SIGNALCORE SC5305A Owner's manual

© 2012-2015 SignalCore, Inc.

support@signalcore.com

SC5305A

1 MHz to 3.9 GHz RF Downconverter

for PXI Express

Operating & Programming Manual

SC5305A Operating & Programming Manual Rev 2.0.0 i

CO N T E N T S

Important Information 1

Warranty 1

Copyright & Trademarks 2

International Materials Declarations 2

CE European Union EMC & Safety Compliance Declaration 2

Recycling Information 3

Warnings Regarding Use of SignalCore Products 3

Getting Started 4

Unpacking 4

Verifying the Contents of your Shipment 4

Setting Up and Configuring the SC5305A 4

Signal Connections 6

Indicator LEDs 6

SC5305A - Theory of Operation 7

Overview 7

Signal Path Description 8

Local Oscillator Description 11

Frequency Tuning Modes 12

Setting the SC5305A to Achieve Best Dynamic Range 13

Operating the SC5305A Outside Normal Range 14

SC5305A Programming Interface 15

Device Drivers 15

Using the Application Programming Interface (API) 15

Setting the SC5305A - Writing To Configuration Registers 16

Configuration Registers 16

Tuning the RF Frequency 16

Changing the Attenuator Settings 17

Enabling and Disabling the RF Preamplifier 17

Changing the RF Synthesizer Mode 17

SC5305A Operating & Programming Manual Rev 2.0.0 ii

Selecting the IF Filter Path 17

Setting the Reference Clock Behavior 17

Adjusting the Reference Clock Accuracy 18

Setting Spectral Inversion in the IF 18

Storing Data into the User EEPROM Space 18

Setting the Phase of the IF Signal 18

Querying the SC5305A - Writing To Request Registers 19

Reading the Device Status 19

Reading the Device Temperature 20

Reading the Calibration EEPROM 21

Reading the User EEPROM 21

Working With Calibration Data 22

EEPROM Data Content 23

Frequency Correction 25

Gain Correction 25

IF Response Correction 27

Software API Library Functions 29

Constants Definitions 30

Type Definitions 31

Function Definitions and Usage 32

Calibration & Maintenance 47

Appendix A - Specifications 49

SC5305A Operating & Programming Manual Rev 2.1.0 1

The warranty terms and conditions for all SignalCore products are also provided on our corporate

website. Please visit http://www.signalcore.com/ for more information.

IM P O R T A N T IN F O R M A T I O N

Warranty

This product is warranted against defects in materials and workmanship for a period of one year from

the date of shipment. SignalCore will, at its option, repair or replace equipment that proves to be

defective during the warranty period. This warranty includes parts and labor.

Before any equipment will be accepted for warranty repair or replacement, a Return Material

Authorization (RMA) number must be obtained from a SignalCore customer service representative and

clearly marked on the outside of the return package. SignalCore will pay all shipping costs relating to

warranty repair or replacement.

SignalCore strives to make the information in this document as accurate as possible. The document has

been carefully reviewed for technical and typographic accuracy. In the event that technical or

typographical errors exist, SignalCore reserves the right to make changes to subsequent editions of this

document without prior notice to possessors of this edition. Please contact SignalCore if errors are

suspected. In no event shall SignalCore be liable for any damages arising out of or related to this

document or the information contained in it.

EXCEPT AS SPECIFIED HEREIN, SIGNALCORE, INCORPORATED MAKES NO WARRANTIES, EXPRESS OR

IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR

NEGLIGENCE ON THE PART OF SIGNALCORE, INCORPORATED SHALL BE LIMITED TO THE AMOUNT

THERETOFORE PAID BY THE CUSTOMER. SIGNALCORE, INCORPORATED WILL NOT BE LIABLE FOR

DAMAGES RESULTING FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR

CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY THEREOF. This limitation of the

liability of SignalCore, Incorporated will apply regardless of the form of action, whether in contract or

tort, including negligence. Any action against SignalCore, Incorporated must be brought within one year

after the cause of action accrues. SignalCore, Incorporated shall not be liable for any delay in

performance due to causes beyond its reasonable control. The warranty provided herein does not cover

damages, defects, malfunctions, or service failures caused by owner’s failure to follow SignalCore,

Incorporated’s installation, operation, or maintenance instructions; owner’s modification of the product;

owner’s abuse, misuse, or negligent acts; and power failure or surges, fire, flood, accident, actions of

third parties, or other events outside reasonable control.

SC5305A Operating & Programming Manual Rev 2.1.0 2

Copyright & Trademarks

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic

or mechanical, including photocopying, recording, storing in an information retrieval system, or

translating, in whole or in part, without the prior written consent of SignalCore, Incorporated.

SignalCore, Incorporated respects the intellectual property rights of others, and we ask those who use

our products to do the same. Our products are protected by copyright and other intellectual property

laws. Use of SignalCore products is restricted to applications that do not infringe on the intellectual

property rights of others.

“SignalCore”, “signalcore.com”, and the phrase “preserving signal integrity” are registered trademarks

of SignalCore, Incorporated. Other product and company names mentioned herein are trademarks or

trade names of their respective companies.

International Materials Declarations

SignalCore, Incorporated uses a fully RoHS (Restriction of Hazardous Substances) compliant

manufacturing process for our products. Therefore, SignalCore hereby declares that its products do not

contain restricted materials as defined by European Union Directive 2011/65/EU (EU RoHS) in any

amounts higher than limits stated in the directive. This statement is based on the assumption of reliable

information and data provided by our component suppliers and may not have been independently

verified through other means. For products sold into China, we also comply with the “Administrative

Measure on the Control of Pollution Caused by Electronic Information Products” (China RoHS). In the

current stage of this legislation, the content of six hazardous materials must be explicitly declared. Each

of those materials, and the categorical amount present in our products, are shown below:

組成名稱

Model Name

鉛

Lead

(Pb)

汞

Mercury (Hg)

镉

Cadmium

(Cd)

六价铬

Hexavalent

Chromium

(Cr(VI))

多溴联苯

Polybrominated

biphenyls

(PBB)

多溴二苯醚

Polybrominated

diphenyl ethers

(PBDE)

SC5305A

A indicates that the hazardous substance contained in all of the homogeneous materials for this

product is below the limit requirement in SJ/T11363-2006. An X indicates that the particular hazardous

substance contained in at least one of the homogeneous materials used for this product is above the

limit requirement in SJ/T11363-2006.

