SICK flexLock User manual

OPERATING INSTRUCTIONS

flexLock

Safety locking device

Review version 2021-04-30

Described product

flexLock

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is

only permissible within the limits of the legal determination of Copyright Law. Any modi‐

fication, abridgment or translation of this document is prohibited without the express

written permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2O P E R A T I N G I N S T R U C T I O N S | flexLock 8020562/2021-04-30 | SICK

Subject to change without notice

Review version 2021-04-30

Contents

1 About this document........................................................................ 5

1.1 Scope......................................................................................................... 5

1.2 Target groups of these operating instructions........................................ 5

1.3 Additional information.............................................................................. 5

1.4 Symbols and document conventions...................................................... 5

2 Safety information............................................................................ 7

2.1 General safety notes................................................................................ 7

2.2 Intended use............................................................................................. 7

2.3 Improper use............................................................................................. 7

2.4 Requirements for the qualification of personnel.................................... 7

3 Product description........................................................................... 9

3.1 Design and function................................................................................. 9

3.2 Product characteristics............................................................................ 9

3.3 Manual unlocking..................................................................................... 11

4 Project planning................................................................................ 13

4.1 Manufacturer of the machine.................................................................. 13

4.2 Operator of the machine.......................................................................... 13

4.3 Design........................................................................................................ 13

4.4 Integration in the electrical control system............................................. 15

5 Mounting............................................................................................. 18

5.1 Safety......................................................................................................... 18

5.2 Orientation of the safety switch............................................................... 18

5.3 Mounting several safety switches............................................................ 18

5.4 Mounting the safety switch...................................................................... 19

5.5 Mounting the actuator.............................................................................. 19

6 Electrical installation........................................................................ 20

6.1 Safety......................................................................................................... 20

6.2 Notes on cULus......................................................................................... 21

6.3 Device connection.................................................................................... 21

6.4 Connection of a safe series connection.................................................. 22

7 Commissioning.................................................................................. 24

7.1 Teach-in..................................................................................................... 24

7.2 Testing....................................................................................................... 26

7.3 Regular thorough check........................................................................... 26

8 Operation............................................................................................ 28

8.1 Actuating the mechanical unlocking mechanism................................... 28

8.2 Preventing unintentional closing of the protective device..................... 28

CONTENTS

8020562/2021-04-30 | SICK O P E R A T I N G I N S T R U C T I O N S | flexLock 3

Subject to change without notice

Review version 2021-04-30

9 Maintenance...................................................................................... 29

9.1 Cleaning..................................................................................................... 29

10 Troubleshooting................................................................................. 30

10.1 Safety......................................................................................................... 30

10.2 LED indicators........................................................................................... 30

11 Decommissioning............................................................................. 34

11.1 Disposal..................................................................................................... 34

12 Technical data.................................................................................... 35

12.1 Data sheet................................................................................................. 35

12.2 Connecting cables.................................................................................... 37

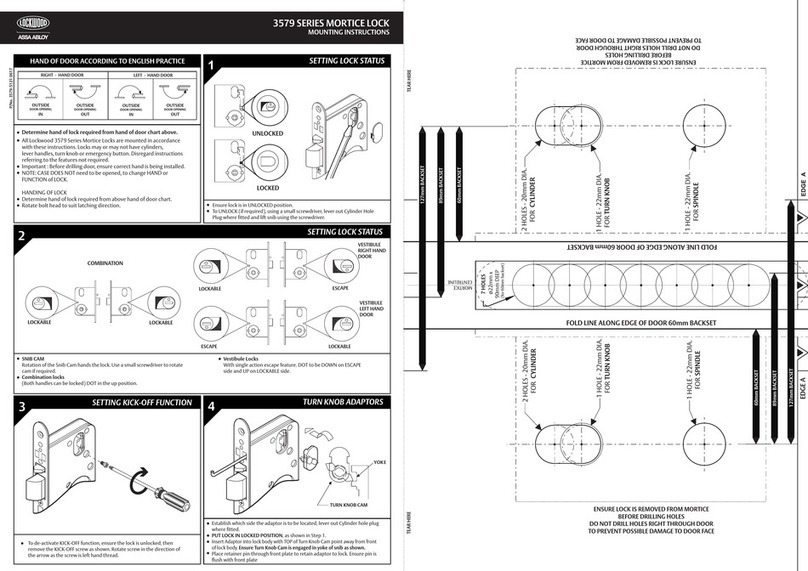

12.3 Safety switch dimensional drawings....................................................... 38

