is MANDATORY and required for the

proper device functionality. It must be done before any other connection;

SICES srl is no in any way liable for damage or person injury due to the

lack or the incorrect safety ground connection.

Connection is made by a 6MA bolt on the panel internal bottom; it is highlighted by the following

symbol

The wire used for safety ground connection must have at least the same cross section

as the power cable.

6 DST2600 User’s Manual

A magnetic-thermal over-current breaker or security fuses on mains line are

mandatory and they are to the system installer care; the same for the generator lines in

the version provided without the internal over-current breaker.

Load wiring must be made on the most right contactors marked as “KG”(a label “LOAD

LINE” is placed on the panel bottom). Connections have to be made in parallel to the wires

that connect “KM”and “KG”contactors together.

Starting from left to right, terminals are the followings:

N (neutral)

L1

L2

L3

For single-phase systems, connect neutral to terminal N and phase to terminal L1.

REMARK: the wiring cross section to be used for generator power lines is

16mm2for 40kVA applications

DST2600 is equipped with a charge maintainer that has the purpose of supply the internal

logic and compensate the self discharge of the main engine battery. It is supplied from phase

L1 of the mains line; it is thus required that in three-phases system the neutral line is connected

in order to proper supply the battery maintainer.

A green LED, named “CHARGER ON”, quite in the middle of the interface board, signals that

it is properly working.

In stand-by mode it is able to supply to the battery about 650mA plus the current required to

supply the internal logic.

Even if the system is only a charge maintainer, it can charge the battery in constant current

mode up to a voltage of 13.5V.

DST2600 User’s Manual 7

DST2600 has over-current protection for the battery connection and for the mains and genset

connections. They are made by fuses.

Before change any fuse, check that no harmful voltages are present: stop the

genset by emergency stop, open the mains line and disconnect the genset battery.

Replace them only with the same fuse types as those listed below.

There are:

-One ATO (or AL) fuse of 35A: it is connected between the battery and the power outputs

“START” and “FUEL”. It fuses in case of overload on these outputs.

-An auto resettable fuse of 5A is inserted between the positive battery and the panel supply:

it open in case of panel failure or polarity inversion or overload at the auxiliary relay output

J200-7. If mains is present, the opening of the fuse doesn’t shutdown the panel that is

supplied by the charge maintainer; if mains is not present that panel will shutdown. Do not

overcharge the auxiliary output J200-7 (max. 3A).

-An auto resettable fuse of 2.5A acts as charge maintainer protection. It opens in case of

hardware failure.

-Two auto resettable fuses of 2.5A and 5A, to protect the auxiliary outputs at battery voltage

respectively J405 and J406

Auto resettable fuses work as thermal switch and don’t require any operator procedure:

remove the overload source and wait for protection cooling down.

Each line input, both mains and generator, has a protection fuse. The fuse type is a 5x20mm,

1A and it is used to protect against internal faults. Only exceptions: fuse F203 on mains phase

L1 and F200 on generator phase L1 are 2A fuses. The reason is that F203 output supplies the

contactor “KM”and the charge maintainer. F200 supply the contactor “KG”.

To summarize:

4 5x20mm fuses of 1A: F201, F202, F204, F205

2 5x20mm fuses of 2A: F200, F203

The fuse of one of this protection yields a measurement error, like the phase missing.

In auto mode, the opening of one of the fuses placed as mains line protection (F203, F204,

F205) will cause the genset start for mains failure; F203 will cause, in addition, the switch off

of the charge maintainer and the drop of “KM”changeover (so loads will be no more supplied

by mains).

The opening of one of the fuses placed as generator line protections (F200, F201 and F202)

will cause in “AUTO”mode an anomaly activation upon the generator status (“operating

condition failure”, “under-voltage” or “under-frequency” depending by the opened fuse and

when the failure appears); in manual mode there isn’t any signalling of anomalies but the

changeover on genset is not allowed since the generator is not seen in the “ready to supply”

window .