CE European Union EMC & Safety Compliance Declaration

The European Conformity (CE) marking is affixed to products with input of 50 - 1,000 VAC or 75 - 1,500

VDC and/or for products which may cause or be affected by electromagnetic disturbance. The CE

marking symbolizes conformity of the product with the applicable requirements. CE compliance is a

manufacturer’s self-declaration allowing products to circulate freely within the European Union (EU).

SignalCore products meet the essential requirements of Directives 2014/30/EU (EMC) and 2014/35/EU

SC5305A Operating & Programming Manual Rev 2.1.0 3

(product safety), and comply with the relevant standards. Standards for Measurement, Control and

Laboratory Equipment include EN 61326-1:2013 and EN 55011:2009 for EMC, and EN 61010-1 for

product safety.

Recycling Information

All products sold by SignalCore eventually reach the end of their useful life. SignalCore complies with EU

Directive 2012/19/EU regarding Waste Electrical and Electronic Equipment (WEEE).

Warnings Regarding Use of SignalCore Products

(1)

PRODUCTS FOR SALE BY SIGNALCORE, INCORPORATED ARE NOT DESIGNED WITH COMPONENTS NOR TESTED FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN ANY LIFE SUPPORT

SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT INJURY TO A HUMAN.

(2)

IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE IMPAIRED BY ADVERSE

FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY, COMPUTER HARDWARE MALFUNCTIONS,

COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN

APPLICATION, INSTALLATION ERRORS, SOFTWARE AND HARDWARE COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF

ELECTRONIC MONITORING OR CONTROL DEVICES, TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE),

UNANTICIPATED USES OR MISUSES, OR ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS

THESE ARE HEREAFTER COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD CREATE A

RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD NOT BE SOLELY RELIANT

UPON ANY ONE COMPONENT DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID DAMAGE, INJURY, OR DEATH, THE USER OR

APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO PROTECT AGAINST SYSTEM FAILURES, INCLUDING BUT NOT

LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS. BECAUSE EACH END-USER SYSTEM IS CUSTOMIZED AND DIFFERS FROM

SIGNALCORE' TESTING PLATFORMS, AND BECAUSE A USER OR APPLICATION DESIGNER MAY USE SIGNALCORE PRODUCTS IN

COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT EVALUATED OR CONTEMPLATED BY SIGNALCORE, THE USER OR

APPLICATION DESIGNER IS ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING THE SUITABILITY OF SIGNALCORE PRODUCTS

WHENEVER SIGNALCORE PRODUCTS ARE INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT LIMITATION, THE

APPROPRIATE DESIGN, PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

SC5305A Operating & Programming Manual Rev 2.1.0 4

Ground yourself using a grounding strap or by touching a grounded metal object.

Touch the antistatic bag to a grounded metal object before removing the hardware

from its packaging.

Never touch exposed signal pins. Due to the inherent performance degradation

caused by ESD protection circuits in the RF path, the device has minimal ESD

protection against direct injection of ESD into the RF signal pins.

When not in use, store all SignalCore products in their original antistatic bags.

GE T T I N G ST A R T E D

Unpacking

All SignalCore products ship in antistatic packaging (bags) to prevent damage from electrostatic

discharge (ESD). Under certain conditions, an ESD event can instantly and permanently damage several

of the components found in SignalCore products. Therefore, to avoid damage when handling any

SignalCore hardware, you must take the following precautions:

Remove the product from its packaging and inspect it for loose components or any signs of damage.

Notify SignalCore immediately if the product appears damaged in any way.

Verifying the Contents of your Shipment

Verify that your SC5305A kit contains the following items:

Quantity

Item

1

SC5305A RF Downconverter for PXI Express

1

Software Installation USB Flash Drive (may be combined with other products onto a single drive)

Setting Up and Configuring the SC5305A

The SC5305A is a designed for use in a PXI Express (PXIe) or PXIe hybrid chassis. Chassis manufacturers

must provide at least the minimum required per-slot power dissipation cooling capability to be

compliant with the PXIe specifications. The SC5305A is designed to be sufficiently cooled in either all-

PXIe chassis or PXIe hybrid chassis (chassis with a mix of PXI Express slots and traditional PXI slots).

However, certain environmental factors may degrade performance. Inadequate cooling can cause the

temperature inside the RF housing to rise above the maximum for this product, leading to improper

performance and potentially reducing product lifespan or causing complete product failure. Maintain

adequate air space around the chassis at all times, and keep the chassis fan filters clean and

unobstructed.

Refer to your chassis manufacturer’s user manual for proper setup and maintenance of your

PXIe or PXIe hybrid chassis. The SC5305A on-board temperature sensor should indicate a rise

of no more than 20 °C above ambient temperature under normal operating conditions.

!

!

SC5305A Operating & Programming Manual Rev 2.1.0 5

The SC5305A is a PXIe RF downconverter with all user I/O located on the front face of the module as

shown in Figure 1. Each I/O location is discussed in further detail below.

Figure 1. PXI Express chassis view of the SC5305A. Module is shown installed in slot 2.

All signal connections (ports) on the SC5305A are SMA-type, with the exception of the PXI backplane

clock connection (MCX connection). Exercise caution when fastening cables to the signal connections.

Over-tightening any connection can cause permanent damage to the device.

The condition of your system‘s signal connections can significantly affect measurement

accuracy and repeatability. Improperly mated connections or dirty, damaged or worn

connectors can degrade measurement performance. Clean out any loose, dry debris from

connectors with clean, low-pressure air (available in spray cans from office supply stores).

If deeper cleaning is necessary, use lint-free swabs and isopropyl alcohol to gently clean

inside the connector barrel and the external threads. Do not mate connectors until the

alcohol has completely evaporated. Excess liquid alcohol trapped inside the connector may

take several days to fully evaporate and may degrade measurement performance until fully

evaporated.

Tighten all SMA connections to 5 in-lb max (56 N-cm max)

!

!

SC5305A Operating & Programming Manual Rev 2.1.0 6

Signal Connections

RF IN This port accepts input signals from 1 MHz to 3.9 GHz to the downconverter. The nominal

input impedance is 50 Ω. Maximum input power is +27 dBm.

