Sicma TR80 Operating instructions

SEMI-MOUNTED HARVESTER WITH

TRUNK SHAKER - TR80

Code -000202

Date -05/2021

Revision -0

USER AND MAINTENANCE MANUAL

Translation of the original instructions

SICMA S.r.l. | Località Callipo, Zona Industriale - 88022 Acconia di Curinga (CZ) - Italy

tel. +39 0968 78240

Dear Customer,

Sicma srl congratulates and thanks you for choosing one of our machines.

We have compiled this User and Maintenance Manual with the intention of

helping you appreciate and fully exploit the quality and performance of Sicma

technology, while respecting the safety of the operator and the vehicle.

We recommend that you read and understand the entire User and Maintenance

Manual before you start operating the machine.

The manual contains important information, advice and warnings for the

correct use, driving and operating safety as well as for the maintenance of

the vehicle over time.

People who, with daily passion, gave life to the machine are the same ones

who will assist you in the future and meanwhile wish you every success in your

business, certain that with this tool it will be even easier to operate your new

machine, because “who well harvests is half done”!

Yours Faithfully,

Sicma Staff

Loc. Callipo, Z.I., 88022 Acconia di Curinga (CZ), Italy

VAT number: 01805340799

www.sicmasrl.com

Phone +39 0968 78240

Index

1. General information 7

1.1 Introduction...................................................................................... 7

1.2 Importance of the manual................................................................. 7

1.3 How to store the manual................................................................... 7

1.4 Reproduction and copyright restrictions.............................................. 8

1.5 Updating the User & Maintenance Manual......................................... 8

1.6 Manufacturer’s data ......................................................................... 9

1.7 Technical assistance service............................................................... 9

1.8 Consultation method ...................................................................... 10

2. Safety 11

2.1 General safety instructions .............................................................. 11

2.1.1 Warnings for coupling/uncoupling the machine................................. 13

2.1.2 Warnings on the cardan shaft........................................................... 15

2.1.3 Warnings on machine transportation................................................. 17

2.1.4 Warnings for using the harvesting machine ....................................... 18

2.1.5 Warnings on machine cleaning, adjustment and maintenance............ 20

2.2 Precautions for health ..................................................................... 21

2.3 Safety distance from overhead power lines....................................... 22

2.4 Intended use .................................................................................. 23

2.5 Improper use ................................................................................. 24

2.6 Forbidden use ................................................................................ 25

2.7 Staff qualification............................................................................ 26

2.8 Personal Protective Equipment (PPE)................................................. 27

2.9 Safety signs.................................................................................... 28

2.10 Residual risks ................................................................................. 30

2.11 Safety devices................................................................................. 33

1

SICMA S.r.l.