8 DST2600 User’s Manual

On the front panel there is normally a thermo-magnetic breaker to command and protect the

engine warming resistor (if present).

In some version it can be substituted with a breaker on the device supply at battery voltage,

with the rule to disconnect the device when its use is not scheduled.

The upper part of the control panel is made of polycarbonate, resistant to oil and solvents,

which has symbols and identification strings.

Here there are all the commands, the alphanumerical signalling and the warning lights; these

will be described in details in the following paragraphs.

The frontal panel can be different in the graphical aspect with respect to the one shown here;

however the functions of the keys, the warning lights and of the display stay unchanged

DST2600 User’s Manual 9

DST2600 has eleven lights, to signal status, events and for the working and visualization

modes.

In the “OFF_RESET”, by pressing the “STOP” key, all the lights will be lighted on (“LAMP

TEST”) allowing to check their proper working.

They’re three yellow lights on the left side of the arrow keys. They signal the working mode of

the device (for a complete description of the working modes see par. 8.3.1). The third lamp

signals both the “AUTO”, “REMOTE START”(if fixed) and the “TEST” modes (if flashing).

They are four yellow lights, on the right side of the multifunctional display. They show what is

the actual visualization of the display; press the “MODE/ACK” key to scan the four modes.

The “MODE 2 WARNING” light also flashes when a warning arises (an anomaly that doesn’t

cause the engine shutdown); the “MODE 3 ALARM” instead flashes when a block or a

deactivation has occurred. When a new anomaly occurs (of any type) the display visualizations

is forced to “MODE 1”, allowing the visualization of the description of the anomaly. It is however

possible to select any other mode, also with one or more anomalies pending.

The “MAINS LIVE” (green) light shows the mains status. It has the following meanings:

OFF: mains not present.

Flashing: the mains is present but the voltage on one or more phases is not between

the programmed tolerance thresholds (or they are but from a time shorter than the

one configured); if loads are changed over on generator, they must stay on it.

Furthermore, the light signals also the genset inhibition status (see par. 11.6). If the

inhibition status is active, the light flashes also if mains is present.

10 DST2600 User’s Manual

ON: mains is steady present between its tolerance thresholds and so loads can be

changed over on it.

The “GENERATOR/ENGINE” (green) light shows the engine and generator status. It has the

following meanings:

OFF: if the devices diagnoses the “ENGINE STOPPED” status

Flashing: if the devices diagnoses the “ENGINE RUNNING” status but the generator

frequency and/or voltages aren’t between their tolerance thresholds

ON: if generator frequency and voltages are steadily between their tolerance

thresholds

The two lights (green) show if the loads are supplied by mains (“KM”) or by generator (“KG”).

The device has seven key switches; each of them has associated one or more function,

depending on the context.

With the “UP” and “DOWN” keys it is possible to select the genset working mode

(“OFF_RESET”, “MAN”, “AUTO”). Each mode is signalled with the corresponding light. To

pass from one mode to another, keep pressed the arrow key for about one second; to pass

from “OFF_RESET” to “AUTO” and vice-versa it is necessary to pass from “MAN”.

DST2600 User’s Manual 11

In details:

a) “OFF_RESET”: in this mode the board is switched on but all the genset control and

management functions are excluded. This is the mode to use when the automatic genset

starting is not required (for instance, to avoid automatic starting, useless during a factory

closing time, etc.) and above all as security position for genset maintenance. When the

“OFF_RESET” mode is selected the genset cannot start if mains fails. The mains switch

is forced at work and so loads are supplied from mains (if mains is present). In any case

the surveillance on mains, generator and engine status, and the display visualizations are

active. When the “OFF_RESET” status is selected, the following operations are carried

out:

1) The loads changeover is forced to mains (if loads were supplied from

generator).

2) The engine shutdown sequence is activated (if the engine was running).

3) Reset of all the eventual memorized anomalies that caused the genset

shutdown.

