Siel SOLEIL DSPX TLH 1500 User manual

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

1

di

26

Inverter for photovoltaic applications

INSTALLATION MANUAL

SOLEIL DSPX TLH 15

EEP FOR FUTURE REFERENCE

for the entire life of the appliance

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

2

di

26

INDICE

1

AIM OF THE DOCUMENT .................................................................................................................................... 3

1.1

O

VERVIEW

............................................................................................................................................................ 3

1.2

G

RAPHIC SYMBOLS USED

.......................................................................................................................................... 3

2

POSITIONING...................................................................................................................................................... 5

3

POWER CONNECTIONS AND AUXILIARIES .......................................................................................................... 6

3.1

M

ECHANICAL LAYOUT

............................................................................................................................................. 6

3.2

C

ABLE QUANTITY AND SECTION

................................................................................................................................. 9

3.3

G

ROUND CONDUCTOR

S

IZING

................................................................................................................................. 10

3.4

M

AXIMUM TORQUE TIGHTENING CABLES

.................................................................................................................. 11

3.5

FAN

CHARACTERISTIC

........................................................................................................................................... 11

4

INSTALLATION .................................................................................................................................................. 12

4.1

V

ISUAL INSPECTION

.............................................................................................................................................. 12

4.2

U

NPAC ING

........................................................................................................................................................ 12

4.3

S

AFETY CONSIDERATIONS

....................................................................................................................................... 14

4.4

E

NVIRONMENTAL CONSIDERATIONS

......................................................................................................................... 15

4.4.1

Load-bearing capacity of the floor .............................................................................................................. 15

4.4.2

Temperature and humidity ......................................................................................................................... 15

4.5

I

NSTALLATION

L

OCATION OF INVERTERS

.................................................................................................................... 15

4.6

I

NSTALLATION

L

OCATION OF OUTDOOR INVERTERS

...................................................................................................... 16

4.7

POSITIONING

AND

VENTILATION .................................................................................................................... 16

4.8

E

LECTRICAL CONSIDERATIONS

................................................................................................................................. 17

4.9

M

EDIUM TO

L

OW VOLTAGE TRANSFORMER FOR CONNECTION TO

MV

GRID

:

CRITERIA OF CHOICE

. ....................................... 17

4.10

P

REVENTIVE

M

AINTENANCE

................................................................................................................................... 17

5

BASIC INSTALLATION HINTS ............................................................................................................................. 18

5.1

P

OSITIONING OF THE INVERTERS AND VENTILATION

..................................................................................................... 18

6

SYNCHRONIZATION CABLE AND CAN-BUS (MULTI-INVERTER SYSTEMS) .......................................................... 19

7

CONNECTION OF THE EPO CIRCUIT (EMERGENCY POWER OFF) ........................................................................ 21

7.1

C

ONNECTION OF THE MODULES

’

TEMPERATURE SENSOR

.............................................................................................. 21

8

SERIAL COMMUNICATION CONNECTIONS ........................................................................................................ 22

8.1

T

YPE OF CABLES TO BE USED

................................................................................................................................... 22

8.2

M

ONITORING SYSTEM AND

P

OWER

P

LANT

C

ONTROLLER

(PPC)

RS485

M

ODBUS COMMUNICATION

................................... 22

8.3

C

ONNECTION OF THE

M

ODBUS SERIAL PORT SHIELD

.................................................................................................... 22

8.4

C

ONNECTION OF THE

SAC

BUS

SERIAL SHIELD

........................................................................................................... 22

8.5

R

ULES FOR THE LAYING OF

RS485

SERIAL CABLES

....................................................................................................... 22

9

USER SETTINGS ................................................................................................................................................. 25

9.1

C

ONNECTING AN INPUT POLE TO THE PHOTOVOLTAIC FIELD EARTH

................................................................................. 25

9.2

C

ONTROL FEATURES

–

N

ETWOR SERVICES

................................................................................................................ 26

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

3

di

26

1AIM OF THE DOCUMENT

1.1 Overview

This document constitutes a rapid guide for the installation of the product in the operating room and

provides summary and schematic instructions for the positioning and network connection of the product

and signal connections.

In no way can this document be considered a substitute for the IV346

Instruction Manual to which reference is made particularly for the

recommendations contained in it on the issue of safety regarding the handling

and electrical connection of the equipment.

The failure to follow the recommendations contained in the IV346 Instruction

Manual may have serious consequences, such as the destruction of the

apparatus, injury to persons and death due to electrocution.

The information and technical features contained in this manual refer to the

date of the drafting of the document. SIEL SPA reserves the right to modify

such technical features at any moment and without warning.