Index

Rev. 0 - 05/2021

3. Machine description and technical information 34

3.1 Orientation of the machine ............................................................. 34

3.2 Machine identification..................................................................... 35

3.2.1 Warranty terms................................................................................ 36

3.3 General description ........................................................................ 36

3.3.1 Main components............................................................................ 37

3.4 Description of main components ..................................................... 38

3.4.1 Vibrating head................................................................................. 38

3.4.2 Telescopic arm ................................................................................ 40

3.4.3 Hydraulic system ............................................................................. 41

3.4.4 Electrical system .............................................................................. 43

3.5 Technical characteristics .................................................................. 45

3.5.1 Size in working configuration............................................................ 45

3.5.2 Size in transport configuration .......................................................... 46

3.5.3 Work areas ..................................................................................... 47

3.5.4 Features of the harvester .................................................................. 49

3.5.5 Technical data of the vibrating head ................................................. 50

3.5.6 Technical data of the electric system ................................................. 50

3.5.7 Technical data of the hydraulic system .............................................. 52

3.6 Sound emissions............................................................................. 52

3.7 Vibrations ...................................................................................... 53

4. Machine transport and handling 54

4.1 Transport of the machine ................................................................ 54

4.2 Loading and unloading of the machine ........................................... 55

4.2.1 Loading of the machine by means of a ramp..................................... 56

4.2.2 Loading of the machine by means of a platform ................................ 60

4.2.3 Anchoring to the transport vehicle..................................................... 63

4.2.4 Unloading of the machine by means of a ramp ................................. 64

4.2.5 Unloading of the machine by means of a platform............................. 67

2

Index

4.3 Adjustments ................................................................................... 71

4.4 Handling ....................................................................................... 71

5. Machine use 72

5.1 Coupling to the tractor.................................................................... 72

5.1.1 Preliminary to the coupling phase ..................................................... 73

5.1.2 Coupling of the machine.................................................................. 74

5.1.3 Connection to power/power take-off (PTO 540 rpm)......................... 76

5.1.4 Electrical connection ........................................................................ 77

5.1.5 Steering wheel control engagement (hydraulic steering aid) ............... 79

5.1.6 Engagement of hydraulic brake control (brake aid)............................ 79

5.2 Uncoupling from the tractor ............................................................ 80

5.3 Control panel................................................................................. 82

5.3.1 Remote control ................................................................................ 83

5.3.2 Controls on the machine.................................................................. 89

5.4 Commissioning .............................................................................. 90

5.4.1 (Daily) Preventive checks.................................................................. 90

5.4.2 Machine start-up.............................................................................. 91

5.5 Operation...................................................................................... 92

5.6 Machine operating cycle ................................................................. 93

5.6.1 Machine start and positioning .......................................................... 95

5.6.2 Operation of the radio control.......................................................... 96

5.6.3 Processing steps / vibration .............................................................. 97

5.7 Stopping the machine..................................................................... 99

5.7.1 Short stops ...................................................................................... 99

5.7.2 Emergency stop............................................................................. 100

3

SICMA S.r.l.

Index

Rev. 0 - 05/2021

6. Maintenance 101

6.1 Introduction.................................................................................. 101

6.2 Precautions .................................................................................. 101

6.2.1 Precautions for hydraulic system ..................................................... 103

6.2.2 Precautions for greasing and lubrication.......................................... 103

6.3 Consumables............................................................................... 104

6.3.1 Product Specifications .................................................................... 105

6.4 Routine maintenance .................................................................... 106

6.4.1 Intervention table........................................................................... 107

6.5 Complete machine ....................................................................... 110

6.5.1 Check all bolts and nuts................................................................. 110

6.5.2 Cleaning the machine.................................................................... 111

6.5.3 Check of tolerance limits between pins and bushings of all joints...... 111

6.6 Hydraulic system .......................................................................... 112

6.6.1 Hydraulic fittings tightening control ................................................. 112

6.6.2 Oil leaks check.............................................................................. 112

6.6.3 Check and reset hydraulic oil level ................................................. 113

6.6.4 Replacement of hydraulic oil filter cartridge ..................................... 114

6.6.5 Replace hydraulic oil...................................................................... 115

6.6.6 Check of wear and efficiency of hydraulic pipes ............................. 117

6.6.7 Replacement of fittings and hydraulic pipes .................................... 118

6.7 Speed multiplier gearbox .............................................................. 119

6.7.1 Checking and restoring the lubricating oil level................................ 119

6.7.2 Lubricating oil replacement ............................................................ 120

6.8 Wheels ........................................................................................ 122

6.8.1 Wheel jack pin lubrication.............................................................. 122

6.8.2 Wheel hub lubrication.................................................................... 123

6.8.3 Checking the tightening of the wheel bolts ...................................... 124

6.8.4 Tyre pressure check........................................................................ 124

6.8.5 Tires replacement .......................................................................... 124

4

Index

6.9 Electrical system ........................................................................... 125

6.9.1 Emergency stop button efficiency check .......................................... 125

6.9.2 Electric cables position check ......................................................... 125

6.10 Vibrating head ............................................................................. 126

6.10.1 Greasing the vibrating head........................................................... 126

6.10.2 Greasing of jack pins and jaws....................................................... 128

6.10.3 Greasing the pins of the vibrating head tilting jack........................... 129

6.10.4 Greasing of the jack pins for transversal inclination (tilting) and

spider ........................................................................................... 130

