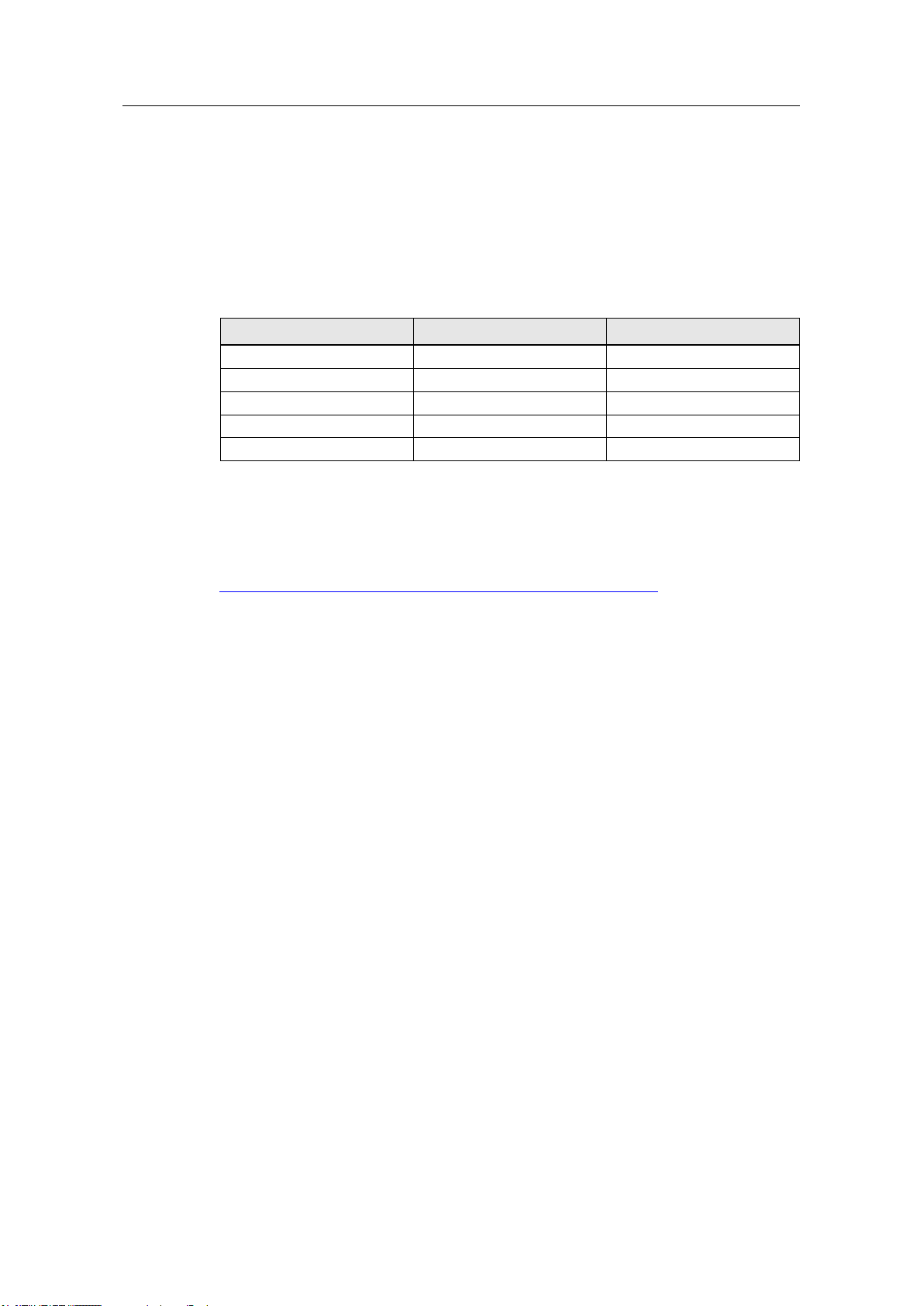

Table of contents

Legal information......................................................................................................... 2

1Preface................................................................................................................ 5

2Introduction........................................................................................................ 7

2.1 Description ........................................................................................... 7

2.2 EtherNet/IP........................................................................................... 8

2.3 Function principle ................................................................................. 9

2.4 Scope of delivery................................................................................ 10

3Commissioning................................................................................................ 11

3.1 Preparation......................................................................................... 11

3.2 Connecting the hardware components .............................................. 11

4Configuration/Engineering ............................................................................. 13

4.1 Creating and managing projects ........................................................ 13

4.2 Creating the EtherNet/IP IO system................................................... 15

4.2.1 Creating an Adapter description......................................................... 16

4.2.2 EDS files............................................................................................. 17

5Operating.......................................................................................................... 29

5.1 Start the application............................................................................ 29

5.2 Troubleshooting.................................................................................. 30

5.2.1 Physical check.................................................................................... 30

5.2.2 Network Settings ................................................................................ 32

5.2.3 SIMATIC Program.............................................................................. 34

6LCCF_EnetScanner block............................................................................... 36

6.1 Parameters......................................................................................... 36

6.1.1 Block status messages....................................................................... 38

6.1.2 Technical data.................................................................................... 41

6.2 What’s next?....................................................................................... 44

7Appendix .......................................................................................................... 45

7.1 Service and support ........................................................................... 45

7.2 Industry Mall....................................................................................... 46

7.3 Links and literature............................................................................. 46

7.4 Change documentation...................................................................... 46