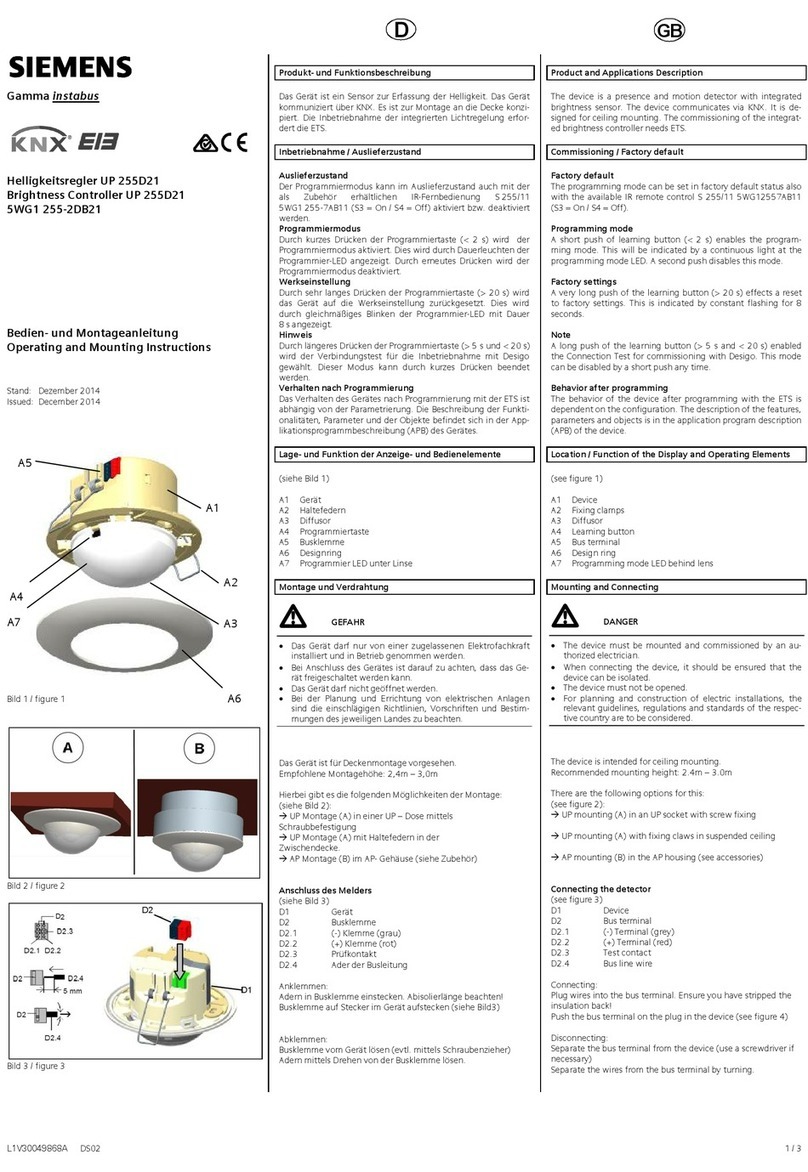

GAMMA instabus

Technical product information

February 2012

UP 258D11 OPTISENS OFFICE Pre ence detector / motion detector with lighting control 5WG1 2582DB11

Siemens AG UP 258D11, 8 pages Technical manual

In rastructure & Cities Sector, Building Technologies

Control Products and Systems © Siemens AG 2012 Update: http://www.siemens.com/gamma

P.O. Box 10 09 53, D93009 Regensburg Subject to change without urther notice

2.13.1.6/1

Product and functional de cription

The UP 258D11 is a presence/motion detector with inte

grated 2point light control. The UP 258D11 device com

municates via KNX/EIB with actuators or other KNX de

vices. It is designed or mounting on the ceiling. Owing

to its tilting sensor head, the UP 258D11 can be aligned

with the required capture area. The main application or

the device is automatic lighting control in an o ice

workplace.

The UP 258D11 senses the presence o a person or that

there is no longer anyone in its detection area. The de

tector signal can be analyzed via two separate communi

cation channels, termed motion detector and presence

detector.

Additionally, the UP 258D11 provides an output or con

trol o HVAC applications. For example, this unction can

switch systems that are used or heating, ventilating and

airconditioning control (HVAC) o the room rom “En

ergy saving mode” in an unused room to “Com ort mode”

in an occupied room and back to “Energy saving mode”

when the room is again unoccupied.

For each detector unction block (presence, motion,

HVAC) 4 communication objects are available, in total 12

di erent communication objects. Depending on con igu

ration, one or two KNX telegrams are sent onto the bus

when motion is irst detected and when, a ter the last

motion was detected, an overshoot time has expired.

The values o the communication objects are con igured

or each unctional block (motion detector, presence

detector, HVACdetector) via corresponding parameters.

Each time a presence is detected, the overshoot time is

started. Its duration is separately con igurable or each

unctional block. The end o presence is determined by

the end o the overshoot time.

The duration o the dead time is also con igurable per

unctional block. It is used to protect the actuators that

are connected to the detector. I a presence is detected

during the dead time, neither telegrams are sent nor the

overshoot time is started.

In the ollowing the telegrams, which are sent at the

beginning o a presence, are called A and B, the tele

grams, which are sent at the end o a presence, are

called C and D.

Operating Sequence

A ter the device has detected a presence, telegram A is

sent immediately. I it has been con igured to send also a

telegram B, then telegram B is sent a ter the con igured

time (optionally also cyclically).

I there are no motions any more, at the end o the over

shoot time telegram C and (i con igured) telegram D are

sent. Telegram D can also be sent cyclically.

I there are motions while the overshoot time is running,

the overshoot time is restarted.

Flowchart:

motion

A B C D

bus telegrams

dead time

overshoot time

U e a ingle device or a main detector (ma ter),

re pectively econdary detector ( lave)

The detector can be operated as an independent device,

as the main or secondary detector.

According to the requirement, additional presence detec

tors can be connected with the “main detector” via

KNX/EIB as “secondary detectors” to extend the presence

detection zone. “Secondary detectors” supply motion

in ormation only to the main detector.

Brightne mea uring – adju table via KNX/EIB

The UP 258D11 contains an independent light sensor.

The signal measured there is available both at the

KNX/EIB and internally.

Because the light sensor measures directly, it must be

possible to calibrate it or indirect measurement, so that

it can be adapted to the di erent installation sites. Rapid