6.10.5 Greasing the vibrating head support chains .................................... 131

6.10.6 Vibrating head hardware tightening check....................................... 132

6.10.7 Replacement of the rubber suspensor ............................................. 132

6.10.8 Replacement of rubber bands......................................................... 133

6.10.9 Replacement of rubber pillows........................................................ 134

6.10.10 Chain replacement ........................................................................ 135

6.11 Telescopic arm ............................................................................. 136

6.11.1 Greasing of the arm support pin..................................................... 136

6.11.2 Greasing the jack pins for arm lifting .............................................. 137

6.11.3 Greasing of arm total rotation pins and rotation jack pins ................ 138

6.11.4 Greasing of the vibrating head oscillation jack pins ......................... 139

6.11.5 Greasing of the joint and vibrating head holder arm........................ 140

6.11.6 Greasing the telescopic extension and the rollers ............................ 141

6.11.7 Replacement of the sliding runners ................................................. 142

6.11.8 Wear of sliding blocks check .......................................................... 143

6.12 Extraordinary maintenance ........................................................... 143

7. Troubleshooting 144

7.1 General warnings......................................................................... 144

7.2 Troubleshooting............................................................................ 144

5

SICMA S.r.l.

Index

Rev. 0 - 05/2021

8. Decommissioning 146

8.1 Short breaks................................................................................. 146

8.2 Extended stops/storage................................................................. 146

8.3 Machine disposal ......................................................................... 147

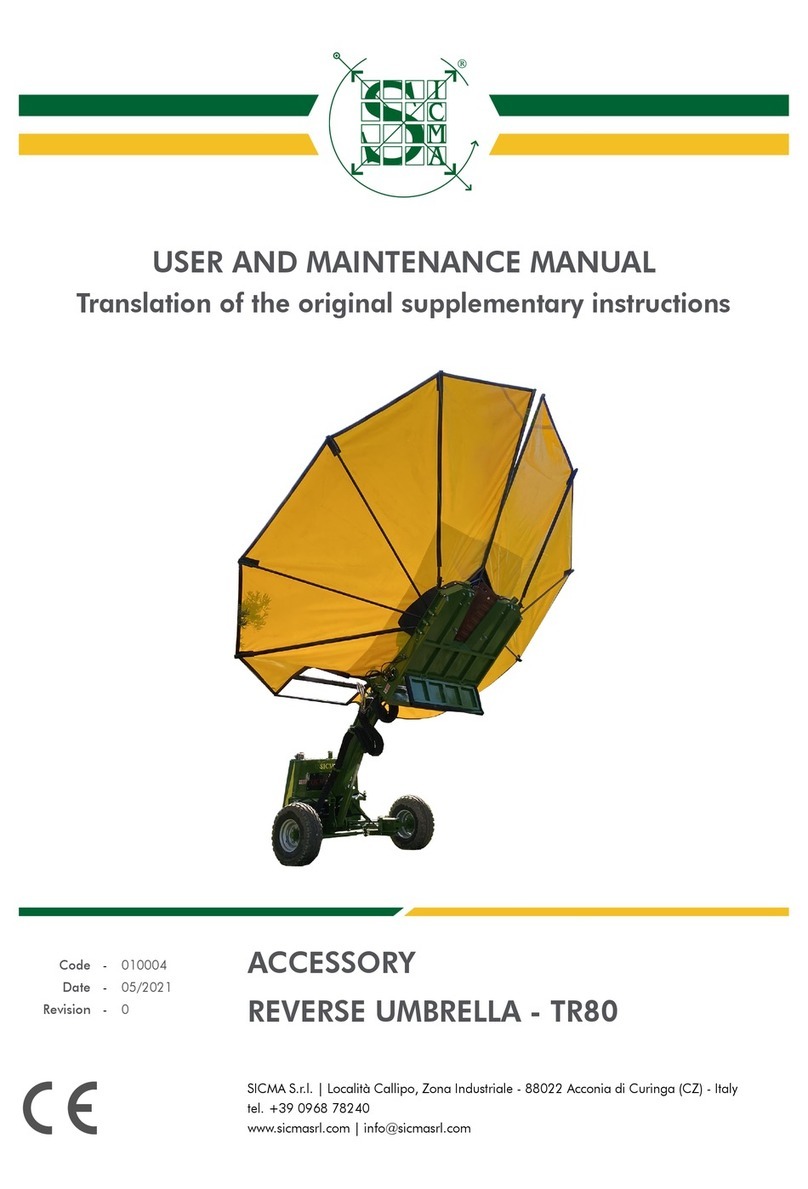

9. Optional accessories 149

9.1 Reverse umbrella.......................................................................... 149

10. Attachments 150

10.1 Electrical diagram......................................................................... 151

10.2 Hydraulic diagrams ...................................................................... 152

10.2.1 Service hydraulic diagram .............................................................. 152

10.2.2 Vibration hydraulic diagram ........................................................... 153

6

General information

1. General information

1.1 Introduction

The TR80 semi-mounted rear application, hereinafter, will simply be called

"MACHINE" or “HARVESTER”; while the drive unit to which it is coupled with

will be called “TRACTOR” or “DRIVE UNIT”.

1.2 Importance of the manual

1.3 How to store the manual

The manual is an integral part of the machine and contains essential

information so that the owner and his staff, operators and qualified

technicians can use it safely.

It is forbidden to carry out any operation on the machine without having