IF OUT This port outputs the 70 MHz IF signal from the downconverter. The nominal output

impedance is 50 Ω.

REF IN This port accepts an external 10 MHz reference signal, allowing an external source to

synchronize the internal reference clock. This port is AC-coupled with a nominal input

impedance of 50 Ω. Maximum input power is +13 dBm.

REF OUT This port outputs the internal 10 MHz or 100 MHz reference clock. If the internal reference

clock is synchronized to an external reference clock through the 10 MHz “ref in”port, this

output port will also be synchronized. This port is AC- coupled with a nominal output

impedance of 50 Ω.

PXI CLK10 This port outputs the 10 MHz chassis reference signal from the chassis backplane, allowing it

to synchronize the internal reference clock. An MCX male to SMA male cable is required (but

not supplied) to connect this port to the “ref in”port in order to use this reference for

synchronization. This port may be enabled or disabled through a software switch to

minimize possible clock noise when not in use. This port has a nominal output impedance of

50 Ω and drives 0 dBm into a 50 Ω load.

Indicator LEDs

The SC5305A provides visual indication of important modes. There are two LED indicators on the device.

Their behavior under different operating conditions is shown in Table 1.

Table 1. LED indicator states.

LED

Color

Definition

STATUS

Green

“Power good” and all oscillators phase-locked

STATUS

Red

One or more oscillators off lock

STATUS

Off

Power fault

ACTIVE

Green/Off

Device is open (green) /closed (off) , this indicator is also

user programmable (see register map)

ACTIVE

Orange

User initiated standby mode

SC5305A Operating & Programming Manual Rev 2.1.0 7

S C 5 3 0 5 A TH E O R Y O F OP E R A T I O N

Overview

The SC5305A operates on the principle of heterodyning, a process whereby an incoming RF signal is

mixed with specific oscillator frequencies in stages, producing both sum and difference frequency

products. At each stage the summed frequency product (or image) is removed through low-pass

filtering, allowing the difference frequency product to continue through the signal path. Repeating this

process several times using carefully selected local oscillators (LOs) and well-designed band-pass

filtering, the original signal is translated or “downconverted” in frequency low enough for inexpensive

digitizers to acquire the signal with reasonable bandwidth. The resultant output signal of a heterodyne

downconverter is known as the intermediate frequency (IF). Using a tunable LO as the first mixing

oscillator allows the downconverter to translate a broad range of frequencies to a common IF output.

When combined, a tunable LO and extraction of the lower mixed frequency product creates an

important and useful variant of the heterodyne process known as superheterodyning.

The SC5305A is a three-stage superheterodyne downconverter that delivers superior image rejection

over single stage conversion and offers both high signal-to-noise dynamic range and high spurious-free

dynamic range. The RF input ranges from 1 MHz to 3.9 GHz, and the IF output is fixed at 70 MHz. When

the input frequency is lower than the intermediate frequency, the device technically behaves as an

upconverter. The SC5305A up-converts when the input frequency ranges from 1 MHz to 70 MHz. The

converted spectrum polarity may be inverted or non-inverted by programming the device accordingly.

Fundamentally, each conversion stage consists of a frequency mixer that mixes two input signals and

producing a wanted third. The wanted third component is selected, via a frequency filter, among other

signals generated in the mixing process. The three primary components of the signals in each conversion

mixer are commonly known as the local oscillator (LO), radio frequency (RF), and the intermediate

frequency (IF) as shown in Figure 2.

Figure 2. Frequency conversion stage using a mixer.

Where R represents the RF component, L represents the LO component, and I represents the IF

component. The LO is resident in the downconverter and is either frequency tunable or fixed in

frequency depending on the stage.

The first IF stage is an upconversion stage - all input signals are converted to an IF higher than the

highest input frequency specified. The second and third stages successively convert this high first IF

down to the final IF of 70 MHz. Having a high first IF allows the downconverter to achieve very high

image rejection ability. This image-free architecture achieves high image rejection without the need for

sharp cut-off pre-select band-pass filters. Having high image rejection makes the SC5305A suitable for

L

RI

RF

LO

IF

SC5305A Operating & Programming Manual Rev 2.1.0 8

applications such as spectral monitoring, broadband spectral analysis, and others where the spectral

environment cannot be controlled.

The SC5305A exhibits very low phase noise of -107 dBc/Hz at 10 kHz offset on a 1 GHz RF carrier with a

typical noise floor of -150 dBm/Hz. The noise floor can be further reduced below -165 dBm/Hz by

enabling the internal preamplifier. With gain control between -60 dB to +50 dB, a measurement signal-

to-noise dynamic range greater than 180 dB is achievable. Using high reverse isolation devices and sharp

cutoff filters, LO leakages and other spurious contents at the input connectors are well below -120 dBm.

Inter-stage LO leakages are also kept very low through sophisticated circuit and shielding design to

ensure that spurious in-band signals remain less than -80 dBc. The excellent spurious free dynamic range

is achieved using low noise linear amplifiers, low loss mixers, and high performance solid state

attenuators. State-of-the-art solid state attenuators have improved linearity over earlier designs. Their

attenuation level changes settle under a microsecond, and for applications that involve frequent range

changing, they offer a vastly superior lifetime over mechanical attenuators.

The real-time bandwidth is shaped primarily by the final 70 MHz IF surface acoustic wave (SAW) filter.

The final IF filter has two programmatically selectable paths, switching either between two filter paths

with different bandwidths or between one filter and one bypass (no filter) path. Filters in the first and

second IF stages are not as selective as the final IF filter but they ensure good isolation between local

oscillators (LO). Keeping each LO isolated helps to suppress unwanted spurious signals.

Frequency accuracy is provided by an onboard 10 MHz temperature compensated crystal oscillator

(TCXO) which can be phase-locked to an external reference source if required, and it is recommended to

do so in applications that may require a more stable and accurate base reference.

