Ironcraftusa.com Ironcraftusa.com1.1 Welcome2 3Table of Contents

WARNING

READ AND UNDERSTAND MANUAL.

To prevent personal injury or even death, be sure you read and understand all of the

instructions in this manual and other related OEM equipment manuals! The disc mulcher,

if not used and maintained properly, can be dangerous to users unfamiliar with its

operation. Do not allow operating, maintaining, adjusting, or cleaning of this disc mulcher

until the user has read this manual and has developed a thorough understanding of the

safety precautions and functions of the unit. This disc mulcher is designed for the specic

purpose of tree removal. DO NOT modify or use this disc mulcher for any application other

than that for which it was designed. Disc mulchers maintained or operated improperly or

by untrained personnel can be dangerous; exposing the user and/or bystanders to possible

serious injury or death.

INTRODUCTION

1.1 WELCOME

Congratulations on your choice of an IronCraft Forestry Disc Mulcher. This equipment has been

designed and manufactured to meet the needs of discerning users. Many features incorporated into

this disc mulcher are the result of suggestions made by customers like you.

Read this manual carefully to learn how to operate the disc mulcher safely and how to set it to provide

maximum mulching eciency. By following the operating instructions, in conjunction with a good

maintenance program, your IronCraft disc mulcher will provide many years of trouble-free service.

1.2 SAFE OPERATION

Safe, ecient, and trouble-free operation of your disc mulcher requires that you, and anyone else

who will be using or maintaining the unit, read and understand the information contained within the

Owner’s Manual. Use this manual for frequent reference and to pass on to new operators or owners.

Upon reading this manual, all users should sign the “Safety Acknowledgement Form” at the end of this

manual. Please record your model and dealer information on page 5. You will be asked to provide this

information when ordering parts or requesting service. If you need more information on this product,

contact your local dealer or visit www.ironcraftusa.com.

STORE THIS MANUAL IN THE DOCUMENT

CANISTER ATTACHED TO THIS MACHINE.

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Welcome 3

1.2 Safe Operation 3

1.3 Model Comparison 4

1.4 Specications 4

1.5 Register This Product 5

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Introduction 6

2.2 Safety Alert Symbols 7

2.3 Safety Pictograms 8

2.4 General Safety Instructions 9

SAFETY SIGNS AND LABELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Safety Decals 10

3.2 Safety Sign Locations 11

3.3 Skid Steer Loader Requirements 12

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

operating procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

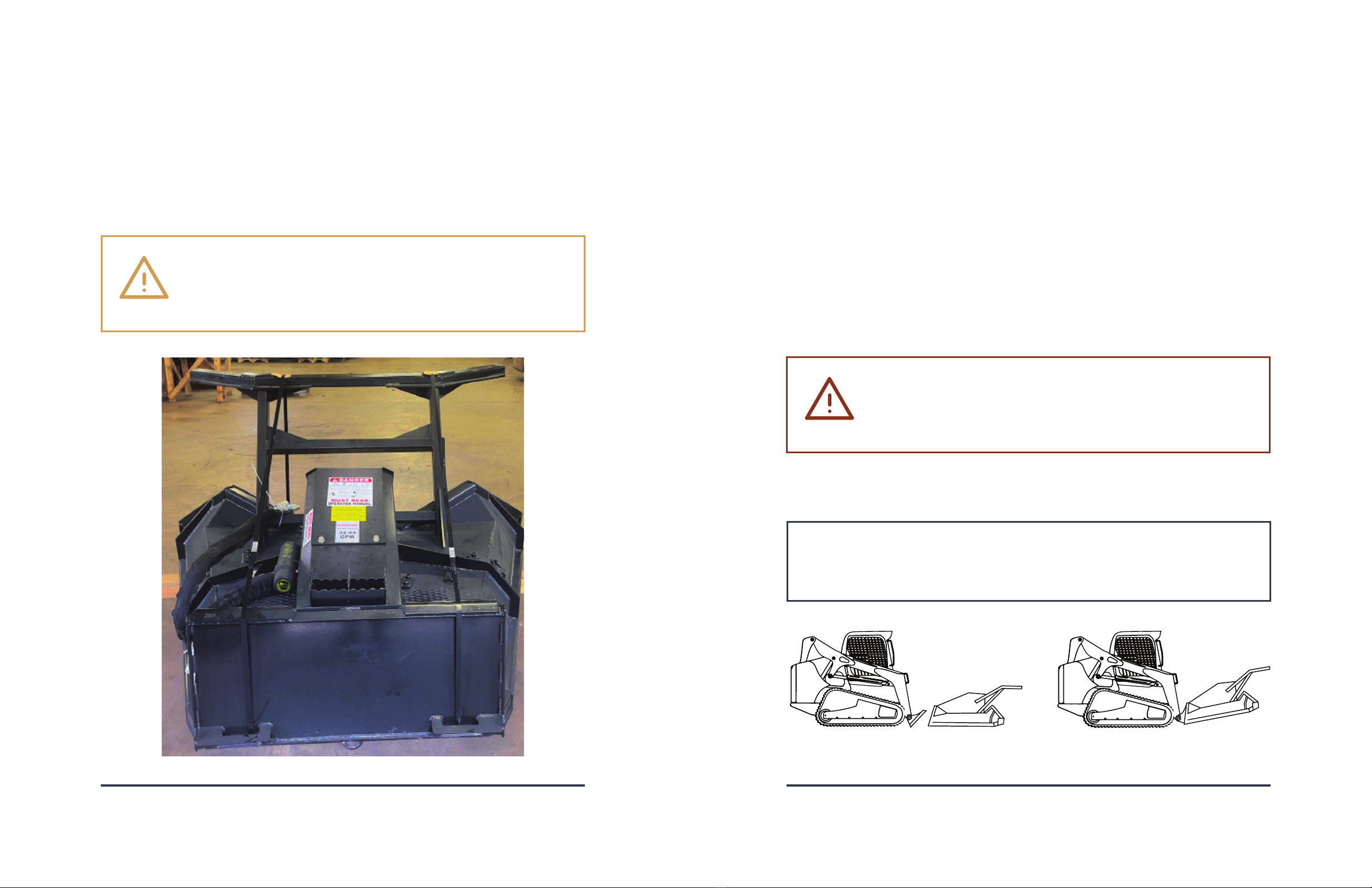

4.1 Unpacking Your Forestry Disc Mulcher 14

4.2 How To Mount Disc Mulcher 15

4.4 How To Start And Stop The Disc Mulcher 16

4.3 How To Dismount Disc Mulcher 16

4.5 Initial Use Procedure 19

4.6 General Operating Tips 21

4.7 Tree Cut Procedures 22

4.8 Tree Cutting Tips 25

Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.1 Maintenance Overview 26

5.2 Maintenance Schedule 27

5.3 Storage tips 28

5.4 Mulching Disc Maintenance 29

5.5 Gear Box Maintenance 30

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Parts Information 33

Limited Warranty 36

SAFETY ACKNOWLEDGEMENT FORm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

MAINTENANCE LOg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Revised September 29, 2023

©2023 IronCraft Attachments. All rights reserved.

www.ironcraftusa.com