carefully read and understood all of the instructions contained in this manual.

If in doubt, please contact the Manufacturer.

WARNING

Failure to comply with any of the instructions in this manual, even partial,

relieves the Manufacturer of all responsibility.

Use the manual in such a way as not to damage all or part of the contents.

Do not remove, tear, alter or rewrite any part of the manual for any reason.

Store the manual in a dry place, protected from humidity and heat sources.

Keep the manual and all attached publications in a place accessible and

known to all relevant personnel.

7

SICMA S.r.l.

User and maintenance manual - SEMI-MOUNTED HARVESTER WITH TRUNK SHAKER - TR80

Rev. 0 - 05/2021

1.4 Reproduction and copyright restrictions

1.5 Updating the User & Maintenance Manual

The instructions, drawings and documentation contained in this manual

are of technical nature, they are confidential and they are property of the

Manufacturer and may not be reproduced in any way, either partially or

entirely.

All rights are reserved and protected by copyright, other ownership laws and

treaties.

No part of this manual may be reproduced in any form or by any means

without explicit permission from Manufacturer.

All unauthorised reproductions will be prosecuted in the manner and within

time limits provided for by current laws.

NOTE

The images contained in the manual are purely indicative. The machine you

own may differ in some respects from the one pictured.

Without prejudice to the special features of the machine described in the

manual, the Manufacturer reserves the right to make changes to any

component of the machine at any time, dictated by technical or commercial

requirements, without prior notice.

The illustrations, data and contents of the manual are therefore not binding.

8

General information

1.6 Manufacturer’s data

1.7 Technical assistance service

SICMA S.r.l.

C.da Callipo - Zona Industriale Acconia di Curinga (CZ)

88022 Acconia di Curinga (CZ) - Italy - +39 0968 78240

www.sicmasrl.com

SICMA is available for any technical problem and when in need of spare

parts.

Only by using original spare parts can the optimum performance of the

machine be guaranteed.

NOTE

SICMA declines all responsibility for any loss of performance of the machine

or for any damage caused to it by the use of non-original spare parts.

The manufacturer commits itself in providing technical assistance according

to the contract agreement.

9

SICMA S.r.l.

User and maintenance manual - SEMI-MOUNTED HARVESTER WITH TRUNK SHAKER - TR80

Rev. 0 - 05/2021

1.8 Consultation method

Consultation of the manual is facilitated by the inclusion, on the first page,

of the general index, which makes it possible to locate the topic of interest

immediately.

Chapters too are organised to ease the research of the information needed.

For better comprehension of the information provided in this manual, the

warnings and instructions that are considered critical or hazardous are

highlighted with the following symbols:

DANGER

Report to the relevant personnel situations that may involve serious danger

to the safety of the operator and/or persons in the vicinity of the machine.