In this mode the battery charger is in any case active

In “OFF_RESET” mode (and only in this mode) it is possible to visualize and change the

device programmable parameters.

b) “MAN” (MANUAL): in this mode the board is ready to manage a manual use of the

genset. In brief:

1) The manual start and stop procedure are enabled, where the automatic

procedure are disabled (so the engine won’t never start automatically by the

board).

2) It is possible to changeover the loads on generator with the explicit command

of the operator (only if the generator is in the proper condition to supply). The

changeover won’t never be done by the board (except the changeover to

mains if a block or a deactivation arises)

No action upon engine and changeover will be made when passing from “AUTO” to “MAN”:

the engine maintains its status (running/stopped) and loads too (on mains/on generator).

It is only stopped the eventual start attempt in progress.

c) AUTO (AUTOMATIC): this is the normal working mode of the board. In this mode the

engine is started/stopped automatically when mains fails or with regular intervals to keep

the genset efficient. In the same way loads are automatically changed over on mains or

generator, according to the conditions of both of them.

REMARKS: when the AUTO mode is selected, it is forbidden every kind of

maintenance on genset.

In this mode is furthermore possible to run a manual “TEST”, besides the automatic

periodical running test (see par. 10). Moreover, it is possible to pass to “REMOTE START”

mode, by a digital input command or by a serial port command.

12 DST2600 User’s Manual

The “MODE/ACK” allows to select the visualization on the multifunctional LCD display (see

par. 8.4.2). Pressing one time the key, the visualization mode passes to the next in a cyclical

way (from “MODE 4”, pressing the “MODE/ACK” the display visualization will come back to

“MODE 1”).

If the key is pressed together with the “AUX/PROGRAM” key, it allows the manual regulation

of the display’s contrast level (this regulation is available only for some display models and

only from software version 00.03; with previous version this keys combinations allows to stop

the generator phases scanning on the phase visualized on display at the moment).

The key allows moreover to “acknowledge” the anomalies by the operator, stopping the

internal horn. NOTE: the horn is silenced when the key is released.

During the parameters programming (see par.15) the key works as “ENTER” allowing to

“enter” in menu and sub-menu, to start the modify operation of a parameter and to confirm the

new selected value.

The “AUX/PROGRAM “ allows scanning all the windows related to a visualization mode of the

multifunctional display currently selected. Press the key to pass to the next window of the

mode, in a cyclical way.

If the key is pressed together with the “MODE/ACK” key, it allows the manual regulation of the

display’s contrast level (this regulation is available only for some display models and only from

software version 00.03; with previous version this keys combinations allows to stop the

generator phases scanning on the phase visualized on display at the moment).

If “MODE 1” visualization (which has only one window) is selected and the device is not in

“OFF_RESET” mode, the key hides the description of a pending anomaly, in such a way to

allow the visualization of the power measurements.

If “MODE 1” visualization is selected and the device is in “OFF_RESET” mode, the key allows

to enter in the parameters programming procedure.

During the parameters programming the key is used as “EXIT”: it allows to exit from sub menu

to return to the upper level menu; press it from main menu to exit from programming procedure.

The key allows moreover to abort the modification of a parameter when in progress (the

parameter will keep its previous value). The key finally allows, if used together with the

“START” and “STOP” keys to modify the value of a parameter of 10 units at time (“SHIFT”

function).

DST2600 User’s Manual 13

When the genset is running in “MAN” or “TEST” mode, the key “KM/KG” allows, with proper

generator conditions, to changeover the loads from mains to generator and vice-versa. It has

no effect while working in “AUTO”and “REMOTE START” modes.

-In “MAN” the key command the engine start; the key must stay pressed until the engine

will start. The engine starter is automatically released when the engine is acknowledged

as running.

-In “AUTO” mode, the key starts the manual “TEST” (see par. 10.1). This is possible only

if the engine is stopped with mains present or with inhibit contact activated.

-During the parameters programming the key is used to scan the menu items in the

increasing direction. During the modification of a parameter it increases the parameter

value: each pressure increases the value of one unit. Keep the key pressed to

automatically increase the value; it will restart from its minimum after the maximum will be

reached. Used together with the “AUX/PROGRAM” key (press and keep pressed

“AUX/PROGRAM” first and then use “START”), each pressure increments the value of 10

units.