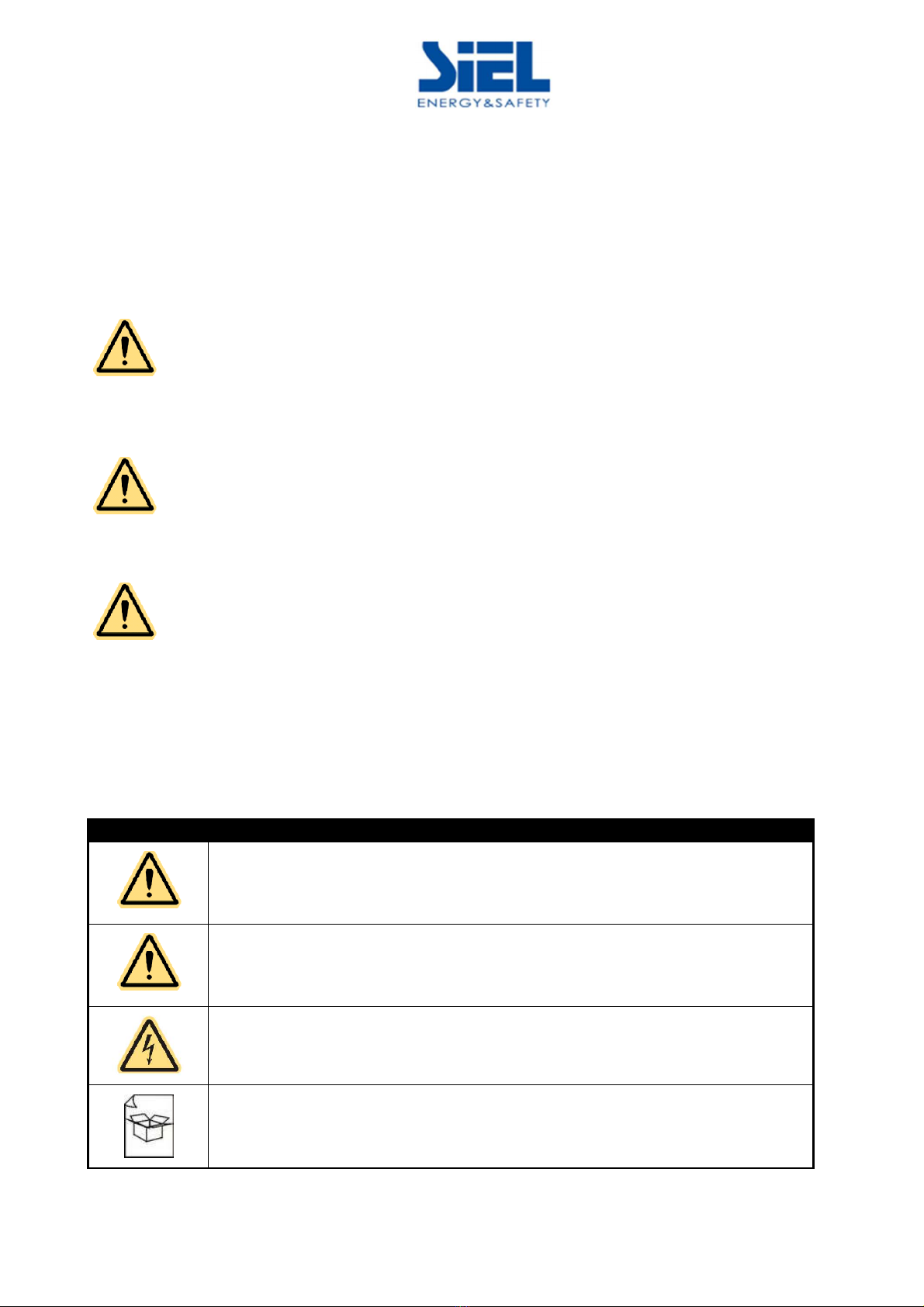

1.2 Graphic symbols used

The following symbols are used in this manual to warn and inform users of particular situations of special

importance. The symbols used and their meanings are explained below.

Simbolo

Descrizione

INFORMATION

Supplementary description to be taken into due consideration.

Used for important notes and/or recommendations

CAUTION

Danger (situation which may cause severe injuries to persons and/or damage to

equipment)

ELECTRICAL DANGER

Serious risk of electrocution.

These warnings signal compulsory behaviour.

UNPACKING INSTRUCTIONS

Describe how to unpack equipment.

