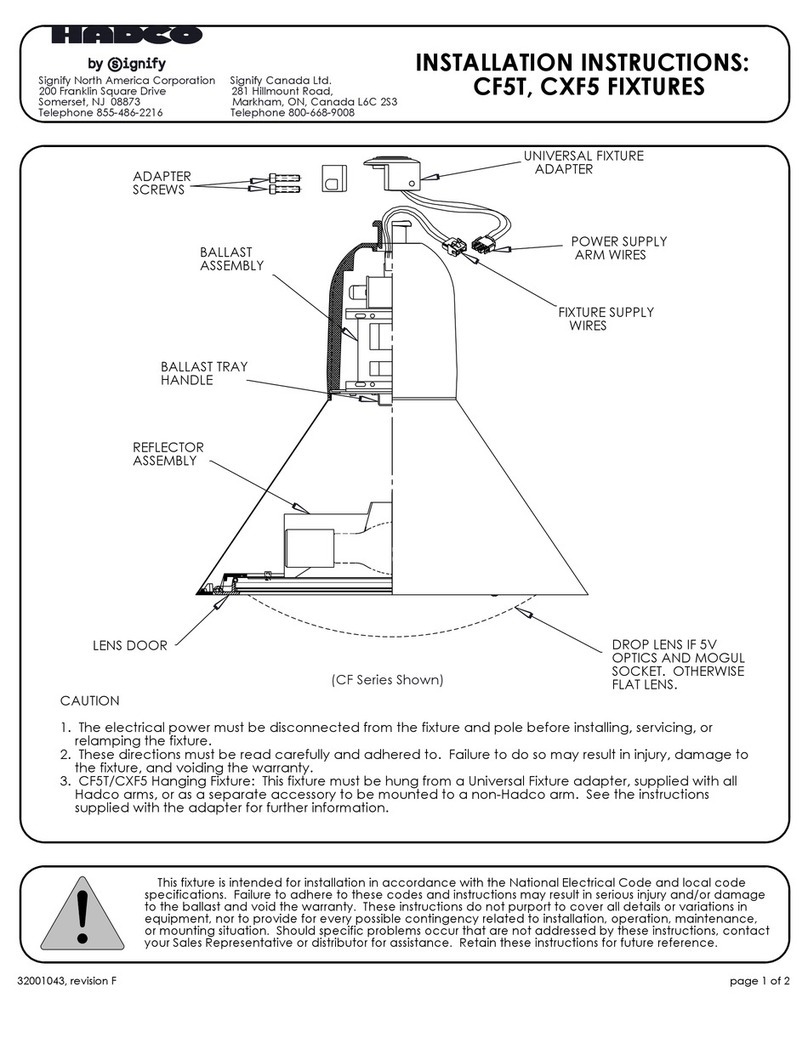

ATTENTION: Install in accordance with national and local building and electrical codes.