CAUTION

Report situations that may cause data loss or machine damage to the relevant

personnel.

WARNING

Report information to relevant personnel that is of importance and should

not be overlooked.

NOTE

Report tips for the practical use of the machine to relevant personnel.

RESPECT THE ENVIRONMENT

Report important environmental information to relevant personnel.

10

Safety

2. Safety

2.1 General safety instructions

This chapter includes safety topics; before using the equipment, pay

special attention to the contents of the following pages.

WARNING

The Manufacturer is relieved of any responsibility if the safety instructions in

this manual are not followed.

1. Safety

DANGER

It is responsibility of the employer to inform the personnel about the following

matters concerning safety while using the machine:

• accidents risk;

• devices pre-arranged to keep operators safe;

•

accident prevention general rules, provided for by international

regulations and by the laws of the machine destination country.

The employer must provide and instigate the use of personal protective

equipment conforming to the prescriptions of Directive 89/391/EEC (and

subsequent revisions). During use and maintenance of the machine it is

mandatory to use the personal protective equipment (PPE) indicated in this

manual.

The operator, before operating in the field, must know perfectly:

-all commands positions, function and use;

-the location, function and use of safety devices;

-all machine features;

-the User and Maintenance Manual and how to consult it.

Moreover, the operator must:

-have received adequate training in the use of the machine;

-check the proper operation of all safety devices on the machine.

DANGER

Always apply and enforce all safety regulations. In case of doubt, please

consult the present User Manual once again, before operating.

The following general precautions should be followed:

-The machine may only be operated by properly trained and authorized

personnel.

-Maintenance must always be performed by qualified staff.

-Pay close attention to all caution, warning or hazard signs on the

machine.

-Do not damage the signs and pictograms posted on the machine.

If they are damaged inadvertently, immediately replace them with

identical ones.

-Do not wear clothing, ornaments or accessories that could become

entangled in moving parts.

-It is good practice to wear the prescribed personal protective equipment,

always and without exception.

-Do not smoke during work or maintenance operations, especially in

case solvents or flammable materials are used.

-Operating the machine is forbidden when under the influence of

alcohol, psychotropics or drugs.

-Never direct jets of water towards electrical parts, even if they are

protected by casings.

-Never use open flames (or instruments producing sparks) near to

flammable materials or plastic/rubber ones.

-In case fire escape equipment is used (fire extinguisher, fire hose,

fire hose reel, etc.), proceed to its functional reinstatement or to the

required maintenance work (for example: loosening and drying of the

fire hose), as prescribed.

-Do not climb on the equipment as it could lead to falls and serious

accidents.

-Do not assume unstable positions to perform repairs or adjustments.

-Do not modify the machine safety protections.

-Do not start the machine in automatic mode with disassembled (fixed

and/or mobile) protections.

-Do not operate on switches, valves and photocells without permission.

-Do not operate on moving components, not even by means of objects

or utensils.

-Do not put hands, arms or any part of the body near moving parts.

-Do not oil or grease moving parts by hand, except for those parts

expressly marked.

-Do not modify parts of the machine to adapt other devices unless

previously authorized by the Manufacturer; in case of unauthorized

modifications the Manufacturer will not be held responsible for the

consequences.

-Do not use the machine for uses other than those listed in this manual.

11

SICMA S.r.l.

User and maintenance manual - SEMI-MOUNTED HARVESTER WITH TRUNK SHAKER - TR80

Rev. 0 - 05/2021

DANGER

It is responsibility of the employer to inform the personnel about the following

matters concerning safety while using the machine:

• accidents risk;

• devices pre-arranged to keep operators safe;

• accident prevention general rules, provided for by international

regulations and by the laws of the machine destination country.

The employer must provide and instigate the use of personal protective

equipment conforming to the prescriptions of Directive 89/391/EEC (and

subsequent revisions). During use and maintenance of the machine it is

mandatory to use the personal protective equipment (PPE) indicated in this

manual.

The operator, before operating in the field, must know perfectly:

-all commands positions, function and use;

-the location, function and use of safety devices;

-all machine features;

-the User and Maintenance Manual and how to consult it.