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

4

di

26

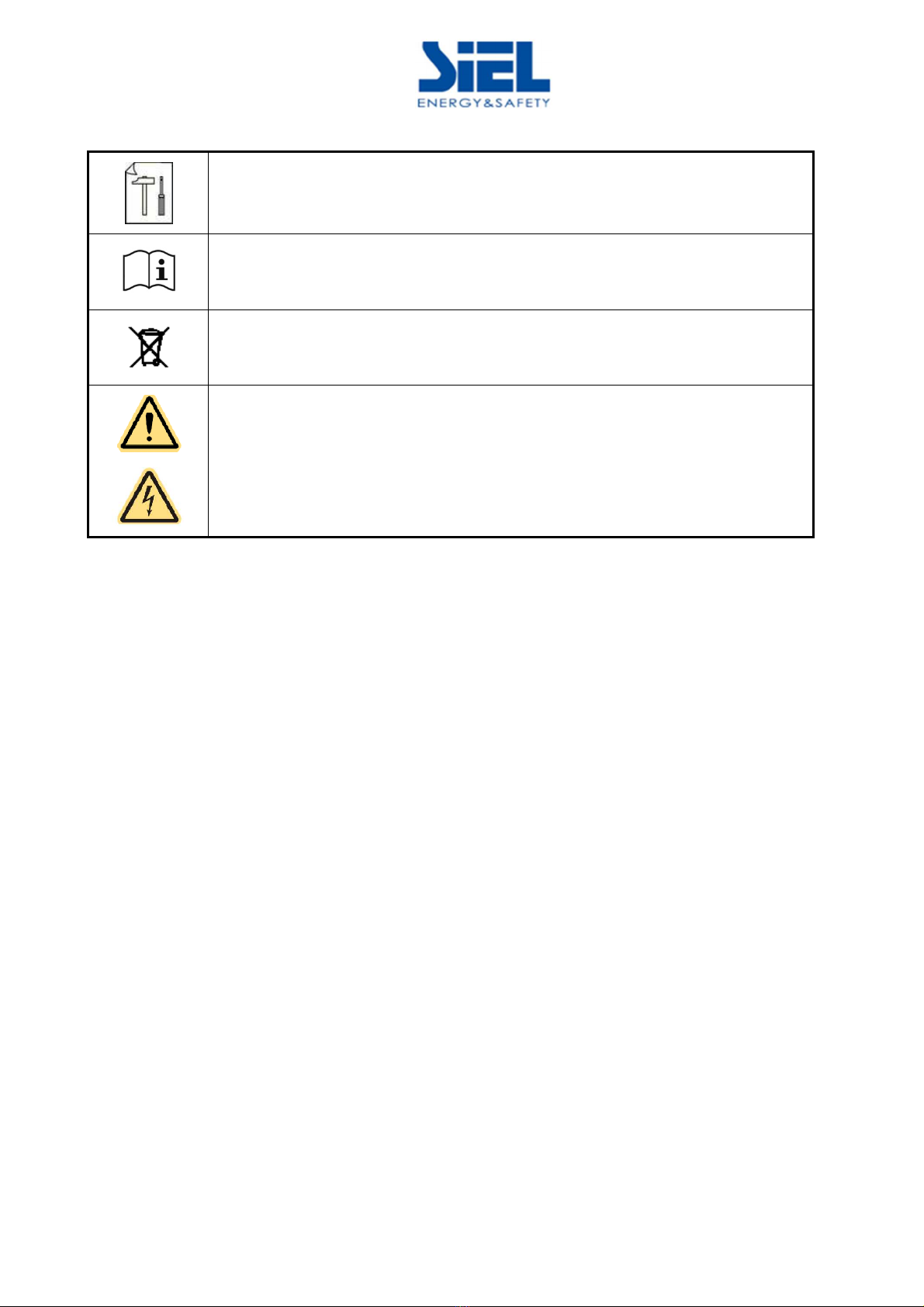

INSTALLATION INSTRUCTIONS

Describe the inverter installation process step by step.

MANDATORY INSTRUCTIONS

Read and understand the instruction manual before working on the inverter.

DISPOSAL

Contains information useful for disposal of the equipment.

THE WARNING TRIANGLES INDICATE INSTRUCTIONS REGARDING SAFETY FOR

STAFF. FOLLOW THEM CAREFULLY TO AVOID DAMAGES TO PERSONS OR OBJECTS.

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

5

di

26

2POSITIONING

In the installation of the Soleil product, it is recommended that the distance

between the inverter and any walls or other objects be respected, as shown in

the following diagrams.