! Page 3

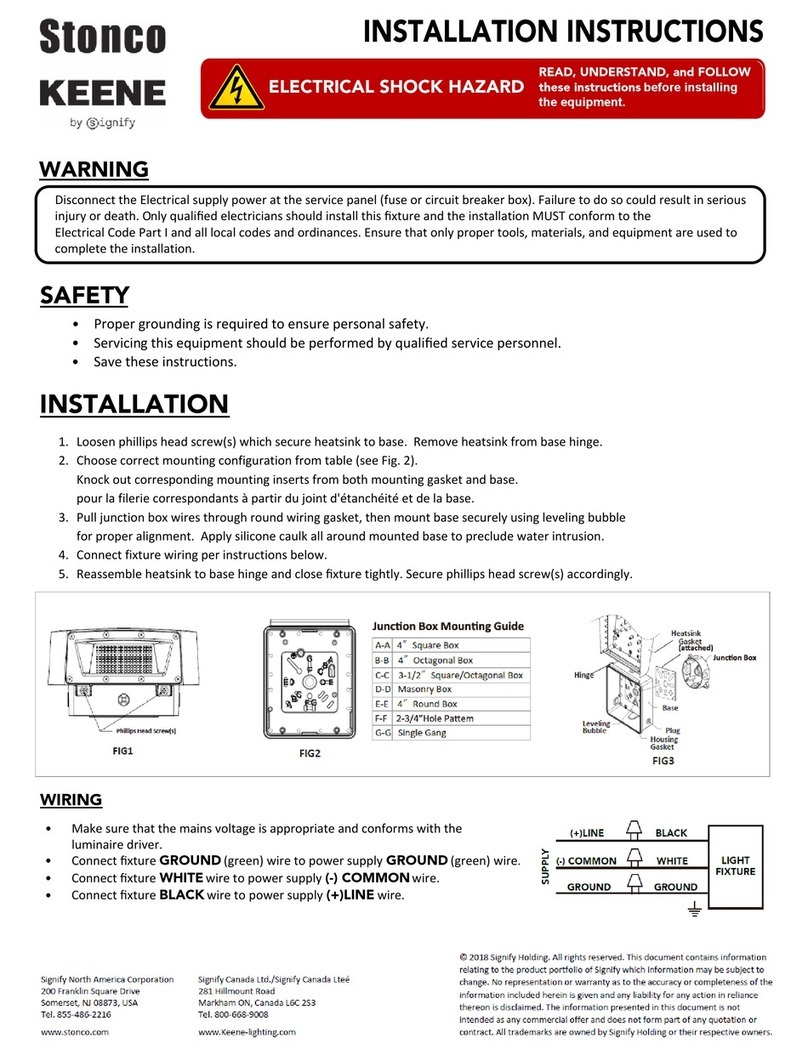

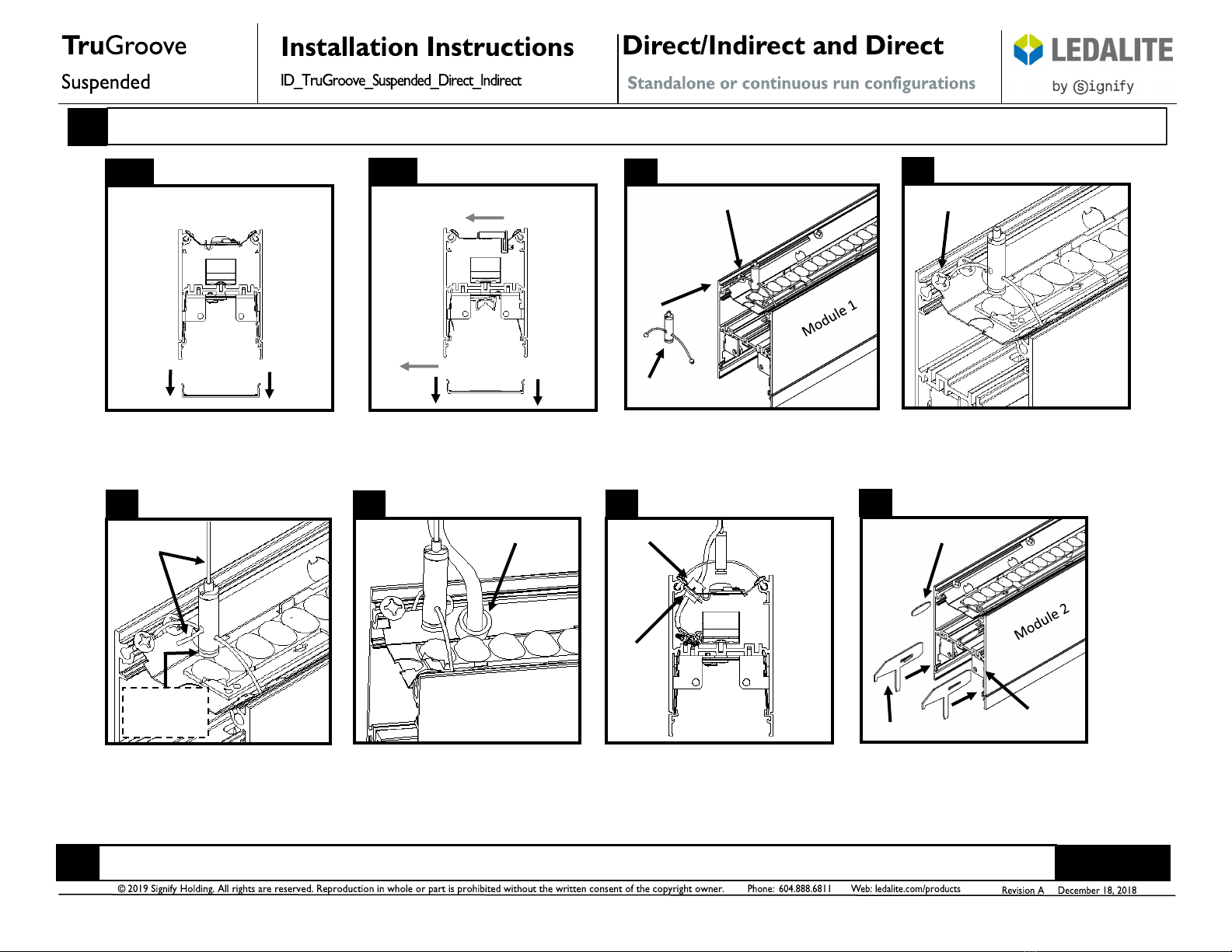

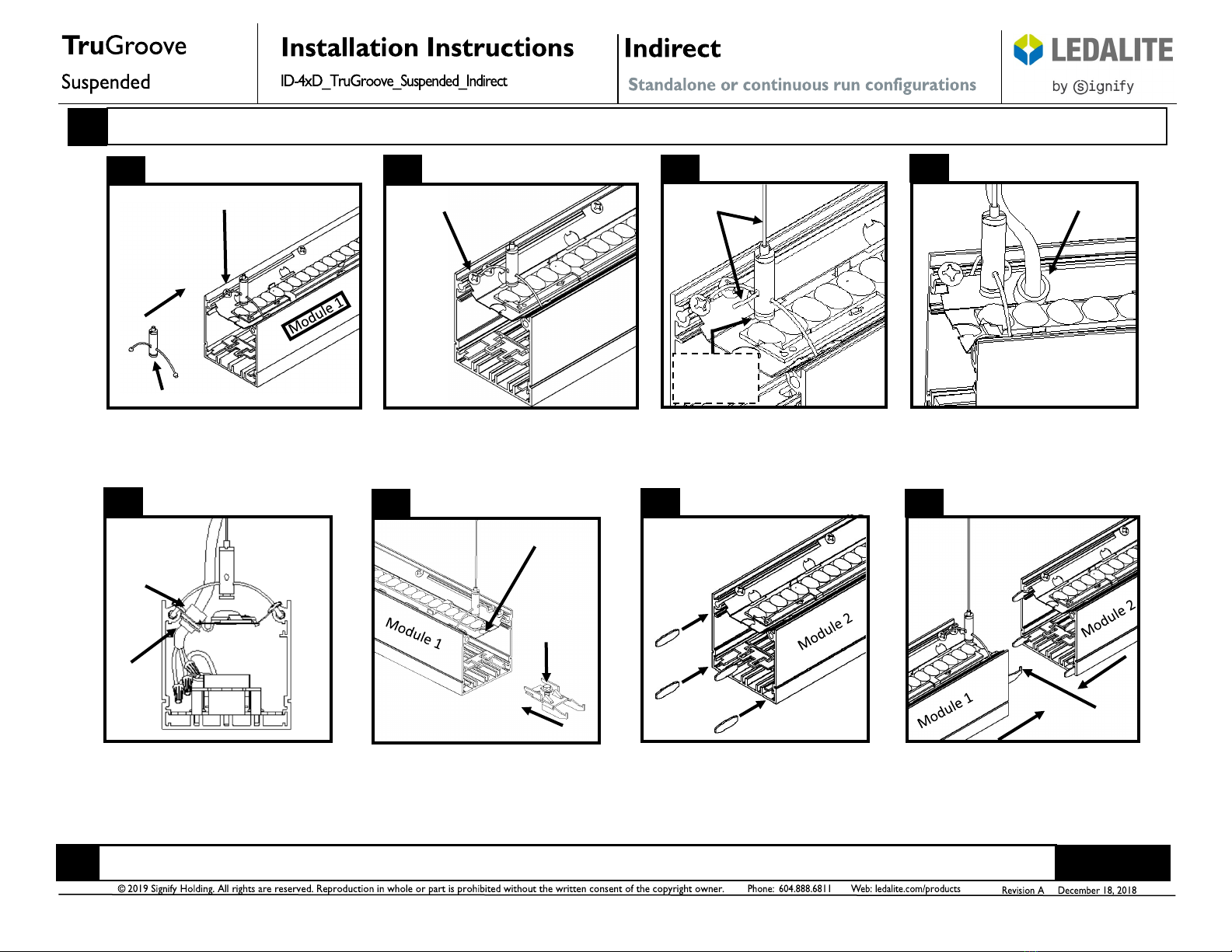

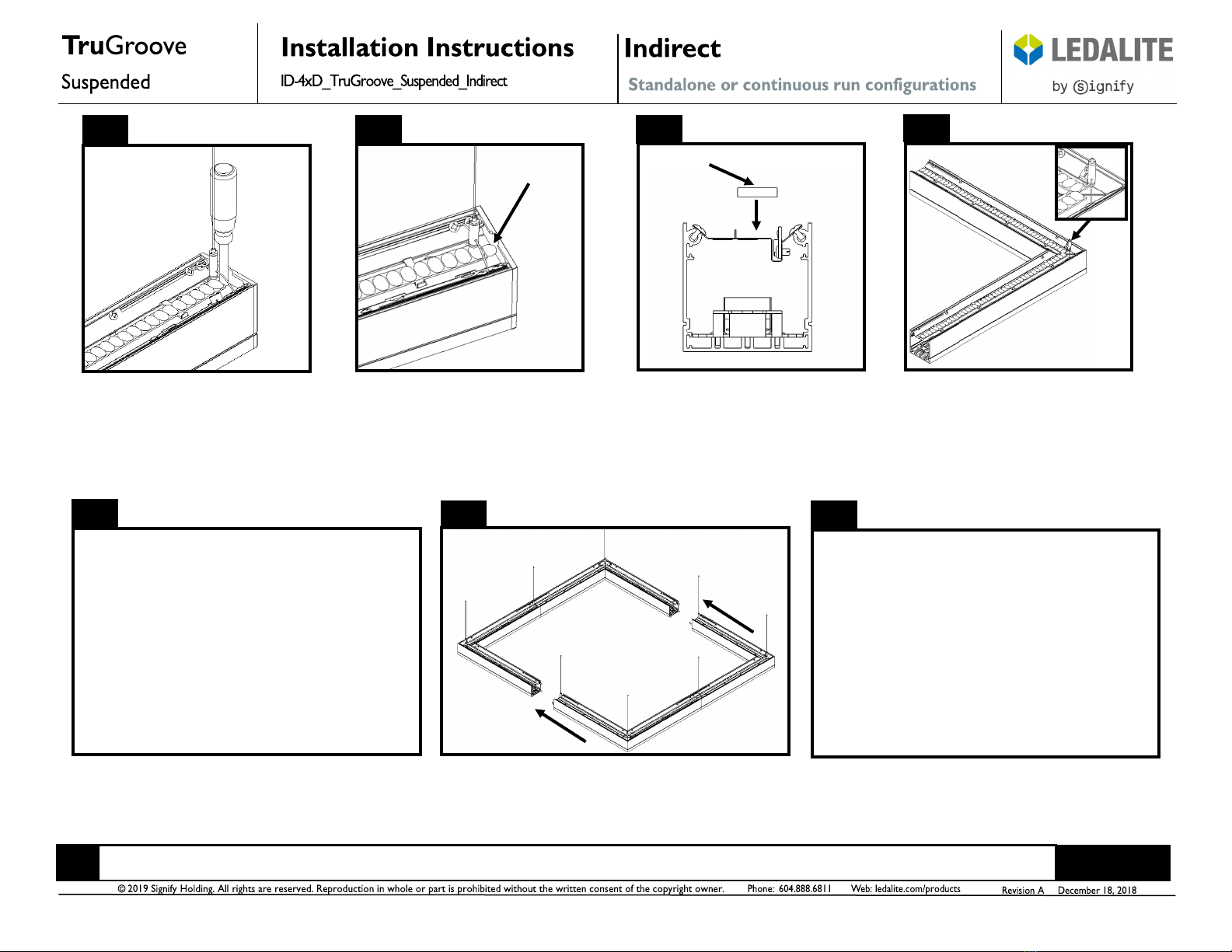

Module 1 Module 2

Ensure all connections are secure and all

wires are neatly tucked inside fixture

wiring cavity. Slide fixture modules

together gently.

Secure fixture modules together using the

two #10-32 machine screws and the two

#10-32 nuts supplied. Tighten until joint

seam is tight. Note: Do not overtighten.