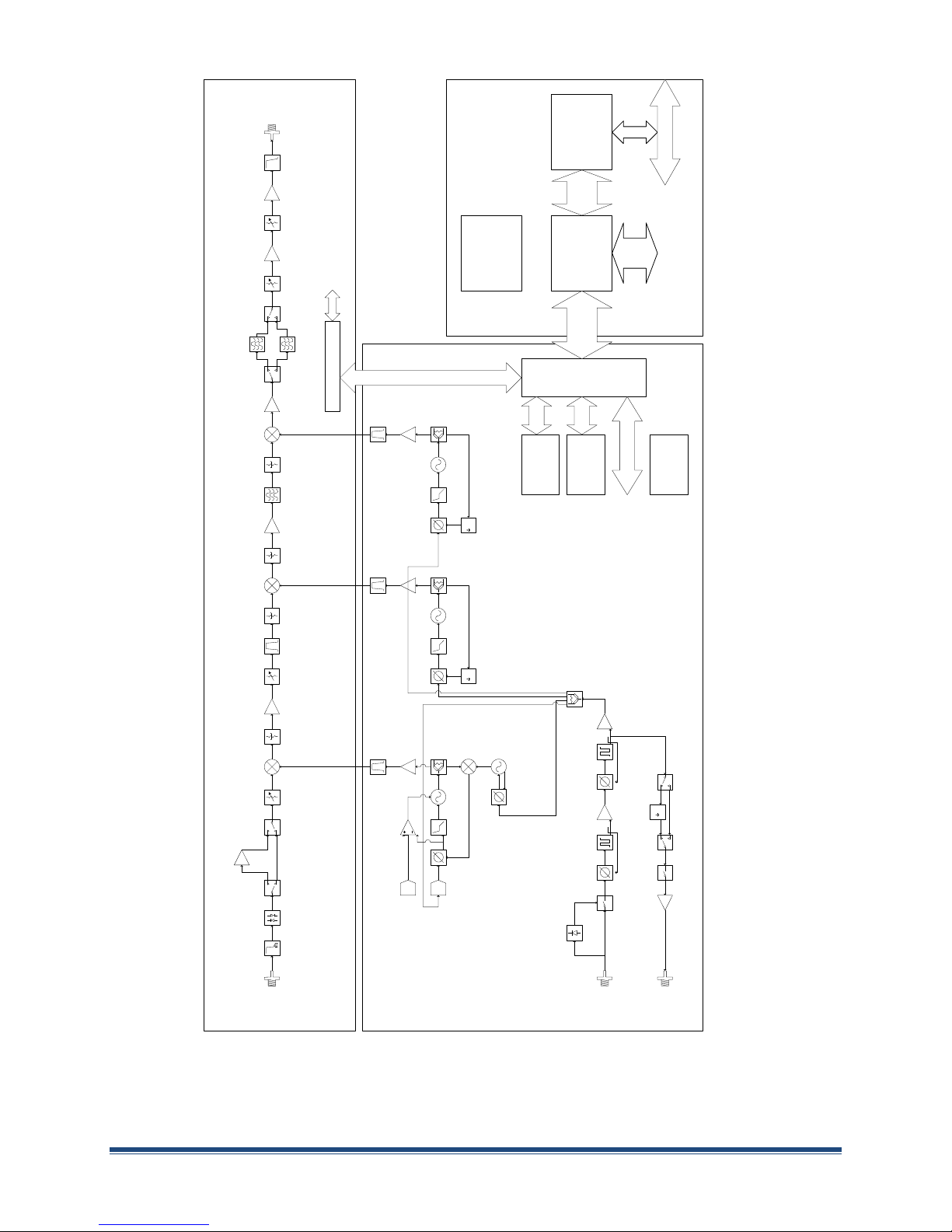

Signal Path Description

Figure 3 depicts an overall block diagram of the SC5305A. Starting from the upper left, the RF input of

the SC5305A is AC coupled, followed by an elliptic low-pass filter which has a sharp cut-off frequency

slope to ensure the images and unwanted frequencies are well suppressed. Next, a bypass switch

enables or disables the internal preamplifier in the path of the RF signal, directly after the input filter.

The advantage of placing the amplifier before the attenuators is to increase the downconverter

sensitivity when the preamplifier is selected. This switch is programmatically controlled and can be

toggled as required, enabling the preamplifier to boost input signals of very small amplitude. Due to

losses in the attenuators, the noise figure of the system is proportional to their accumulated losses if the

attenuators were placed before the amplifier. The trade-off for better sensitivity is the lack of

attenuation adjustment for larger signals when the amplifier is enabled. The user will need to provide

good judgment when enabling the preamplifier.

SC5305A Operating & Programming Manual Rev 2.1.0 9

Figure 3. Block diagram of the SC5305A.

R

I

LR

I

LR

I

L

N.M

N

R

I

L

10 MHZ

TCXO 100 MHZ

VCXO

Ref.

Detector

4000 MHz

PLL 605/745 MHz

PLL

4675MHz to

8575MHz PLL

YIG Driver

Fine Tune

DDS

Coarse Tune

PLL

DDS

DAC

RF

Filter

RF

PreAmp

RF Atten

0-30 dB 4675 MHz

Filter

IF1_Atten

0-30 dB

IF3 Atten1

0-30 dB IF3 Atten2

0-30 dB

675 MHz

Filter

IF3 FL 0

ESD

RF In

1 MHz –

3900 MHz

IF Out

70 MHz

Ref. In

10 MHz

Ref. Out

10/100 MHz

3.9 GHz Three Stage Downconverter

Nom Input level -20 dBm

Max Input level 27 dBm Nom output level 0 dBm

Max out level 20 dBm

IF3 FL 1

10

Module B

Module A

MCU

Power

Regulation

Digital Interface

Temp

Sensor

Calibration

EEPROM

PLL,

Attenuator,

ADC, DAC,

other devices

SPI, RS-232, USB

PCIe Bridge

PXIe

Switchers

Linear Reg.

Module C

Digital Interface Attenuators, Switches

SC5305A Operating & Programming Manual Rev 2.1.0 10

The RF attenuator, with a 0 to 30 dB attenuation range and attenuation steps of 1 dB, is located

between the preamplifier and the first mixer. The RF attenuator is used to set the signal amplitude to a

user-defined level at the mixer when the RF input level is higher than that level. This attenuator is

adjusted to obtain the required distortion levels. Lowering the RF level with the attenuator at the mixer

operates the device in a more linear region. However suppressing the RF level too low before the mixer

reduces the signal-to-noise ratio, so the user must set this level to compromise between noise and

linearity. The RF signal is mixed with the first local oscillator, LO1, and the difference component is

selected as the wanted intermediate frequency (IF).