12.4 Actuator dimensional drawings................................................................ 38

12.5 Dimensional drawings of the mounting bracket..................................... 38

13 Ordering information........................................................................ 39

13.1 Scope of delivery....................................................................................... 39

13.2 Ordering information................................................................................. 39

14 Accessories........................................................................................ 40

14.1 Actuator..................................................................................................... 40

14.2 Connectivity............................................................................................... 40

15 Annex.................................................................................................. 42

15.1 Compliance with EU directives................................................................. 42

15.2 FCC and IC radio approval........................................................................ 43

CONTENTS

4O P E R A T I N G I N S T R U C T I O N S | flexLock 8020562/2021-04-30 | SICK

Subject to change without notice

Review version 2021-04-30

1 About this document

1.1 Scope

These operating instructions are valid for the flexLock safety locking device.

This document is included with the following SICK part numbers (this document in all

available language versions):

8025630

1.2 Target groups of these operating instructions

Some chapters of these operating instructions are intended for certain target groups.

However, the entire operating instructions are relevant for intended use of the product.

Table 1: Target groups and selected chapters of these operating instructions

Target group Chapters of these operating instructions

Project developers (planners, developers,

designers)

"Project planning", page 13

"Technical data", page 35

Installers "Mounting", page 18

Electricians "Electrical installation", page 20

Safety experts (such as CE authorized repre‐

sentatives, compliance officers, people who

test and approve the application)

"Project planning", page 13

"Commissioning", page 24

"Technical data", page 35

Operators "Troubleshooting", page 30

Maintenance personnel "Troubleshooting", page 30

1.3 Additional information

www.sick.com

The following information is available on the Internet:

•This document in other languages

•Data sheets and application examples

•CAD data and dimensional drawings

•Certificates (e.g. EU declaration of conformity)

•Guide for Safe Machinery Six steps to a safe machine

1.4 Symbols and document conventions

The following symbols and conventions are used in this document:

Safety notes and other notes

DANGER

Indicates a situation presenting imminent danger, which will lead to death or serious

injuries if not prevented.

WARNING

Indicates a situation presenting possible danger, which may lead to death or serious

injuries if not prevented.

ABOUT THIS DOCUMENT 1

8020562/2021-04-30 | SICK O P E R A T I N G I N S T R U C T I O N S | flexLock 5

Subject to change without notice

Review version 2021-04-30

CAUTION

Indicates a situation presenting possible danger, which may lead to moderate or minor

injuries if not prevented.

NOTICE

Indicates a situation presenting possible danger, which may lead to property damage if

not prevented.

NOTE

Indicates useful tips and recommendations.

Instructions to action

bThe arrow denotes instructions to action.

1. The sequence of instructions for action is numbered.

2. Follow the order in which the numbered instructions are given.

✓The check mark denotes the result of an instruction.

LED symbols

These symbols indicate the status of an LED:

oThe LED is off.

ÖThe LED is flashing.

OThe LED is illuminated continuously.

1 ABOUT THIS DOCUMENT

6O P E R A T I N G I N S T R U C T I O N S | flexLock 8020562/2021-04-30 | SICK

Subject to change without notice

Review version 2021-04-30

2 Safety information

2.1 General safety notes

DANGER

If the safety component is integrated incorrectly, the dangerous state may be ended to

late.

bPlan the integration of the safety component in accordance with the machine

requirements, see "Project planning", page 13.

2.2 Intended use

The safety locking device is a locking unit with a safety locking function and is suitable

for the following applications:

•Temporarily preventing access to a hazardous area

•Monitoring of movable physical guards

•Locking for process protection

In conjunction with a movable physical guard and the machine controller, the safety

locking device prevents the protective device from being opened. The locking device

remains locked for as long as the hazardous machine function is performed or until the

production step has finished.

The product is only suitable for use in industrial environments.

Incorrect use, improper modification of or tampering with the safety locking device will

invalidate any warranty from SICK AG; in addition, any responsibility and liability of SICK

AG for damage and secondary damage caused by this is excluded.

2.3 Improper use

The safety locking device is not suitable, among other things, for the following ambient

conditions:

•Outdoor areas

•Residential areas

•Vacuum

•High pressure

•Strong UV exposure

•Near low-frequency transponders (e.g., RFID)

•Near magnetic fields

•Increased radiaoactivity (> natural radioactivity)

•High sulfur concentration

•High salt concentration

2.4 Requirements for the qualification of personnel

The safety locking device must be planned in, installed, connected, commissioned, and

serviced only by qualified safety personnel.