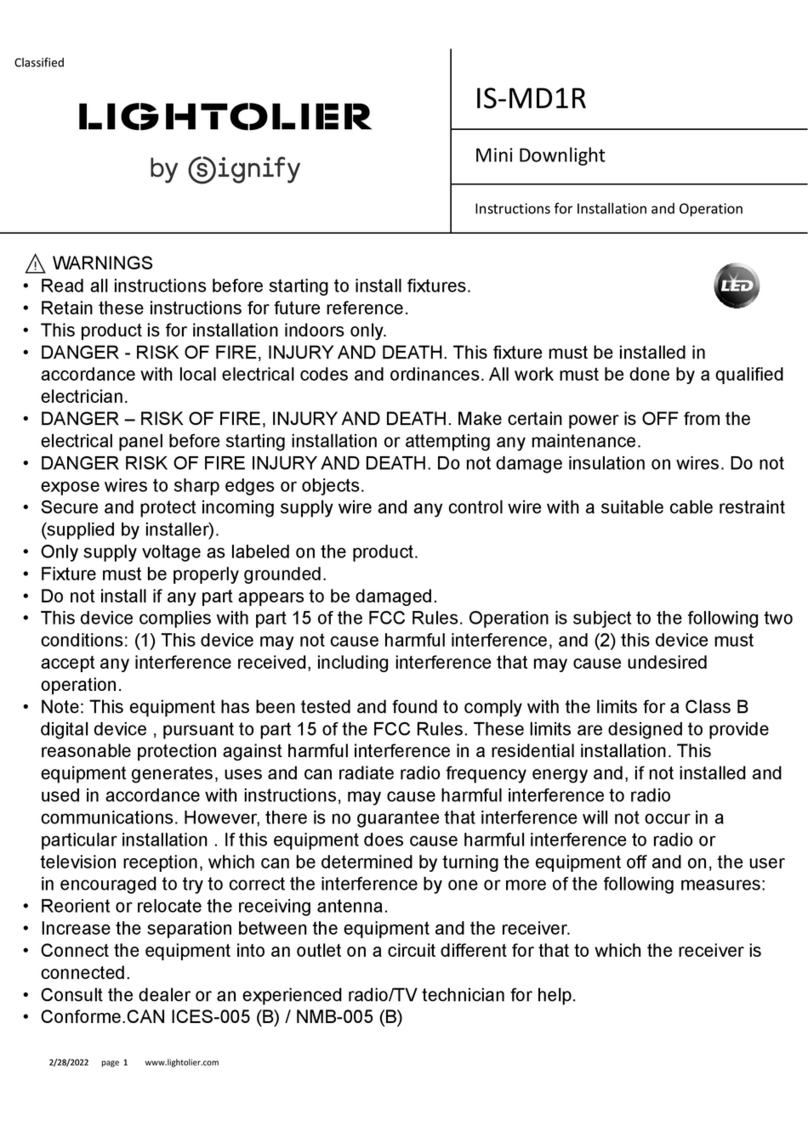

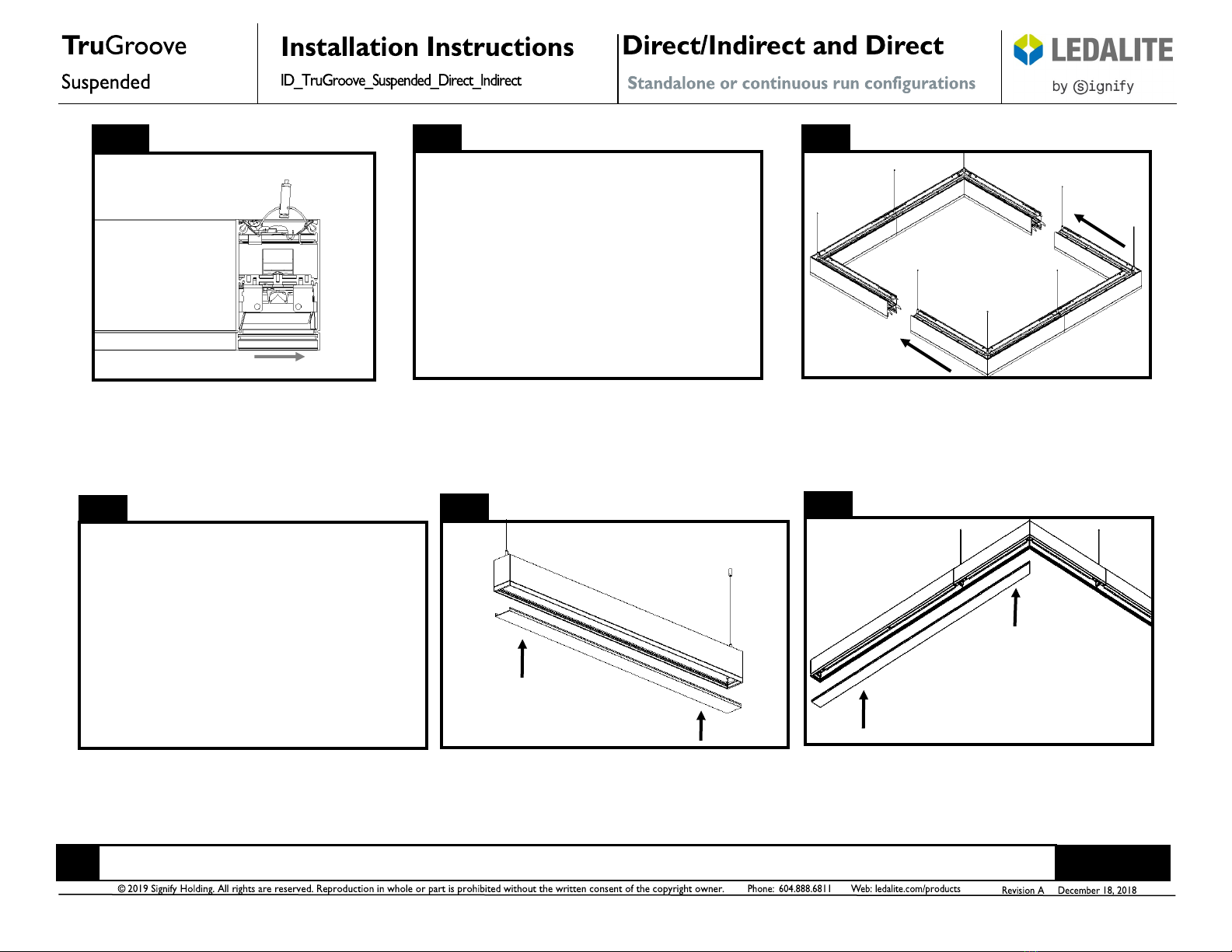

Slide endcap onto end of fixture module

and secure from below using two #8-32 X

5/16” screws. Ensure excess aircraft cable

does not interfere with endcap attach-

ment. Tighten screws until endcap seam is

tight. Note: Do not overtighten.