The first IF stage after the RF mixer, referred to as IF1 in the programming section, is heavily filtered and

carefully amplified to maintain the best compromise between signal dynamic range and linearity. The

filters provide isolation between the first and second stage mixers to reduce in-band inter-modulation

spurious signals from the mixing of high order harmonics of the IF and LO frequencies. The filters in this

stage also suppress the mixer LO leakage. If not filtered, LO leakages can potentially cause saturation in

the preceding stages of the signal path and degrade the linearity performance of the device. There is an

adjustable attenuator following the output of the first mixer, which is used to suppress leakages from

LO1 that appear in-band when the downconverter is tuned to frequencies less than the bandwidth of

the device. For example, if the bandwidth of the system is 20 MHz, LO1 leakage will appear in-band if

the frequency is tuned below 20 MHz. Technically, LO leakages should not appear in-band until the

device is tuned below 10 MHz, but the non-ideality of the filter allows sufficient leakage at higher

frequencies. Setting this attenuator will attenuate both the IF1 signal and the LO1 leakage, making the

device respond more linearly. As always, the compromise is that the SNR will degrade. The LO1 leakage

signal will appear as DC when the IF is digitized and converted to baseband. By design, setting the IF

frequency at 4675 MHz allows sufficient frequency separation from the highest RF frequency so that the

IF1 filter, despite its non ideal roll-off response, can suppress the RF signal by more than -100 dB.

The first IF is then down-converted to the second IF of 675 MHz by mixing with the second LO (LO2).

Similarly, as with the first IF section, the second IF (IF2) section is also well filtered and amplified.

Keeping isolation between the second and third mixers is important to ensure spurious signals

generated within the device are kept significantly low when compared to the primary signal of interest.

Finally, the second IF is converted to the third and final IF by mixing with the third LO (LO3). Located in

this stage are the primary band-pass filters that define the bandwidth of the device. The final IF filters

are selectable between two filters of different bandwidths centered at 70 MHz. The standard

bandwidths for these filters are 5 MHz, 10 MHz, 20 MHz, and 40 MHz. These surface acoustic wave

(SAW) filters provide excellent filter response. The user may choose to use one of these two filter paths

as a bypass, that is, no band-pass filter in the path. One reason for bypassing the final IF filter is to

improve the group delay through the device; with the filters enabled the delay is approximately 1 s.

Bypassing the filter reduces the delay to about 100 ns, which may be preferred in some applications.

Following the band-pass filter are the IF attenuators, IF3_Atten1 and IF3_Atten2. These IF attenuators

control the IF gain of the device and set the desired output IF level at the IF output port. The

recommended output level is 0 dBm. However, the level may be set to other values that suit the

particular application. Finally, a low pass filter suppresses the harmonics of the IF signal. It is important

that the IF harmonics are kept as low as possible because they appear in-band as higher order images

SC5305A Operating & Programming Manual Rev 2.1.0 11

when digitized. The harmonics are typically below 90 dBc at the IF. In applications where this may not be

acceptable, external analog filtering is recommended.

Local Oscillator Description

The signal path circuit is separate from the local oscillator generation circuits to maximize isolation

between the RF/IF signals and the local oscillators, except for the LO injection paths into the mixers.

Although the both circuits reside within the same module, well-designed shielding and circuit layouts

ensures leakages between them are kept to a minimum.

The first local oscillator, LO1, is an agile, tunable phase-lock synthesizer. The synthesizer tunes from

4675 MHz to 8575 MHz, a tuning range of 3900 MHz. The minimum step size is 1 Hz, and is

accomplished through a multiple phase-locked loop and DDS hybrid architecture. The use of a hybrid

tuning architecture is important for improved phase noise and improved close-in phase spurious

responses. Operating LO1 at such high frequencies internally to obtain a 1 MHz to 3.9 GHz RF range

requires that the phase noise at these frequencies is sufficiently low so that the converted RF signal

phase noise is not degraded significantly. For example, to downconvert a 100 MHz RF signal, LO1 is

tuned to 4775 MHz, which is about 48 times higher in frequency than the input frequency. To further

ensure phase noise remains low farther away from the carrier, especially at 100 kHz and 1 MHz offsets,

a YIG oscillator is used. It important to realize that having a phase noise “plateau” out to several tens of

MHz, which is a very common phenomenon with VCO-based synthesizers, is not acceptable for many

applications.

Another reason for a hybrid tuning architecture is to reduce the phase spurs associated with phase-

locked loops. A simple fractional PLL may provide resolution to 1 Hz, but it cannot provide 1 Hz

frequency tuning steps with low fractional phase spurs. By using two DDS circuits to provide the 1 Hz

tuning steps and mathematically ensuring that DDS-generated spurs are suppressed within the

architecture, LO1 is made to fine tune to exact frequencies, that is, the frequency synthesized is an exact

integer multiple or division of the reference signal.

The second local oscillator, LO2, is fixed at 4.0 GHz, synthesized using an integer PLL and a fixed narrow

tune VCO with very low phase noise. The typical raw phase noise of the second stage oscillator is less

than -150 dBc/Hz @ 1 MHz offset. LO2 phase noise contribution to the overall phase noise of the device

is less than 1 dB. LO1 dominates the phase noise of the device.

The third local oscillator, LO3, is synthesized using a fractional PLL and has phase noise lower than both

LO1 and LO2, and is switchable between two frequencies: 605 MHz and 745 MHz, the later frequency

being the default. Both of these frequencies will set the output IF center frequency at 70 MHz. However,

at the default LO3 frequency the final 70 MHz IF output spectral polarity is the same as that of the input

RF, whereas the 605 MHz frequency will create an inverted IF spectrum. If LO3 is set to 605 MHz by

calling the sc5305a_SetIfInversion function or register, the IF output spectral content will be inverted

with respect to the input RF spectrum. See Figure 4 for a graphical representation of this process.

SC5305A Operating & Programming Manual Rev 2.1.0 12

Figure 4. Graphical representation of IF inversion.

Inverted spectral conversion is convenient for digitizers that sample the IF in the even Nyquist zones

because it eliminates the need to perform digital inversion of the acquired spectrum.