Project planning

For project planning, a person is considered competent when he/she has expertise and

experience in the selection and use of protective devices on machines and is familiar

with the relevant technical rules and national work safety regulations.

SAFETY INFORMATION 2

8020562/2021-04-30 | SICK O P E R A T I N G I N S T R U C T I O N S | flexLock 7

Subject to change without notice

Review version 2021-04-30

Mechanical mounting, electrical installation, and commissioning

For the task, a person is considered qualified when he/she has the expertise and

experience in the relevant field and is sufficiently familiar with the application of the

protective device on the machine to be able to assess whether it is in an operationally

safe state.

Operation and maintenance

For operation and maintenance, a person is considered competent when he/she has

the expertise and experience in the relevant field and is sufficiently familiar with the

application of the protective device on the machine and has been instructed by the

machine operator in its operation.

2 SAFETY INFORMATION

8O P E R A T I N G I N S T R U C T I O N S | flexLock 8020562/2021-04-30 | SICK

Subject to change without notice

Review version 2021-04-30

3 Product description

3.1 Design and function

Design

The safety locking device is a locking unit with a safety locking function. The safety

locking device comprises a safety switch with transpondermonitoring and a coded

actuator.

Function

The safety locking device is used on a movable physical guard. The safety switch is

located on the frame of the movable guard, the actuator on the moving part. When the

protective device is closed, the actuator is inserted into the safety switch. The safety

switch reads the code of the actuator. If the code is valid, the safety locking function

can be locked via a signal. The movable guard is held closed.

3.2 Product characteristics

3.2.1 Device overview

$

!

(

"

§

%

?

?

)

)

&

!

/

é

Figure 1: Device overview

1Guiding ball

2Locking bolt

3Safety switch

4LEDs

5Connection

6Auxiliary release

7Mounting holes of the safety switch

8Sealing plug for mounting holes of the safety switch

9Actuator tongue

10 Mounting plate of the actuator

11 Sealing plug for mounting holes of the actuator

PRODUCT DESCRIPTION 3

8020562/2021-04-30 | SICK O P E R A T I N G I N S T R U C T I O N S | flexLock 9

Subject to change without notice

Review version 2021-04-30

3.2.2 Locking principle

Overview

The method of locking depends on the safety locking device variant selected. There are

two variants:

•Power to lock

•Power to release

Important information

DANGER

Hazard due to lack of effectiveness of the protective device

For power to lock variants only: In the event of a voltage drop, the locking device

unlocks regardless of whether the dangerous state of the machine has ended.

bDo not use the safety switch in applications in which the dangerous state cannot

be ended immediately (stopping/run-down time).

Power to lock

•Lock locking device: voltage at locking device input

•Unlock locking function: no voltage at locking device input

If voltage is interrupted, the locking device is unlocked and protective device can be

opened immediately.

Power to release

•Lock locking device: no voltage at locking device input

•Unlock locking device: voltage at locking device input

If the voltage is interrupted, the locking device retains its last state (bistable coil). If the

locking device was locked before, the protective device cannot be opened. If the locking

device was not locked before, the protective device can be opened.

Only the power to release variants have a mechanical unlocking mechanism.

3.2.3 OSSD

Output signal switching device: signal output for the protective device, which is used for

stopping the dangerous movement.

An OSSD is a safety switching output. The functionality of each OSSD is tested periodi‐

cally. OSSDs are always connected in pairs and must undergo dual-channel analysis for

safety reasons. An OSSD pair is formed from 2 OSSDs that are connected and analyzed

together.

3.2.4 Switching behavior of the OSSDs

Overview

The safety locking device is available in variants for protecting people or for process

protection. The variants differ with regards to the switching behavior of the OSSDs:

Variants for people protection (locking monitoring)

OSSDs go into the ON state as soon as the following requirements are all fullfilled.

•Movable physical guard is closed.

•Locking device is locked.

•There is a valid signal at the inputs In1 and In2.

3 PRODUCT DESCRIPTION

10 O P E R A T I N G I N S T R U C T I O N S | flexLock 8020562/2021-04-30 | SICK

Subject to change without notice

Review version 2021-04-30

Variants for process protection (actuator monitoring)

OSSDs go into the ON state as soon as the following requirements are all fullfilled.

•Movable physical guard is closed.

•There is a valid signal at the inputs In1 and In2.