SOLEIL DSPX xxxx TLH 15

3

cm

1

cm

1

cm

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

6

di

26

3POWER CONNECTIONS AND AUXILIARIES

3.1 Mechanical layout

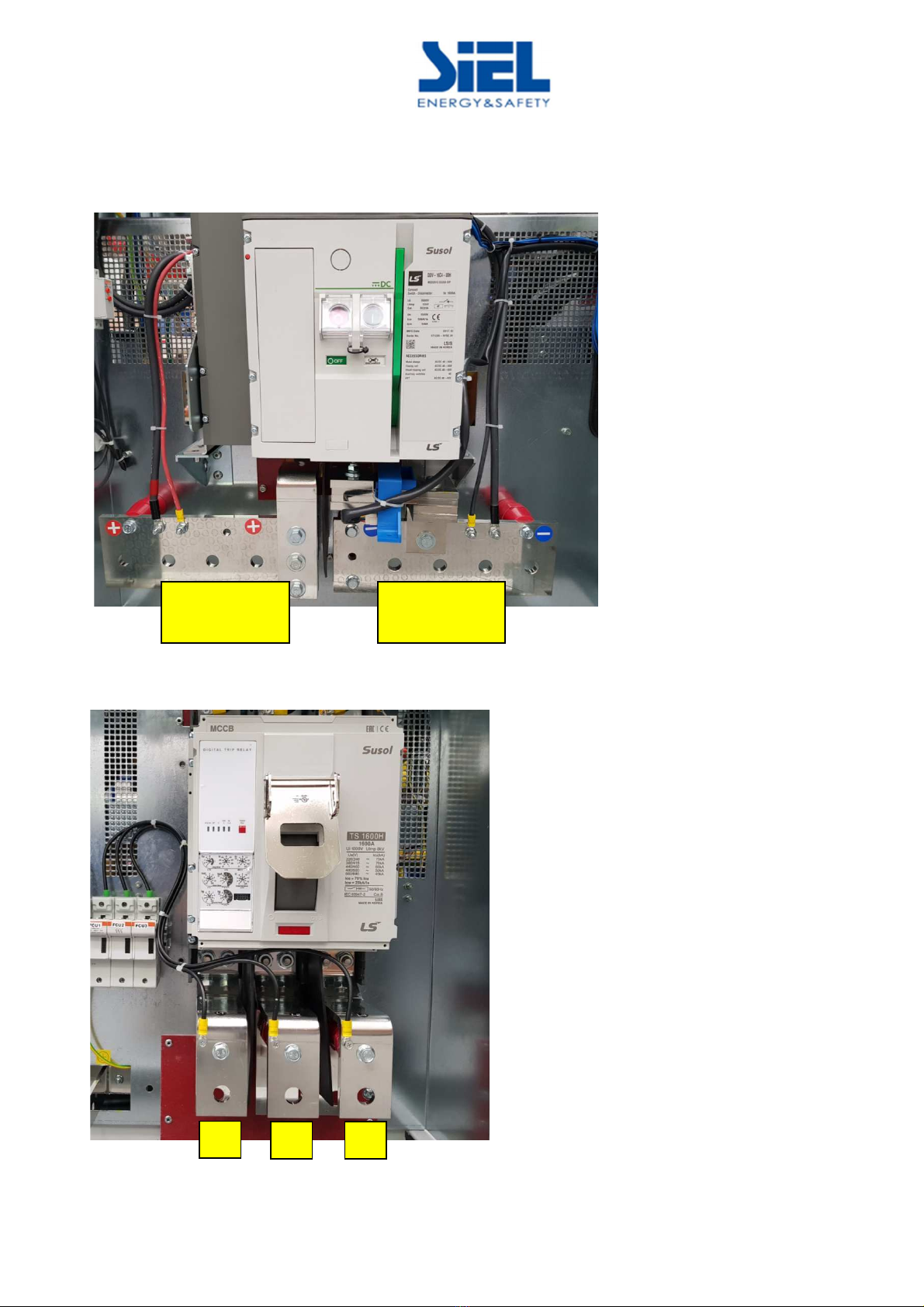

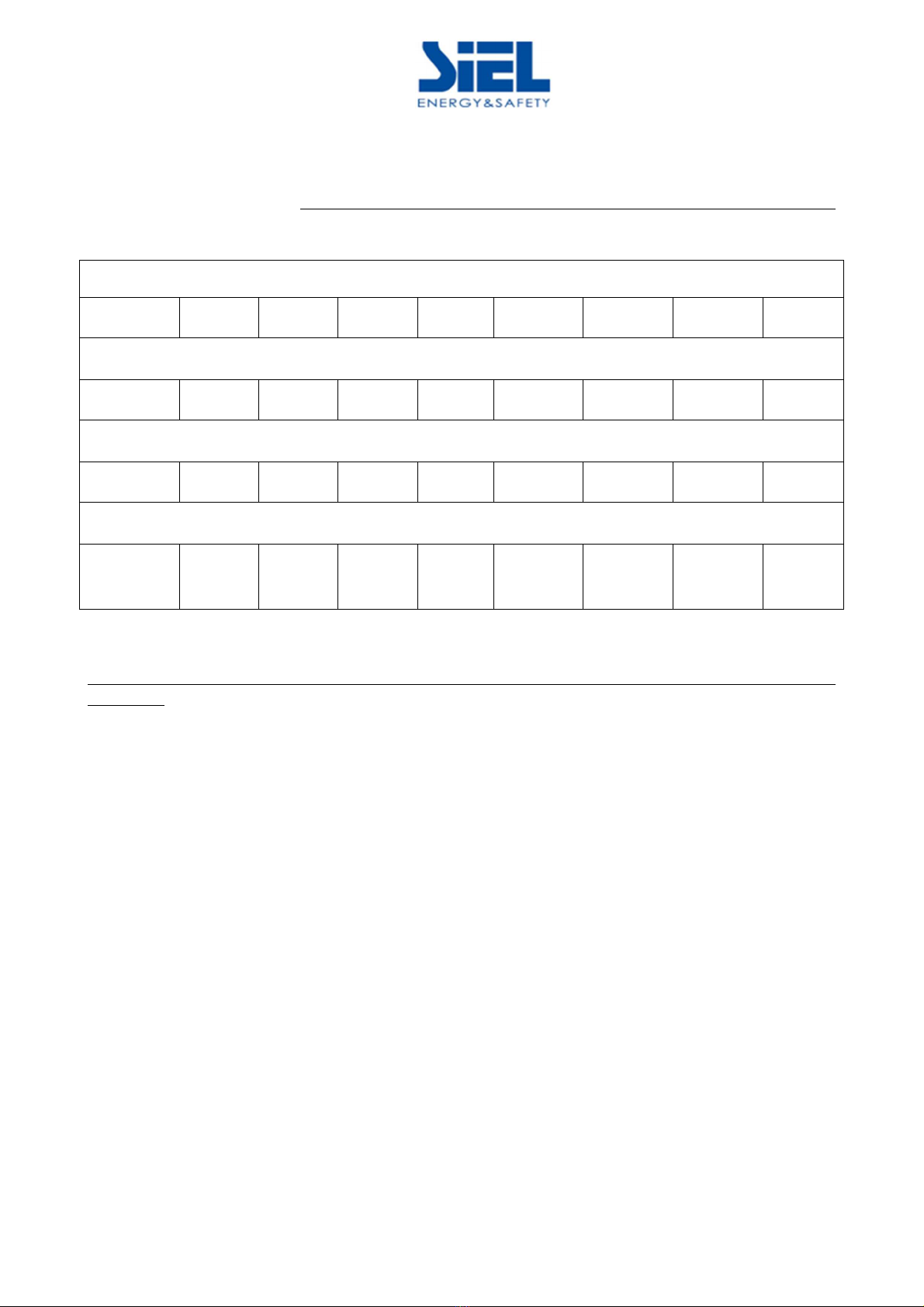

The following figures illustrate the power terminals of the DC (input) and AC (output) sections.

Frontal view of the inverter:

Internal view of the inverter:

Display Touch-screen User

interface

Air-intake grid for power

modules

Air-intake grid for magnetic

cores

Power core ‘B’

Power core ‘A’

Input DC Switch

Fuses and SPD

Output AC Circuit

Breaker

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

7

di

26

DC Terminal side:

AC terminal side:

Positive pole

(+)

Negative pole

(-)

L1

L2

L3

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

8

di

26

Connecting AC side cables are dimensioned taking into account the electrical parameters of the circuit

breakers, summarised in the following table:

Current(A)

-

Curve

Magnetic curve

Breaking capacity [kA]

1600A

10 In (Programmab

le

)

50kA

The characteristics (curve type, magnetic current) of the switch on the

electrical board connected to the inverter must be compatible with the

characteristics of the machine switch.