All local oscillators are phase-locked to an internal 100 MHz voltage controlled crystal oscillator (VCXO),

which sets their close-in phase noise performance. The 100 MHz VCXO is in turn phase-locked to the

internal 10 MHz TCXO for frequency accuracy and stability. For better frequency accuracy and stability

than the TCXO onboard the SC5305A, or for frequency synchronization, the user can programmatically

set the device to phase lock the TCXO to an external 10 MHz reference source by programming the

REFERENCE_SETTING register. It is important to note that the TCXO will only attempt to lock to an

external source if one is detected. A typical external reference source minimum level of -10 dBm is

required for detection to be successful. A reference source level of 0 dBm to +3 dBm is recommended

for normal operation. The reference source is fed into the device through the “ref in”port. The device

can also export a copy of its internal reference through the “ref out”port. The output reference

frequency is selectable for either 10 MHz or 100 MHz output. By default, routing of the reference signal

to the “ref out” port is disabled. It can be enabled by programming the REFERENCE_SETTING register.

This reference frequency is sourced from the internal 100 MHz OCXO, and the default output selection is

10 MHz, which is divided down from the 100 MHz VCXO. The output reference level is typically +3 dBm.

Frequency Tuning Modes

Tuning of SC5305A superheterodyne downconverter is accomplished through the tuning of LO1. LO1 has

two sets of control parameters that can be explored to optimize the device for any particular

application. The first set of parameters, TUNE SPEED, set the tuning and phase lock time as the

frequency is changed. TUNE SPEED consists of two modes - Fast Tune mode and the Normal mode; both

of these modes directly affect the way the YIG oscillator is configured. The Fast Tune mode deactivates a

noise suppression capacitor across the tuning coil of the YIG oscillator, and doing so increases the rate of

current flow through the coil, correspondingly increasing the rate of frequency change. In Normal mode

the capacitor is activated, slowing down the rate of frequency change. The advantage of activating the

capacitor is that it shunts the noise developed across the coil, decreasing close-in phase noise. Refer to

Appendix A for specifications regarding tuning speed.

RF

A

fc

IF

A

ifc

IF

A

ifc

Non Inverted Conversion

Inverted Conversion

SC5305A Operating & Programming Manual Rev 2.1.0 13

The other set of control parameters, FINE TUNE, sets the tuning resolution of the device. There are three

modes: 1 MHz, 25 kHz, and 1 Hz tuning step sizes. The first two modes use only fractional phase

detectors to tune the frequency of the LO1 synthesizer, while the third mode enables the DDS to

provide 1 Hz resolution. The PLL-only modes (1 MHz and 25 kHz) provide the ability to realize exact

frequencies with tuning as fine as 25 kHz. Use of these modes offers several advantages - lower phase

spurs and less computational burden to set a new frequency. These modes have the lowest phase

spurious signals, below the levels published in the product specification. The DDS mode also tunes to

exact frequencies, however it requires many more computing cycles and additional register-level writes

in order to set a new frequency. Comparing times, the device requires up to 175 microseconds to

compute and change to a new frequency in PLL only modes, but requires up to 350 microseconds in the

DDS tuning mode. At first glance it may seem that these differences would directly impact frequency

tuning times. However, tuning times are predominantly set by the physical parameters of the YIG

oscillator. Computation and register writes typically account for less than 25% of the total tune time of a

10 MHz step change in frequency.

It is important to note that although the synthesized frequencies are exact frequencies, there are

observable random phase drifts in the downconverted signals. These drifts are due to PLL non-idealities

rather than a frequency error in the DDS tuning circuit. Having exact frequency synthesis is important for

many applications. Published phase noise and spurs specifications are based on the 1 Hz (DDS) mode.

Setting the SC5305A to Achieve Best Dynamic Range

When discussing dynamic range, there are two distinct quantities which are specified. First is the

compression-to-noise density (per Hz) dynamic range, commonly referred to in SignalCore literature as

the signal-to-noise ratio dynamic range (SNRDR). Second is the third order spurious free dynamic range,

commonly known as the SFDR. In traditional radio terminology, the SFDR strictly refers to the third order

effects of nonlinearity whose products are generally close to the carrier signal and are very difficult to

filter out. In analog to digital conversion, the SFDR term takes on a different definition, referring to the

ratio of the input signal strength to all the spurious products appearing within the Nyquist band. These

later spurious signals may be caused by harmonics, inter-modulation, and digital quantization.

These two dynamic ranges are instantaneous, in that the signal and the noise or spurs are observed at

the same time. On the other hand, the measurement dynamic range, specifically referring to SNRDR, is

not instantaneous. The user may enable RF attenuation to receive signals levels much greater than the

instantaneous compression point, or enable the preamplifier to detect signals below the instantaneous

noise density level. The measurement dynamic range is thus much greater than the instantaneous

equivalent.

The SC5305A is designed with a focus on having a high dynamic range, not just low in noise or having

high compression points. It is designed as a receiver for signal analyzers, which require that it handle

larger signals well. For weak signals, the RF preamplifier should be enabled. The design ensures the SFDR

dynamic range specification is met when the RF signal level at the input mixer is -20 dBm and the IF level

is at 0 dBm. This requires a total IF attenuation of 10 dB for a typical device gain of 30 dB (preamplifier

disabled). This setting is typical for broadband signals with more than a few MHz of real-time

bandwidth.

SC5305A Operating & Programming Manual Rev 2.1.0 14

For applications where the SNR must be maximized, such as examining the close-in characteristics of a

sine tone, the input mixer should be set to accept 0 dBm power and the IF set at 0 dBm or higher. This is

a likely setting for making phase noise measurements of an RF signal (assuming the specified phase

noise of the SC5305A is low enough for measuring that particular signal). It is important to first set the

necessary attenuators before injecting a 0 dBm level signal to the mixer, otherwise heavy saturation of

the mixer or the output amplifiers may cause degradation or even possible failure of the receiver over

time.

The SC5305A is designed for a nominal output IF level of 0 dBm, ensuring the IF signal is about 3-4 dB

below the full-scale value of many 50 analog-to-digital data converters (ADCs). Depending on the

application, the user will need to set the appropriate gain of the device (via attenuation), and hence the

output level, to suit the particular application. For broadband signals, it is recommended that the IF

output level be about 7 dB below the full-scale value of a digitizer because of possible high crest factors

that may saturate the digitizer. For sine-tone or narrowband application, the output IF level should be

about 3 dB below full-scale of the digitizer to maximize its signal-to-noise dynamic range.