-In “OFF_RESET” press this key to switch on all the LED lights (“LAMP TEST”), to diagnose

possible failures.

-In “MAN” mode, when pressed the key immediately stops the engine; if the load was

supplied from generator, it is immediately changed over on mains before commanding the

engine stopping. It is not necessary to keep pressed the key until the engine will be

stopped.

-In “TEST” mode, pressing the key the test ends; that is the engine will be stopped, in case

after the cooling time if the load was changed over on generator, and the device will return

to “AUTO” mode.

-In “AUTO” and “REMOTE START“ modes, press the key to execute an emergency stop

of the engine, signalled with the block “A007-STOP PRESSED IN AUTO”.

-During the parameters programming the key is used to scan the menu items in the

decreasing direction. During the modification of a parameter it decrease the parameter

value: each pressure decreases the value of one unit. Keep the key pressed to

automatically decrease the value; it will restart from its maximum after the minimum will

be reached. Used together with the “AUX/PROGRAM” key (press and keep pressed

14 DST2600 User’s Manual

“AUX/PROGRAM” first and then use “STOP”), each pressure decrements the value of 10

units.

The multifunctional display is the means to visualize measures, status indications, and

alphanumerical anomalies. The visualization is on two rows and sixteen columns.

The contrast level can be manually regulated by pressing the keys “MODE/ACK” and

“AUX/PROGRAM” at the same time: if you first press “MODE/ACK” the contrast level

increases, if you first press “AUX/PROGRAM” the contrast level decreases. The regulated

level is stored in non-volatile memory and so it is preserved even if power supply is

disconnected. ATTENTION: the manual contrast regulation is available only from software

release 00.03. On some board is mounted a display with automatic contrast regulation: in this

case the manual regulation has no effects.

The display has an internal backlight, which allows the reading of the indications also in bad

light condition or at night.

The internal lamp is switched on pressing any key; its turn off can be configured with the

parameter P.492: it is the maximum working time (in seconds) of the lamp since the last key

was pressed. Setting the parameter to zero to leave the lamp always on.

NOTE: if the lamp is switched off, the pressure of a key causes only the switching on of the

lamp and doesn't involve the action predefined for the key: to obtain this action the key must

be pressed again.

While the engine starter is running, the lamp is automatically switched off to reduce the current

consumption of the board, in such a way to leave more energy to the board if the engine battery

voltage is low. When the engine is running (only if started by DST2600), the light is always

switched on to improve the readability of the display

The display foresees four visualization modes, selected with the “MODE/ACK” key and

highlighted by the four LEDs on the right side of the display. Except for “MODE 1”, each mode

has more than one page: it is possible to select these pages with the “AUX/PROGRAM” key.

Passing from one mode to another, the display shows as first the last page visualized in that

mode.

DST2600 User’s Manual 15

In this mode are usually shown the fundamental electrical measurements of the generator.

Phase: in the left side of the first row there is the indication of the phase (phase L1 in

the example) to which the voltage and current visualized in the rest of the row are

referred. With single-phase systems the phase indication is always L1. With three-

phases systems the phase shown changes cyclically following the order L1, L2 and

L3. ATTENTION: only with software release lower or equal to 00.03 is however

possible to force the visualization of one phase pressing together in the order the

“AUX/PROGRAM” and “MODE/ACK” keys: the visualization is halted and so the

present phase stays visualized. In this condition the phase indication flashes.

Generator voltages: again, on the first row is shown the generator voltage expressed

in volts. Voltages are visualized with maximum three digits, with no decimals. If the

value is lower than 10V the visualization is forced to zero.

For three-phases systems it is shown the phase-to-phase voltage:

oL1-L2 if it is currently visualized the phase L1.

oL2-L3 if it is currently visualized the phase L2.

oL3-L1 if it is currently visualized the phase L3.

For single-phase systems it is visualized the phase–to-neutral voltage.