Moreover, the operator must:

-have received adequate training in the use of the machine;

-check the proper operation of all safety devices on the machine.

DANGER

Always apply and enforce all safety regulations. In case of doubt, please

consult the present User Manual once again, before operating.

The following general precautions should be followed:

-

The machine may only be operated by properly trained and authorized

personnel.

-Maintenance must always be performed by qualified staff.

-

Pay close attention to all caution, warning or hazard signs on the

machine.

-

Do not damage the signs and pictograms posted on the machine.

If they are damaged inadvertently, immediately replace them with

identical ones.

-

Do not wear clothing, ornaments or accessories that could become

entangled in moving parts.

-

It is good practice to wear the prescribed personal protective equipment,

always and without exception.

-

Do not smoke during work or maintenance operations, especially in

case solvents or flammable materials are used.

-

Operating the machine is forbidden when under the influence of

alcohol, psychotropics or drugs.

-

Never direct jets of water towards electrical parts, even if they are

protected by casings.

-

Never use open flames (or instruments producing sparks) near to

flammable materials or plastic/rubber ones.

-

In case fire escape equipment is used (fire extinguisher, fire hose,

fire hose reel, etc.), proceed to its functional reinstatement or to the

required maintenance work (for example: loosening and drying of the

fire hose), as prescribed.

-

Do not climb on the equipment as it could lead to falls and serious

accidents.

-Do not assume unstable positions to perform repairs or adjustments.

-Do not modify the machine safety protections.

-

Do not start the machine in automatic mode with disassembled (fixed

and/or mobile) protections.

-

Do not operate on switches, valves and photocells without permission.

-

Do not operate on moving components, not even by means of objects

or utensils.

-Do not put hands, arms or any part of the body near moving parts.

-

Do not oil or grease moving parts by hand, except for those parts

expressly marked.

-

Do not modify parts of the machine to adapt other devices unless

previously authorized by the Manufacturer; in case of unauthorized

modifications the Manufacturer will not be held responsible for the

consequences.

-

Do not use the machine for uses other than those listed in this manual.

12

Safety

2.1.1 Warnings for coupling/uncoupling the machine

-The machine is semi-mounted, trailed by an agricultural tractor, to

which it is coupled by means of the 3-point hitch. The structure of the

vibrating head and its anchorage, if carried out correctly, ensures that

there is no risk of sudden movement of the same.

-

The machine is driven by the tractor (PTO 540 rpm) carrying by means

of a cardan shaft (supplied). The use of the protected cardan shaft,

compliant with the standards (CE marked), and its correct installation

are essential safety conditions.

-

The machine, through the brakes and gears of the tractor, complies

with the stopping and immobilization requirements for safety in all

operating conditions foreseen by the Manufacturer, and normally

encountered. Therefore, it must be mounted on tractors that have the

characteristics suitable for these purposes, with respect to the semi-

mounted mass, in terms of weight and power, in compliance with the

coupling limits, as well as on the basis of the characteristics of the

ground, in terms of grip and slope.

-

Before coupling the machine, always check the tractor’s compatibility

with the same, scrupulously following the requirements provided (*)

.

Only carry out coupling if the tractor is suitable to the machine and

vice versa. If not, desist from coupling.

-

Only use the systems and procedures envisaged and illustrated in this

manual to connect the machine to the tractor.

-

The coupling/uncoupling operations of the machine to the tractor must

only be carried out by qualified operators experienced in carrying out

this operation.

-

The coupling/uncoupling of the machine to the tractor must never,

for any reason and in any case, be performed by more operators

simultaneously. The presence and actions of each operator may be

extremely dangerous for other operators.

-

During the coupling/uncoupling operations of the machine, it is

mandatory for the operator to equip himself with suitable approved

protection devices.

-

The area for coupling/uncoupling the machine to the tractor must be

flat, clean and free from any source of danger. The approach of any

unauthorized person to this area is prohibited.

-

Before carrying out any work on the machine, make sure that the

tractor is switched off, that the ignition key has been removed and that

the parking brake has been applied.