SignalCore provides a simulation tool that mimics the behavior of the SC5305A. The user may run the

simulator to get an understanding of what the parameters need to be set on the downconverter to

achieve certain performance. Additionally, the function sc5305a_CalcAutoAttenuation helps the user

obtain the necessary attenuator parameters to setup the device for the best compromise of linearity

and noise performance for a given set of input and output parameters.

There is a programmable attenuator in the first IF section, IF1_Atten, that can be used to improve

linearity in general. The primary use of this attenuator is to suppress the LO1 leakage in the IF band

when the downconverter is tuned below the bandwidth frequency. This in-band leakage affects the

linearity of the device as it may inter-modulate with the IF signal to produce third order spurious

products. The level of the leakage is equivalent to a typical -25 dBm RF signal at the mixer. The user

should set 5 dB to 10 dB OF attenuation when operating at these low frequencies.

Operating the SC5305A Outside Normal Range

The SC5305A is capable of tuning below 1 MHz and above 3.9 GHz. These frequencies lie outside of the

specification range and performance will be degraded if operated in these outer margins. However, for

some applications, the reduced dynamic range or elevated spurious levels in these ranges may not pose

an application concern. The lowest tunable frequency is 0 MHz (DC). However, for input frequencies

below 1 MHz, the AC coupling capacitors in the circuit limit/attenuate the signal significantly. On the

upper end of the spectrum, the input low-pass filter will attenuate the signal rapidly as the frequency

increases above 3.9 GHz. Calibration stored on the device EEPROM does not account for these out of

range frequencies, so applying any correction using the stored calibration is not valid.

SC5305A Operating & Programming Manual Rev 2.1.0 15

S C 5 3 0 5 A PR O G R A M M I N G IN T E R F A C E

Device Drivers

The SC5305A is programmatically controlled by writing to its set of configuration registers, and its status

read back through its set of query registers. The user may choose to program directly at the register

level or through the API library functions provided. These API library functions are wrapper functions of

the registers that simplify the task of configuring the register bytes. The register specifics are covered in

the next section. Writing to and reading from the device at the register level through the API involves

calls to the sc5305a_RegWrite and sc5305a_RegRead functions respectively.

For Microsoft WindowsTM operating systems, The SC5305A API is provided as a dynamic linked library,

sc5305a.dll. This API uses NI-VISATM to communicate with the device. Inclusion of the NI-VISA driver is

required for code development in programming languages such C, C++, or LabVIEWTM. For LabVIEWTM

support, an additional LabVIEW API, sc5305a.llb, is also provided. The functions in the LabVIEW API are

primarily LabVIEW VI wrappers to the standard API functions. NI-VISATM is available from National

Instruments Corporation (www.ni.com).

For other operating systems or VISA implementations such as Agilent VISA, users will need to access the

device through their own proprietary PXIe driver. The VISA-based driver code is available to our

customers by request. This code can be compiled with Agilent VISA with minimal or no code change.

Should the user require assistance in writing an appropriate API other than that provided, please contact

SignalCore for additional example code and hardware details.

Using the Application Programming Interface (API)

The SC5305A API library functions make it easy for the user to communicate with the device. Using the

API removes the need to understand register-level details - their configuration, address, data format,

etc. For example, to obtain the device temperature the user simply calls the function

sc5305a_GetDeviceTemperature, or calls sc5305a_SetFrequency to set the device frequency. The

software API is covered in detail in the “Software API Library Functions”section.

SC5305A Operating & Programming Manual Rev 2.1.0 16

SE T T I N G T H E S C 5 3 0 5 A : WR I T I N G TO

CO N F I G U R A T I O N RE G I S T E R S

Configuration Registers

The users may write the configuration registers (write only) directly by calling the sc5305a_RegWrite

function directly. Table 2 lists the register address (command) and the effective bytes of command data.

Data must be formatted into an unsigned integer of 32 bits prior to passing it to the function. As an

example to write the byte 0xEE into address 0xA8BB of the user EEPROM, the user would call the

sc5305a_RegWrite as follows:

sc5305a_RegWrite(deviceHandle, 0x23, 0x00A8BBEE)

Table 2: Configuration registers.

Register (Address)

Data

Bytes

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 Default

INITIALIZE (0x01) [7:0] Open Open Open Open Open Open Open Mode 0x00

SET_SYSTEM_ACTIVE (0x02) [7:0] Open Open Open Open Open Open Open

Enable

SYS LED

0x00

POWER_SHUT_DOWN (0x05) [7:0] Open Open Open Open Open Open Open Enable 0x00

[7:0] 0x00

[15:8] 0x00

[23:16] 0x00

[31:24] 0x00

[7:0] 0x00

[15:8] 0x00

RF_PREAMPLIFIER_SETTING (0x12) [7:0] Open Open Open Open Open Open Open Enable 0x00

RF_MODE_SETTING (0x13) [7:0] Open Open Open Open Open

Fast

Tune

Enable

0x00

IF_BAND_SELECT (0x15) [7:0] Open Open Open Open Open Open Open Band 0x00

REFERENCE_SETTING (0x16) [7:0] Open Open Open Open Reserv

100 MHz

Out Sel

Ref Out

Enable

Lock

Enable

0x00

[7:0] 0x00

[15:8] 0x00

IF_INVERT_SETTING (0x1D) [7:0] Open Open Open Open Open Open Open Enable

[7:0]

[15:8]

[23:16]

[7:0] 0x00

[15:8] Open Open 0x00

Units Value [13:8]

PHASE_SETTING (0x32)

EEPROM DATA [7:0]

WRITE_USER_EEPROM (0x23)

EEPROM Address [7:0]

EEPROM Address [15:8]

Tenths Value

Units Value[7:4]

Attenuator Value

Attenuator

ATTENUATOR_SETTING (0x11)

Fine Tune

REFERENCE_DAC (0x17)

DAC word [7:0]

DAC word [15:8]

Frequency Word [23:16]

Frequency Word [7:0]

Frequency Word [15:8]

Frequency Word [31:24]

RF_FREQUENCY (0x10)

Tuning the RF Frequency

The frequency of the first local oscillator (LO1) is set by writing the RF_FREQUENCY register (0x10). This

register requires four data bytes, these data bytes being the bytes comprising an unsigned 32-bit

integer. The data bytes contain the frequency tuning word in Hertz. For example, to tune to a frequency

of 2.4 GHz, the data word would be d2400000000 in decimal or 0x8F0D1800 in hexadecimal.