Generator currents: in the first row, in the centre, it is shown the current

measurement of the phase currently visualized, expressed in Amperes. It is visualized

with two decimal digits if lower than 10 amps, otherwise with only one decimal digit. If

the value is lower than 0.66A for 20kVA version or 1.2A for 40kVA version, the

visualization is forced to zero.

Generator frequency: in the right side of the first row there is shown the frequency

of the generator voltage, always related to the L1 phase. It is expressed in hertz and

is visualized with a decimal digit.

Active power: in the left side of the second row there is the indication of the total

active power supplied by the generator, expressed in kW. In case of power reverse,

the active power has negative sign. If the currents values (or voltages values) drop

lower than their visualization thresholds (see above), the visualization is forced to

zero.

Reactive power: in the centre of the second row there is the indication of the total

reactive power supplied by the generator, expressed in kvar.

Power factor: on the right side of the second row there is the indication of the total

power factor of the load connected to the generator. To its right there is the “i” letter if

the load has inductive characteristics or the “c” letter if capacitive. Normally the

indication is with one integer and two decimal digits; if the currents drop lower than

1/10 of their full scale value (that is 3.3A for 20kVA version and 6.2A for 40kVA

version) the power factor is forced to one. In the case of power reverse the indication

is preceded by a minus sign and the integer digit is not shown.

L1 400 10.1 50.0

6.97 0.0 1.00i

16 DST2600 User’s Manual

If the engine is in a transitory phase (starting, stopping, cooling, that is the engine is not neither

in running nor in stopped status) the first row alternates the visualization of the electrical

measurements seen above with the description of the present engine status. The possible

indications are:

"STOP CYCLE ": the engine is stopping.

"ABORT STOP ": the stop cycle is interrupted for a new start request.

"ENG. NOT STOPPED": the engine is not stopped after a stop cycle.

"PREHEAT": it is active the glow plugs command foe Diesel engines, awaiting the real

start.

"FUEL SOLENOID ON": the “FUEL” command is active but the “START” command

not yet.

"CRANK IN PROGR.": the “START” command (engine starter) is active for the engine

crank.

"DELAY": one crank attempt was not successful and it is in progress the pause before

next attempt.

"CHECK FOR RUN": the “START” key, in MAN mode, has been released before the

engine was really running; the device waits some seconds to check if the engine really

starts or it dies.

"WAIT FULL SPEED": the engine is running; the devices is waiting that the generator

electrical measurements reach their proper tolerance thresholds.

" COOLING ": cooling cycle in progress

"CLEANING": washing cycle in progress.

" WAITING FOR STOP": stop cycle in progress, excitation engine stop time elapsed.

" IDLE SPEED.": the engine is running but it is active the idle speed command.

With these visualizations, keep pressed the “AUX/PROGRAM” key to hide the engine status

and to show the generator electrical measurements.

Some of the status above described take place only if programmed on purpose (i.e. “cleaning”

or “idle speed”)

If any anomaly is present, on second row there is the description of the anomaly/anomalies

pending. The description of the anomaly slides on second row; if more than one anomaly is

active, they are visualized cyclically. In this situation, keeping the ”AUX/PROGRAM” key

pressed the anomalies are hided and the power measurements return visible.

Only if the device is in “OFF_RESET” mode, press the “AUX/PROGRAM” key to enter in the

parameter programming procedure.

Whatever is the visualization mode, when an anomaly occurs the visualization is forced

to “MODE1”.

In “MODE2”, pressing more time the “AUX/PROGRAM” key, it is possible to visualize four

different pages, containing measurements related to generator and to mains

- Page 1:

DST2600 User’s Manual 17

On the first row is shown the total apparent power expressed in kVA. On the second

row, with three-phases systems, there is a text showing the phase sequence of the

generator (CW = clockwise / CCW = counter clockwise). If the system is configured

as single phase, the text is substituted with dashes (as in the example).