Important information

DANGER

Hazard due to lack of effectiveness of the protective device

bDo not use variants for process protection in applications in which the dangerous

state cannot be ended immediately (stopping/run-down time).

3.2.5 Application diagnostic output

Important information

NOTE

The application diagnostic output cannot be evaluated for a safe series connection with

T-connectors.

Switching behavior

The application diagnostic output switches parallel the detection of the actuator. This is

not a safety output.

Status of the movable physi‐

cal guard

Switching behavior of the application diagnostic output

Open OFF

Closed ON

3.2.6 Coded actuators

The safety locking device comes with coded actuators with transponders.

•Uniquely coded

Only one actuator is valid at any one time. Actuators need to be taught-in

to become valid. Each time a new actuator is taught-in, the previous actuator

becomes invalid.

Coding level: High (ISO 14119)

•Universally coded

The device accepts all actuators that are suitable for the device.

Coding level: Low (ISO 14119)

3.3 Manual unlocking

In some situations, it necessary to unlock the locking device manually (e.g. if faults are

present). When unlocking, the safe output signal switching devices (OSSD) switch to the

OFF status. A stop command must be generated as a result.

After manual unlocking, a function test must be performed (see "Testing", page 26).

3.3.1 Auxiliary release

Using the auxiliary release, the safety locking device can be unlocked manually regard‐

less of the status.

PRODUCT DESCRIPTION 3

8020562/2021-04-30 | SICK O P E R A T I N G I N S T R U C T I O N S | flexLock 11

Subject to change without notice

Review version 2021-04-30

!

Figure 2: auxiliary release

1Auxiliary release

Only the power to release variants have a auxiliary release.

3 PRODUCT DESCRIPTION

12 O P E R A T I N G I N S T R U C T I O N S | flexLock 8020562/2021-04-30 | SICK

Subject to change without notice

Review version 2021-04-30

4 Project planning

4.1 Manufacturer of the machine

The manufacturer of the machinery must carry out a risk assessment and apply appro‐

priate protective measures. Further protective measures may be required in addition to

the safety locking device.

The device must not be tampered with or changed, except for the procedures described

in this document.

The device must not be repaired. Defect devices have to be replaced.

Observe EN ISO 14119 when using interlocking devices in conjunction with physical

guards.

4.2 Operator of the machine

Changes to the electrical integration of the device in the machine controller and

changes to the mechanical mounting of the device necessitate a new risk assessment.

The results of this risk assessment may require the entity operating the machine to

meet the obligations of a manufacturer.

The device must not be tampered with or changed, except for the procedures described

in this document.

The device must only be repaired. Improper repair can result in the device not providing

correct protection.

Restrict access to replacement actuators, so they cannot be used for bypassing.

4.3 Design

4.3.1 Features of the actuator

The actuator is available in different designs.

•Rigid

•Flexible

Table 2: Features of the actuator

Flexible Rigid

Alignment of actuator to

mounting surface

Straight Angled

Minimum door radius for door

stop above the device

500 mm 800 mm

Minimum door radius for door

stop on left or right of device

180 mm 150 mm

Max. horizontal deviation !3 mm 0.5 mm

Max. vertical deviation §3 mm 0.5 mm

Max. offset angle about X-axis

$

2.5° 0°

Max. offset angle about Y-axis

"

2.5° 0°

PROJECT PLANNING 4

8020562/2021-04-30 | SICK O P E R A T I N G I N S T R U C T I O N S | flexLock 13

Subject to change without notice

Review version 2021-04-30

Flexible Rigid

Max. offset angle about Z-axis

%

2,5° 0°

Rotable and spring loaded

actuator

Yes No

!"

$ %

§

Figure 3: Offsets and offset angle

4.3.2 Actuating direction

The safety locking device can be actuated horizontally within a continous 180° radius.

180°

Figure 4: Possible actuating directions

The flexible actuator can only move for‐

wards for actuation.

The rigid actuator can move forwards or

sideways for actuation.

4 PROJECT PLANNING

14 O P E R A T I N G I N S T R U C T I O N S | flexLock 8020562/2021-04-30 | SICK

Subject to change without notice

Review version 2021-04-30

Figure 5: Sideways approach with flexible actua‐

tor

Figure 6: Sideways approach with rigid actuator

4.3.3 Measures to protect against unintentional damage

You can use the following measures to avoid unintentional damage to the safety switch:

•Select the mounting location so that the safety switch is protected from impacts

and mechanical pressure.

•Fit an additional stop for the door. The safety switch must not be used as a stop.

