5

INSTALLATION

The dispenser should be placed at least 4 feet

from the machinery that it will be serving.. The

Options Section contains the optional hardware

required to accommodate the less common

locations relative to the machine. Once

permanent location has been determined, use

the base as a template to transfer the mounting

hole locations to the floor to accept 3/8"

anchors. Securely fasten the dispenser in

place.

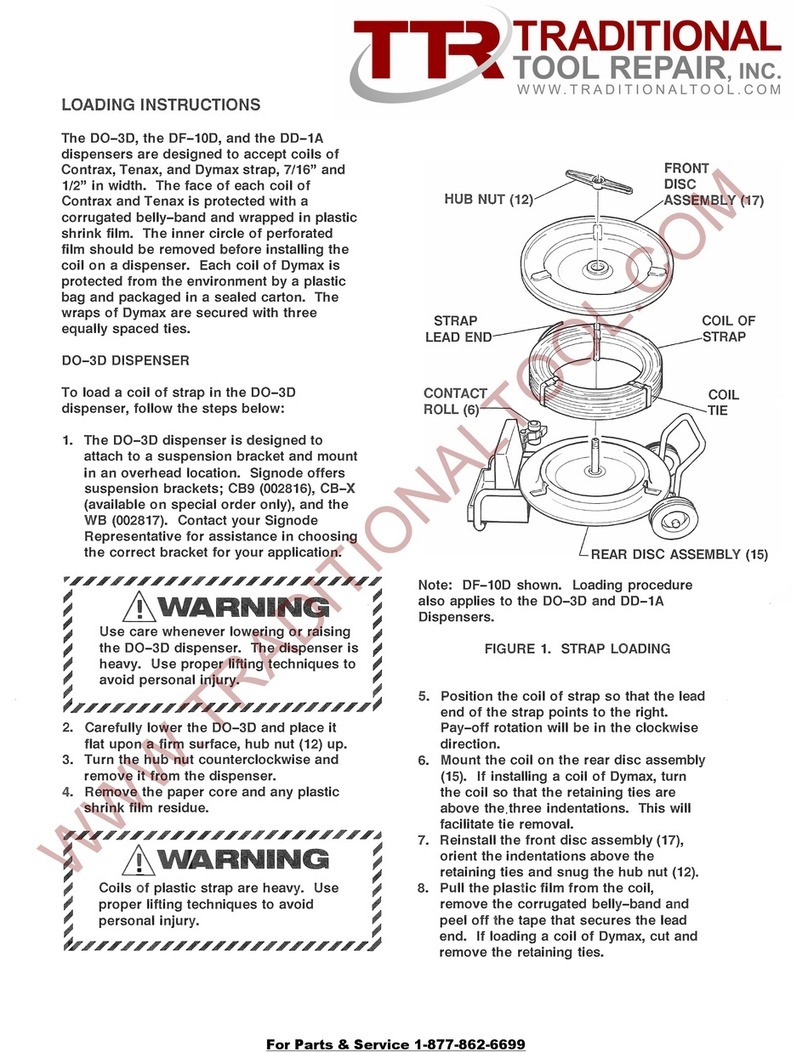

COIL LOADING INSTRUCTIONS

There are two methods used to load a coil of strap into the dispenser. The first assumes that

there is no strap in the dispenser and requires hand threading the multi-roller accumulating

system. The second method takes advantage of strap already threaded through the system.

NO STRAP IN THE DISPENSER

1. Remove the wing nut then lift the outer flange

from the dispenser.

2. Swing the lacing latch down from the upper arm.

Raise the dancer arm and hook it onto the latch.

This will release the brake and reduce the

distance between the dancer arm and the upper

arm.

3. Before installing the coil of strap, note the

direction of pay-off of the lead end. The coil

should be placed on the dispenser with the lead

end of hte strap feeding off the top towards the

upper roller stack, (1).

4. Leave the crossties and the face blocks intact.

Place new coil on the step of the rear flange and

reinstall the outer reel disc assembly. Snug the wing nut.

5. Cut the crossties on the coil, carefully remove the ties and the face blocks and securely

tighten the wing nut.

6. Make sure there are no twists or kinks in the strap. Feed it around the outermost roller on the

upper roller stack.

7. Direct the lead end down and around the outermost roller on the lower roller stack (2).