-Page 2:

This page is shown only with three phases systems. It shows the powers related to

each single phase, cyclically. In the first row it is shown the present phase (1 in the

example), followed by its apparent phase power (in kVA), by its power factor and by

the indication of the type of its load (i if inductive, c if capacitive). The second row

shows the active power (in kW) and the reactive power (in kvar) of that phase. If the

active power and the power factor have negative sign, the system is working in a

power reverse situation.

NOTE: if in “MODE1” the phases scansion is halted, this page will result halted too.

-Page 3:

In the first row it is shown the total active energy supplied by the generator (in kWh).

In the second row it is shown the counter of the total reactive energy supplied by the

generator, in kvarh.

-Page 4

Total kVA: 10.1

Phase sequence: --

1 0.0kVA 1.00i

0.0kW 0.0kvar

kWh: 13

kvarh: 1

MAINS R S T Hz

399 398 396 50.0

18 DST2600 User’s Manual

On the second row are shown the three mains phase-to-phase voltages, L1-L2, L2-

L3, L3-L1. The measurements are in volts wit no decimals. For single-phase system,

the second and the third measurement are substituted with dashes, and the first shows

the phase-to-neutral voltage. On the right side there is shown the mains frequency, in

hertz, with one decimal digit.

In “MODE 3”, pressing more times the “AUX/PROGRAM” key, it is possible to visualize three

different pages containing measurements related to the engine:

-Page 1:

On second row there are visualized the total engine starts number (only when the

engine was really started), both manual and automatic, and the engine start battery

voltage, in volts with one decimal digit. The start counter can be reset

-Page 2

On second row there are visualized three counters related to the engine running hours.

On the left side there is the total engine running hours (absolute hours), in the centre

the partial engine running hours and on the right side the engine running hours missing

before the engine maintenance (this function must be set with parameter P.424,

otherwise dashes are shown).

-Page 3

On second row are shown in the order: the engine oil pressure (in bar), the coolant

temperature (in °C) and the fuel level (as percentage with respect the full tank).

These measurements are available only if engine instruments were been

properly configured. If one or more measurement is not available because not

configured, the indication is substituted with dashes

START#/ BATTERY

224 13.4Vdc

HOUR ABS/PAR/MIS

51 48 -------

Bar °C Lev%

3.8 82 32

DST2600 User’s Manual 19

In “MODE4”, pressing more time the “AUX/PROGRAM” key it is possible to visualize four

different pages:

-Page 1

Some particular events can be shown on the second row. If no events is active, the

second row is empty. If more than one event is active, they are shown cyclically,

switched every two seconds. This page is available starting from software 00.06.

Actually the following events can be shown:

Inhibition of generator automatic operations (requested by digital input).

Inhibition of generator automatic operations (requested by clock).

REMOTE START mode activated

-Page 2

On the first row there is shown the total working hour of DST2600 (since it was

supplied), on the second row there is an alphanumerical code with 12 characters,

unambiguous for each device (serial number)

-Page 3

This page shows the internal clock of DST2600 (see next). Date and time are

flashing if the clock have not yet been configured from DST200 power on.

-Page 4

BOARD H.: 135

SN: 000009FBF4F9

STATUS

Inhib. From I/O

CLOCK 08:29:57

31/01/2008

20 DST2600 User’s Manual

The first row shows the communication resource presently connected to the serial

port. The indication can be:

-RS232: if there is a RS232/RS485 connection.

-Modem: to the serial port it is connected an analogue modem. The rest of the row

shows the modem status (at rest, incoming call, outgoing call etc.).

-GSM: to the serial port it is connected a GSM modem. The rest of the row shows

the modem status (at rest, incoming call, outgoing call etc.). The second row

shows the GSM service provider’s name and the present signal level (from one to

four notches).

DST2600 manages an internal clock/calendar. Attention: there isn’t any internal real clock

circuit, so if you remove power supply from DST2600, when you power it again the date will

be “01/01/2000” and the time will be “00:00:00”. In this case, date and time are marked as “not

valid” (in some cases this situation causes the activation of a warning signaling). Date and

time are marked as “valid” only when you change them (or a part of them), even if you simply

confirm actual values. You can change date and time by the serial port (SicesSupervisor PC

software) or manually by the standard parameter programming function: the year, the month,

the day etc are normal configurable parameters of DST2600.