4.3.4 Measures against tampering

The safety switch must not be defeated (contacts jumpered), rotated away, removed, or

rendered ineffective in any other way. You must put measures in place, if necessary, to

reduce the possibilities for defeating the device.

4.4 Integration in the electrical control system

You need to take the following into consideration when integrating the safety locking

device into the electrical control system.

Requirement for use

•The safety locking device must not be bypassed by electrical means, e.g. by

bridging the contacts. You may need to take measures to prevent this.

•The connected controller and all devices responsible for safety must comply with

the required performance level and the required category (for example according

to ISO 13849-1).

•The overall concept of the control system in which the device is integrated must be

validated in accordance with ISO 13849-2.

•The inputs of a connected evaluation unit must be positive-switching (PNP) inputs

because the two outputs of the safety switch supply a level of the supply voltage in

the switched-ON state.

Generating the signals for the safety locking device

•Only variants for people protection: The locking device may only be unlocked when

the dangerous state has ended. Depending on the safety concept, the signal is

analyzed, for example, by a safety relay or a safety controller.

•Use control without test pulses. The safety switch generates its own testpulses.

Evaluating the signals from the safety locking device

•In the closed or locked state, the OSSDs signal the ON state with the signal level

HIGH (non-isolated). When opened or unlocked or there is a device fault, the

OSSDs signal the OFF state with the signal level LOW.

•Downstream control elements must evaluate the output signals of the protective

device in such a way that the dangerous state of the machine is safely ended. The

machine switches to the safe state if, at any time, at least one OSSD in the OSSD

pair switches to the OFF state.

PROJECT PLANNING 4

8020562/2021-04-30 | SICK O P E R A T I N G I N S T R U C T I O N S | flexLock 15

Subject to change without notice

Review version 2021-04-30

•Switch-on commands that put the machine in a dangerous state may only be

activated when the OSSDs of the safety locking device are in the ON state.

•Closing or locking the protective device must not trigger the automated starting

of a hazardous machine function. This must occur by means of a separate start

command.

•The safety switch tests the OSSDs at regular intervals. To do this, the safety switch

switches each OSSD briefly (for max. 300 µs) to the OFF state and checks whether

this channel is voltage-free during this time. Make sure that the machine’s control

does not react to these test pulses and the machine does not switch off.

4.4.1 Safe series connection

Overview

Several safety switches can be connected in series in a safe series connection. The

connected devices act like a single device. The type of safe series connection depends

on the safety switch variant selected.

The following options are available:

•Safe series connection with Flexi Loop (with diagnostics)

In a series connection with Flexi Loop, the safety switches are connected to

Flexi Loop nodes. Each Flexi Loop node evaluates a safety switch and sends the

information to the Flexi Soft safety controller.

•Safe series connection with T-connector (without diagnostics)

In a series connection with T-connectors, several safety switches are connected

via T-connectors and connected to the safe evaluation unit.

•Safe series connection in control cabinet (with diagnostics)

In a series connection in the control cabinet, the safety switches are led to the

control cabinet individually. The OSSDs of the safety switches are connected in

series there and evaluated by the evaluation unit. The Aux outputs can be individu‐

ally connected to the programmable logic controller (PLC).

Safe series connection with T-connectors or in the control cabinet

1 1 1 1 1 2

OSSD1

OSSD2

OSSD1

OSSD2

OSSD1

OSSD2

OSSD1

OSSD2

OSSD1

OSSD2

Figure 7: Switching with 5 safety switches connected in series

1Safety switch

2Safe evaluation unit

The voltage drop in the series connection must be checked so that the defined mini‐

mum voltage is still applied to the last safety switch.

For connection cables with a length of 2 m and a cable cross-section of 0.25 mm², the

maximum number of safety switches connected in series depends on the voltage as

follows:

4 PROJECT PLANNING

16 O P E R A T I N G I N S T R U C T I O N S | flexLock 8020562/2021-04-30 | SICK

Subject to change without notice

Review version 2021-04-30

Table 3: Maximum number of safety switches in a series connection depends on the voltage

Voltage Connection cables, uni‐

form for the entire series

connection

Input voltage at 30th

safety switch

Maximum number of

safety switches in ser‐

ies connection

24 V Length: 2 m

Cable cross-section:

•General: 0,34 mm²

•Connection between

safety switch and junc‐

tion: 0,25 mm²

19.2 V 4

26 V 19.5 V 5

Additional voltage supply

The voltage drop in the safe series connection must be checked so that the defined

minimum voltage is still applied to each safety switch. If the defined minimum voltage

is no longer applied to a safety switch, a node for voltage supply must be integrated.