-

Pay maximum attention to the operations of coupling/uncoupling the

machine to the tractor; never position yourself between the tractor and

the machine when approaching, when moving the three-point lifter or

the hydraulic devices.

-Proceed with coupling only after having checked that all coupling system

elements are free from abnormal wear, cracks, breaks, looseness or

lack of components.

-Proceed with caution to hook up the hydraulic couplings. Follow

the identification codes shown on each pipe and the identification

pictogram of the hydraulic movements shown in this manual. Before

putting the hydraulic lines under pressure, always check the correctness

of the connection and the presence of any damage.

-It is strictly forbidden to modify or alter the machine’s hydraulic system.

It is forbidden to install any oil-hydraulic component in the cab,

additional to the machine hydraulic system.

-Park or stop the machine only on a solid and perfectly flat surface,

scrupulously observing the procedures illustrated in this manual. Never

abandonthedriver’sseatof thetractor beforehaving stoppedthe engine,

removed the ignition key, engaged the parking brake and properly

parked the machine.

-It is forbidden for unauthorized persons to approach the parked

machine.

(*) See par. “5.1” pag. 72

13

SICMA S.r.l.

User and maintenance manual - SEMI-MOUNTED HARVESTER WITH TRUNK SHAKER - TR80

Rev. 0 - 05/2021

-The machine is semi-mounted, trailed by an agricultural tractor, to

which it is coupled by means of the 3-point hitch. The structure of the

vibrating head and its anchorage, if carried out correctly, ensures that

there is no risk of sudden movement of the same.

-The machine is driven by the tractor (PTO 540 rpm) carrying by means

of a cardan shaft (supplied). The use of the protected cardan shaft,

compliant with the standards (CE marked), and its correct installation

are essential safety conditions.

-The machine, through the brakes and gears of the tractor, complies

with the stopping and immobilization requirements for safety in all

operating conditions foreseen by the Manufacturer, and normally

encountered. Therefore, it must be mounted on tractors that have the

characteristics suitable for these purposes, with respect to the semi-

mounted mass, in terms of weight and power, in compliance with the

coupling limits, as well as on the basis of the characteristics of the

ground, in terms of grip and slope.

-Before coupling the machine, always check the tractor’s compatibility

with the same, scrupulously following the requirements provided (*).

Only carry out coupling if the tractor is suitable to the machine and

vice versa. If not, desist from coupling.

-Only use the systems and procedures envisaged and illustrated in this

manual to connect the machine to the tractor.

-The coupling/uncoupling operations of the machine to the tractor must

only be carried out by qualified operators experienced in carrying out

this operation.

-The coupling/uncoupling of the machine to the tractor must never,

for any reason and in any case, be performed by more operators

simultaneously. The presence and actions of each operator may be

extremely dangerous for other operators.

-During the coupling/uncoupling operations of the machine, it is

mandatory for the operator to equip himself with suitable approved

protection devices.

-The area for coupling/uncoupling the machine to the tractor must be

flat, clean and free from any source of danger. The approach of any

unauthorized person to this area is prohibited.

-Before carrying out any work on the machine, make sure that the

tractor is switched off, that the ignition key has been removed and that

the parking brake has been applied.

-

Pay maximum attention to the operations of coupling/uncoupling the

machine to the tractor; never position yourself between the tractor and

the machine when approaching, when moving the three-point lifter or

the hydraulic devices.

-

Proceed with coupling only after having checked that all coupling system

elements are free from abnormal wear, cracks, breaks, looseness or

lack of components.

-

Proceed with caution to hook up the hydraulic couplings. Follow

the identification codes shown on each pipe and the identification

pictogram of the hydraulic movements shown in this manual. Before

putting the hydraulic lines under pressure, always check the correctness

of the connection and the presence of any damage.

-

It is strictly forbidden to modify or alter the machine’s hydraulic system.

It is forbidden to install any oil-hydraulic component in the cab,

additional to the machine hydraulic system.

-

Park or stop the machine only on a solid and perfectly flat surface,

scrupulously observing the procedures illustrated in this manual. Never

abandonthedriver’sseatof thetractor beforehaving stoppedthe engine,

removed the ignition key, engaged the parking brake and properly

parked the machine.