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

9

di

26

3.2 Cable quantity and section

The following tables indicate the maximum quantity and the maximum section of copper-made cables

that can be connected to the DC input and the AC output.

Inverter soleil DSPX xxxx TLH 15

Inverter 55 665 7 8 75 11 M 133 M 1415M 15 M

AC Cables ( cables number x section in mmq )

Suggerito 2 x 400 2 x 400 2 x 400 2 x 400 4 x 400 4 x 400 4 x 400 4 x 400

DC Cables (cables number x section in mmq)

Suggerito 2 x 400 2 x 400 2 x 400 2 x 400 4 x 400 4 x 400 4 x 400 4 x 400

Ground Conductor (PE) (cables number x section in mmq)

Suggerito 1 x 240

(Nota 1)

1 x 240

(Nota 1)

1 x 240

(Nota 1)

1 x 240

(Nota 1)

1 x 300

(Nota 1)

1 x 400

(Nota 1)

1 x 400

(Nota 1)

1 x 400

(Nota 1)

Note 1: Refer to the table for the sizing of the earth wires for the calculation of the total cable section

The type of cable and its cross section to be used must be determined at the design stage by the designer

or installer

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

10

di

26

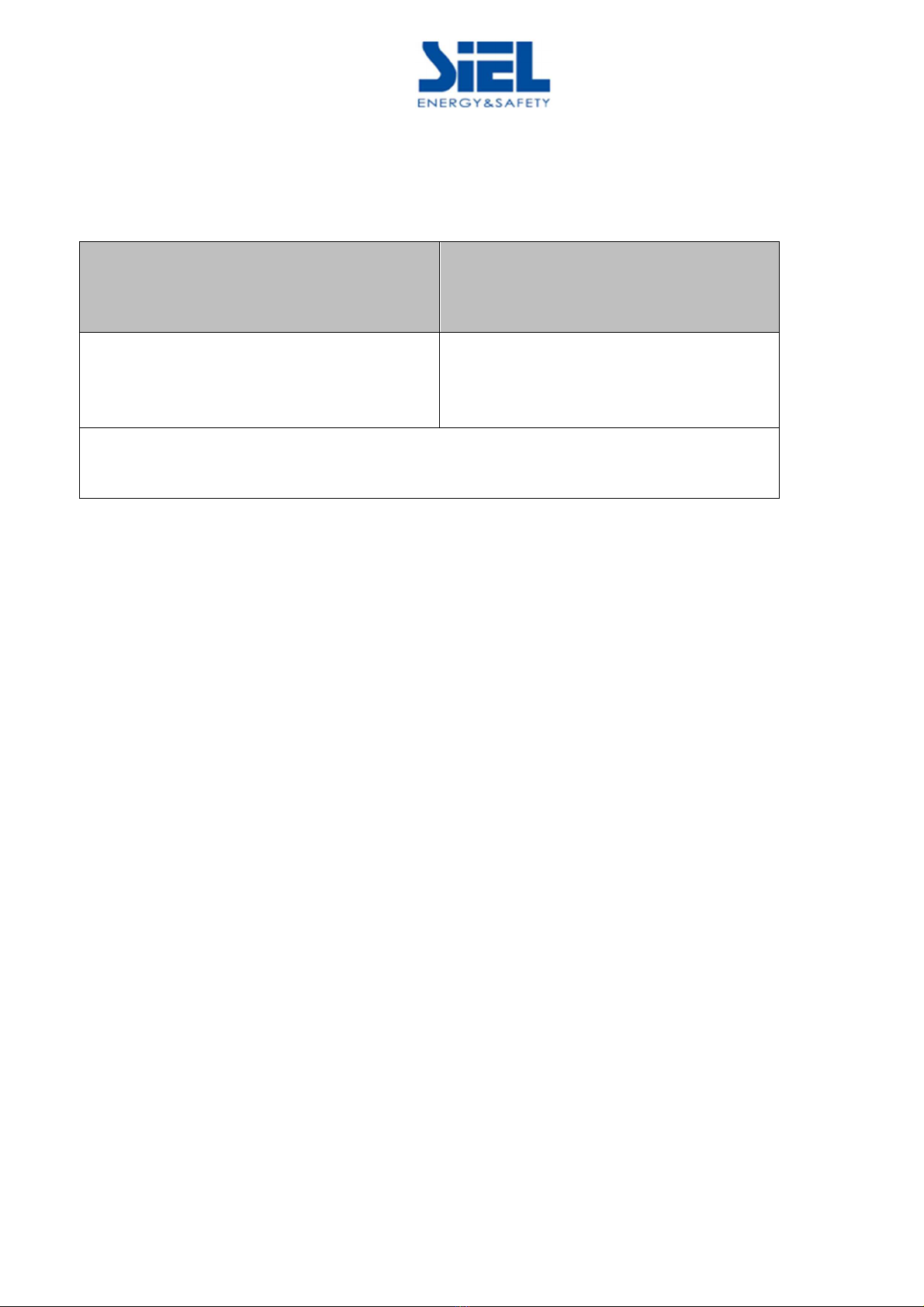

3.3 Ground conductor Sizing

The size of the ground conductor must be made according to the following table, extracted from the

product Safety standard CEI EN 62109-1.