The node for voltage supply must be integrated in the safe series connection in the

direction of the safe evaluation unit, as close as possible to the relevant switch.

Complementary information

Number of safety locking devices in a safe series connection

The maximum number of safety locking devices in a safe series connection

depends on the following factors:

•Technical realisation of the safe series connection (T-Connector, Flexi Loop or

series connection in the cabinet)

•Applied supply voltage

•Length of cables used

•Cable cross-section of cables used

•Load current

•Required performance level

The number of safety locking devices in a safe series connection affects the

response times of the system (see "Data sheet", page 35).

PROJECT PLANNING 4

8020562/2021-04-30 | SICK O P E R A T I N G I N S T R U C T I O N S | flexLock 17

Subject to change without notice

Review version 2021-04-30

5 Mounting

5.1 Safety

DANGER

Hazard due to unexpected starting of the machine

Death or severe injury

bMake sure that the dangerous state of the machine is and remains switched off.

NOTICE

If incorrectly installed or if the ambient conditions are not suitable, the safety locking

device can be damaged.

bArrange the safety switch and actuator so that damage due to unintentional out‐

side influences is prevented.

bDo not use a safety switch and actuator as a stop.

bSecure the safety switch and actuator using screws of strength class 8.8 or higher

(For stainless steel screws: A2-70 or higher).

bSecure the fastening materials against loosening, e.g., using a medium-strength,

material-bonding screw adhesive.

bThe set-up and mounting of the safety switch and actuator must be stable enough

to maintain proper operation.

bUse only reliable mounting elements that can only be removed with tools.

bProtect the switch head against damage and ingress of foreign bodies, e.g., chips,

sand, abrasives, etc.

bIf an opening is created in the physical guard due to alignment errors, it must not

impair the protective function.

bChecking for environmental influences before using the safety locking device, e.g.,

UV radiation or corrosion. If necessary, mount device protected.

bWhen using a custom bracket: Ensure that the bracket can absorb at least the

same level of mechanical forces that the safety locking device can absorb when

the locking device is locked.

5.2 Orientation of the safety switch

The safety switch can be mounted in any orientation.

5.3 Mounting several safety switches

If several safety switches are mounted on the machine, they must be mounted at a

minimum distance to one another.

> 30 mm

>30 mm

Figure 8: Minimum distance of safety switches

5 MOUNTING

18 O P E R A T I N G I N S T R U C T I O N S | flexLock 8020562/2021-04-30 | SICK

Subject to change without notice

Review version 2021-04-30

5.4 Mounting the safety switch

Approach

1. Select a position for the safety switch on the fixed part of the protective device.

The safety switch must be positioned in such a way that the actuator is inserted

into the safety switch when the movable physical guard is closed.

2. Attach the safety switch to the protective device.

Minimum requirements for mounting screws

°Number: 4

°Size: M5 × 25 (or longer)

°Strength class: Class 8.8 or higher (For stainless steel screws: A2-70 or

higher).

°Tightening torque: 5 Nm

3. Apply at least a middle strength adhesive screw locker.

5.5 Mounting the actuator

Approach

1. Select a position for the actuator on the movable physical guard. Select the

position in such a way, that when the movable guard is closed, the actuator is

inserted into the safety switch.

For flexible actuators, the actuator tongue can be rotated in 90° increments if

necessary. To do so, press and rotate the actuator tongue in the actuator.

2. Attach the actuator to the movable physical guard.

Minimum requirements on the mounting screws

°Type : Use one ways screws when doing so to make unauthorized removal of

the actuator difficult (manipulation protection).

°Number: 2

°Size: M5

°Tightening torque: 5 Nm

3. Apply at least a middle strength adhesive screw locker.

MOUNTING 5

8020562/2021-04-30 | SICK O P E R A T I N G I N S T R U C T I O N S | flexLock 19

Subject to change without notice

Review version 2021-04-30

6 Electrical installation

6.1 Safety

Overview

You can directly integrate the safety switch into the machine controller via the safety

outputs (OSSDs). The OSSDs indicate the ON state with the HIGH signal level (non-iso‐

lated). The OFF state is indicated with the LOW signal level.

Downstream control elements must evaluate the output signals of the protective device

in such a way that the dangerous state of the machine is safely ended. Depending on

the safety concept, the signal is analyzed by, e.g., safety relays or a safety controller.