-

It is forbidden for unauthorized persons to approach the parked

machine.

14

Safety

2.1.2 Warnings on the cardan shaft

The machine, driven by a cardan shaft, despite the protections, presents a

residual risk of dragging. Do not remove any of the guards on the rotating

parts and, in case of damaged guards, stop the machine until the guards

have been restored.

Protection of rotating parts

-All rotating parts must be protected.

-The tractor and machine guards must create an integrated system

with protection of the cardan shaft.

Guards state

-Before starting work, check that all the protections on the cardan shaft

and the protective boots on the joints of the cardan transmission, of

the tractor and of the operating machine are installed and efficient.

-Any damaged or missing parts must be replaced with original spare

parts and installed properly before using the transmission.

Control dashboard

-Stop the tractor engine, remove the keys from the control panel and

check that all rotating parts are stopped before approaching the

machine or before carrying out maintenance operations.

Twisting hazard

-Do not go near rotating components.

-Avoid work clothing with belts, flaps, or parts that could be caught.

-Contact with rotating parts can be fatal.

Forbidden use

-Do not lean on or step on the cardan shaft.

-It is absolutely forbidden to climb over the cardan shaft.

Protection chains

-Attach the protective retaining chains.

-The best operating conditions occur with the chain in the radial

position compared to the shaft. Adjust the length of the chains to

allow articulation of the transmission in every operating, transport,

and manoeuvring condition.

-Keep the chains from twisting around the transmission due to

excessive length.

Cardan shaft support

-Do not use the chains to transport or support the cardan shaft at the

end of work. Use the proper support.

DANGER

For safety reasons with respect to unforeseeable accidents, in the absence

of the operator near the machine, the power take-off must always be

disconnected.

15

SICMA S.r.l.

User and maintenance manual - SEMI-MOUNTED HARVESTER WITH TRUNK SHAKER - TR80

Rev. 0 - 05/2021

The machine, driven by a cardan shaft, despite the protections, presents a

residual risk of dragging. Do not remove any of the guards on the rotating

parts and, in case of damaged guards, stop the machine until the guards

have been restored.

Protection of rotating parts

-All rotating parts must be protected.

-The tractor and machine guards must create an integrated system

with protection of the cardan shaft.

Guards state

-Before starting work, check that all the protections on the cardan shaft

and the protective boots on the joints of the cardan transmission, of

the tractor and of the operating machine are installed and efficient.

-Any damaged or missing parts must be replaced with original spare

parts and installed properly before using the transmission.

Control dashboard

-Stop the tractor engine, remove the keys from the control panel and

check that all rotating parts are stopped before approaching the

machine or before carrying out maintenance operations.

Twisting hazard

-Do not go near rotating components.

-Avoid work clothing with belts, flaps, or parts that could be caught.

-Contact with rotating parts can be fatal.

Forbidden use

-Do not lean on or step on the cardan shaft.

-It is absolutely forbidden to climb over the cardan shaft.

Protection chains

-Attach the protective retaining chains.

-

The best operating conditions occur with the chain in the radial

position compared to the shaft. Adjust the length of the chains to

allow articulation of the transmission in every operating, transport,

and manoeuvring condition.

-

Keep the chains from twisting around the transmission due to

excessive length.

Cardan shaft support

-Do not use the chains to transport or support the cardan shaft at the

end of work. Use the proper support.

DANGER

For safety reasons with respect to unforeseeable accidents, in the absence

of the operator near the machine, the power take-off must always be

disconnected.

16

Other manuals for TR80

1

Table of contents

Other Sicma Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Spearhead

Spearhead Multicut 620 Handbook

KELLO-BILT

KELLO-BILT 8226B owner's manual

USC

USC AT500H DUAL PUMP STAND Operator's manual

Schmeiser

Schmeiser TILL AN'PAK TPP3510 Operation and parts manual

Strautmann

Strautmann Verti-Mix SF Translation of the original operating instructions

Fast

Fast A10 owner's manual