The cross section of the phase conductors

connected to the inverter, ‘S’

mm²

Relevant minimum cross section of the

protective conductor to the ground, Sp

S ≤ 16

16 < S ≤ 35

35 < S

S

16

S/2

NOTE: The values shown in the previous table are valid only if the protective earthing conductor is made of the same

material used for the phase conductors AC. If not, the cross section of the protective conductor to ground must be

determined in order to get the same conductance value equivalent.

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

11

di

26

3.4 Maximum torque tightening cables

Coppia massima di serraggio

Ingresso DC

Uscita AC

Cavo di Terra

30 N m

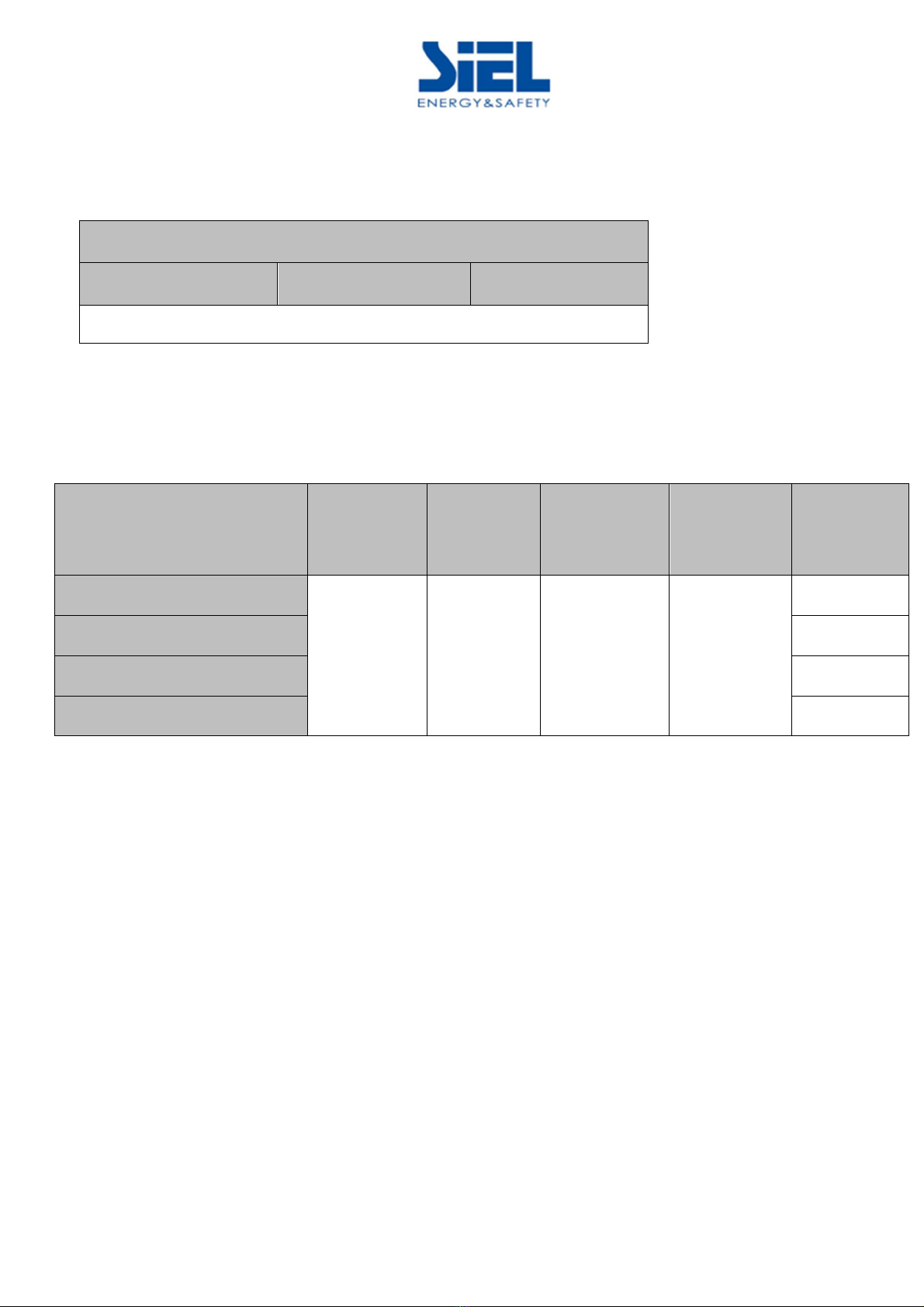

3.5 FAN characteristic

The following table includes the air flow volume and the power dissipation values

.

Model

Air capacity

aria [m³/h]

Inverter

FAN

Air capacity

aria [m³/h]

Magnetics

FAN

Inverter

FAN

consumption

[W]

Magnetics

FAN

consumption

[W]

Dissipated

power

[kW]

SOLEIL DSPX 1528M TLH 1500

7000 4000 1200 420

17,5

SOLEIL DSPX 1415M TLH 1500

17,5

SOLEIL DSPX 1330M TLH 1500

16,5

SOLEIL DSPX 1100M TLH 1500

13,5

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

12

di

26

4INSTALLATION

4.1 Visual inspection

All inverter components (electrical and mechanical) are carefully inspected

before the unit is delivered to the customer and must be integral even after

delivery. Always visually check a UPS after delivery for any transit damage, and

immediately inform Siel SPA if such damage is evident.

4.2 Unpacking

The inverter packaging is usually consitituted by a plastic ground cloth, put on from the top part of the

equipment and lowered till the lower limit of the equipment. Above the ground cloth, a carton box is

secured with plastic strips.