Important information

DANGER

Hazard due to electrical voltage

Hazard due to unexpected starting of the machine

bMake sure that the machine is and remains disconnected from the power supply

during the electrical installation.

bMake sure that the dangerous state of the machine is and remains switched off

during electrical installation.

bMake sure that the outputs of the safety switch have no effect on the machine

during electrical installation.

DANGER

Hazard due to lack of effectiveness of the protective device

The dangerous state may not be stopped in the event of non-compliance.

bAlways connect the two OSSDs separately. The two OSSDs must not be connected

to each other.

bConnect the OSSDs such that the machine controller processes both signals

separately.

Isolated connection of OSSD1 and OSSD2

Figure 9: Dual-channel and isolated connection of OSSD1 and OSSD2

6 ELECTRICAL INSTALLATION

20 O P E R A T I N G I N S T R U C T I O N S | flexLock 8020562/2021-04-30 | SICK

Subject to change without notice

Review version 2021-04-30

Other manuals for flexLock

1

Table of contents

Other SICK Lock manuals

Popular Lock manuals by other brands

Stealth SAFES

Stealth SAFES ShadowVault Instructions & Troubleshooting

Metra Electronics

Metra Electronics Door Access Terminal Combo Technical manual

PacSafe

PacSafe prosafe 900 instructions

Schlage

Schlage L9000 Series installation instructions

Schlage

Schlage B664 installation instructions

Stock Loks

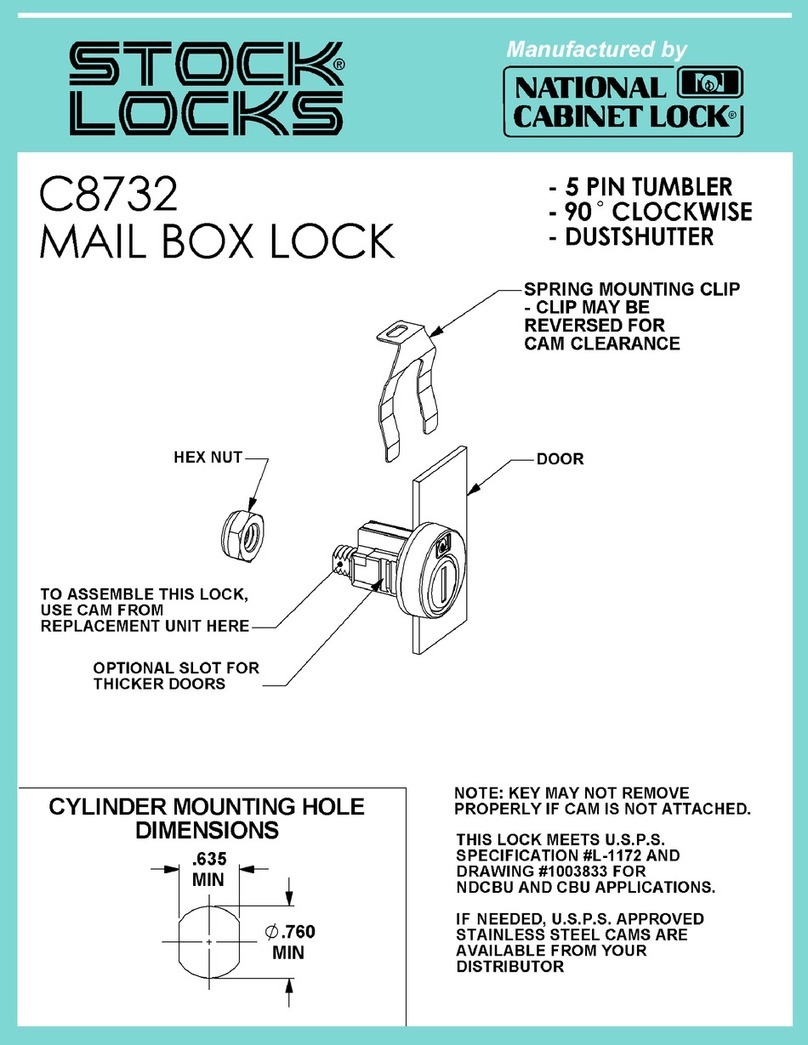

Stock Loks C8732 instruction sheet

suprema

suprema BioLite Solo user guide

Gianni Industries

Gianni Industries EM-1200 specification

D&D Technologies

D&D Technologies MagnaLatch MLSPS2 installation instructions

COMPX

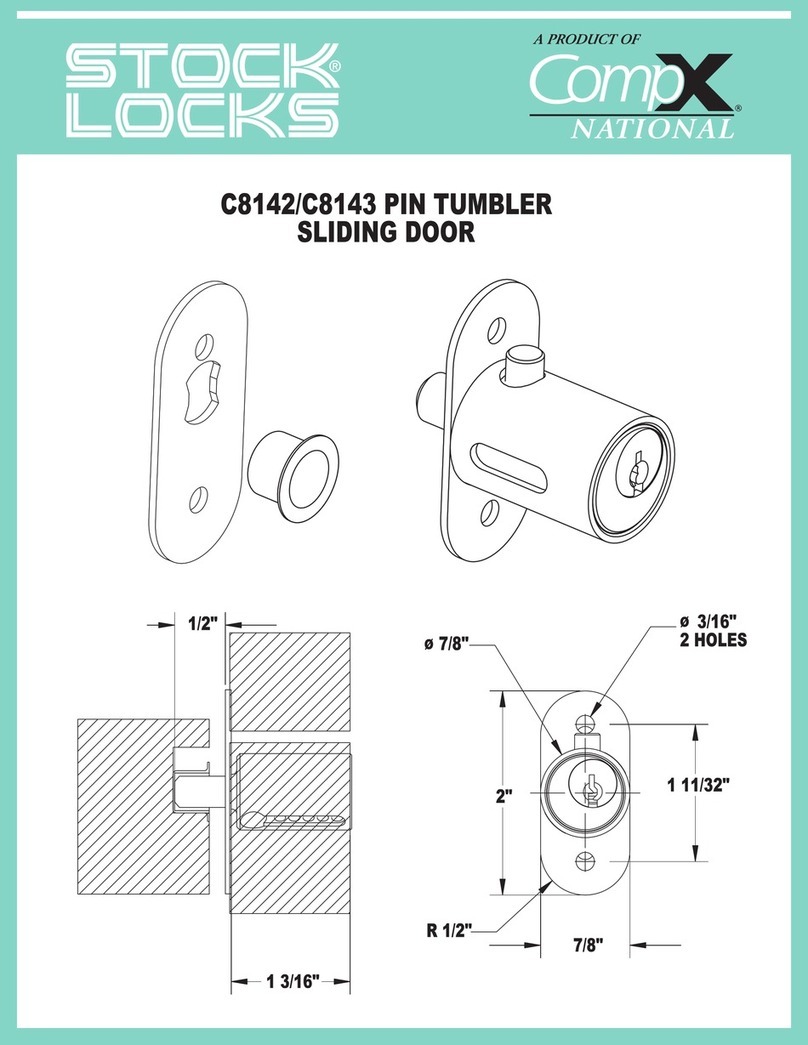

COMPX C8142-3 Dimensional drawing

Kaba

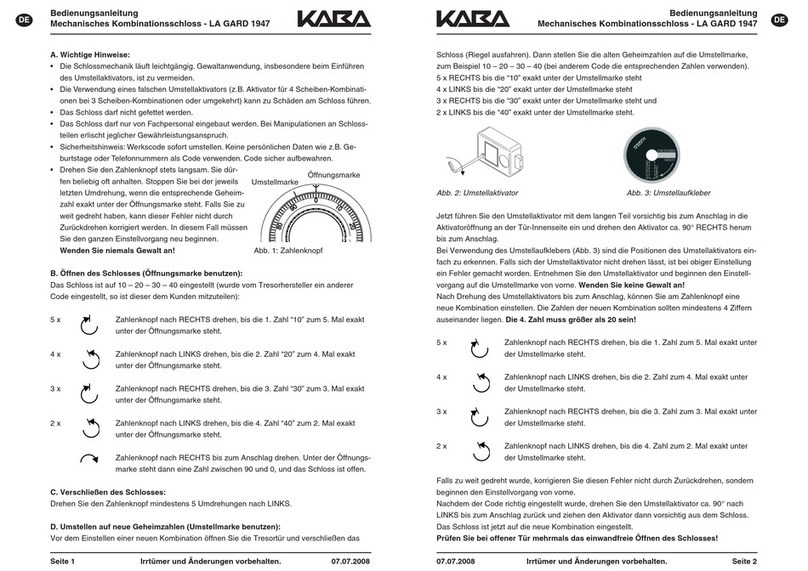

Kaba LA GARD 1947 operating instructions

Assa Abloy

Assa Abloy Lockwood 3579 Series Mounting instructions