Factory

installed

corner

mount

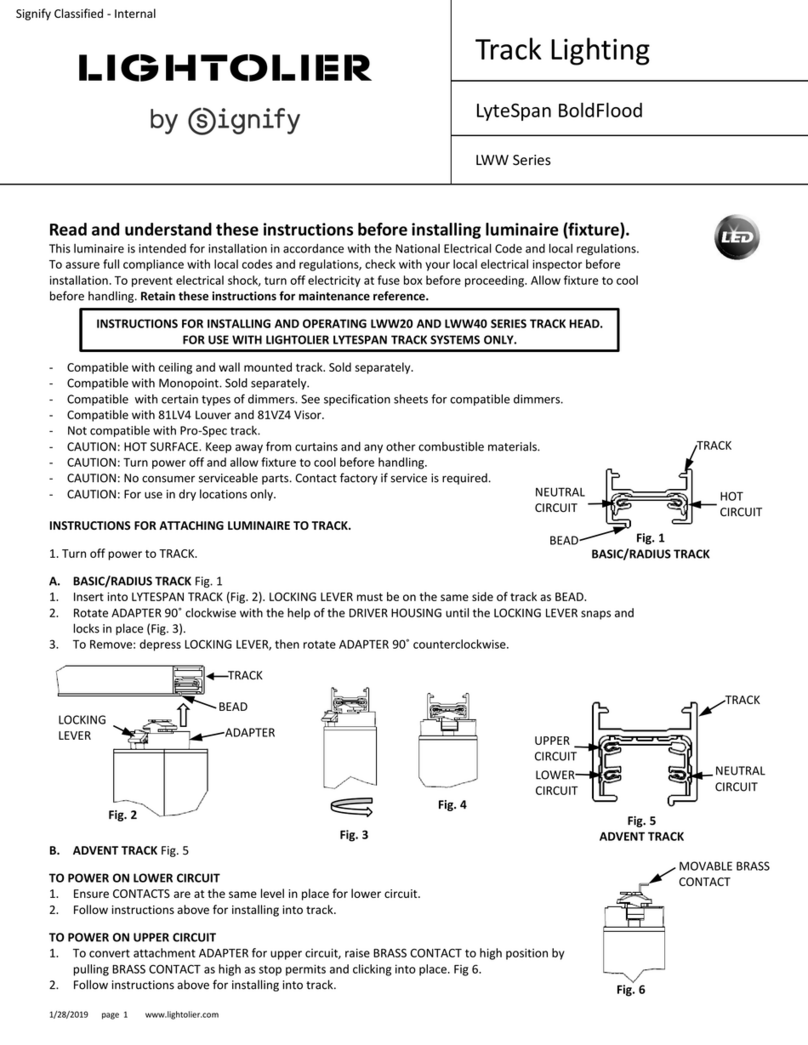

Asymmetric Inside Cross Secon

Direcon of light

Symmetric Cross Secon

910 11 12

13 14

Bring modules together and engage joiner

aligners in module 2 on fixture bracket in

module 1. With fixtures modules supporting

each other, complete wiring connections

between modules.

15a 15b

If a corner is required, it is recommended

the 2’X2’ corner module be installed

first. All corners come with a factory

installed cable sling assembly in the mid-

dle. Refer to supplied corner run layout

drawings and figures 15a, 15b and 15c for

correct locations and corner orientation.

Graphic above shows a symmetric corner

cross-section. Refer to supplied layout

drawings for mounting locations.

Graphic above shows the direct/indirect

inside asymmetric corner cross-

section. This corner directs all lower

light toward the inside of the corner.

Refer to supplied layout drawings for

required corner orientation (direction of

light) and mounting locations.

#10-32 Screw

#10-32 Nut

Quick Wire

Connectors

(Supplied)

Raise module 2 to installed module 1

position.

Important: Use Wire Nuts ( Supplied By

Others) At Power Feed Location

Fixture Joining Fixture Joining Fixture Joining Fixture Joining

Endcap Installation Corner Installation Corner Installation Corner Installation