10

DF-2D BRAKE PAD ASSEMBLY

Lower the

hex nuts on

the brake

rod to

have the

dispenser

brake

engage

sooner.

Raise the

hex nuts on

the brake

rod to

have the

dispenser

brake

engage later.

DISPENSER ADJUSTMENTS

WEAR SAFETY GLASSES WITH SIDE SHIELDS WHICH CONFORM TO ANSI STANDARD Z87.1

OR EN 166. FAILURE TO WEAR SAFETY GLASSES COULD RESULT INN SEVERE PERSONAL

INJURY. PROTECT YOUR EYES.

!Only trained people should service this dispenser.

!Unless specified, shutoff and lock out all electrical power.

!Follow all service instructions.

!Never adjust, repair or oil moving machinery.

READ THE GENERAL SAFETY INSTRUCTIONS IN THE FRONT OF THIS MANUAL.

COIL BRAKE

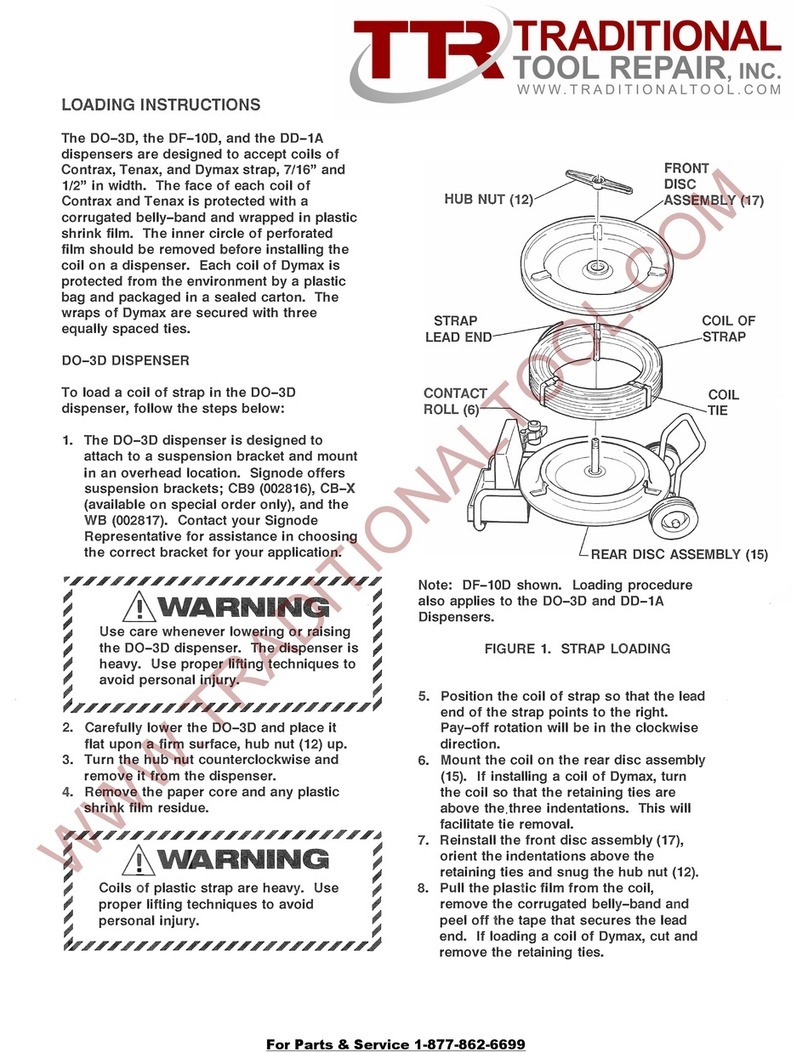

The DF-2D brake engages when the brake rods which are

connected to the lower arm are lowered as the arm swings

down. As the brake rods lower the brake pad arms pivot

downward to engage the brake pad against the inner contact

surface of the disk flanges. The amount of brake pretravel is

adjusted by moving the hex nut (two per brake rod) positions.

The amount of strap accumulated from the strapping machine

by the dispenser is dependent upon the position of the lower

arm when the brake is engaged. If the brake engages too late, as

the arm descends, very little strap can be retracted and

accumulated. If the brake engages too soon the arm may not

lower to the full bottom position.

NOTE: Since proper strap accumulation also depends on the

application, the factory setting must be considered nominal and

some fine tuning may be required.

To adjust the brake engagement point, rotate the two sets of hex nuts (four hex nuts total) up or

down the brake rods as required. Turn the nuts even amounts of turns to keep the distance from

one nut to the other from changing.