The clock is used for two main functions:

Periodical test.

Inhibition of automatic genset operations in predefined time intervals.

Both functions will be explained in the next paragraphs.

DST2600 allows to execute genset running tests, in such a way to check its efficiency and to

assure the lubrication of the engine internal parts. The test can be run:

On operator direct command (on START key).

From digital input command.

Automatically with regular intervals.

From serial port command.

From SMS command.

To run the test, DST2600 must be in “AUTO” mode.

GSM: idle

Vodafone [### ]

Other Sices Control Panel manuals

Popular Control Panel manuals by other brands

vita

vita vPad comfort operating manual

Siemens

Siemens SIMATIC HMI OP 73micro operating instructions

Allen-Bradley

Allen-Bradley RediPANEL installation instructions

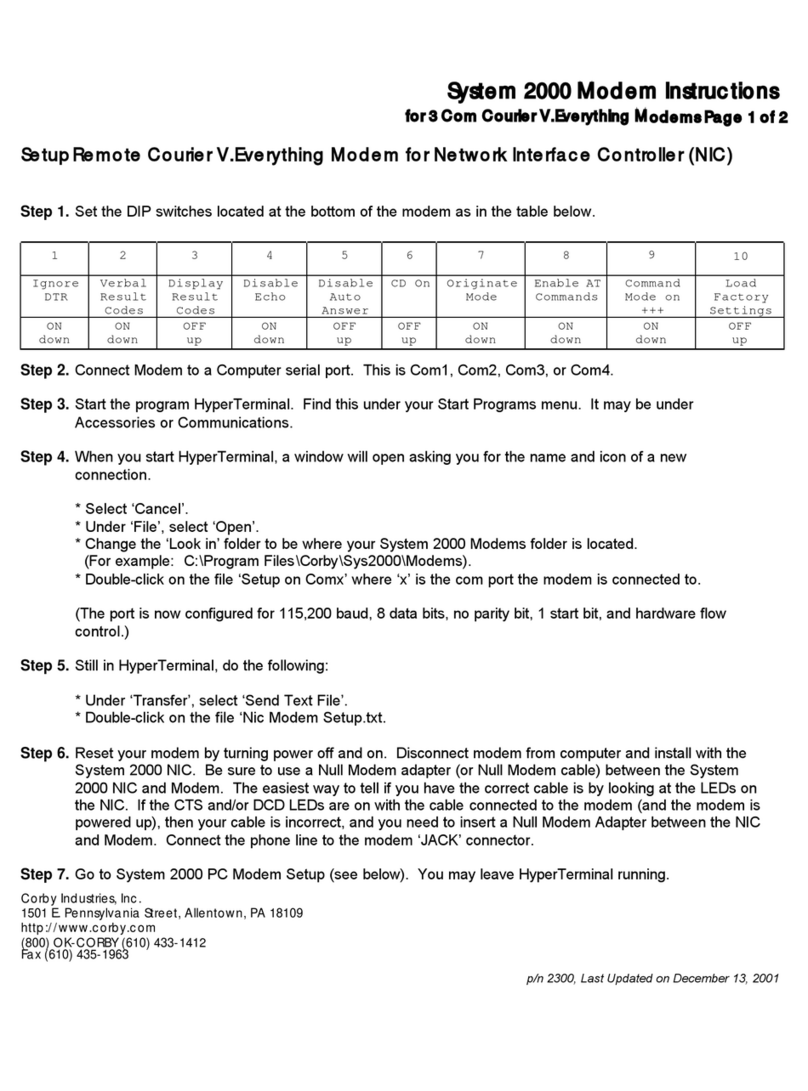

Corby

Corby System 2000 instructions

weintek

weintek MT8073iE Series Installation instruction

Bosch

Bosch AMAX panel 2100 Quick installation guide