SC5305A Operating & Programming Manual Rev 2.1.0 17

Changing the Attenuator Settings

The ATTENUATOR_SETTING (0x11) register has two data bytes needed to set the value of a specific

attenuator. The MSB sets the target attenuator, and the least significant byte (LSB) contains the

attenuation value. The MSB values and corresponding attenuator locations are as follows:

MSB value

Attenuator

0x00

IF3_ATTEN2

0x01

IF3_ATTEN1

0x02

RF_ATTEN

0x03

IF1_ATTEN

The LSB contains the attenuation value in 1 dB steps for the attenuator specified in the MSB. For

example, to set the RF attenuator to 15 dB, the command data would be 0x020F.

Enabling and Disabling the RF Preamplifier

The RF_PREAMPLIFIER_SETTING (0x12) register has one data byte that enables or disables the RF

preamplifier. It is recommended that the preamplifier only be enabled when the RF input signal is less

than or equal to -30 dBm. Enabling the preamplifier increases the receiver sensitivity for low-level

signals. Setting the LSB of the data byte high or low will enable or disable the RF preamplifier,

respectively. For example, to turn on the preamplifier the command data is 0x01.

Changing the RF Synthesizer Mode

The RF_MODE_SETTING (0x13) register has one data byte that provides two tuning modes for the

device: Fast Tune and Fine Tune. By default the Fast Tune mode is disabled (Normal mode). Asserting

high bit 3 of the data byte will enable Fast Tune mode. Fast Tune enables the device to achieve faster

lock and settling times between frequency changes. Please refer to Appendix A for more information

regarding Fast Tune mode. The second mode, Fine Tune mode, has three options: 1 MHz (PLL), 25 kHz

(PLL), and 1 Hz (DDS). Selection of these options requires setting the first two bits of the data byte to 0,

1, and 2 respectively. See the “Frequency Tuning Modes”section for more information. For example, to

set the device for Fast Tune and a 1 Hz tuning step resolution, the command data would be 0x06.

Selecting the IF Filter Path

The IF_FILTER_SELECT (0x15) register has one data byte that selects between two installed IF filters;

IF3_FILTER0 and IF3_FILTER1. Setting bit 0 high will select IF_FILTER1. The exact bandwidths of the filters

depend on the available installed options and are stored in the device calibration EEPROM.

Setting the Reference Clock Behavior

The REFERENCE_SETTING (0x16) register has one data byte which sets the reference clock behavior of

the device. The default state of this register is 0x00, which disables the export of the internal reference

Table of contents

Other SIGNALCORE Media Converter manuals

Popular Media Converter manuals by other brands

Erma Electronic

Erma Electronic SSI 9001 instruction manual

HEIDENHAIN

HEIDENHAIN LIDA 573 Mounting instructions

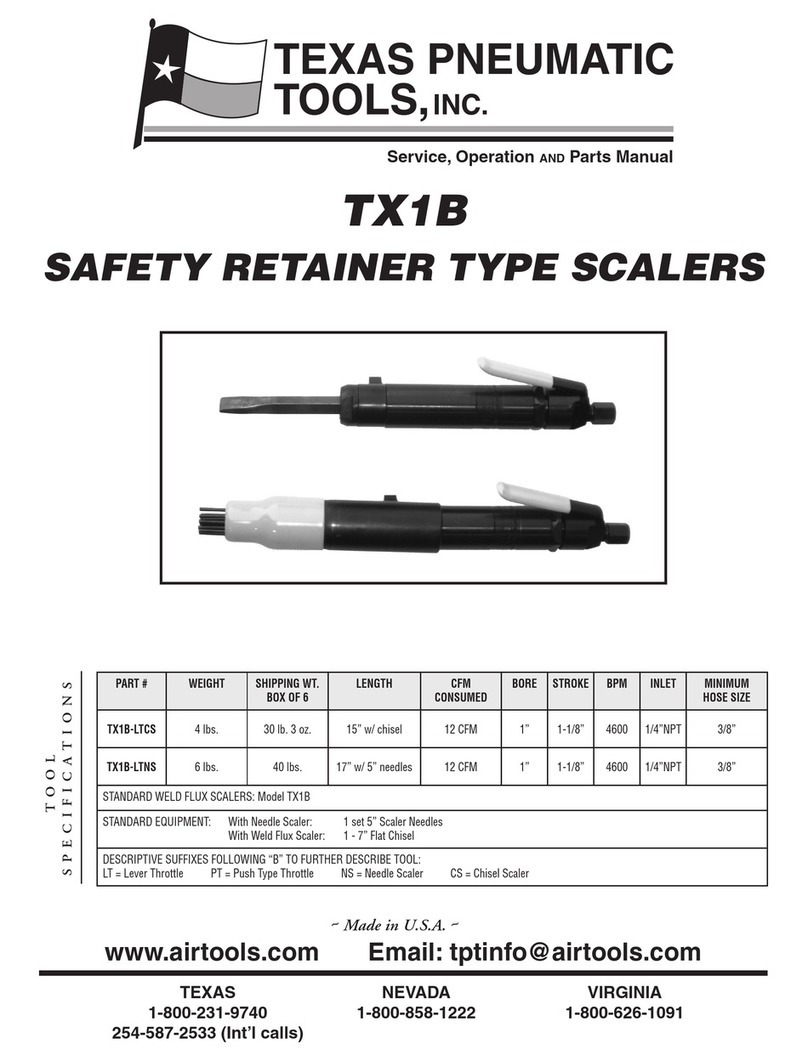

Texas Pneumatic Tools

Texas Pneumatic Tools TX1B Service, Operation and Parts Manual

Mainstream

Mainstream omni manual

Ross

Ross openGear UDC-8225 user manual

Taga

Taga DA-300 v.3 instruction manual