In order to unpack the inverter, it firstly required to cut the plastic strips and push the carton toward the

top of the unit, until the equipment is totally out of the box. Once this operation is done, it is possible to get

the inverter out of its plastic ground cloth.

Removal from the pallet: please use a forklift (with proper capacity for weight). Please refer to chapter

(TECHNICAL INFORMATION) of this manual to retrieve the weight information.

Forks of the forklift have to be inserted either from the front or from the rear of the cabinet (never from

the lateral side of it).

Due to the eight of the equipment, it is strongly recommended the use of all the safety tools as

prescribed by the safety regulation in force in any specific country here the equipment is installed.

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

13

di

26

The drive comes with plinths which close the base of the equipment.

When the apparatus comes from the factory skirtings are not mounted

so that it can be lifted from the bottom with a forklift.

Please do not tilt or lay down the inverter on either lateral side.

Following tools can be used for tran sport:

- Crane Forks

- Forklift

- Transpallets

Please use only tools designed to stand the weight of the inverter to be lifted.

In case of a pre-installed inverter removal, please remove the grid at the bottom of the equipment.

For weights and dimensions refer to the chapter "T CHNICAL INFORMATION" section of the instruction

manual.

Due to the order of magnitude of the weights, it is strongly recommended to use all the safety devices

required by current safety-related standards for movement and placement.

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

14

di

26

4.3 Safety considerations

Accidents can be prevented by simply following a few precautions:

•Walls, ceilings, floors and any other item placed next to the converter

should not be made of inflammable materials.

•The floor on which the inverter is installed should always be kept clean to

prevent metal particles or scraps of iron or metal from being sucked inside

the unit and causing short circuits.

•A dry powder fire extinguished should be positioned at the installation

site.

•For units of 100kW or higher, an automatic fire-fighting system should be

installed (as explained in the section “choice of installation site”).

•Access to the inverter installation site should only be given to service staff

and maintenance personnel; inward opening doors (with handles) to the

room where the inverted is sited and to the inverter itself) should be kept

closed at all times (limited access area).

•All service and electrical maintenance personnel must be trained and able

to perform both ordinary and emergency procedures. New personnel

must be given suitable training before being allowed to work on inverters.

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

15

di

26

4.4 Environmental considerations

The environmental factors that need to be taken into account are detailed in

the paragraphs that follow.

4.4.1 Load-bearing capacity of the floor

The weight of the inverter (specified in the Technical specifications in the instruction

manual) is taken by a small floor area. Therefore, it is important to make sure that the

area selected for installation can bear the weight of the appliance.

If the UPS is installed on a raised floor, it is important to use a base with pedestals (this

base can be provided by Siel SPA upon request).

All cables should be routed from below the floor.

4.4.2 Temperature and humidity

The premises where the inverter is to be installed must be able to disperse the

w that the device gives off during operation to keep the temperature

between -5°C and 45°C; with a humidity percentage between 0 and 95% as

shown on the technical specifications table.

The type and the implementation of any air distribution line must be checked

and approved by Siel SPA. The manufacturer is not in any way liable for

inverter malfunctions due to the failure to observe the rules of Installation,

particularly the permitted temperature and humidity requirements. It is

recommended therefore to adopt design features (for example air-

conditioning, heating or dehumidification of the premises), suitable to

guarantee the maintenance of the permitted temperature and humidity

conditions.

4.5 Installation Location of inverters

The inverter must be installed on a stable, level surface that is longer and wider than

the base of the appliance.

The inverter is not designed to be installed in areas where it could be exposed to

impacts or vibration: being transported by road, rail, sling, air or ship or by similar

equipment (e.g. cranes, moving parts of the appliance etc.).

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

16

di

26

The room intended for installation of the inverter must be a access-restricted only, such

as containers, electrical substations or suitable technical rooms suited to accommodate

electrical power, where no risk of items falling from above is present. The requirement

of security to prevent falling objects from that area is IP3X.

For indoor-type inverters, the installation site must be kept clean and dry at all

times so as to prevent foreign material or liquids from entering the

equipment.

1 m clearance, at least, must be kept in front of the inverter to allow all

routine and maintenance operations to be carried out.

The top of the equipment should be positioned at least 1m from the ceiling in order to

ensure good ventilation.

As these appliances can reach significant power levels, the site where an

inverter is positioned should be fitted with an automatic smoke detector that

has a remote alarm system that stops the unit and cuts off the power supply.

The detector should also be able to set off a fire-fighting system suitable for

an electrical device.

4.6 Installation Location of outdoor inverters

The inverter must be installed on concrete reinforced basement, such to stand the

weight of the inverter. The basement has to be prepared with cable conduits and

fixation holes before the installation. The inverter has to be secured to the basement

through dedicated screws inserted into the fixation holes.

The inverter is not designed to be installed in areas where it could be exposed to

impacts or vibration.

4.7 POSITIONING AND VENTILATION

Although “SOLEIL DSPX” series inverters are highly efficient, be aware that during

normal operation a certain amount of heat is generated. If this heat is not properly

dissipated, it can lead to an increase in temperature in the room where the inverter is

located and so the inverter itself can start to overheat.

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

17

di

26

4.8 Electrical considerations

Please refer to document IT0068 “Guidelines for the creation of photovoltaic plants” for the design

recommendations for the creation of LV and MV plants based on SOLEIL DSPX inverters.

4.9 Medium to Low voltage transformer for connection to MV grid:

criteria of choice.

