3

MAN-100472 RD150 - Operating Instructions

57030-EN-18071757030-EN-180717

Contents

1 About this document............................................................................................................... 5

1.1 Function ........................................................................................................................... 5

1.2 Target group ..................................................................................................................... 5

1.3 Symbols used................................................................................................................... 5

2 For your safety ......................................................................................................................... 6

2.1 Authorised personnel ....................................................................................................... 6

2.2 Appropriate use................................................................................................................ 6

2.3 Warning about incorrect use............................................................................................. 6

2.4 General safety instructions............................................................................................... 6

2.5 EU conformity................................................................................................................... 7

2.6 NAMUR recommendations .............................................................................................. 7

2.7 Installation and operation in the USA and Canada ........................................................... 7

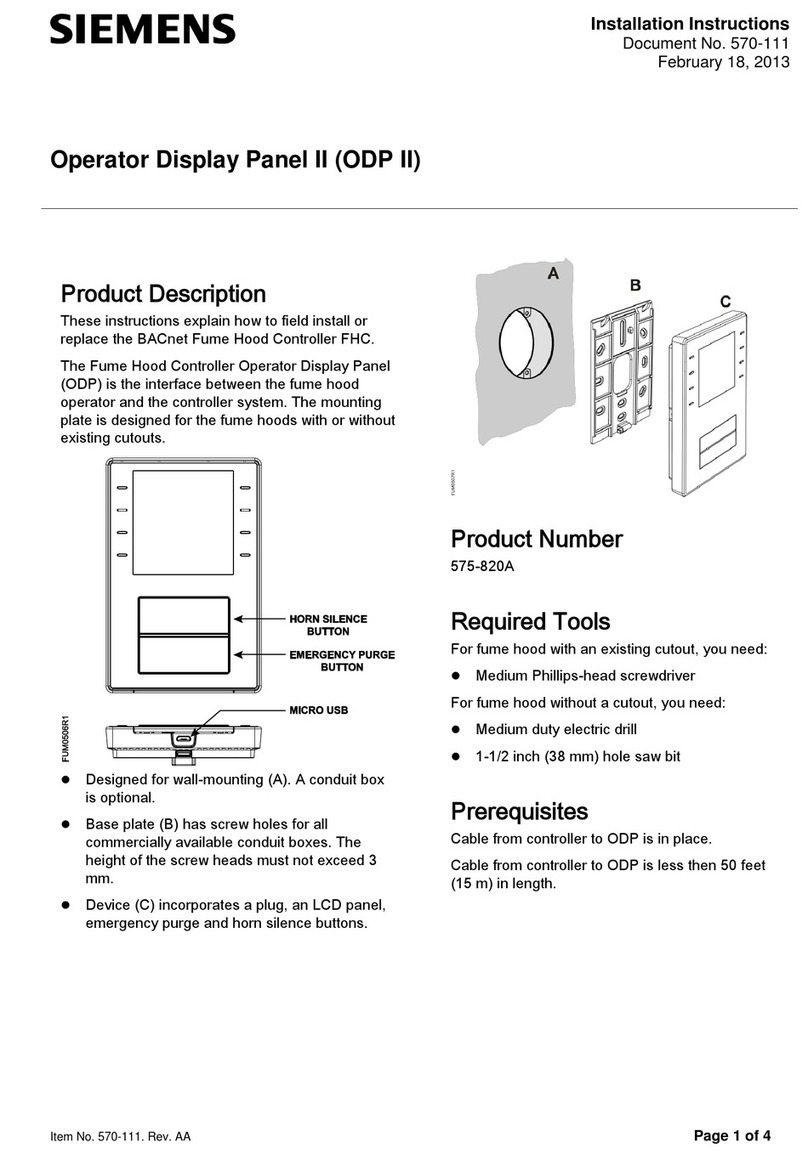

3 Product description................................................................................................................. 8

3.1 Conguration.................................................................................................................... 8

3.2 Principle of operation........................................................................................................ 9

3.3 Packaging, transport and storage................................................................................... 10

3.4 Accessories and replacement parts ............................................................................... 11

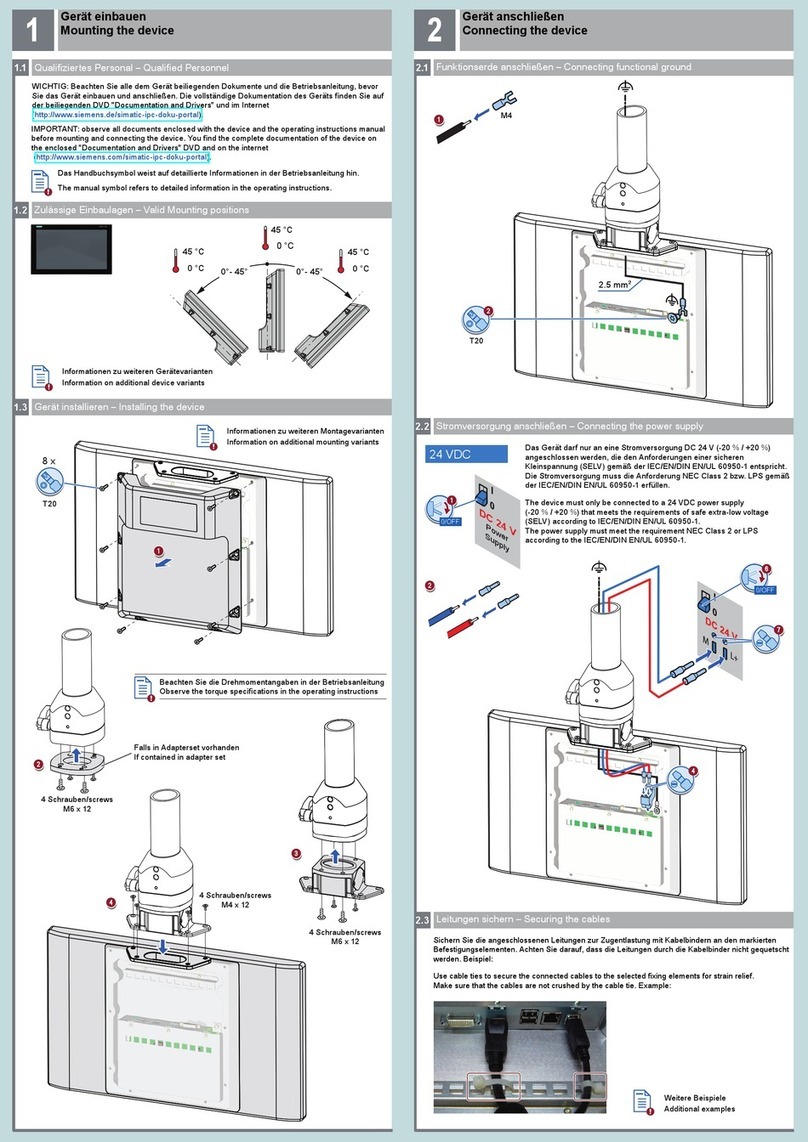

4 Mounting................................................................................................................................. 12

4.1 General instructions ....................................................................................................... 12

4.2 Mounting instructions ..................................................................................................... 12

5 Connecting to power supply.................................................................................................15

5.1 Preparing the connection ............................................................................................... 15

5.2 Connection technology and steps .................................................................................. 16

5.3 Wiring plan ..................................................................................................................... 18

5.4 Connection HART standard ........................................................................................... 18

5.5 Connection HART multidrop........................................................................................... 19

5.6 Connection signal conditioning instrument/four-wire sensor .......................................... 19

5.7 Connection example ...................................................................................................... 20

5.8 Switch-on phase............................................................................................................. 20

6 Set up with the display and adjustment module................................................................21

6.1 Short description ............................................................................................................ 21

6.2 Insert display and adjustment module............................................................................ 21

6.3 Adjustment system......................................................................................................... 22

6.4 Measured value indication - Selection of national language........................................... 23

6.5 Start menu...................................................................................................................... 24

6.6 Parameter adjustment - RD150...................................................................................... 24

6.7 Parameter adjustment - Sensors via Generic HART....................................................... 29

7 Setup via PACTware...............................................................................................................31

7.1 Connect the PC.............................................................................................................. 31

7.2 Parameter adjustment with PACTware............................................................................ 32

7.3 Saving the parameterisation data................................................................................... 33

8 Diagnostics and servicing .................................................................................................... 34

8.1 Maintenance .................................................................................................................. 34

8.2 Asset Management function........................................................................................... 34

8.3 Rectify faults................................................................................................................... 35