The choice of MV/LV transformer for connection to MV grid, has to be done paying attention to the hints

provided by document IT0124 ‘Technical Properties MV trafo for oleil TL D PX 1000&1500Vdc’.

4.1 Preventive Maintenance

To ensure the functionality of the inverter over time, it is necessary to carry out some checks periodically:

-Check status connections (any oxidation) - Annual

-Check tightening of power connections - Annual

-Check tightening signal connections (terminals) - Annual

-Check correct operation of the cooling fans – Every 6 months

-Check integrity of fuses – Every 6 months

The equipment must also internally and externally cleaned-up, at least every six months.

It is strongly recommended to replace capacitors AC side and DC before the end of life expectancy (10

years). This activity, due to its complexity, requires being done by qualified personnel.

Replacement of fans is better done at intervals of five years, to prevent their failure or performance de-

rating due to the aging of its components (rotor, winding, bearings, etc.)

All the above operations and access to the internal components have to be carried out by trained

technicians.

During operation the inverter must be switched off and secured, opening the switches / disconnectors

side AC and DC side,

Particularly, for access to the upper compartment and the rear part of the unit:

1- disconnect the DC input

2- disconnect the AC output

3- if the fans are po ered by an external source, please make sure that the external s itch for

selecting the source of the aux circuits, is open.

To access the lower compartment, where the connection terminals and bars are located, in addition to

the steps described above, it is necessary to disconnect the incoming DC source from the photovoltaic

field and open the AC switch downstream the inverter.

Before accessing any part of the inverter, make sure that the capacitors are completely discharged and

that the fans are not operating.

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

18

di

26

5BASIC INSTALLATION HINTS

This Chapter contains a brief summary of the criteria for a correct installation of a multi-inverter system, in

order to get it into operation in the quickest and most reliable way.

5.1 Positioning of the inverters and ventilation

The positioning of the inverter has to take into account the type of installation:

Dedicated concrete-made technical room : the inverter can be positioned either on a floating floor

or on a concrete soil (in this case, power cables have to be routed to the inverter’s power

connection through underground dedicated conduits). In both cases, a dedicated mounting kit

provided by SIEL has to be used to secure the inverter to the hosting surface.

Containerized Metal Conversion Unit: the best practice to position the inverter, is placing it on a

metal frame of crossbeams, covering the perimeter of the inverter itself.

A dedicated mounting kit provided by SIEL has to be used to secure the inverter to the metal frame.

Regardless of the type of installation, the inverter has to lie on a horizontal surface, able to carry at least

1000kg/m^2.

If the system is a multi-inverter system, all the inverters have to be placed one beside the other, all front-

sided, as per following figure (example: DSPX TLH 5660M TLH 1500):

Fresh air intake is from the front , hot air exhaust from

the rear of the unit.Proper clearance (1m from the front,

1m from the rear side) must be left respect to walls and

possible obstacles, in order to ensure proper ventilation

to the inverter.

Following table shows the required minimum air flow:

Model

Air flow (m^3/h)

550, 665, 708

, 750

5500

1100M, 1330M, 1415M

, 1500M

11000

2200M, 2660M, 2830M

, 3000M

22000

3300M, 4000M, 4245M

, 4500M

33000

4400M, 5330

M

, 5660

M

, 6000M

44000

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

19

di

26

6SYNCHRONIZATION CABLE AND CAN-BUS (MULTI-INVERTER

SYSTEMS)

In multi-inverter models (2200M, 2660M, 2830M, 3000M, 3300M, 4000M, 4245M, 4500M, 4400M, 5330M,

5660M, 6000M), every inverter is connected in a daisy-chain fashion with the next one and the previous

one (except the Master and the last inverter of the system) as far as:

•Synchronization channel: the synchronized firing commands are received by one unit on the

‘Interface Board’ and retransmitted forward, by using a twisted multi-conductor, shielded cable ,

terminated with a multi-pole DIN connector (link ‘Sync_in’ & ‘Sync_out’ in the figure below).

• CAN-bus channel: the CAN link carrying the status information of every unit, is received by one

unit on the ‘DSP control board’ and retransmitted forward, by using a twisted multi-conductor

shielded cable for high frequency, terminated with a CAT5 – RJ45-like connector (‘CAN-in’ & ‘CAN-

out’ in the figure below).

As anticipated, these two communication links are functional to the Master & Slave operation of

the system.

In a multi-inverter system, the overall length of these two connection has to be kept as low as possible and,

however, less than 20m, for signal integrity and timing constraints.

This is the main reason why, as recommended in previous paragraph, it is essential to keep the inverters

aligned to each other on the front side.

Next figure shows the path of both ‘Sync’ and ‘CAN’ connections among units:

IV408E

Rev.

0

1

Installation manual

Dateof issue

: 20

21

-

03

-

1

0

Pag.

20

di

26

SINCHRONIZATION AND CAN BUS CONNECTION EXAMPLE (DSPX 4 M TLH 15 )

•Synchronization connections: black lines

•CAN bus connections: white lines

This manual suits for next models

4

Table of contents

Other Siel Inverter manuals

Popular Inverter manuals by other brands

SolarEdge

SolarEdge StorEdge SE5000H-O4 quick guide

Patron

Patron GI-3500P user manual

True blue power

True blue power TI1200 Installation manual and operating instructions

Northern Lights

Northern Lights Lugger P984 Operator's manual

Atlas Copco

Atlas Copco QAX 12 Dd S2 APP instruction manual

Go Power

Go Power SOLAR EXTREME user manual